McQuay MicroTech II Operation & Maintenance Manual

Unit ventilator controls for aaf®

-hermannelson® classroom unit ventilators

Hide thumbs

Also See for MicroTech II:

- Operation manual (136 pages) ,

- Installation manual (58 pages) ,

- Installation and maintenance manual (48 pages)

Table of Contents

Advertisement

MicroTech II

™

for AAF

®

-HermanNelson

Model AZV, AZU, AZR – Floor Mounted Self Contained Air Conditioner

Develop a thorough understanding before starting the commissioning procedure.

This manual is to be used by the commissioner as a guide. Each installation is unique, only general topics are covered.

The order in which topics are covered may not be those required for the actual commissioning.

©2002 AAF

®

-HermanNelson

®

Operation Maintenance Manual

Unit Ventilator Controls

®

Classroom Unit Ventilators

DX Cooling with Electric Heat – Software Model UV04

Used with AAF-HermanNelson Classroom Unit Ventilator

Model AVV, AVR – Floor Mounted

Model AHV, AHR – Ceiling Mounted

Before unit commissioning, please read this publication in its entirety.

IMPORTANT

OM 750

Group: Unit Ventilator

Part Number: 106506303

Date: August 2002

Supercedes: New

Advertisement

Table of Contents

Summary of Contents for McQuay MicroTech II

- Page 1 Operation Maintenance Manual OM 750 Group: Unit Ventilator Part Number: 106506303 Date: August 2002 Supercedes: New MicroTech II ™ Unit Ventilator Controls for AAF ® -HermanNelson ® Classroom Unit Ventilators DX Cooling with Electric Heat – Software Model UV04 Used with AAF-HermanNelson Classroom Unit Ventilator Model AVV, AVR –...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Abbreviations Table ............3 Space Temperature Setpoints ............19 Safety Information ............4 Networked Setpoint Capability ..........19 Introduction ..............5 Networked Setpoint Offset Capability ........19 Getting Started ............... 5 Networked Setpoint Shift Capability ........19 Using the Local User Interface (LUI) .......... -

Page 3: Abbreviations Table

UVC Input and Output Table ..........27 Discharge Air Temp Sensor Failure ........28 Diagnostics and Service ..........27 Outdoor Coil DX Temp Sensor Failure ........28 Alarm and Fault Monitoring ............27 Space Humidity Sensor Failure (optional) ......28 Space Temp Sensor Failure ........... -

Page 4: Safety Information

This equipment must be properly grounded. Connections and temperatures from -40°F to 158°F. It can be stored in ambient service to the MicroTech II control panel must be performed only by temperatures from -65°F to 176°F. The controller is designed to... -

Page 5: Introduction

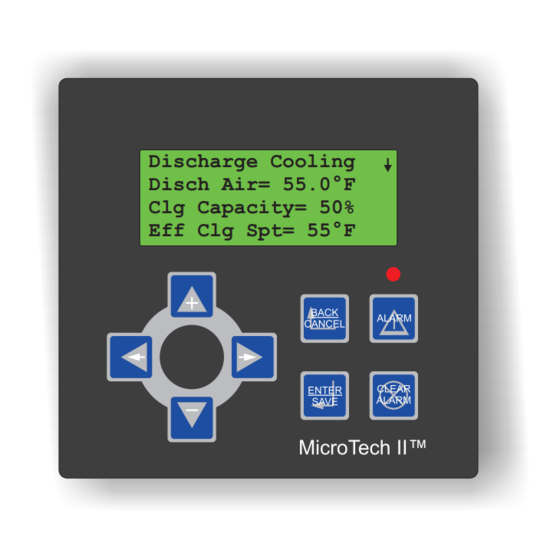

GETTING STARTED Using the Local User Interface (LUI) NOTICE The MicroTech II UVC is a self-contained device that is capable of Many UVC parameters are accessible both through the LUI and the complete, stand-alone operation. Information in the controller can be network interface. -

Page 6: Fan Button

NOTICE NOTICE The setpoint offset is cleared after every power cycle. When The UVC archives each change to the LUI Fan and Mode buttons. changing the setpoint offset after a power cycle, or for the first time, When the On/Stop button is used to bring the unit out of Off mode, this cleared value will be shown as the highest allowed value (5°F the UVC will implement the last active fan and unit modes. -

Page 7: Lui Menu Reference

Personal Computer or network interface. The LUI menu is accessed via an unmarked, Hidden button. This Hidden button is located behind the letter “h” in the MicroTech II logo on the LUI face. The LUI menu consists of two levels. The first level is the LUI Menu Item List containing alphanumeric characters which represent each parameter. - Page 8 Table 6. LUI Menu Item List (Continued) Two Digit Display LUI Menu Item List Abr. Description Default Economizer Enable Set economizer status: 0 = disable, 1 = enable. Economizer OA Temp Setpoint Adjust economizer OA temperature setpoint. F (20 Economizer IA/OA Temp Differential Adjust economizer IA/OA temperature differential.

