McQuay MicroTech II Installation And Maintenance Manual

Vertical self-contained systems unit controller, used with mcquay models: swp and swt

Hide thumbs

Also See for MicroTech II:

- Operation manual (136 pages) ,

- Installation manual (58 pages) ,

- Installation and maintenance manual (48 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for McQuay MicroTech II

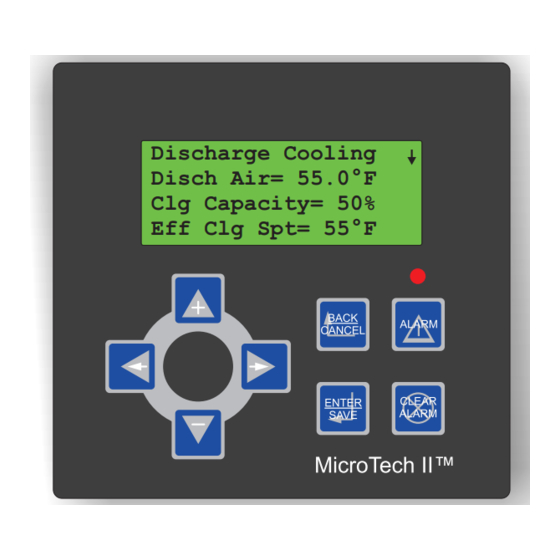

- Page 1 Installation and Maintenance IM-710 Group: Applied Systems Part Number: IM710 Date: February 2002 MicroTech™ II Vertical Self-contained Systems Unit Controller • Used with McQuay models: SWP and SWT BACK ALARM CANCEL ENTER CLEAR SAVE ALARM © 2002 McQuay International...

-

Page 2: Table Of Contents

Service Information ......20 “McQuay,” “MicroTech II,” are trademarks of McQuay International, Minneapolis, Minnesota Copyright © 2002 McQuay International. All rights reserved throughout the world. -

Page 3: Introduction

Electric shock hazard. Can cause personal injury or equipment damage. This equipment must be properly grounded. Connections and service to the MicroTech II control panel must be performed only by personnel that are knowledgeable in the operation of the equipment being controlled. - Page 4 Extreme temperatures can cause damage to system components. The MicroTech II controller is designed to operate in ambient temperatures from -20°F to 125°F. It can be stored in ambient temperatures from -40°F to 140°F. The controller is designed to operate in a 10% to 90% RH (non-condensing) and be stored in a 5% to 95% RH (non-condensing) environment.

-

Page 5: General Description

Component Data trol, the controller can provide alarm monitoring and alarm- specific component shutdown if critical system conditions The main components of the MicroTech II control system occur. include the main control board (MCB), and one or two The operator can access temperatures, pressures, operating... -

Page 6: Main Control Board (Mcb)

Main Control Board (MCB) 12 binary inputs from each optional auxiliary control board (CCB1, CCB2). Auxiliary control boards communicate this Figure 2 shows the main control board (MCB). It contains a data with the MCB via a N2 communication bus interface. microprocessor that is programmed with the main applica- The MCB controls its own 16 binary outputs and up to 9 tion code to control the unit. -

Page 7: Communication Cards

Binary Inputs Terminal Blocks Communication Cards The communications system on the MicroTech II main con- The MCB receives up to 16 binary input signals on 3 termi- trol board is designed to accept one communication card. In nal blocks located on the top of the board. From right to left,... - Page 8 RS232 Connection Port For a detailed description and troubleshooting information A PC loaded with MicroTech II Service Tool software can be regarding this communications card, refer to installation and connected directly or via a telephone modem to the RS232...

-

Page 9: Auxiliary Control Boards (Ccb1And Ccb2)

Main Control Board LEDs on the right side of the MCB. These LEDs are lit when the corresponding Binary Output is turned ON. For information There are a number of LEDs in various locations on the regarding the functions of the Binary Outputs refer to MCB. - Page 10 Figure 4: Auxiliary Control Board (CCB1 Board Shown) Analog Inputs Terminal Block (J8) The auxiliary control board receives up to six analog input Binary Inputs Terminal Blocks (J9 and J10) signals via the AI (J8) terminal block on the right side of the board.

