Summary of Contents for Vision 5 Series

- Page 1 Vision 1612, 1624, 2424 and 2448 Series 5 User Guide © 2019 Vision Engraving Systems Revised: 7/3/2019...

- Page 2 Vision 1612, 1624, 2424 and 2448 Series 5 Installation Guide © 2019 Vision Engraving Systems All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the written permission of the publisher.

-

Page 3: Table Of Contents

4 Series 5 Controller Connections ........................... 23 5 Pendant Holder Installation ........................... 26 Part III Network Connection Part IV Vision Mov UI Software Installation Part V Vision Software Installation Part VI Operation 1 Starting the Vision Mov UI spooler ........................... 52 2 Pendant Controls ........................... - Page 4 Vision Series 5 Controller User Manual Part VIII Controller Maintenance Part IX Using the Measure Feature © 2019 Vision Engraving Systems...

-

Page 5: Part I Introduction

Vision Computerized Engraving and Routing Systems (Vision) warrants that for a period of two (2) years from the date of shipment to the original purchaser of either a Series 5 Controller, Phoenix, Vision or Table Retrofit (the System), that the System will be free from defects in material and workmanship under normal use and service. - Page 6 Vision does not warrant defects caused by a failure to provide a suitable environment for the system, by unauthorized attachments, by modifications or repairs other than by Vision, by use of the System for other than its original intention, or by other misuse or abuse of the System.

-

Page 7: Safety Precautions

User's Guide! Failure to comply may result in damage to the equipment and/or inflict serious personal injury! Ø Only trained personnel should operate the Vision Engraver or Router. All individuals operating this system should have read and understand this complete User's Guide. Ø... - Page 8 Operators should inspect the machine daily for damage or modifications. Under no circumstances should the machine be operated if there is any doubt about the machine condition. If there are any questions call the Vision Engraving Systems technical support team at 602-439-0600. Ø...

- Page 9 If there are any questions about the abilities of your machine, please call the Vision Engraving Systems technical support team at 602-439-0600. Ø...

-

Page 10: Computer Requirements

IMPORTANT: The Vision software is available in two versions; one with a USB dongle, and one that is "dongleless" and is loaded on to a USB Memory stick. If your machine was delivered with, or you currently have the silver, white/blue or orange software dongle, DO NOT LOSE IT! The Vision software will NOT run without the dongle plugged into the computer. -

Page 11: General Electrical And Facility Requirements

Introduction General Electrical and Facility Requirements Machine Model Requirements Vision 1612, 1624, 2424 or 2448 One 110 VAC 15 Amp OR One 220 VAC 10 Amp Single Phase Optional Equipment Required in addition to the machine power above: Engraving Chip Removal System... -

Page 12: Installation

Cutters and sample materials must be available before the scheduled installation/machine orientation date. If a chip extraction unit has not been purchased from Vision, it is highly recommended that one is available for the installation/machine orientation. If you ordered the NSK High Frequency Spindle, a clean air source is required. The air requirement is 1 CFM @ 40 psi. -

Page 13: Installation Layout Diagrams

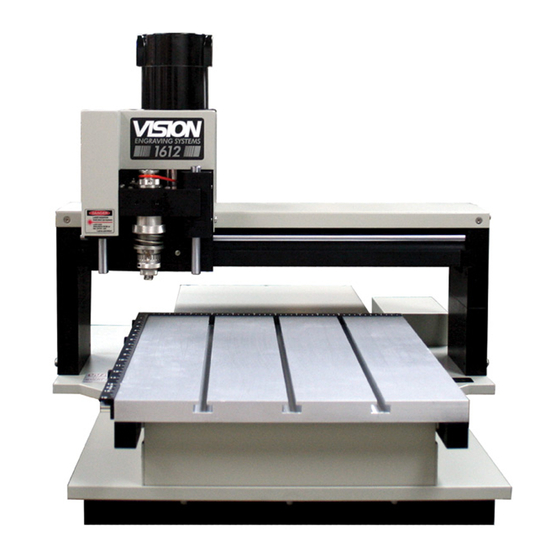

1612, 1624, 2424 and 2448 Series 5 Installation Installation Layout Diagrams 2.2.1 1612 and 1624 Engraver Layout Diagram © 2019 Vision Engraving Systems... -