-

Page 9: Description Of Operation

UVC to determine which state should be made active, these are the “questions” the UVC will continually consider. The MicroTech II UVC takes advantage of state machine programming The transition point is simply a point through which a number of to define and control unit ventilator operation. -

Page 10: Uvc Unit Modes

UVC Unit Modes Transition (UVC Mode = Off) into State The UVC provides several “normal” modes of unit operation, these include Off, Night Purge, Fan Only, Cool, Emergency Heat, Auto, Operation When Off mode becomes active, the UVC stops all Heat and Cool. -

Page 11: Fan Only Mode

Figure 10. Emergency Heat State Diagram purging process. In the Night Purge mode the space fan will be set to high speed, the OA damper will be set to 100% open, and the Exhaust Fan binary output (see External Binary Outputs) will be set to On. If not set to another mode within 1-hour, the UVC will force itself into the Fan Only mode (see Fan Only Mode). -

Page 12: Cant Heat State

HEAT MODE (SUPER STATE) Cant Heat State (state number D) When in Heat mode the UVC will use primary heat (electric heat) as The Cant Heat state is a “non-normal” state that the UVC can go into when Emergency Heat mode is active. Only an IAT or DAT sensor needed to maintain the effective heating setpoint (see Space Temperature fault during Emergency Heat mode will cause the UVC to make this Setpoints). -

Page 13: Heat State

Heat State (state number 5) Low Limit State (state number E) The Heat state is the “normal” state that the UVC will go into when The Low Limit state is a “non-normal” state that the UVC can go into Heat mode is active. while Heat mode is active when the unit reaches 100% heating and still cannot meet the current DATS (see Discharge Air Temperature Control) required to maintain the effective heating setpoint (see Space... -

Page 14: Cool Mode (Super State)

Transition (UVC Mode = Cool) COOL MODE (SUPER STATE) into When in Cool mode the UVC will use primary cooling (economizer) Super State (UVC Mode = Auto AND Space Temperature = Warm) and secondary cooling (mechanical, DX) as needed to maintain the effective cooling setpoint (see Space Temperature Setpoints). -

Page 15: Econ State

Econ Mech State (state number 1) Econ State (state number 3) The Econ Mech state is a “normal” state that the UVC can go into when The Econ state is a “normal” state that the UVC can go into when Cool Cool mode is active. -

Page 16: Mech State

Mech State (state number 2) Operation When the Cant Cool state becomes active, no cooling within State will take place. The Mech state is a “normal” state that the UVC can go into when Cool The UVC will remain in this state until one of the mode is active. -

Page 17: Active Dehumidify State

Table 8. Actions during Special Purpose Unit Modes The UVC will remain in this state until one of the transition out conditions become true, or until one of Indoor Air Outdoor Air the super state transition out conditions becomes true. Exhaust Fan Output Fan (IAF) Damper (OAD) -

Page 18: Occupancy Modes

Table 9. Special Purpose UVC Unit Mode Priority Priority Result Emergency Override Remote Shutdown Energy Hold Energy Hold Unit Mode Actual UVC Input Binary Input Off Input Off Output Output Action See the Normal Normal Normal UVC Mode Priority table De-energized Normal Energy Hold Off... -

Page 19: Occupied Mode

OCCUPIED MODE Table 12. Remote Wall-Mount Sensor Status LED The occupied mode is the normal day time mode of UVC operation. Indication LED Operation During occupied mode the UVC will use the occupied heating and Occupied On Continually cooling setpoints, the OAD will operate normally, and by default the Unoccupied On 1-sec / Off 9-sec IAF will remain on. -

Page 20: Lui Setpoint Offset Adjustment

LUI SETPOINT OFFSET ADJUSTMENT EFFECTIVE SETPOINT CALCULATION EXAMPLES The LUI can be used to make adjustments to the value of the Setpoint The UVC calculates the effective setpoint (Effective Setpoint Output) Offset Input variable. See “Using the LUI to adjust Setpoint Offset”. based upon the six occupancy setpoints for heating and cooling, occupancy mode, and the value of the network variables Space Temp NOTICE... -

