Summary of Contents for Leuze BCL 92

- Page 1 Original operating instructions BCL 92 Bar code reader We reserve the right to make technical changes EN • 2020-04-28 • 50144007...

- Page 2 © 2020 Leuze electronic GmbH + Co. KG In der Braike 1 73277 Owen / Germany Phone: +49 7021 573-0 Fax: +49 7021 573-199 www.leuze.com info@leuze.com Leuze electronic GmbH + Co. KG BCL 92...

-

Page 3: Table Of Contents

Downloading configuration software ................. 21 6.2.2 Installing the Sensor Studio FDT frame ................ 21 6.2.3 Install the communication DTM and device DTM .............. 21 6.2.4 Connecting device to PC .................... 21 Starting Sensor Studio ...................... 22 Exiting Sensor Studio ...................... 23 Leuze electronic GmbH + Co. KG BCL 92... - Page 4 12.2 Reading fields ........................ 56 12.3 Dimensioned drawings ...................... 59 Order guide and accessories................ 61 13.1 Type overview........................ 61 13.2 Accessories........................... 62 EC Declaration of Conformity................ 63 Appendix...................... 64 15.1 Bar code samples ......................... 64 Leuze electronic GmbH + Co. KG BCL 92...

-

Page 5: About This Document

Text passages with this symbol provide you with further information. Symbol for action steps Text passages with this symbol instruct you to perform actions. Symbol for action results Text passages with this symbol describe the result of the preceding action. Leuze electronic GmbH + Co. KG BCL 92... -

Page 6: Terms And Abbreviations

(Human Interface Device) This pin is not contacted at the device (Not Connected) SELV Safe Extra Low Voltage Programmable Logic Control (corresponds to Programmable Logic Controller (PLC)) SW_IN Switching input SW_OUT Switching output Leuze electronic GmbH + Co. KG BCL 92... -

Page 7: Safety

Ä Only operate the device in accordance with its intended use. Ä Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use. Ä Read these operating instructions before commissioning the device. Knowledge of the oper- ating instructions is an element of proper use. -

Page 8: Foreseeable Misuse

Ä The device must not be opened. There are no user-serviceable parts inside. Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG. NOTICE Ä To increase the decoding reliability, it is recommended that only the actually needed code types be enabled. -

Page 9: Disclaimer

Ä Observe the applicable statutory and local laser protection regulations. Ä The device must not be tampered with and must not be changed in any way. There are no user-serviceable parts inside the device. Repairs must only be performed by Leuze electronic GmbH + Co. KG. NOTICE Laser aperture! The glass optics cover is the only aperture through which laser radiation may be observed on this product. -

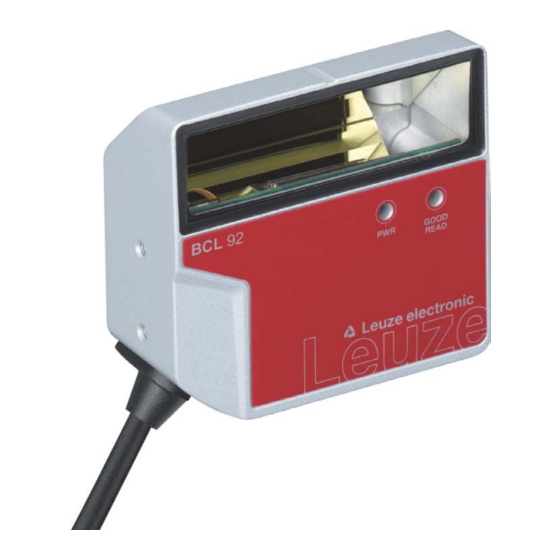

Page 10: Device Description

• Two switching inputs and two switching outputs • Sturdy diecast zinc housing • Connection cable 0.8 m or 3 m with Sub-D connector, 15-pin • Connection cable 0.8 m with M12 connector, 12-pin • Process and service interface RS 232 Leuze electronic GmbH + Co. KG BCL 92... -

Page 11: Device Construction

Red, continuous light Error, no function Orange, flashing 200 ms Service operation Decode LED Green, 200 ms on Reading successful (GOOD READ) Red, 200 ms off No reading result Orange, continuous light Reading gate active Leuze electronic GmbH + Co. KG BCL 92... -

