Summary of Contents for Peri VST

- Page 1 Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Confi guration Edition 01 | 2017...

-

Page 3: Table Of Contents

Introduction Assembly of the VST Leg Target groups Preparation of the RCS Rail Additional technical documentation Preparation of the Prop Base VST 48 intended use Preparation of the Prop Connector VST 48 Instructions for Use Prop Connector VST 48 Cleaning and maintenance instructions... -

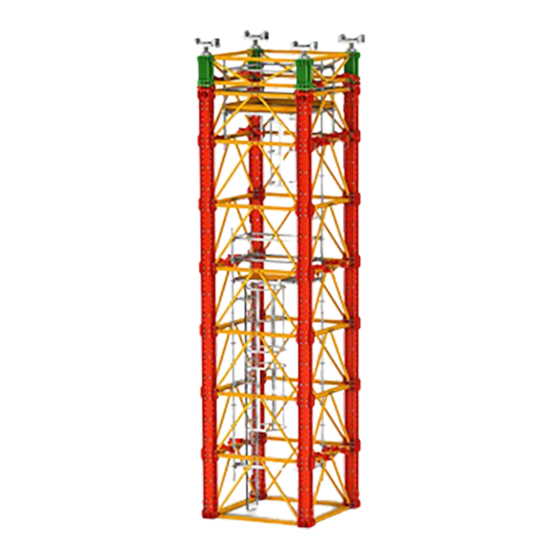

Page 4: Overview

Overview Main components B2 Assembly of the VST Leg B3 Module Assembly B4 Head Spindle Frame B5 Tower Assembly D1 Height Adjustment Head Spindle VST (+/- 140 mm) VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 5: Key

For a better understanding, detailed illustrations are partly incomplete. The safety installations which have possibly not been featured in these detailed drawings must nevertheless still be available. VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 7: Introduction B2

ƒ – PERI UP Rosett 72 Instructions for Use ƒ – Pallets and Stacking Devices – Hydraulic Head Spindle Device VST Brochure ƒ – VARIOKIT Engineering Construction Kit VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 8: Intended Use

Ledgers VST 200 and Diagonal Struts Up to 700 kN (height-dependent) per ƒ tural components. VST at a centre distance of 2 m. leg. The system can be used for all types of The Climbing Rail RCS is additionally supporting structures, with a permissi-... -

Page 9: Cleaning And Maintenance Instructions

Do not clean components suspended on a crane. Any repairs to PERI products are to be carried out by qualified PERI personnel only. VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 10: Safety Instructions

Instructions for Assembly and Use sup- operational safety as well as stability are for the assembly, modification or dis- plied by PERI are available at all times and to be determined. mantling of the system, e.g. are understood by the site personnel. -

Page 11: System-Specific 7 B3

For information regarding the mainte- Use PERI load-bearing devices and lifting nance of the Hydraulic Head Spindle gear as well as only those load-bearing Device VST, see Instructions for Use. points provided on the component. During the moving procedure, ensure that components are picked ƒ... -

Page 12: A1 Module Overview

A1 Module overview Overview of Module VST VST 125 VST 175 VST 275 Head Spindle Frame VST 100 VST 375 VST 525 VST 775 VST 1025 Fig. A1.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 13: Arrangement Of The Bracing

A1 Module overview Arrangement of the Bracing Connectors VST Observe the assembly position of the Prop Base VST and Prop Connector VST. (see Section B2) VST 125 VST 175 VST 275 Head Spindle Frame VST 100 VST 375 VST 525... -

Page 14: Module Vst Components

Climbing Rail RCS 498 109471 Climbing Rail RCS 748 109472 Climbing Rail RCS 998 109610 The VST module consists of 2 VST Legs plus Bracing Connector VST 117411 Fitting Pin Ø 21 x 120 104031 Cotter Pin 4/1, galv. 018060 Fitting Pin Ø... -

Page 15: Additional Components

A1 Module overview Additional components Name Item no. Head Spindle VST 100 117465 28.1 Fork Head 28.2 Spindle Nut 28.3 Spindle Sleeve Mounting Shaft VST 117377 Heavy-Duty Spindle SLS Push-Pull Prop RS 1000, galv. 028990 Push-Pull Prop RS 1400, galv. -