Page 21: Pi Control Loops

PI Control Loops The MicroTech II UVC uses PI-loop control for heating, cooling and ventilator configuration. The UVC uses “single” and “cascading” PI ventilation processes within the unit ventilator. As many as six PI loops where needed. algorithms may be used for software model 04, dependent upon the unit Table 15. -

Page 22: Pi Control Parameters

Figure 22. Proportional Band too Large PI CONTROL PARAMETERS Associated with each PI loop is a set of two adjustable PI parameters. These parameters are “Proportional Band” and “Integral Time”. When the unit ventilator is properly sized for the space, the factory settings for these parameters will provide the best and most robust control action. -

Page 23: Indoor Air Fan Operation

Indoor Air Fan Operation NOTICE The UVC supports a 3-speed IA fan: Low, Medium, and High. The UVC will calculate the effective fan speed and operation based upon If the CO Demand Controlled Ventilation (DCV) option is used, then the UVC will only use the IA fan high speed OA damper the unit mode, the occupancy mode, and the values of several network minimum position regardless of fan speed, the DCV function will variables. -

Page 24: Temperature Comparison With Enthalpy Comparison Economizer (Optional)

Temperature Comparison with Enthalpy Comparison NOTICE Economizer (optional) The UVC uses four configuration variables to determine if the The CO DCV function can increase the OA damper position past that required by the economizer and vice versa. economizer can be used: Economizer OA Temp Setpoint, Economizer Temp Differential and Economizer OA Enthalpy Setpoint, and Economizer EnthalpyDifferential. -

Page 25: Compressor Cooling Lockout

(no voltage source) to be used as a signal to the UVC, multiple units can be connected to a single set of dry-contacts. For wiring see MicroTech II Unit Ventilator Controller IM747. COMPRESSOR COOLING LOCKOUT The UVC is configured to lockout compressor cooling when the OA... -

Page 26: Remote Shutdown Input Signal

(contacts open). intended to be used with signal level voltages (24vac max) only. For wiring see MicroTech II Unit Ventilator Controller IM747. NOTICE Not all of the functions listed can be used at the same time. The... - Page 27 UVC INPUT AND OUTPUT TABLE All UVC input and output connections and their corresponding unit ventilator usage are shown in the following table. Table 20. Inputs and Outputs for Software Model 04 – DX Cooling with Electric Heat AI-2 Remote Setpt. Adjust. Pot. Description AI-3 DA Temp Sensor...

- Page 28 DIAGNOSTICS AND SERVICE (continued) SPACE TEMP SENSOR FAILURE ( SPACE COIL DX TEMP SENSOR FAILURE ( The Space Temp Sensor Failure fault will occur when the UVC detects The Space Coil DX Temp Sensor Failure fault will occur when the UVC an open or a short condition from the space temperature sensor.

- Page 29 DIAGNOSTICS AND SERVICE (continued) SPACE CO SENSOR FAILURE (OPTIONAL) ( The following procedure can be used to troubleshoot a suspect humidity sensor. The Space CO Sensor Failure fault will occur when the UVC detects 1. Disconnect the sensor(s)’ output voltage lead from the UVC analog an open or a short condition from the Space CO sensor.

- Page 30 UVC CONFIGURATION PARAMETERS The UVC has been provided with a number of configuration variables NOTICE as listed in the following table. These configuration variables are stored in UVC non-volatile memory. The software ServiceTools™ can be used to adjust parameters not For a description of supported network variables for each protocol refer adjustable through the LUI.

- Page 31 Table 25 . UVC Configuration Parameters (Continued) LUI Menu Configuration Parameter Name Abr. Notes Default Item Secondary Cool Integral Time 600 sec Primary Heat Proportional Band F (6 Primary Heat Integral Time 600 sec Discharge Air Temp Proportional Band 13.5 F (7.5 Discharge Air Temp Integral Time 900 sec...

- Page 32 This document contains the most current product information as of this printing. For the most up-to-date product information, please go to www.mcquay.com. ® ©2002 McQuay International • www.mcquay.com • 800-432-1342 OM 750 (8/02) Page 32 of 32 OM 750...

Need help?

Do you have a question about the MicroTech II and is the answer not in the manual?

Questions and answers