Page 12: Mounting

• The bar code labels are of good print quality and have good contrast ratios. • You are not using glossy labels. • The bar code is moved past the reading window with an angle of rotation of approx. 15°. Leuze electronic GmbH + Co. KG BCL 92... - Page 13 Ä The bar code label must be rotated by > 10 ° to avoid a reflection of the laser beam in the case of glossy labels. γ β α α Azimuth angle β Angle of inclination γ Angle of rotation Recommended angle of rotation: γ > 10° Fig. 4.1: Definition of the reading angles Leuze electronic GmbH + Co. KG BCL 92...

-

Page 14: Electrical Connection

The operating voltage of the bar code reader is 10 … 30 V DC. • NEC Class 2 • Protection class III with SELV Power Supply The operating voltage is fed in via the connection cable (see chapter 5.3 "Pin assignment"). Leuze electronic GmbH + Co. KG BCL 92... -

Page 15: Housing Ground

Res. Reserved Res. Reserved GNDIN Negative operating voltage 0 V DC Metal flange FE (functional earth) Connection cable shield. The shield of the connection cable is on the metal flange of the Sub-D connector. Leuze electronic GmbH + Co. KG BCL 92... -

Page 16: Connecting Bar Code Reader To Ma 150 Connection Unit

• Photoelectric sensor/diffuse sensor to activate the bar code reader • Voltage supply • Serial communication RS 232 NOTICE Supply voltage! A supply voltage of 18 … 30 V DC is necessary if connecting via the modular connection unit. Leuze electronic GmbH + Co. KG BCL 92... - Page 17 50108595 Cable, M12 socket/open cable end, 5-pin, 2 m e.g., 50104555 Cable, M12 socket/connector, 4-pin, 2 m e.g., 50110126 Cable, M12 socket/connector, 12-pin, 2 m e.g., 50130284 Fig. 5.3: Circuit diagram example with MA 150 connection unit Leuze electronic GmbH + Co. KG BCL 92...

-

Page 18: Switching Inputs

+ 12 ... + 30 V DC + 12 … + 30 V DC SW_IN 1/SW_IN 2 Connection version PNP: inverted setting (high = active); input resistance: 13.3 kΩ Fig. 5.5: Switching input for connection variant PNP ("inverted" setting) Leuze electronic GmbH + Co. KG BCL 92... -

Page 19: Switching Outputs

Via the RS 232 service interface, you can configure the bar code reader by means of a PC or a terminal program. For this, you need an RS 232 connection that establishes the RxD, TxD and GND connections between PC and bar code reader (see chapter 5.3 "Pin assignment"). Leuze electronic GmbH + Co. KG BCL 92... -

Page 20: Configuration And Diagnostics Software - Sensor Studio

Configurations can be saved and reopened as projects for transferring back to the device at a later time. NOTICE Only use the Sensor Studio configuration software for products manufactured by Leuze. The Sensor Studio configuration software is offered in the following languages: German, Eng- lish, French, Italian and Spanish. -

Page 21: Installing Sensor Studio

Installing Sensor Studio NOTICE The installation files of the Sensor Studio configuration software must be downloaded from the Internet at www.leuze.com. For subsequent updates, you can find the most recent version of the Sensor Studio installation software on the Internet at www.leuze.com. 6.2.1 Downloading configuration software Ä... -

Page 22: Starting Sensor Studio

ð In the Sensor Studio FDT frame, click on the [Establish connection with device] button ( ð In the Sensor Studio FDT frame, click on the [Upload parameters to device] button ( ð The current configuration data is displayed in the device manager (DTM). Leuze electronic GmbH + Co. KG BCL 92... -

Page 23: Exiting Sensor Studio

The Sensor Studio configuration software offers the following buttons in the CONFIGURATION menu: • : [Reset all parameters in the GUI to their factory default settings] Resets all parameters in the graphical user interface to the factory settings. Leuze electronic GmbH + Co. KG BCL 92... -

Page 24: Decode Tab

Here, the number of the bar codes to be decoded within a read cycle (one reading gate) is set. (COMPLETENESS / Number of bar codes) NOTICE If the code EAN128 is to be read, 3 additional characters are to be set for the code identifier. Leuze electronic GmbH + Co. KG BCL 92... - Page 25 Alternatively, you can select the property settings directly via the nav- igation tree with the [Symbologies] button. The properties can be individually set for each code type. Fig. 6.4: Standard settings of the Properties dialog box (SYMBOLOGY PROPERTIES) Leuze electronic GmbH + Co. KG BCL 92...