Page 16: A2 Module Vst

Horizontal Ledger VST 200 Diagonal Strut VST 200/112.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 125 is 370.20 kg. Fig. A2.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 17: A3 Module Vst

Diagonal Strut VST 200/112.5 Diagonal Strut VST 200/62.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 175 is 528.44 kg. Fig. A3.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 18: A4 Module Vst

Diagonal Strut VST 200/150 Diagonal Strut VST 200/112.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 275 is 644.02 kg. Fig. A4.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 19: A5 Module Vst

Diagonal Strut VST 200/100 Diagonal Strut VST 200/112.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 375 is 852.64 kg. Fig. A5.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 20: A6 Module Vst

Diagonal Strut VST 200/100 Diagonal Strut VST 200/112.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 525 is 1123.66 kg. Fig. A6.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 21: A7 Module Vst

Diagonal Strut VST 200/100 Diagonal Strut VST 200/112.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 775 is 1601.30 kg. Fig. A7.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 22: A8 Module Vst 1025

Diagonal Strut VST 200/150 Diagonal Strut VST 200/112.5 Connecting means are pre-assembled in the VST components. The total weight of a Module VST 1025 is 1987.12 kg. Fig. A8.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 23: A9 Head Spindle Frame Vst

A9 Head Spindle Frame VST Parts list for the Head Spindle Frame VST Pos. Name Quantity Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Horizontal Ledger VST 200 Diagonal Strut VST 200/62.5 Head Spindle VST 100 The total weight of a Head Spindle Frame VST is 424.62 kg. -

Page 24: A10 Head Spindle Vst

A10 Head Spindle VST 100 Parts list for a Head Spindle VST 100 Pos. Name Quantity Head Spindle VST 100 28.1 28.1 Fork Head 28.2 Spindle Nut 28.3 Spindle Sleeve Mounting Shaft VST 43.4 Hydraulic Cylinder The maximum spindling length must not exceed 1138 mm measured from 28.2... -

Page 25: A11 Vst Tower Configuration 1

Cotter Pin 4/1, galv. Horizontal Ledger VST 200 Diagonal Strut VST 200/150 Diagonal Strut VST 200/100 Diagonal Strut VST 200/112.5 Diagonal Strut VST 200/62.5 Total weight for one VST Tower (configuration 1) Name Total weight (kg) Tower 125 912.80 Tower 175 1,324.52... -

Page 26: A12 Vst Tower Configuration 2

A12 VST Tower Configuration 2 Tower configuration 2.0 x 1.0 – 4.5 m Pos. Name Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Heavy-Duty Spindle SLS Connecting means for Heavy-Duty Spindles SLS must be ordered separately. Fig. A12.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use –... -

Page 27: A13 Vst Tower Configuration 3

A13 VST Tower Configuration 3 Tower configuration 1.25 – 6.5 x 1.0 – 4.5 m Pos. Name Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Heavy-Duty Spindle SLS Steel Waler Universal SRU U120 Adapter VST-SRU Connecting means for Heavy-Duty Spindles SLS and Steel Waler Universal SRU U120 must be ordered separately. -

Page 28: A14 Vst Tower Configuration 4

A14 VST Tower Configuration 4 Tower configuration 1.25 – 6.5 x 1.25 – 6.5 m Pos. Name Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Heavy-Duty Spindle SLS Steel Waler Universal SRU U120 Adapter VST-SRU Connecting means for Heavy-Duty Spindles SLS and Steel Waler Universal SRU U120 must be ordered separately. -

Page 29: A15 Arrangement Of The Height Adjusts

A15 Arrangement of the Height Adjusts When arranging the Height Adjusts VST 25 and VST 12.5, the following must be observed: – Maximum one Height Adjust VST 12.5 (44) and one Height Adjust VST 25 44 & 45 (45) may be placed under the head spindle (28). -