Page 14: 2424 And 2448 Engraver Layout Diagram

Vision Series 5 Controller User Manual 2.2.2 2424 and 2448 Engraver Layout Diagram © 2019 Vision Engraving Systems... - Page 15 The engraving motor drives a belt and pulley system, which turns the engraving cutter during the engraving process. 12. Spindle Cable. Connects to the system controller and provides power to the engraving motor. © 2019 Vision Engraving Systems...

- Page 16 Vision Series 5 Controller User Manual 13. Quick Lock Vise. A “cam” type locking device that allows quick change of parts for engraving. © 2019 Vision Engraving Systems...

- Page 17 1612, 1624, 2424 and 2448 Series 5 Installation Typical 16 Series Engraver Diagrams © 2019 Vision Engraving Systems...

- Page 18 Vision Series 5 Controller User Manual 16 and 24 Series Engravers Carriage Descriptions (Refer to the diagram below) 1. Z-Axis Stepper Motor. The small motor under the carriage cover that provides the spindle up and down motion of the spindle during the engraving process.

- Page 19 1612, 1624, 2424 and 2448 Series 5 Installation © 2019 Vision Engraving Systems...

- Page 20 Vision Series 5 Controller User Manual 24 Series Engraver Descriptions (Refer to the Diagrams on the following page) 1. Table Base Plate. This is the large flat plate upon which everything else is mounted. All mechanical alignments are referenced to this plate, so the space upon which you place the engraving table must be a reasonably level surface.

- Page 21 1612, 1624, 2424 and 2448 Series 5 Installation Typical 24 Series Engraver Diagrams © 2019 Vision Engraving Systems...

- Page 22 Vision Series 5 Controller User Manual © 2019 Vision Engraving Systems...

-

Page 23: Series 5 Controller Connections

On the rear of the Vision Series 5 controller, there are 13 connection ports. Plug in all of the cables unless noted below. 1. The Aux Table plug connects to a 15 pin connector on the Vision 2424 and 2448. NOTE: This is not used with the 1612 or 1624. - Page 24 Vision Series 5 Controller User Manual Vision Series 5 controller (rear view) © 2019 Vision Engraving Systems...

- Page 25 1612, 1624, 2424 and 2448 Series 5 Installation Vision Series 5 pendant (rear view) NOTE: If the emergency stop screen appears on the LCD when the machine is powered on, then the emergency stop button is pressed in. This can either be the emergency stop button on the table or the emergency stop button on the pendant.

-

Page 26: Pendant Holder Installation

Vision Series 5 Controller User Manual Pendant Holder Installation The 2424 and 2448 machines are shipped with a Pendant Holder to give the user a place to secure the Pendant. NOTE: Not required for 1612 or 1624. To install the Pendant Holder on the 25 Series machines, follow the below procedure. - Page 27 1612, 1624, 2424 and 2448 Series 5 Installation © 2019 Vision Engraving Systems...

-

Page 28: Part Iii Network Connection

Vision Series 5 Controller User Manual Network Connection NOTE - This following section is shown on a Windows 10 PC. For Windows 7 or Windows 8, the screens are slightly different. Plug the USB end of the USB to Ethernet adapter into any open USB port on the computer. - Page 29 Network Connection Select "Change adapter options". Right click on the Asix USB Ethernet connection. Select Properties. © 2019 Vision Engraving Systems...

- Page 30 Vision Series 5 Controller User Manual Select "Internet Protocol Version 4 (TCP/IPv4). Select Properties. © 2019 Vision Engraving Systems...