- Page 26 Identical labels are treated as a single label. NOTICE In general, the remaining parameters must not be changed. In the worst case, this could corrupt the read result! Leuze electronic GmbH + Co. KG BCL 92...

-

Page 27: Output Tab

The structure of this message string is depicted symbolically in the preview window. Text in the case of misreading This character is set for each unrecognized bar code. Multiple characters (=string) may be entered (No read string) here. Up to 20 characters are possible. Leuze electronic GmbH + Co. KG BCL 92... - Page 28 Output different result only checkbox is selected. The timeout time between the last reading and dele- tion of the difference memory can be set from 100 ms to 5000 ms. Leuze electronic GmbH + Co. KG BCL 92...

-

Page 29: Control Tab

(e.g. for test purposes). Scans without info Following a successful read, the code reader waits for this number of scans (sequential scans with no read result) before it automatically deactivates itself. Leuze electronic GmbH + Co. KG BCL 92... -

Page 30: Host Interface Tab

To be able to continue to communicate with a device following a parameter transfer, you may need to make appropriate adjustments to the communication properties of the device in the Sensor Studio configuration software. Leuze electronic GmbH + Co. KG BCL 92... -

Page 31: Reference Code Tab

For this purpose, the switching output must be set to Reference Code Compare (Positive Reference Code Compare or Negative Reference Code Compare) in the switching output (switch) menu. Leuze electronic GmbH + Co. KG BCL 92... - Page 32 Select here how the internally stored reference code is to be compared with the decoded result. For additional comparison possibilities, select the Properties dialog box. Fig. 6.11: Standard settings of the Properties dialog box (PROPERTIES) Leuze electronic GmbH + Co. KG BCL 92...

-

Page 33: Switching Input Tab

After the end of the trigger signal, the pulse is extended internally by this time period. (Delay off time) Function Event that is started when the switching input is activated. (Control) NOTICE If switch-off delay is activated, the pulse duration parameter should be "0". Leuze electronic GmbH + Co. KG BCL 92... -

Page 34: Switching Output Tab

Multiple events can also be simultaneously activated. Inverted Here, the input level can be inverted Pulse duration Duration of the switching output pulse. Pulse delay Length of time before the switching output is activated. (Pulse delay time) Leuze electronic GmbH + Co. KG BCL 92... -

Page 35: Diagnosis

Factory Default Activates the device with the factory settings. Activate Decoding Activates/deactivates decoding. Deactivate Decoding Start Continuous Decoding Starts/stops continuous decoding. Stop Continuous Decoding Leuze electronic GmbH + Co. KG BCL 92... -

Page 36: Firmware Reload

• If the new firmware is compatible, the firmware is automatically installed in the device. • If the new firmware is not compatible with the device or is identical with the current firmware ver- sion, a dialog box for canceling or continuing the installation is displayed. Leuze electronic GmbH + Co. KG BCL 92... -

Page 37: Starting Up The Device - Configuration

10 "Diagnostics and troubleshooting". If a problem occurs that cannot be rectified even after checking all electrical connections and settings on the devices and on the host, contact your responsible Leuze subsidiary or Leuze customer service (see chapter 11 "Service and support"). -

Page 38: Starting Up With Factory Settings

• Via the internal setup of the bar code reader (start with the online command CA; see chapter 7.4.2 "Parameter sets") • Via online commands (see chapter 8.4 "Online commands for the parameter set operations"). Leuze electronic GmbH + Co. KG BCL 92... -