Page 30: A16 Assembly Of Two Cross Connectors Vst E1

Nut ISO 7042 M20-8, galv. Sleeve VST, galv. Cyl. Bolt ISO 4762 M20x150-8.8, galv. Assembly 1. Insert Sleeve VST, galv. (16) in the Bracing Connector VST (8). 2. Position 2x Cross Connector VST (13) on the Climbing Rail RCS 148 (2)*. -

Page 31: A17 Connecting Adapter Vst-Sru

Steel Waler SRU U120 (33) using 2x Fitting Pins Ø 21 x 120 (9) and secure with Cotter Pins 4/1, galv. 2. Mount Adapter VST-SRU (34) on the Cross Connector VST (13) in the cen- tre using 1x Fitting Pin Ø 21 x 120 (9) and secure with Cotter Pin 4/1, galv. -

Page 32: A18 Vst Module With Working Platform

A18 VST Module with working platform PERI UP Rosett Flex components Project-specific planning is required for the working platforms. Components Pos. Name Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Connector UP / VST Bolt Ø 20 x 140, galv. - Page 33 A18 VST Module with working platform Connector UP-VST Pos. Name Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Connector UP-VST 38.1 Retaining Lug Bolt Ø 20 x 140, galv. Wedge K, galv. 38.1 Fig. A18.02 VST Heavy-Duty Shoring Tower...

-

Page 34: A19 Vst Module With Additional Legs

A19 VST Module with additional legs Components Pos. Name Fitting Pin Ø 21 x 120 Cotter Pin 4/1, galv. Leg Connector VST 200/37.5 Horizontal Connector VST 37.5 Fig. A19.01 Fig. A19.01a VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 35: A20 Hydraulic Unit Vst

A20 Hydraulic Unit VST 43.2 Follow Instructions for Use for the Hydraulic Head Spindle Device VST. 43.4 43.3 Hydraulic Head Spindle Device VST Item no. 117465 | Item no. 117678 Translation of the Original Instructions for Use Fig. A20.01 43.1 Edition 02 | 2016 Fig. -

Page 36: Operating State: Mounting

– After the upper construction has Head Spindle VST 100 reached the required load-bearing capacity, the VST Heavy-Duty Shoring Tower is then lowered according to specifications laid down by the responsible structural engineer. – Dismantling of additional load-bearing elements according to project-specific planning. -

Page 37: Preparation Of The Rcs Rail

B2 Assembly of the VST Leg Preparation of the RCS Rail 1. Supporting the RCS Rails with timbers or the like (h ≥ 10 cm) on a flat surface. 2. Remove the first pair of bolts (M20 and M24) from the climbing rail. -

Page 38: Prop Connector Vst 48

Six rows of holes are free Bolting the Prop Connector VST 48 to the Climbing Rail RCS 1. Insert Prop Connector VST 48 (21) into the Climbing Rail RCS (3)* on the side with the six free rows of holes. -

Page 39: Prop Base Vst 48

Bolting the Prop Base VST 48 to the Climbing Rail RCS Five rows of holes are free 1. Insert Prop Base VST 48 (17) into the Climbing Rail RCS 248 (3)* on the side with the five free rows of holes. -

Page 40: Bracing Connector Vst

B2 Assembly of the VST Leg Bracing Connector VST Risk of crushing fingers when inserting. – The Bracing Connector VST (8) must be connected at the height of the Horizontal Ledger VST (23). – The positions are indicated through the distances in Section A1 Overview. -

Page 41: Cross Connector Vst

B2 Assembly of the VST Leg Cross Connector VST Mounting of the Cross Connector VST (13) on the Climbing Rail RCS 1. Position the Cross Connector VST (13) on the axis of the Bracing Connector VST (8). 2. Insert 2 x Bolts ISO 4014 M24 (19). -

Page 42: Horizontal Ledger Vst

Cross Connector VST. – Bracing above the Bracing Connector VST is not permitted. – Position VST Legs at a distance of 2.0 m to each other on a flat assembly surface. – Firstly, the Horizontal Ledgers VST... -

Page 43: Diagonal Strut Vst

Horizontal Ledger VST 200 (23). (Fig. B3.02a) 3. Connect the second Diagonal Strut VST 200/150 (24b)* to the other Prop Base VST 48 (17) using 1x Fitting Pin Ø 21 mm (9). 4. Swivel second Diagonal Strut VST 200/150 (24b)* into the Horizontal Ledger VST 200 (23). -

