Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Wasp WPS1500

- Page 1 WPS1500 QUICK REFERENCE GUIDE Omnidirectional Imaging Scanner...

- Page 2 "Contact" page. Disclaimer Wasp has taken reasonable measures to provide information in t his manual that is complete and accurate, however, Wasp shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages result-ing from the use of this material.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Quick Reference ............... 1 Features ................1 German GS Safety Certification ..........3 Installation ............... 3 Optional Stand/Riser..............4 Removing the Stand/Bottom Cover ........4 Magnetic Base Mounting.............. 4 How to Scan ..............5 Handheld Scanning Mode............. 5 Center Zone Qualification ............. 6 Scanner Button ................ - Page 4 NOTES WASP WPS1500...

-

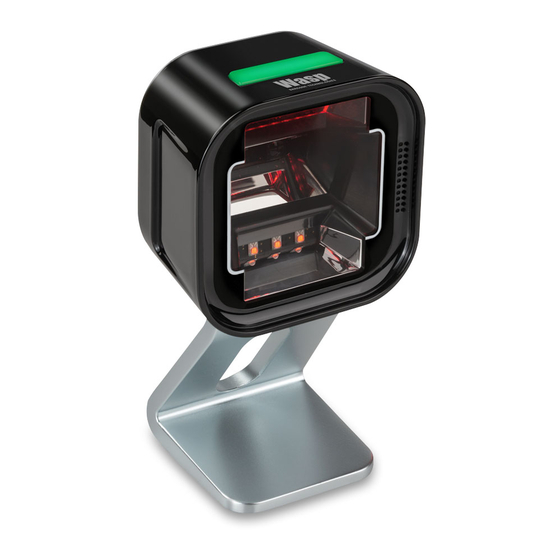

Page 5: Quick Reference

This guide is provided to help get your scanner up and running quickly and efficiently. For more details, including a nal programming informa on, reference the Product Reference Guide (PRG), which is available from the Wasp website. FEATURES Figure 1. Scanner Features - Front View Good Read Light Pipe/... - Page 6 Regulatory bottom cover) Label (under bottom cover) Remove the stand/cover to view the Regulatory Labeling, as described on page 4. Labels are shown to illustrate their location only. Please view the labels on your product for actual details. NOTE WPS1500...

-

Page 7: German Gs Safety Certification

Here A/C Adapter (if needed) The WPS1500 uses intelligent illumination technology to optimize light levels for a variety of bar code scanner functions including automatic reading of bar codes from printed surfaces, mobile devices and image capture in variable contrast environments. -

Page 8: Optional Stand/Riser

Front Window Stand Magnetic Base Mounting The magnetic swivel base can be used to semi-permanently attach a scanner to a flat surface (vertical or horizontal), using the provided adhesive or screw. Both the stand and riser options mount onto the WPS1500... -

Page 9: How To Scan

magnetic swivel base and are held magnetically in place. The scanner can easily be rotated to a desired orientation. The scanner (along with the riser or stand) can be detached for portable use by lifting the entire unit as shown in Figure 4 on page HOW TO SCAN Bar codes can be presented to the scanner while it is resting on the... -

Page 10: Center Zone Qualification

2 seconds, then Hold, then release release. Each time this is done, when the beeper Increments tone the beeper will sound at one of sounds three tones. Stop when the desired tone (high, medium or low) is sounded. 6 WPS1500... - Page 11 PRESS FUNCTION COMMENT DURATION This mode allows system support personnel to troubleshoot problems with the scanner and is used to Scanner Diagnostics 4 Seconds determine if it can read bar Mode codes. Press the button for 8 seconds or cycle power to exit Scanner Diagnostics Mode and reset the scanner.

-

Page 12: Led And Beeper Indicators

The LED can provide diagnostic Codes" on page 16 Diagnostics feedback if the scanner discovers a for more problem during SelfTest. information) Constant green flash Prog. Mode at 1 Hz (500 ms on, The scanner is in Programming Mode. 500 ms off). 8 WPS1500... - Page 13 BEEPER INDICATION COMMENT INDICATION The Power-On LED indication is a configurable feature which can be enabled or disabled. When enabled, this Power On Beep Single beep beep indicates the scanner has finished all its power-up tests and is now ready for operation.