-

Page 11: Main Control Board (Mcb) Output Relays And Triacs

Binary Outputs Terminal Block the MCB. The output terminals of these relays are connected to a set of binary output terminal blocks located on the right The auxiliary control board includes nine binary output side of the MCB. These relays are designed for Class 2 oper- relays (BO1 through BO9) that are energized based on com- ation and to switch loads with any of the following charac- mands received from the MCB. -

Page 12: Temperature Sensors

Pressure Transducers nals to modulate the drive speed. The MicroTech II controller uses 0 to 5“ WC, 1 to 6 VDC Speed feedback is supplied to the controller via a 0-10 VDC static pressure transducers for measuring duct static pres- signal from the VFD. -

Page 13: Field Wiring

The following are descriptions of the various options and keeps the outside air dampers open in case there is a failure or features that may require field wiring to the MicroTech II external override that keeps the fan running after it is turned controller. -

Page 14: Vav Box Output

VAV boxes fully open when heat- minal 118 on the field terminal block (TB2) when the output ing is required. If necessary, the MicroTech II controller is on. To use this signal, the coil of a field supplied and... -

Page 15: Staged Cooling Outputs

6 shows the required wiring termination points. units equipped with a MicroTech II controller. A zone tem- perature sensor (ZNT1) is optional for all vertical self-con- tained units except for the 100% outdoor air CAV-ZTC CAUTION (SCC) unit in which case one is required. -

Page 16: Tenant Override (Timed)

Ground loop current hazard. Can cause equipment damage. The external reset signal must be isolated from all grounds other than the MicroTech II controller chassis ground. If it is not, ground loop currents can damage or cause erratic operation of the MicroTech II controller. If the... -

Page 17: Field Actuator Feedback

0 to 1000 ohms as the actuator strokes from 0 to 100% open can be wired to ter- When the MicroTech II controller is interfaced with a field minals 91 and 92 on the terminal block (TB2). These termi- supplied steam/hot water, airside economizer, or chilled nals are factory-wired to analog input MCB-AI10. -

Page 18: Humidity Sensors

The humidity sensor wiring to terminals 126 and 127 must be field-wired to the unit using a twisted pair, shielded cable When the MicroTech II controller is configured for constant (Belden 8761 or equivalent). Cable with 22 AWG conduc- volume zone temperature control (SCC), a dehumidification sequence is available and can be activated through the key- tors is sufficient. -

Page 19: Field Binary Input Signals

Field Binary Input Signals External Time Clock or Tenant Override There are several methods of switching the vertical self-con- The following sections describe options that, if used, require tained unit between occupied and unoccupied operation. It field wiring to binary input terminals. Twisted pair, shielded can be done by the controller internal schedule, a network cable is not required for binary input wiring. -

Page 20: Service Information

Service Information Controller Inputs log inputs. Each set contains eight switches numbered 1 through 8. Refer to Figure 10. The switches on SW1 corre- Analog Inputs-Main Control Board (MCB) spond to inputs MCB-AI1 through MCB-AI8 and the switches on SW4 correspond to inputs MCB-AI9 through The 16 analog inputs to the MCB are configurable for four MCB-AI16. - Page 21 Table 7: Analog Inputs for Main Control Board (MCB) - Discharge Air Controller (DAC) Input Analog Input Input Description Input Jumper Switch MCB-AI1 Zone (Space) Air Temperature (Optional) 1-RTD T (OFF) MCB-AI2 External Discharge Air Temperature Reset NJ-VDC (No Jumper) V (ON) MCB-AI3 Discharge Air Temperature...

