Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sorel HCC 6

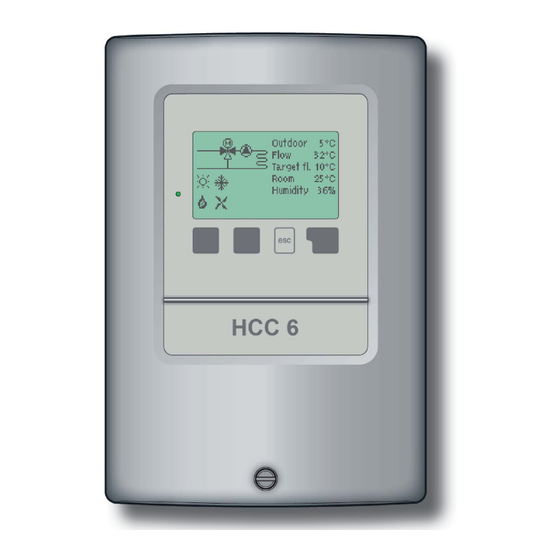

- Page 1 Heating-Controller HCC 6 Weather controlled heat circuit regulator Installation and operating instructions Read carefully before installation, commissioning and operation carefully before i i nst t al l l l at t i i on commi i ssi i oni i ng and operation...

-

Page 2: Table Of Contents

Content A.1. - EC declaration of conformity 5.1.7. - Reference/actual - A.2. - General instructions 5.1.8. - Reference/actual + A.3. - Explanation of symbols 5.1.9. - Delay A.4. - Changes to the unit 5.1.10. - min. fl ow (heating) A.5. - Warranty and liability 5.1.11. -

Page 3: Ec Declaration Of Conformity

Safety instructions A.1. - EC declaration of conformity By affi xing the CE mark to the unit the manufacturer declares that the HCC 6 conforms to the following relevant safety regulations: EC low voltage directive 73/23/EEC, as amended by 93/68/EEC... -

Page 4: Changes To The Unit

Safety instructions A.4. - Changes to the unit Changes to the unit can compromise the safety and function of the unit or the entire system. Danger Changes, additions to or conversion of the unit are not permitted without written permission from the manufacturer It is likewise forbidden to install additional components that have not been tested together with the unit If it becomes clear that safe operation of the unit is no longer possible,... -

Page 5: Specifi Cations

Description of controller B.1. - Specifi cations 2.1 Specifi cations: Mains Voltage 230VAC +/- 10% Mains frequency 50...60Hz Power consumption Total switched power 460VA (Relay outputs 1-3) Switched power per relay 460VA for AC1 / 185W for AC3 Internal fuse 2A slow blow 250V Protection category IP40... -

Page 6: About The Controller

Description of controller B.3. - About the controller The weather controlled Heat Circuit Controller HCC 6 facilitates effi cient use and func- tion control of your heating system. The device is impressive most of all for its function- ality and simple, almost self-explanatory operation. For each step in the input process the individual entry keys are assigned to appropriate functions and explained. -

Page 7: Hydraulic Variants

Description of controller B.6. - Hydraulic variants The following illustrations should be viewed only as schematic dia- grams showing the respective hydraulic systems, and do not claim to be complete. The controller does not replace safety devices under any circumstances. Depending on the specifi c application, additional system components and safety components may be mandatory, such as check Caution valves, non-return valves, safety temperature limiters, scalding protec-... -

Page 8: Wall Installation

Installation C.1. - Wall installation Install the controller only in dry areas and under the ambient conditions described under B.1 „Specifi cations“. Carry out the following steps 1-8. Caution 1. Unscrew cover screw completely C.1.1. 2. Carefully pull upper part of housing from lower part. -

Page 9: Electrical Connection

Installation C.2. - Electrical connection Before working on the unit, switch off the power supply and secure it against being switched on again! Check for the absence of power! Danger Electrical connections may only be made by a specialist and in compli- ance with the applicable regulations. -

