Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BLAUBERG Ventilatoren Tower A Series

- Page 1 Tower A(L) User's manual...

-

Page 2: Delivery Set

PURPOSE A roof axial fan Tower A(L) enclosed into a metal casing, having impeller diameter 200 to 350 mm (hereinafter referred to as "the fan") is intended for use in ventilation systems of housing, public and industrial premises heated during winter. The air coming out of the fan should not contain dust, other solid admixtures, sticky substances, and fibrous materials. - Page 3 table 1 Tower A Tower A Tower A Tower A Tower A Tower A Tower AL Tower AL Tower AL 200 2E 250 2E 250 4E 300 2E 300 4E 350 4E 1~230 0.26 0.28 0.42 0.22 0.24 0.66 0.79 0.35 0.65 0.66...

-

Page 4: Safety Requirements

SAFETY REQUIREMENTS It is necessary to take measures to prevent penetration of black gases into premises through open smoke ducts or other fire-prevention facilities. Fan installation and connection should be performed by qualified electrician according to effective regulations. Disconnect fan from the mains prior to maintenance and repair. Before connection of the fan to power mains it is necessary to ensure that there are no visible damages of impeller, casing, grating, as well as foreign objects in the blowing part of the casing,... -

Page 5: Installation And Connection

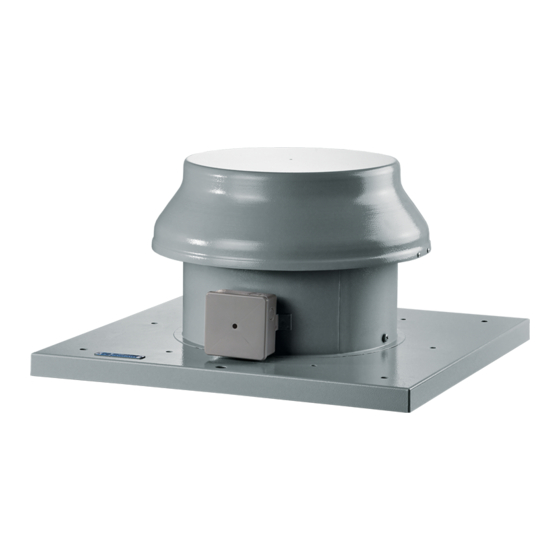

INSTALLATION AND CONNECTION TO POWER MAINS The fan (fig. 1) consists of a casing 1 with an electric motor and an impeller 7 fixed therein. The cover 2 and the protective grille 6 are fastened to the bracket 4 by self-cutting screws. The terminal box 5 is fixed at the outer side of the casing for connecting the fan to power mains. -

Page 6: Maintenance

MAINTENANCE POWER OFF THE POWER SUPPLY PRIOR TO ANY OPERATIONS WITH THE UNIT. Maintenance comprises periodical cleaning of the surfaces from dust and dirt, when the fan is disconnected from power mains. To remove the dust, use a soft dry brush or compressed air. The blades of the impeller require careful cleaning every 6 months. - Page 7 Problem Possible reasons Elimination The fan motor runs at The fan supplies Measure network resistance. Throttle overload capacity with more air than down the network (add aerodynamic current consumption in expected upon motor resistance to the air duct network). excess of the rated capacity selection.

- Page 8 Problem Possible reasons Elimination The fan supplies more The resistance Check the air ducts for proper shape air than expected. values used during and cross section as well as for any the ventilation dampers present. network calculations are too conservative. The cross section of Throttle down the network (add air ducts increased...

-

Page 9: Storage And Transportation Regulations

STORAGE AND TRANSPORTATION REGULATIONS Store the unit in the manufacturer's original packaging box in a dry closed ventilated premise with temperature range from +5 °C to + 40 °C and relative humidity up to 70 %. Storage environment must not contain aggressive vapors and chemical mixtures provoking corrosion, insulation, and sealing deformation. -

Page 11: Warranty

WARRANTY The manufacturer hereby warrants normal operation of the unit for 24 months after the retail sale date provided the user's observance of the transportation, storage, installation, and operation regulations. In case of absence of the entry specifying the date of sale, the warranty period is calculated from the date of manufacture. - Page 12 Tower A 200 2E Tower A 250 2E Tower A 250 4E Tower A 300 2E The fan has been duly certified as serviceable. Tower A 300 4E Tower A 350 4E Tower AL 200 Tower AL 250 Tower AL 315 Purchase Date Manufacture Date Sold...

Need help?

Do you have a question about the Tower A Series and is the answer not in the manual?

Questions and answers