Page 44: Mounting The Head Spindle Frame

B4 Head Spindle Frame Mounting the Head Spindle Frame Frame assembly 1. Place Head Spindles VST 100 (28) on timbers. 2. Connect the bottom Horizontal Ledger VST 200 (23a) to the first Head Spindle VST 100 (28a) using 1x Fitting Pin Ø 21 mm (9) and secure with Cotter Pin 4/1, galv. - Page 45 B4 Head Spindle Frame 6. Connect the first Diagonal Strut VST 200/62.5 (27a) to the Head Spindle VST 100 (28a) using 1x Fitting Pin Ø 21 mm (9) and secure with Cotter Pin 4/1, galv. 7. Connect the first Diagonal Strut VST 200/62.5 (27a) to the Horizontal...

-

Page 46: Adjusting The Spacer Plates Of The Head Spindle Vst

B4 Head Spindle Frame Adjusting the spacer plates of the Head Spindle VST 100 – The Head Spindle VST 100 (28) is adjustable for cross beam widths from 20 cm to 32 cm. – For the centric position of the cross... -

Page 47: Tower Assembly With Vst Components

2. On each side, connect 1x Horizontal Ledger VST 200 (23) to the Prop Bases VST 48 (17) and Prop Connec- tors VST 48 (21) by means of 1x Fitting Pin Ø 21 mm (9) respectively. (Fig. B5.01) Fig. B5.01 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use –... - Page 48 Fitting Pins Ø 21 mm (9) can be mounted. (Fig. B5.02) 3. Connect the Horizontal Ledgers VST 200 (23) to the bottom module using 1x Fitting Pin Ø 21 mm (9) each. 4. Secure position, e.g. with timbers.

- Page 49 B5 Pre-assembly of the tower segments At least one Diagonal Strut VST (26) must always be installed per side before the crane lifting gear is re- moved. Assembly of the Diagonal Strut VST 1. On each side, insert 1x Diagonal Strut VST (26)* into the Horizontal Ledger VST 200 (23).

-

Page 50: Tower Assembly With Sls Spindles

1. Attach the crane lifting gear to the spacers. 2. Connect 2x Heavy-Duty Spindles SLS Fig. B5.07 (30) each to the Prop Bases VST 48 (17) and Prop Connectors VST 48 (21) by means of 1x Fitting Pin Ø 21 mm (9) each. - Page 51 SLS (30) to the bottom module using 1x Fitting Pin Ø 21 mm (9) each. 4. Secure position, e.g. with timbers. (Fig. B5.09) Fig. B5.08 Timber Fig. B5.09 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

- Page 52 Prop Base VST 48 (17). 2. Connect the Heavy-Duty Spindle SLS (30) to the Bracing Connector VST (8) and Prop Base VST 48 (17) by means of 1x Fitting Pin Ø 21 mm (9) each. (Fig. B5.10) 3. Remove crane lifting gear from the spacers.

-

Page 53: Working Platform

Mounting the Connector UP-VST 1. Insert 1x Connector UP-VST (38a) from below into the Horizontal Ledger VST 200 (23a) as a horizontal bearing on the left and right. 2. Secure Connectors UP-VST (38) with Fitting Pins Ø 21 mm (9) or PERI Wedge K (40). - Page 54 – Project-specific planning is always required for the working plat- forms. – Follow the Instructions for Assembly and Use for the PERI UP Rosett 72. Installing the platform 1. Installation of the required brackets and standard components of the PERI UP system.

-

Page 55: Erecting The Tower With Vst Components

C1 Erecting the tower with VST components – Observe the information on at- taching lifting gear in Section F4. – Use textile lifting gear with suffi- cient load-bearing capacity. – When erecting the tower, ensure that no persons remain in the area of risk. - Page 56 C1 Erecting the tower with VST components Moving the tower – Check that the foundation is level and sufficiently load-bearing before lower- ing the tower. – Any unevenness must be corrected by using cement grouting which has the same quality as the concrete.