- Page 31 Network Connection The screen below will appear. Enter the settings below. Select: Use the following IP address: Enter an IP address of: 192.168.100.100 Enter a Subnet mask of: 255.255.255.0 © 2019 Vision Engraving Systems...

- Page 32 Select OK. Plug one end of the network cable into the USB to Ethernet adaptor. Plug the other end of the network cable into the COMPUTER connection in the back of the Vision Series 5 controller. The network connection is now complete. Please continue to the network setup section.

-

Page 33: Part Iv Vision Mov Ui Software Installation

Vision Mov UI Software Installation Power the Vision Series 5 controller on with the switch on the front. Insert the Vision USB dongle into the USB port on the computer. Navigate to the USB dongle in Windows File Explorer. Select the Start or Start.exe file to begin. - Page 34 Vision Series 5 Controller User Manual Select Step 1 Setup Machine. © 2019 Vision Engraving Systems...

- Page 35 Vision Mov UI Software Installation Select Next on the "Prerequisites Setup Wizard" screen. NOTE: This screen will not appear if the Windows feature is already installed on the computer. Select Next on the "Prerequisites" installation screen. NOTE: This screen will not appear if the Windows feature is already installed on the computer.

- Page 36 Vision Series 5 Controller User Manual Select Next on the "Microsoft Vision C++ installation" screen. NOTE: This screen will not appear if the Windows feature is already installed on the computer. Select the I have read and accept the license terms box then select Install.

- Page 37 Vision Mov UI Software Installation Select Finish on the "Setup Complete" screen. NOTE: This screen will not appear if the Windows feature is already installed on the computer. Select Next on the "Welcome screen". © 2019 Vision Engraving Systems...

- Page 38 Vision Series 5 Controller User Manual Select Next on the "Choose a file location" screen. Select Install on the "Begin installation" screen. © 2019 Vision Engraving Systems...

- Page 39 Vision Mov UI Software Installation Select Close on the "Successful Install" screen. The VisMovUI screen will appear. Select the Machine in the "Machines Discovered on Network" screen and click Select. © 2019 Vision Engraving Systems...

- Page 40 Vision Series 5 Controller User Manual The VisMovUI program will appear. Select the Minimize button. The Vision Move UI program is now installed. Please continue to the network setup section. © 2019 Vision Engraving Systems...

-

Page 41: Part V Vision Software Installation

Vision Mov UI Software Installation Vision Software Installation Insert the Vision USB dongle into the USB port on the computer. Navigate to the USB dongle in Windows File Explorer. Select the Start or Start.exe file to begin. Select 1612 and larger. - Page 42 Vision Series 5 Controller User Manual Select Step 2 Install Vision Software. Select Next on the "Welcome" screen. © 2019 Vision Engraving Systems...

- Page 43 Vision Software Installation Select Install on the "Ready to Install" screen. Select Finish on the "Complete Install" screen. © 2019 Vision Engraving Systems...

- Page 44 Vision Series 5 Controller User Manual Select the language desired and select OK on the "Vision Pro install" screen. Make sure the USB dongle is installed and select Next on the "USB Flash Dongle" screen. © 2019 Vision Engraving Systems...

- Page 45 Vision Software Installation Select Next on the "Vision 10 setup" screen. NOTE: The installation will display "Vision Pro 10 Setup", "Vision Expert 10 Setup" or "Vision Express 10 Setup" depending on which version has been purchased. Select the I accept the terms of the license agreement box then select Next on the "License Agreement"...

- Page 46 Vision Series 5 Controller User Manual Select Next from the "Choose Destination Location" screen. NOTE: The installation folder will be either "C:\Vision Pro 10", "C:\Vision Expert 10" or "C:\Vision Express 10" depending on which version has been purchased. Select Next on the "Program Folder" screen.

- Page 47 Vision Software Installation The installation will continue. Select Vision S5 - Engravers and select Next. Select the driver for the that matches the machine purchased and select Next. NOTE: If ADA drivers or a center origin driver is needed, select them also.