-

Page 22: Analog Inputs-Auxiliary Control Boards (Ccb1 And Ccb2)

Table 8: Analog Inputs for Main Control Board (MCB) - CAV-ZTC (SCC) Analog Input Input Description AI Jumper AI Switch MCB-AI1 1-RTD T (OFF) Zone (Space) Air Temperature MCB-AI2 Remote Space Temperature Set Point (Optional) NJ-VAC (No Jumper) V (ON) MCB-AI3 Discharge Air Temperature 1-RTD... -

Page 23: Binary Inputs-Main Control Board (Mcb)

Binary Inputs-Main Control Board (MCB) Each binary input has an LED associated with it that lights when 24 VAC is present at the corresponding input terminal. These binary input LEDs are grouped together and are The 16 binary inputs to the MCB are in the form of 0 VAC located in the upper left hand corner of the board. - Page 24 Table 11: Binary Inputs for Circuit #1 through Circuit #4 Auxiliary Cooling Control Board (CCB1) Binary Input Input Description 24 VAC Present Indication Continuity Present CCB1-BI1 High Pressure Switch, Circuit #1 (HP1) Normal CCB1BI2 High Pressure Switch, Circuit #2 (HP2) Normal CCB1-BI3 High Pressure Switch, Circuit #3 (HP3)

-

Page 25: Controller Outputs

Controller Outputs Figure 12: Binary Output Jumper (MCB) Binary Outputs-Main Control Board (MCB) The main control board has 16 binary outputs that provide unit control in responses to input conditions. Binary outputs energize on-board electromechanical relays (BO1 through 1 - SRC V. 2 - BRD24V 3 - OFFBRD BO4, BO11 and BO12) or triacs (BO5 through BO10 and... - Page 26 Table 13: Binary Outputs for Main Control Board (MCB) Binary Output Output Description Lit LED Indication Jumper Position Discharge Air Fan, On/Off Fan On 1-SRC V Outdoor Damper, Open/Closed Open 1-SRC V Fan Operation Output Signal Fan Op 1-SRC V Alarm Output Signal Normal 1-SRC V...

-

Page 27: Binary Outputs-Auxiliary Control Boards (Ccb1 And Ccb2)

Binary Outputs-Auxiliary Control Boards CCB1 & CCB2 (CCB1 and CCB2) Circuit #1 through Circuit #4 are controlled by the CCB1 and Circuit #5 and #6 are controlled by the CCB2. There are The optional auxiliary control boards include 9 binary out- nine binary output relays on each cooling control board. -

Page 28: 4-Compressors/4-Stage

When a capacity decrease is required, the "Lag" compressor by staging compressors on and off. Compressors #1 or #2 with the most hours is turned off. When a further capacity provide the first stage of cooling. The compressor with the decrease is required, the remaining "Lag"... -

Page 29: 1-Small Compressor & 3-Large Compressors/6-Stage

Table 19 summarizes the staging sequencing for the 2-Small cooling. The compressor with the fewest run hours is staged Compressors & 2-Large compressor/ 6-Stage cooling con- on first and staged off last. Compressors #4, #5 or #6 pro- figuration. vide the last three stages of cooling. The compressor with the fewest run hours is staged on first and staged off last. -

Page 30: Software Identification And Configuration

Depending on the unit configuration, there may be one or in the Unit Configuration menu of the keypad/display. These more auxiliary control boards each loaded with an applica- can also be read using the MicroTech II Service Tool Table 21: Software Component Identification Software Label... - Page 31 2, Two Staged Local 4, Steam or Hot Water Not supported by software 0, Constant Volume Discharge Fan Type McQuay_SelfCon. App. McQuay. SC. DF Cap Ctrl. Fan Ctrl Type (2296) 1, Vanes (VIV) 2, VFD Not supported by software 0, None...

-

Page 32: Main Control Board (Mcb) Data Archiving

Main Control Board (MCB) Data the possible MicroTech II keypad items. However, all of these items do not always apply depending on the main con- Archiving trol board configuration string. For this reason, 8 other key- All MCB control parameters and the real time clock settings... -

Page 33: Typical Wiring Diagrams

Typical Wiring Diagrams The following vertical self-contained unit wiring diagrams Note: Some of the component designations depend on are typical. They are included here to show common factory unit sizes. The abridged legend shown in Figure 13 and field wiring schemes. For exact wiring information per- applies to Figure 14 through Figure 20. - Page 34 Figure 14: Input Schematic: Discharge Air Control (DAC) IM710...

- Page 35 Figure 15: Input Schematic: Zone or Space Comfort Control (SCC) IM710...