-

Page 57: Erection Of A Single Module

Attaching to the crane 1. Attach lifting gear to the module (see Section F3). 2. Use the crane to tilt the module over the Prop Base VST 48 (17). Use a rope to guide the tower. Fig. C2.01 Erecting the tower 1. - Page 58 – If no module anchorage for the foun- dation is available, the Heavy-Duty Spindle SLS (30b) must be mounted on the Bracing Connector VST (8) in the top third. Fig. C2.04 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

- Page 59 Securing of the second module 1. Mount the horizontal Heavy-Duty Spindles SLS (30a) on the Prop Connector VST 48 (21) and adjust the spacing between the modules. 2. Install one Heavy-Duty Spindle SLS (30b) as a diagonal strut for bracing the tower.

- Page 60 Assembly work must be carried out from a safe position. Bracing the tower 1. Installation of the statically required Heavy-Duty Spindles SL (30) for brac- ing the tower. Fig. C2.07 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

- Page 61 – Follow the manufacturer’s instruc- tions. – In order to achieve a full-surface con- tact between the foundation and the Prop Base VST 48 (17), the gap must be completely filled with non-shrink- able cement grouting. – The quality of the cement grouting must correspond to the quality of the concrete.

-

Page 62: Manual Adjustment

12 mm. 1. Insert the Mounting Shaft VST (29) into the spindle nut (28.1). (Fig. D1.01) 2. Turn the Mounting Shaft VST (29) in a clockwise direction in order to spindle out the spindle head. -

Page 63: Adjustment With The Hydraulic Cylinder

(43.4). 5. Insert the Mounting Shaft VST (29) into the spindle nut (28.1). (Fig. D1.07) 6. Turn the Mounting Shaft VST (29) in a clockwise direction until the spindle nut (28.1) rests on the head plate. Fig. D1.05 Fig. D1.06 7. - Page 64 1. Insert the Mounting Shaft VST (29) into the spindle sleeve (28.3). 28.3 2. Lower the spindle sleeve (28.3) with Mounting Shaft VST (29) until a 13 mm spacing is between the spindle sleeve (28.3) and hydraulic cylinder (43.4). (Fig. D2.01) 3.

-

Page 65: Preparation Of The Towers

4. Tilt the tower segment and place it on the ground for dismantling. 5. Remove crane lifting gear from the tower segment. Use a rope to guide the tower. Fig. E1.01b VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 66: Module Preparation

3. Leave the area of risk. 4. Lift the module. 5. Place the module on the ground for dismantling. 6. Remove crane lifting gear from the module. Fig. E1.02a Fig. E1.02b VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... -

Page 67: Dismantling The Tower

1. Dismantle the module. 2. Place the spacers of the RCS Rails in the correct position again. (Fig. E1.04a + E1.04b) 3. Fit the VST components with the connection means again. Fig. E1.04a Fig. E1.04b (Fig. E1.05a + E1.05b) Fig. - Page 68 = 2.5 % x F (Fig. F1.02) Maximum leg load [kN] 800.00 700.00 600.00 500.00 Maximum leg 400.00 load 300.00 200.00 100.00 0.00 Tower height [m] Fig. F1.02 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

- Page 69 F Spacer M20-82 Load-bearing capacity: perm. F = 2800 kg Spacer M24-82 Load-bearing capacity: perm. F = 5000 kg Spacer M20-82 Spacer M24-82 Fig. F2.01 Fig. F2.02 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

-

Page 70: Without Head Spindle Frame

Without Head Spindle Frame The lifting gear is attached to 4 Lifting Pins Ø 21 x 120 (9) which are mounted on the Prop Connector VST 48 (21). (Fig. F3.03a) Chain angle of inclination = max. 30° (Fig. F3.02) Per load-bearing point (Fitting Pin Ø... -

Page 71: With Head Spindle Frame

F3 Moving the module With Head Spindle Frame The lifting gear is connected underneath the Diagonal Struts VST 200/62.5 (27). (Fig. F3.05) Chain angle of inclination = max. 30° (Fig. F3.06) Per load-bearing point (Diagonal Strut VST) perm. F = 6.4 kN (Fig. -