- Page 48 Vision Series 5 Controller User Manual Select Continue on the "Font Installation" screen. © 2019 Vision Engraving Systems...

- Page 49 Vision Software Installation The installation will search for Vision fonts. Select the disk drive to search for additional fonts that may be on the computer and select Yes. NOTE: Typically drive C:\ is selected. © 2019 Vision Engraving Systems...

- Page 50 Vision Series 5 Controller User Manual The installation will search for additional fonts. NOTE: This may take a few minutes. Select OK on the "Font Installation Complete" screen. © 2019 Vision Engraving Systems...

- Page 51 Select Finish to complete the installation. NOTE: The install may or may not ask to restart the computer. Select Exit from the initial screen. The Vision 10 software and Vision Manuals icon will now be on the Windows desktop. © 2019 Vision Engraving Systems...

-

Page 52: Part Vi Operation

The Vision Mov UI spooler program must be running and connected before proceeding. The Vision Mov UI program should start automatically after the program is installed and when the computer is restarted. The screen below will appear when it is running. - Page 53 IMPORTANT: Only one Vision Mov UI spooler can be running per machine at a time. If two are running at the same time, one will have a red line through it The Vision Mov UI spooler with the red line through it must be closed. To do this, right click on the icon and select Shutdown.

-

Page 54: Pendant Controls

Vision Series 5 Controller User Manual Pendant Controls The Pendant controls all of the movement of your Vision engraver or router. Below is a picture of the Pendant. The function of each item is explained below. © 2019 Vision Engraving Systems... -

Page 55: Startup Screen

6.2.1 Startup screen When the Vision controller is powered on and the Vision Move UI spooler is connected, the start up screen will appear. Select Start Homing and the machine will initialize and move to the home position. Pressing the Stop button will stop the machine from moving. -

Page 56: Emergency Stop Button

Vision Series 5 Controller User Manual 6.2.2 Emergency Stop Button This button will stop engraving, leaving the cutter in the down position and will power off the X, Y and Z stepper motors. It will also power off the spindle motor and auxiliaries such as a vacuum chip removal system or misting system. - Page 57 The job that was running can be restarted or skipped. NOTE: All emergency stop buttons on the table and pendant must be released for the machine clear the emergency stop message. © 2019 Vision Engraving Systems...

-

Page 58: Setup Screen

Vision Series 5 Controller User Manual 6.2.3 Setup screen The Setup screen is the main screen. All of the options start from this screen. The Setup, Run, Adjust and Search buttons will appear on most other screens allowing for quick access to them. - Page 59 Operation The job information screen will be displayed. Select the image button to display a graphical preview of the currently loaded job. Press the zoom in and out buttons as needed. © 2019 Vision Engraving Systems...

-

Page 60: Run Screen

Vision Series 5 Controller User Manual Pressing the zoom button will return to the standard view. The scroll bars can also be used as needed when the view is zoomed in. Select back two times to return to the setup screen. - Page 61 Pressing continue will continue running the job from the start of the object that was engraving when the stop button was pressed. The job name area displays the name of the job currently loaded or currently running. © 2019 Vision Engraving Systems...

- Page 62 Vision Series 5 Controller User Manual While a job is running, the elapsed time field and the % complete field will display how long the job has been running and the percentage that it is complete. The status field will display messages.

- Page 63 5. Press the Sense button on the Sense Material section on the Set XYZ screen. Once the cutter touches the surface block as shown below, the spindle will stop moving down and the surface will be set. © 2019 Vision Engraving Systems...

- Page 64 The dust extractor button manually activates the dust extractor. Pressing the button again will deactivate the dust extractor. NOTE: This only works if the Vision dust extraction unit is connected to the Series 5 controller. The coolant button manually activates the coolant. Pressing the button again will deactivate the coolant.