Page 39: Service Mode

Ä While the laser switches on for approx. 1 s after power-up, the "Service" label is to be held up in front of the bar code reader at a suitable read distance. When the device is in "Service" mode, the status LED flashes orange. Leuze electronic GmbH + Co. KG BCL 92... -

Page 40: Parameter Sets

• Copying a valid parameter set from the host computer into the bar code reader • Off-line configuration using the Sensor Studio configuration software and then subsequently loading to the bar code reader NOTICE To load the configuration into the bar code reader, select online mode. Leuze electronic GmbH + Co. KG BCL 92... -

Page 41: Online Commands

NOTICE Most online commands are acknowledged by the device and any requested data returned. For commands that are not acknowledged, command execution can be observed or monitored di- rectly on the device. Leuze electronic GmbH + Co. KG BCL 92... -

Page 42: General Online Commands

Description Carries out a software reset. The device is restarted and reinitialized, leaving it in the same state as when the operating voltage is switched on. Parameter None Acknowledgment ’S’ (start signal) Leuze electronic GmbH + Co. KG BCL 92... - Page 43 Pharmacode ’10’ EAN Addendum ’11’ Codabar ’12’ Code 93 Number of digits of the read code zzzzzz Contents of the decoded label. A ↑ appears if the label was not correctly read. Leuze electronic GmbH + Co. KG BCL 92...

- Page 44 Insufficient memory for reference code ’3’ Reference code has not been saved ’4’ Reference code invalid Example Entry = ’RS130678654331’ • Code 1 (1) • RAM only (3) • UPC (06) • Code information Leuze electronic GmbH + Co. KG BCL 92...

- Page 45 Ä After each reading via an ’RTy’ command, explicitly switch off the function again since failure to do so will interfere with other commands as well as prevent execution of a new ’RTy’ command. Leuze electronic GmbH + Co. KG BCL 92...

- Page 46 ’-’ Ends the adjustment mode. Acknowledgment ’xxxxx_yyyyy’ xxxxx "Scans since reading gate release" (Scans_with info): Number of scans that contain valid label information. The maximum value is 100. yyyyy Bar code information. Leuze electronic GmbH + Co. KG BCL 92...

-

Page 47: Online Commands For System Control

Switching output no. ’1’ (Output 1) Acknowledgment None Deactivate switching output Command ’OD’ Description The command deactivates the switching output. Parameter ’ODx’: Deactivate switching output Switching output no. ’1’ (Output 1) Acknowledgment None Leuze electronic GmbH + Co. KG BCL 92... -

Page 48: Online Commands For The Parameter Set Operations

'2': Invalid message length '3': Invalid block check type '4': Invalid bloc checksum '5': Invalid data length '6': Invalid message data '7': Invalid start address '8': Invalid parameter set '9': Invalid parameter set type Leuze electronic GmbH + Co. KG BCL 92... - Page 49 Invalid data length ’6’ Invalid message data ’7’ Invalid start address ’8’ Invalid parameter set ’9’ Invalid parameter type Example ’PR00102004’ Beginning with address 102, four (004) bytes are read out and transferred. Leuze electronic GmbH + Co. KG BCL 92...

- Page 50 ’8’ Invalid parameter set ’9’ Invalid parameter type Example ’PT03203305’ Address 33 (equal scans) is set to 5. Save in RAM with reset (immediate ac- ceptance of the change and temporary storage) Leuze electronic GmbH + Co. KG BCL 92...

-

Page 51: Care, Maintenance And Disposal

Usually, the bar code reader does not require any maintenance by the operator. Repairs to the device must only be carried out by the manufacturer. Ä For repairs, contact your responsible Leuze subsidiary or Leuze customer service (see chapter 11 "Ser- vice and support"). -

Page 52: Diagnostics And Troubleshooting

Using the LED displays, you can determine the causes and initiate troubleshooting measures. NOTICE Contact Leuze subsidiary/customer service! Ä Please contact your responsible Leuze subsidiary or Leuze customer service if you cannot rectify faults and errors with the configuration software (see chapter 11 "Service and support"). -

Page 53: Service And Support

Customer data (please complete) Device type: Serial number: Firmware: Status of LEDs: Error description: Company: Contact person/department: Phone (direct dial): Fax: Street/No: ZIP code/City: Country: Leuze Service fax number: +49 7021 573 - 199 Leuze electronic GmbH + Co. KG BCL 92... -