Page 72: Without Head Spindle Frame

The lifting gear is attached to 4 Lifting Pins Ø 21 x 120 (9) which are mounted on the Prop Connector VST 48 (21). Fig. A4.01 (Fig. F4.03) Chain angle of inclination ... -

Page 73: With Head Spindle Frame

F4 Moving the towers With Head Spindle Frame The lifting gear is connected underneath the Diagonal Struts VST 200/62.5 (27). (Fig. F4.05) Chain angle of inclination = max. 30° (Fig. F4.06) Per load-bearing point (Diagonal Strut VST) perm. F = 640 kg (Fig. -

Page 74: Combination Table 225 - 987.5 Cm

612.5 598.7 626.3 611.2 638.8 637.5 623.7 651.3 636.2 663.8 662.5 648.7 676.3 661.2 688.8 687.5 673.7 701.3 686.2 713.8 712.5 698.7 726.3 711.2 738.8 737.5 723.7 751.3 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... - Page 75 936.2 963.8 962.5 948.7 976.3 961.2 988.8 987.5 973.7 1001.3 Table F5.01 For lowering, a remaining distance for the spindle of approx. 8 cm is to be planned. VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

-

Page 76: Combination Table 1000 - 1987.5 Cm

1413.8 1412.5 1398.7 1426.3 1425 1411.2 1438.8 1437.5 1423.7 1451.3 1450 1436.2 1463.8 1462.5 1448.7 1476.3 1475 1461.2 1488.8 1487.5 1473.7 1501.3 1500 1486.2 1513.8 1512.5 1498.7 1526.3 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... - Page 77 1963.8 1962.5 1948.7 1976.3 1975 1961.2 1988.8 1987.5 1973.7 2001.3 Table F6.01 For lowering. a remaining distance for the spindle of approx. 8 cm is to be planned. VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

-

Page 78: Combination Table 2000 - 2987.5 Cm

2413.8 2412.5 2398.7 2426.3 2425 2411.2 2438.8 2437.5 2423.7 2451.3 2450 2436.2 2463.8 2462.5 2448.7 2476.3 2475 2461.2 2488.8 2487.5 2473.7 2501.3 2500 2486.2 2513.8 2512.5 2498.7 2526.3 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... - Page 79 2963.8 2962.5 2948.7 2976.3 2975 2961.2 2988.8 2987.5 2973.7 3001.3 Table F7.01 For lowering, a remaining distance for the spindle of approx. 8 cm is to be planned. VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

-

Page 80: Combination Table 3000 - 4000 Cm

3413.8 3412.5 3398.7 3426.3 3425 3411.2 3438.8 3437.5 3423.7 3451.3 3450 3436.2 3463.8 3462.5 3448.7 3476.3 3475 3461.2 3488.8 3487.5 3473.7 3501.3 3500 3486.2 3513.8 3512.5 3498.7 3526.3 VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration... - Page 81 3976.3 3975 3961.2 3988.8 3987.5 3973.7 4001.3 4000 3986.2 4013.8 Table F8.01 For lowering, a remaining distance for the spindle of approx. 8 cm is to be planned. VST Heavy-Duty Shoring Tower Instructions for Assembly and Use – Standard Configuration...

- Page 82 48.200 For connecting Climbing Rails RCS with Head 3 pc. 114563 Bolt ISO 4014 M24 x 140-10.9 Spindle VST or Height Adjust VST. 3 pc. 105032 Nut ISO 7042 M24-8, galv. 3 pc. 117452 Bolt ISO 4014 M20 x 130-10.9 3 pc.

- Page 83 Complete with For connecting Horizontal Ledgers VST and 2 pc. 113994 Bolt ISO 4014 M20 x 140-8.8, galv. Diagonal Struts VST cross to the direction of the 2 pc. 781053 Nut ISO 7042 M20-8, galv. frame. 1 pc. 117492 Sleeve VST, galv.

- Page 84 Complete with For connecting Horizontal Ledgers VST and 2 pc. 104031 Fitting Pin Ø 21 x 120 Diagonal Struts VST in direction of the frame. 2 pc. 111567 Fitting Pin Ø 26 x 120 2 pc. 018060 Cotter Pin 4/1, galv.