-

Page 65: Set Xyz Screen

The jog buttons allow the machine to be moved left & right, front & back and the spindle to be moved up and down by pressing the buttons below. © 2019 Vision Engraving Systems... - Page 66 Vision Series 5 Controller User Manual HINT: Pressing the jog speed button will toggle the jog speed between fast, medium and slow. As the jog buttons are pressed, the location of the spindle will be displayed. Both the relative and absolute coordinates are displayed.

- Page 67 Select Set Origin. The default origin will now be set. NOTE: 14 different origins can be stored in the Vision Series 5 controller. To select a different origin to be saved, select the back button on the Set XYZ screen. Press the select button to the right of the origin area.

- Page 68 Vision Series 5 Controller User Manual The Set Surface button is used to set the material surface. This is only needed when the proximity sensor is not being used. The procedure for setting the surface is as follows: 1. Press the X & Y jog buttons to move the spindle over the material to be engraved.

- Page 69 The show outline button will use the red laser pointer to draw a box around the engraving area of the currently loaded job. Pressing stop while the outline is running will stop this process. NOTE: If a job is not currently loaded in the machine, the show outline button will be grayed out. © 2019 Vision Engraving Systems...

- Page 70 Vision Series 5 Controller User Manual The spindle RPM and spindle button are used in conjunction with each other. They are used to manually start the currently selected spindle motor. Select the spindle RPM button. Enter the desired RPM value and press enter.

-

Page 71: Job Select Screen

Pressing the job select button on the setup screen will allow a job to be selected. Select the job to load in the job list and then press select. The job list displayed shows the job files located in the folder shown on the job load screen. © 2019 Vision Engraving Systems... - Page 72 The job list can be sorted by date or by name. Press the date button to change to sort by name. Press the name button will change to sort by date. NOTE: To change the job load location, select the Vision Mov UI program from the Windows task bar. Select the spooler setup button.

- Page 73 Operation Select the job folder button. Select the desired folder location and select OK and then close. © 2019 Vision Engraving Systems...

-

Page 74: Adjust Screen

Vision Series 5 Controller User Manual 6.2.7 Adjust screen The adjust screen allows the XY speed, Z speed and spindle speed to be adjusted while the machine is running a job. © 2019 Vision Engraving Systems... - Page 75 When the reset overrides button is selected, the XY speed or Z speed will take several moves before the speed change is reset. The spindle speed will reset immediately. Selecting the run button will exit the adjust screen and return to the run screen. © 2019 Vision Engraving Systems...

-

Page 76: Search Screen

Vision Series 5 Controller User Manual 6.2.8 Search screen The search screen will allow the job to be started or continued from any location in the job. This feature can be accessed when a job is loaded or if a job is stopped while running. - Page 77 Pressing the goto line number button will display the numeric keypad. Enter the line number in the output file that was sent to the machine and press enter. This will move the tool to the location of that line number. © 2019 Vision Engraving Systems...

- Page 78 Vision Series 5 Controller User Manual NOTE: This is the line number of the output file, not the line number of the text being engraved. The status line displays information on the location of the tool. The X/Y values display the location of the tool. This will be displayed in inches, millimeters, feet or meters depending on how the machine is configured on the Utilities screen.

-

Page 79: Origin Select Screen

The origin select screen is used to select the origin to be used. Pressing the origin select button on the setup screen will allow a different origin to be selected. Fourteen different preset home origins can be stored in the Vision Series 5 controller. © 2019 Vision Engraving Systems... - Page 80 Vision Series 5 Controller User Manual Select preset home origin location by pressing the "Active" button to the right of the desired number and press OK. To set the location for the selected preset home origin, press the Set XYZ button from the setup screen.

- Page 81 HINT: To move the spindle to a precision location, press one of the coordinate boxes and enter the desired location. When Enter is pressed, the spindle will move to that location. © 2019 Vision Engraving Systems...

- Page 82 Select Set Origin. The default origin will now be set. IMPORTANT: When using an origin other than 1, it must be selected in the Vision software. To do this, select the Engrave menu and then Tool Options. Change the preset home position value to the desired origin location.