Page 10: Installing Temperature Sensors

Installation C.3. - Installing temperature sensors The controller operates with Pt1000 temperature sensors which are accurate to the degree, thus ensuring optimal control of system functions. If needed the sensor cables can be extended to a maximum of 30m using a cable with a cross-section of at least 0.75mm². Make sure that there is no contact resistance! Position the sensor precisely in the area to be measured! Caution... -

Page 11: Electrical Terminals

Installation C.4. - Electrical terminals Right-hand terminal com- Left-hand terminal compart- partment only for mains volt- ment only for low voltage if Danger ages of 230VAC 50-60Hz max. 12VAC/DC Caution Connections low voltage: Connections Mains Voltage: - Temperature sensors S1 - S6 and - Protective conductor PE metal terminal jumper terminal block S- (polarity freely block... -

Page 12: Display And Input

Operation E.1. - Display and input The display (1), with its extensive text and graphics mode, is almost self-explanatory, allowing easy operation of the controller. The LED (2) lights up green when a relay is switched on. The LED (2) lights up red when operating mode „Off“... -

Page 13: Commissioning Help

Operation E.2. - Commissioning help The fi rst time the controller is turned on and after the language and time are set, a query appears as to whether you want to parametrise the controller using the commissioning help or not. The commis- sioning help can also be terminated or called up again at any time in the special functions menu.The commissioning help... -

Page 14: Menu Sequence And Menu Structure

Operation E.4. - Menu sequence and menu structure The graphics or overview mode appears when no key has been pressed for 2 minutes, or when the main menu is exited by pressing „esc“. Pressing a key in graphics or overview mode takes you directly to the main menu. -

Page 15: Measurements

Measurements 1. - Measurements Menu “1. Measurement values” is used to display the currently measured tempera- tures. The menu is closed by pressing “esc” or selecting “Exit measurement values”. Selecting “Info” leads to a brief help text explaining the measurement values. -

Page 16: Statistics

Statistics 2. - Statistics Menu “2. Statistics” is used for function control and long-term monitoring of the system. The menu is closed by pressing “esc” or selecting “Exit statistics”. For system data statistics it is essential for the time to be set accurately on the controller. -

Page 17: Times

Times 3. - Times Menu “3. Times” is used to set the time, date, operating times for the heating circuit. The associated temperature reference values are specifi ed in menu 5 “Settings”! Caution The menu is closed by pressing “esc” or selecting “Exit display mode”. -

Page 18: Operating Modes

Operating modes 4. - Operating modes Menu “4. Operating modes” is used to specify the operating modes for the heat- ing circuit. After an interruption of the mains voltage the controller automatically returns to the last operating mode selected! The menu is closed by pressing “esc” or selecting “Exit operating modes”. -

Page 19: Dehumidifi Er

Operating modes 4.3. - Dehumidifi er Summer = Dehumdifi er is active when the temperature set in S/W day resp. S/W night is exceeded. All year = Dehumidifi er tries to keep the humidity level all time. Off = Dehumidifi er switched off Settings range: Summer, All year, Off Default: Off 4.4. -

Page 20: Settings

Settings Heat circuit 5. - Settings 5.1. - Heat circuit The necessary basic settings required for the control function of the heating circuit are made in menu “5. Settings HC”. This does not under any circumstances replace the safety facilities to be pro- Caution vided by the customer! The menu is closed by pressing “esc”... -

Page 21: Curve

Settings Heat circuit 5.1.3. - Curve The characteristic curve is used to control the heat dissipation of the heating circuit relative to the outdoor temperature. The demand for heat is different due to differences in the type of building/insulation/ type of heating/outdoor temperature. For this reason the controller can make use of a normal straight curve (Setting simple) or a split curve (Setting split). -

Page 22: Day Correction

Settings Heat circuit The following settings can be used for parallel translation of the characteristic for certain time periods such as daytime, nighttime and comfort mode. Caution 5.1.4. - Day correction parallel translation of the characteristic curve The day correction produces a parallel translation of the heating characteristic during the daytime operating hours, since depending on the outdoor temperature it is possible that the building may not be optimally heated with the set characteristic. -

