Table of Contents

Advertisement

This manual is part of the documentation package

with order number VIPA HB140E_CPU_SC and relevant for:

Product

Order number

CPU 313SC/DPM

VIPA 313-6CF03

Manual

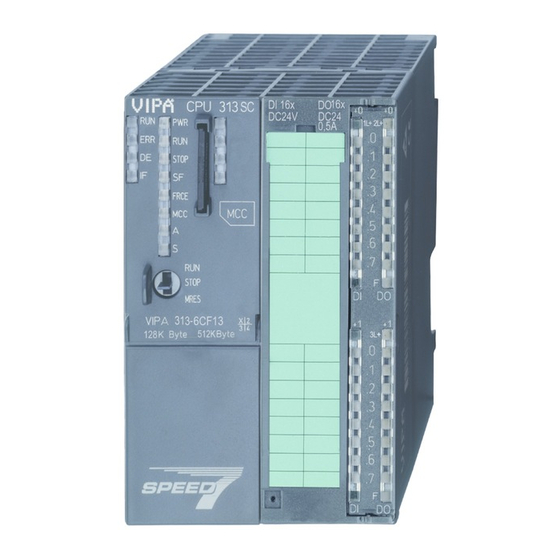

VIPA System 300S

SPEED7 - CPU SC

313-6CF03

Order No.: VIPA HB140E_CPU_SC

Reference: RE_313-6CF03

Rev. 07/45

as of state:

CPU HW

CPU FW

01

V328

DPM FW

V312

Advertisement

Table of Contents

Need help?

Do you have a question about the System 300S SPEED7 CPU 313SC/DPM and is the answer not in the manual?

Questions and answers