-

Page 83: 6.2.10 Surface Location Screen

6.2.10 Surface Location screen The surface location screen is used to select a flat or irregular shaped surface. Pressing the surface location select button on the setup screen will display the select material or surface map screen. © 2019 Vision Engraving Systems... -

Page 84: 6.2.11 Utilities Screen

This button is only used if software other than the Vision software is being used. The default setting is manual but the Vision software overrides this value each time a job is sent to the machine to match the material settings used in the Vision software. -

Page 85: 6.2.12 Diagnostic Screen

This button is only used if software other than the Vision software is being used. The default setting is manual but the Vision software overrides this value each time a job is sent to the machine to match the material settings used in the Vision software. - Page 86 Vision Series 5 Controller User Manual 3. Lower the spindle with the Z down jog button until you reach the desired position. 4. Press the Enter button to set this as the surface position. The spindle will then move up to its lift position.

- Page 87 2. Use the Y jog up and down buttons to select Z Lift Height and press Enter. 3. Enter the lift height using the numeric buttons on the Vision controller and press Enter. 4. Press Exit to return to the main screen.

-

Page 88: Set Home Procedure

2. Make sure that the spindle is locked by tightening the spring adjustment knob all the way down. 3. Make sure that you have entered a depth of cut in the Vision or Vision Pro software. If you are using a different program then Vision or Vision Pro, use the Menu button on the controller to select and enter the Z Cut Depth. - Page 89 If the machine is turned off, the user defined home position will be replaced with the factory home position. To reset the machine to the user defined home position, Press Shift, then Set Home. The machine will now use the user defined home position. © 2019 Vision Engraving Systems...

-

Page 90: Part Vii Sending Jobs To Your Machine

Sending Jobs to Your Machine Once a job has been set up in the Vision 9 software, select the Engrave icon from the left toolbar. The Cut Toolbox window will appear and the top toolbar will change to the Engrave toolbar. - Page 91 Sending Jobs to Your Machine Select the appropriate material from the Material Selection drop down list, then select OK. Verify the Cut Toolbox settings (settings available will depend on device selected and version of Vision 9 software), and click on the Engrave icon.

- Page 92 Vision Series 5 Controller User Manual Controller Maintenance How to Remove and Clean the Air Filter Weekly preventive maintenance should be performed to ensure reliable operation of your controller. It is recommended that the input fan filter be removed weekly and cleaned to ensure proper cooling of the electronics.

- Page 93 Vision 9 software. To use this feature, turn on the engraver and press the Go to Home button. Open the Vision 9 software with a new drawing and select the Plate Size icon on the top toolbar.

- Page 94 Vision Series 5 Controller User Manual The Measure Wizard window will open. The engraver will turn on its red dot laser pointer. Move the spindle over the material and position the laser pointer so that it is in the upper left hand corner of the engraving area you wish to define.

- Page 95 Using the Measure Feature © 2019 Vision Engraving Systems...

- Page 96 If the area appears to be correct. click on OK in the Plate Size window. The plate size in the Vision 9 software now shows the area defined with the measure feature.

- Page 97 Using the Measure Feature © 2019 Vision Engraving Systems...

Need help?

Do you have a question about the 5 Series and is the answer not in the manual?

Questions and answers

I have a vision 1624 system. When I have a job ready to send to the engraver, it sends it over and the green light comes on the start button. I hit start and then the green light goes out and the job will not start. it is not all of the time, but intermittently.

Intermittent issues with starting a job on the Vision 1624 system after sending it to the engraver could be caused by:

1. Loose Table Cable Connection – Ensure the table cable is securely connected. Removing and reconnecting it while tightening the hold-down screws may help.

2. Emergency Stop Button – Check if the emergency stop button is pressed. If so, release it and turn the drives on.

3. Job Not Transferred Properly – Verify that the job has been successfully transferred to the controller by checking if the green start light is on.

If issues persist, further troubleshooting or contacting technical support may be necessary.

This answer is automatically generated