Page 54: Technical Data

UPC-A / UPC-E EAN Addendum EAN-8 / EAN-13 Codabar Pharmacode (available upon consultation) Code 32 Code 93 Module width 0.165 mm … 0.5 mm (6.5 mil … 20 mil) (distance dependent) Print quality Grade A, B acc. to ISO/IEC 15416 Angle of rotation > 10° Leuze electronic GmbH + Co. KG BCL 92... - Page 55 12.3 "Dimensioned drawings" Fastening 2 M2.5 mounting threads, 4 mm deep, on the side of the device 2 M3 mounting threads, 6 mm deep, on the rear of the device Housing Diecast zinc Optics cover Glass Leuze electronic GmbH + Co. KG BCL 92...

-

Page 56: Reading Fields

The origin of the read distance always refers to the front edge of the housing of the beam exit. Tab. 12.7: Reading conditions for the reading field curves Bar code type 2/5 Interleaved Code type Ratio 1:2.5 ANSI specification Class A Reading quality > 75% Leuze electronic GmbH + Co. KG BCL 92... - Page 57 Resolution M = 0.165 mm Code type: Code 128 Resolution M = 0.2 mm Code type: Code 128 Resolution M = 0.3 mm Code type: 2/5 Interleaved Resolution M = 0.5 mm Code type: 2/5 Interleaved Fig. 12.1: BCL 92 reading fields; frontal beam exit Leuze electronic GmbH + Co. KG BCL 92...

- Page 58 Resolution M = 0.165 mm Code type: Code 128 Resolution M = 0.2 mm Code type: Code 128 Resolution M = 0.3 mm Code type: 2/5 Interleaved Resolution M = 0.5 mm Code type: 2/5 Interleaved Fig. 12.2: BCL 92 reading fields; lateral beam exit Leuze electronic GmbH + Co. KG BCL 92...

-

Page 59: Dimensioned Drawings

Technical data 12.3 Dimensioned drawings all dimensions in mm Laser beam Indicator diode – decode LED Indicator diode – status LED Fig. 12.3: BCL 92 SM ..2 - frontal beam exit Leuze electronic GmbH + Co. KG BCL 92... - Page 60 Technical data all dimensions in mm Laser beam Indicator diode – decode LED Indicator diode – status LED Fig. 12.4: BCL 92 SM ..0 - lateral beam exit Leuze electronic GmbH + Co. KG BCL 92...

-

Page 61: Order Guide And Accessories

Single line scanner, RS 232 interface Beam exit: lateral Connection cable 0.8 m with M12 connector, 12-pin 50143266 BCL 92 SM 802 Single line scanner, RS 232 interface Beam exit: frontal Connection cable 0.8 m with M12 connector, 12-pin Leuze electronic GmbH + Co. KG BCL 92... -

Page 62: Accessories

Sensor Studio designed according to the FDT/DTM con- cept. Contains: communication DTM and device DTM Download at www.leuze.com (see chapter 6.2.1 "Downloading configura- tion software") NOTICE On request, Leuze can make available the BCL Configuration Tool editor program. Leuze electronic GmbH + Co. KG BCL 92... -

Page 63: Ec Declaration Of Conformity

EC Declaration of Conformity EC Declaration of Conformity The bar code readers of the BCL 92 series have been developed and manufactured in accordance with the applicable European standards and directives. Leuze electronic GmbH + Co. KG BCL 92... -

Page 64: Appendix

Code type 02: Code 39 Module 0.3 Fig. 15.3: Code type 11: Codabar Module 0.3 Fig. 15.4: Code 128 Module 0.3 Fig. 15.5: Code type 08: EAN 128 SC 2 Fig. 15.6: Code type 06: UPC-A Leuze electronic GmbH + Co. KG BCL 92... - Page 65 Appendix SC 3 Fig. 15.7: Code type 07: EAN 8 Leuze electronic GmbH + Co. KG BCL 92...

Need help?

Do you have a question about the BCL 92 and is the answer not in the manual?

Questions and answers