Page 23: Reference/Actual

Settings heat circuit 5.1.8. - Reference/actual + Switch-off hysteresis for additional heating (only when S3 is connected) This settings determines the allowed overstepping of the heat circuit temperature to the calculated reference fl ow temperature at sensor 3. If the temperature at S3 exceeds the reference fl... -

Page 24: Settings Cooling

Settings cooling 5.2. - Settings cooling The necessary basic settings required for the control of the cooling function are made in menu “6. Settings cooling” This does not under any circumstances replace the safety facilities to be pro- Caution vided by the customer! The menu is closed by pressing “esc”... -

Page 25: On Hysteresis

Settings cooling Settings cooling 5.2.3. - On hysteresis This setting is used to determine the allowed overshoot of the fl ow temperature at sen- sor S2 over the calculated reference fl ow temperature. If the measured temperature at S2 exceeds the reference temperature for the time period set inf 5.2.8, cooling is switched off. -

Page 26: Dehumidifi Er

Dehumidifi er 5.3. - Dehumidifi er 5.3.1. - Reference humidity Dehumidifi er is active as long as the humidity is higher as the value set here. Hysteresis is fi xed on 5%. Settings range: 30 % to 60 % / Default: 50 % 5.4. -

Page 27: Room Controller

Room controller 5.5. - Room controller This menu is used to determine the settings for the room controller RC22. The menu is closed by pressing “esc” or selecting “Exit room controller”. The RC22 is used to set the 3 operating modes Heating, Off and Cool- ing. -

Page 28: Protective Functions

Protective functions 6. - Protective functions Menu “6. Protective functions” can be used by specialists to activate and set various protective functions. This does not under any circumstances replace the safety facilities to be pro- Caution vided by the customer! The menu is closed by pressing “esc”... -

Page 29: Special Functions

Special functions 7. - Special functions Menu “7. Special functions” is used to set basic items and expanded functions. The settings in this menu should only be made by a Caution specialist. The menu is closed by pressing “esc” or selecting “Exit special functions”. -

Page 30: Expansions

Special functions 7.4. - Expansions This menu can only be selected and used if additional options or expansion modules have been built into the controller. The associated supplementary installation, mount- ing and operation instructions are then included with the specifi c expansion. 7.5. -

Page 31: Menu Lock

Menu lock 8. - Menu lock Menu “8. Menu lock” can be used to secure the controller against unintentional changing and compromise of basic func- tions. The menu is closed by pressing “esc” or selecting “Exit menu lock”. The menus listed below remain completely accessible despite the menu lock being activated, and can be used to make adjustments if necessary: 1. -

Page 32: Service Values

Service values 9. - Service values Menu “9. Service values” can be used for remote diagnosis by a specialist or the manufacturer in the event of an error, etc. Enter the values at the time when the error occurs into the table. -

Page 33: Language

Language 10. - Language Menu “10. Language” can be used to select the language for the menu guidance. This is que- ried automatically during initial commissioning. The choice of languages may differ, however, depending on the device design. Language selection is not available in every device design! -

Page 34: Malfunctions With Error Messages

Malfunctions Z.1. Malfunctions with error messages If the controller detects a malfunction, the red light fl ashes and the warning symbol also appears in the display. If the error is no longer present, the warning symbol changes to an info symbol and the (Led blinks + warning symbol) red light no longer fl... -

Page 35: Replacing The Fuse

Malfunctions Z.2. Replacing the fuse Repairs and maintenance may only be performed by a specialist. Before working on the unit, switch off the power supply and secure it against being switched on again! Check for the absence of power! Danger Only use the supplied spare fuse or a fuse of the same design with the follow- ing specifi... - Page 36 Although these instructions have been created with the greatest possi- ble care, the possibility of incorrect or incomplete information cannot be excluded. Subject as a basic principle to errors and technical changes. Manufacturer: Your specialist dealer: SOREL GmbH Mikroelektronik Jahnstr. 36 D - 45549 Sprockhövel Tel. +49 (0)2339 6024 +49 (0)2339 6025 www.sorel.de info@sorel.de...

Need help?

Do you have a question about the HCC 6 and is the answer not in the manual?

Questions and answers