-

Page 14: Programming

Additional programming barcodes are available in the PRG, or use software utilities which are available on the Wasp website. Service Port Mode To program the WPS1500 using Scanalyzer or Aladdin, the unit must first be placed into Service Port mode, as follows: Unplug the unit if needed. -

Page 15: Interface Selection

RS-232 Wincor-Nixdorf 000145(CR) USB-OEM 000135(CR) USB Keyboard 000147(CR) USB COM Interface Reference the Product Reference Guide (PRG) or configuration software for additional options. All are available for download on the Wasp website at no charge. NOTE QUICK REFERENCE GUIDE 11... -

Page 16: Good Read Green Spot Duration

Successful reading can be signaled by a good read green spot. Use the bar codes that follow to specify the duration of the good read pointer beam after a good read. START / END Disabled Short (300 ms) Medium (500 ms) Long (800 ms) 12 WPS1500... -

Page 17: Cell Phone Mode

Cell Phone Mode Enables/disables mobile phone barcode reading. START / END 046700(CR) Cell Phone Mode = Enable (Toggle) 046702(CR) DEFAULT Cell Phone Mode = Enable (Always On) 046701(CR) Cell Phone Mode = Enable (Timer Expiration) QUICK REFERENCE GUIDE 13... -

Page 18: Cell Mode Frequency

NOTE START / END 047100(CR Cell Mode Frequency = Very Low 047101\r Cell Mode Frequency = Low 047102\r DEFAULT Cell Mode Frequency = Medium 047103\r Cell Mode Frequency = Med High 047104\r Cell Mode Frequency = High 14 WPS1500... -

Page 19: Troubleshooting

Reading of the various bar code symbologies can be independently enabled or disabled in the scanner. If the scanner still does not function properly, consult the Product Reference Guide (PRG) or contact your local supplier or Wasp Customer Support Services. QUICK REFERENCE GUIDE 15... -

Page 20: Error Codes

LED simultaneous to the beeps. The table below describes what these codes mean and what action should be taken for each. NUMBER OF LED ERROR CORRECTIVE ACTION FLASHES/ BEEPS Configuration Host Interface Main PCB Contact Helpdesk for assis- tance Button Error USB Device FPGA ID 16 WPS1500... -

Page 21: Cleaning

CLEANING Exterior surfaces and scan windows exposed to spills, smudges or debris accumulation require periodic cleaning to assure best performance during scanning. Use a clean, lint-free cloth or paper towel dampened with a nonabrasive, mild, water-based cleaner to wipe away stains, smudges, fingerprints, spills, etc. -

Page 22: Manufacturer Approved Cleaning Materials

Manufacturer Approved Cleaning Materials Wasp recommends the use of the following cleaners on its products. APPROVED CLEANERS • Hydrogen Peroxide (not to exceed a 3% solution) • Chlorine bleach (not to exceed a 0.25% solution) • Mild detergent and water •... -

Page 23: Warranty

Wasp shall, at its sole option repair or replace the product without additional charge for parts and labor, or give a credit for the defective products duly returned to Wasp. To perform repairs, Wasp may use new or reconditioned parts, components, subassemblies or products that have been tested as meeting applicable specifications for equivalent new material and products. - Page 24 Wasp service center, with shipping charges prepaid. Wasp shall pay for the return of the product to Buyer if the shipment is to a location within the country in which the Wasp service center is located. Buyer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

- Page 25 Buyer remaining liable for damages). Risk of Loss Buyer shall bear risk of loss or damage for product in transit to Wasp. Wasp shall assume risk of loss or damage for product in Wasp's possession. In the absence of specific written instructions for the return of product to Buyer, Wasp will select the carrier, but Wasp shall not thereby assume any liability in connection with the return shipment.

- Page 26 NOTES 22 WPS1500...

- Page 28 Wasp and/or its affiliates • Wasp Barcode Technologies and the Wasp logo are registered trademarks of Wasp in many countries, including the U.S. and the E.U. www.waspbarcode.com Wasp Barcode Technologies 1400 10th St.

Need help?

Do you have a question about the WPS1500 and is the answer not in the manual?

Questions and answers