Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for TREND VARIJIG

- Page 1 VARIJIG Please read these instructions before use.

-

Page 2: Table Of Contents

VARIJIG TECHNICAL DATA Dear Customer Thank you for purchasing this Trend product, we Extrusion thickness 15.8mm (5/8”) hope you enjoy many years of creative and Extrusion width 54.0mm (2 1/8”) productive use. Working area size (max.) 600mm x 600mm Please remember to return your guarantee card (23 5/8”... -

Page 3: Safety

VARIJIG SAFETY and balance at all times. Do not use recommended when working awkward or uncomfortable hand outdoors. Wear protective hair WARNING: positions. covering to contain long hair. Observe the safety regulations in the 5. Consider working environment. Do not 17. - Page 4 15. All fastening screws and nuts should be adhered to. Recommended speeds 4. When using a template guide bush, be tightened using the appropriate are shown in the Trend Routing ensure there is sufficient clearance spanner or key and to the torque Catalogue and/or website.

-

Page 5: Items Enclosed

■ Plunge router with suitable guide bush fitted (minimum spigot projection 8mm, e.g. Ref. GB30/A). ■ Suitable router cutter. ■ No. 2 Phillips ® screwdriver. ■ Square or long rule/tape measure. ■ Hand tools. ■ Clamps x 2 (or Varijig accessory clamps). -

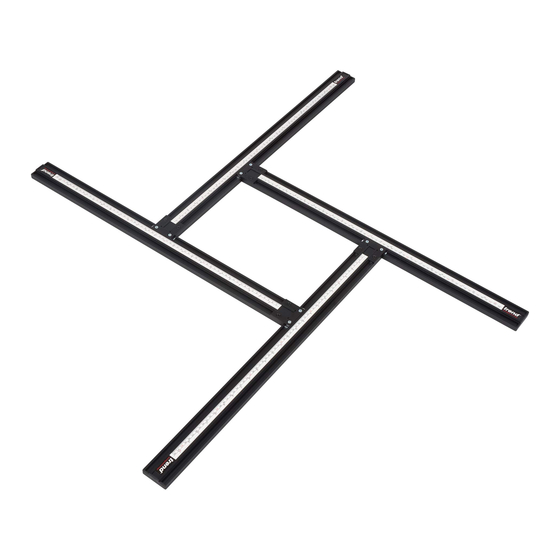

Page 6: Description Of Parts

VARIJIG DESCRIPTION OF PARTS Alloy extrusion T-nut Corner bracket Machine screw M5 (black-fixed) Machine screw M5 (silver-adjustable) Anti-tilt shoe Anti-tilt shoe fixing screw Scale Instructions... -

Page 7: Assembly & Adjustment

VARIJIG ASSEMBLY & ADJUSTMENT ■ Place the ends of each extrusion with the corner bracket fitted onto the bottom slot of The T-nuts are held by the silver screws onto the each extrusion, line up the T-nut and using corner bracket, these will need to be... -

Page 8: Operation

8mm. When using the guide bush the router sits on top of the Varijig frame. Choose a cutter with a diameter which will pass through the centre of the guide bush leaving enough clearance. The cutter can be straight or shaped. -

Page 9: Adjusting Frame For Size

Batten Batten After every adjustment, the frame will need to be checked for squareness. Clamping Varijig Frame Batten Batten ■ Clamp frame to component using shallow battens with pins or gripper clamps if they do not foul router, or use the optional accessory clamps. -

Page 10: Routing Squares And Rectangles

■ Ensure guide bush and cutter is fitted to the router. ■ Set the cutter depth. ■ Place router onto Varijig with the anti-tilt shoe sitting on the component. ■ Place router so that guide bush is touching the inside edge of the frame and switch on router. -

Page 11: Accessories

The corner pieces must be of a suitable thickness. ACCESSORIES Please use only Trend original accessories. Friction clamps are available. One clamp is fitted at either end of the extrusion. Tighten friction screw with No.2 Phillips ®... -

Page 12: Maintenance

VARIJIG MAINTENANCE The accessory has been designed to operate over a long period of time with minimum of maintenance. Continual satisfactory operation depends upon proper tool care and regular cleaning. Cleaning ■ Keep the grooves on the extrusion and knob threads clear of sawdust. -

Page 13: Spare Parts List

VARIJIG Please use only Trend original spare parts. VARIJIG - SPARE PARTS LIST v1.0 03/2005 Qty. Desc. Ref. T-Nut M4 WP-VJS/01 Machine Screw Csk M4 x 6mm Pozi Silver WP-VJS/02 Machine Screw Csk M4 x 6mm Pozi Black WP-VJS/03 Scale Metric/Imperial 640mm... - Page 15 RECYCLABLE © Copyright Trend 2012. No part of this publication may be reproduced, stored or transmitted in any form without prior permission. Our policy of continuous improvement means that specifications may change without notice. Trend Machinery and Cutting Tools...

Need help?

Do you have a question about the VARIJIG and is the answer not in the manual?

Questions and answers