- Page 36 Figure 16: Output Schematic: Actuator Control IM710...

- Page 37 Figure 17: Output Schematic: Auxiliary Fan Start/Stop Control IM710...

- Page 38 Figure 18: Output Schematic: Actuator Control IM710...

- Page 39 Figure 19: Output Schematic: Compressor Control (4 Compressors/4, 5 and 6 Stage) IM710...

- Page 40 Figure 20: Output Schematic: Compressor Control (6 Compressors/6 Stage) IM710...

-

Page 41: Test Procedures

Table 27 on page 50 in the “Parts List” section at the end of board will continue execution of the on-board program. this manual includes a listing of MicroTech II related part Note: After battery replacement, the Error LED will not numbers. - Page 42 MCB LED Power-Up Sequence sequence consists of 3 main components: LED Operational Check period, the MCB Error Code Display period and the The various LEDs on the MCB are shown in Figure 25. MCB Initialization period. These are described in the fol- When power is applied to the MCB the LEDs on the board should execute a specific startup sequence.

- Page 43 LED Operational Check Period. When power is applied controller. Refer to “Main Control Board (MCB) to the MCB or when the MCB is reset, an operational test of Data Archiving” on page 31. the 16 Binary Input LEDs in the upper left corner and the 4 2.

- Page 44 Table 25: Main Control Board LED Startup Error Codes Startup Errors Battery Flash Flash Flash BACnet- Ethernet MSTP/Lon High Expansion Port Mark Port Startup Main/ Config. Byte Byte Port Port Port Boot (Optional) N2 Bus Port RS232 Port Ethernet Port Blinking Blinking Blinking...

-

Page 45: Sram Test

MCB data communication installation and maintenance bulletin IM 704, MicroTech II BACnet/MSTP Communications Module. Replace the N2 channels. Once in the test mode, proper operation of the var- Communication Card if defective. -

Page 46: Troubleshooting Keypad/Display

Troubleshooting Keypad/Display xxx = The version of firmware in the keypad/display yy = The keypad/display address 32 Keypad/Display Power Up Initialization zzzz = OK normally or NO COMM if the MCB is not com- When the keypad/display is connected to the MCB and municating with the keypad/display power is applied, the firmware in the keypad/display will run aaaa = OK normally or IRAM of internal RAM test failed... -

Page 47: Troubleshooting Temperature Sensors

1. Disconnect the sensor from the MCB. Table 26 on page 48, replace the sensor. Figure 22: MicroTech II Temperature Sensor - Temperature (°F) vs. Resistance Graph Figure 23: MicroTech II Temperature Sensor - Temperature (°C) vs. Resistance Graph IM710... -

Page 48: Troubleshooting Communications Cards

IM 702, MicroTech II Lon- Mark Communications Module. For details regarding 23 (-5) LonMark protocol data, refer to engineering data document, 32 (0) ED 15 061, MicroTech II Protocol Information Data for Ver- tical Self-contained Units. 41 (5) 50 (10) Troubleshooting Static Pressure Trans-... - Page 49 If 24 VAC supply reads low and/or the MCB is malfunc- with the suspect transducer or try installing a new trans- tioning, the sensor may be drawing too much current ducer. Restore power by closing S1, and verify whether (the 24 VAC terminals can only supply 30 mA). Discon- the suspect transducer is defective.

-

Page 50: Troubleshooting Refrigerant Pressure Transducers

Troubleshooting Refrigerant Pressure If the measured voltage and pressure match, the MCB may be defective. Transducers The following procedure can be used to troubleshoot a sus- Remove power from the controller. If available, swap a pect sensor: similar good transducer with the suspect transducer or try installing a new transducer. -

Page 51: Parts List

Parts List The following is a partial list of applied self-contained unit replacement parts. Contact a local sales representative for addi- tional information Table 28 Component Description McQuay Part Number Designation Main Control Board 060006101 CCB1 Auxiliary Cooling Control Board... - Page 52 13600 Industrial Park Boulevard, Minneapolis, MN 55441 USA (763) 553-5330...

Need help?

Do you have a question about the MicroTech II and is the answer not in the manual?

Questions and answers