- Page 85 VST Heavy Duty Shoring Tower Item no. Weight kg Diagonal Struts VST 117388 8.910 Diagonal Strut VST 200/62.5 1019 117382 10.900 Diagonal Strut VST 200/100 1271 1201 117385 11.700 Diagonal Strut VST 200/112.5 1367 1297 117379 14.100 Diagonal Strut VST 200/150...

- Page 86 117707 9.200 Connector UP-VST Complete with Adaptor for mounting PERI UP scaffold parts to 1 pc. 104031 Fitting Pin Ø 21 x 120 the VARIOKIT Heavy Duty Shoring Tower. 2 pc. 105400 Pin Ø 20 x 140, galv. 3 pc. 018060 Cotter Pin 4/1, galv.

- Page 87 VST Heavy Duty Shoring Tower Item no. Weight kg Steel Walers Universal SRU 103868 18.100 Steel Waler Universal SRU U120, l = 0.72 m Steel Waler Universal SRU U120, l = 0.97 m 103871 24.200 103874 30.900 Steel Waler Universal SRU U120, l = 1.22 m...

- Page 88 VST Heavy Duty Shoring Tower Item no. Weight kg Climbing Rails RCS 114166 78.200 Climbing Rail RCS 148 1480 Climbing Rail RCS 998 109610 524.000 9980 109472 393.000 Climbing Rail RCS 748 7480 109471 262.000 Climbing Rail RCS 498 4980...

- Page 89 VST Heavy Duty Shoring Tower Item no. Weight kg Heavy Duty Spindles SLS min. L max. L 111035 12.100 Heavy Duty Spindle SLS 40/80 Heavy Duty Spindle SLS 80/140 101773 14.700 1400 101774 18.200 Heavy Duty Spindle SLS 100/180 1000...

- Page 90 VST Heavy Duty Shoring Tower Item no. Weight kg 018060 0.030 Cotter Pin 4/1, galv. Ø4 Bolts ISO 4014 105416 0.360 Bolt ISO 4014 M24 x 80-8.8, galv. 113994 0.421 Bolt ISO 4014 M20 x 140-8.8, galv. Bolts ISO 4014 117452 0.360...

- Page 91 VST Heavy Duty Shoring Tower Item no. Weight kg 105032 0.070 Nut ISO 7042 M24-8, galv. Self-locking. SW 36 Sleeve VST, galv. 117492 0.109 Ø 105400 0.330 Pin Ø 20 x 140, galv. For different connections. Ø8 Ø20 Accessories Cotter Pin 4/1, galv.

- Page 92 VST Heavy Duty Shoring Tower Item no. Weight kg Standards UVR 102860 7.690 Standard UVR 150 1500 100012 14.700 Standard UVR 300 3000 Ø13 Ø 48,3 Ø11 100021 4.690 Ledger UH 150 Note As of 01.07 .2009, only available as rentable item.

- Page 93 VST Heavy Duty Shoring Tower Item no. Weight kg 030130 0.318 Cam Nut DW 15, galv. Technical Data For anchoring with Tie Rod DW 15 and B 15. Permissible load 90 kN. SW 27 DW 15 Wingnut Pivot Plate DW 15, galv.

- Page 94 VST Heavy Duty Shoring Tower Item no. Weight kg 030970 0.800 Hex. Coupler DW 26 SW 46/80, weldable Note For anchoring with Tie Rod DW 26. Weldable! Technical Data Permissible load 250 kN. DW 26 SW 46...

- Page 96 Tunnel Formwork Shoring Systems Construction Scaffold Facade Scaffold Industrial Scaffold Access Protection Scaffold Safety Systems System-Independent Accessories Services PERI GmbH Formwork Scaffolding Engineering Rudolf-Diesel-Strasse 19 89264 Weissenhorn Germany Tel. +49 (0)7309.950 - 0 Fax +49 (0)7309.951- 0 info @ peri.com www.peri.com...

Need help?

Do you have a question about the VST and is the answer not in the manual?

Questions and answers