Subscribe to Our Youtube Channel

Summary of Contents for Krone EasyCut B 970

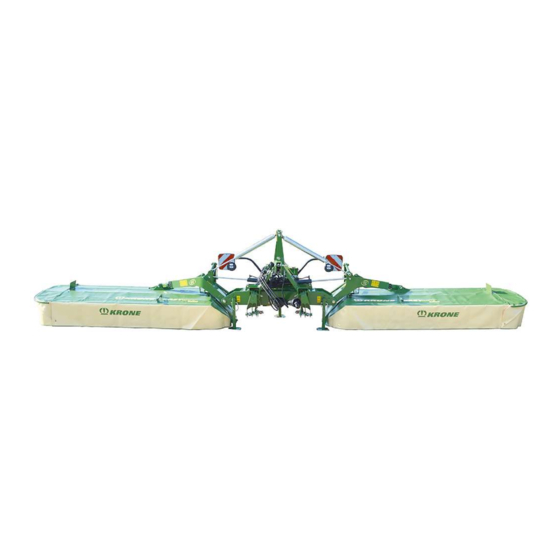

- Page 1 Original Operating Instructions Document no.: 150000711_01_us Mower Combination EasyCut B 970 From machine no.: 976393...

- Page 2 Contact Mailing address Physical address Krone North America, Inc. Krone North America, Inc. P.O. Box 18880 3363 Miac Cove Memphis, TN 38181-0880 Memphis, TN 38118 Phone +1 901 842-6011 +1 901 842-6016 E-mail info@krone-northamerica.com Internet www.krone-northamerica.com Information for enquiries and orders Year Machine no.

-

Page 3: Table Of Contents

Pole protection mechanism ....................... 34 Technical data .......................... 35 Consumables .......................... 35 4.1.1 Oils............................. 36 4.1.2 Lubricating greases ........................ 36 Control and Display Elements .................... 37 Operation panel ......................... 37 Initial operation ........................ 39 EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 4 Cleaning the machine ........................ 72 Maintenance - Hydraulic System.................... 73 12.1 Checking hydraulic hoses ...................... 73 Maintenance - Gearbox ...................... 74 13.1 Input gearbox .......................... 74 13.2 Main gearbox .......................... 75 Maintenance - Cutterbar...................... 77 EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 5 Checking/replacing linings on cutterbar .................. 86 14.8 Checking oil level ........................ 87 Maintenance - Lubrication ...................... 89 15.1 Lubricating universal shaft ...................... 89 15.2 Lubrication chart - Machine ....................... 90 Waste disposal......................... 91 Appendix .......................... 92 Index............................ 93 EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 6: Information On This Document

Information on This Document Validity This document is valid for machines of type: EasyCut B 970 This document only describes the rear combination. If the combination is used with front mounted mower, the operating instructions of the front mounted mower must also be considered. -

Page 7: Figures

This arrow identifies the result of an action step or sequence of actions. This bullet point identifies an enumeration. If the bullet point is intended, it identifies the second level of the enumeration. Icons in figures The following icons can be used in illustrations: EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 8 CAUTION The signal word CAUTION warns of a hazardous situation which will result in minor to moderate injuries if the warning sign is ignored. Example of a warning sign: EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 9: Conversion Table

Volume flow Litres per minute L/min 0.2642 US gallons per minute Cubic metres m³/h 4.4029 per hour Force Newton 0.2248 Pound force Length Millimetre 0.03937 Inch Metre 3.2808 Foot Power Kilowatt 1.3410 Horsepower EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 10 Kilometres per km/h 0.6215 Miles per hour hour Volumes Litres 0.2642 US gallon US gal. Millilitre 0.0338 US ounce US oz. Cubic centi- cm³ 0.0610 Cubic inch in³ metre Weight Kilogram 2.2046 Pound EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 11 Information on This Document How to use this document This page has been left blank deliberately. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 12: Safety

• Attachment of unauthorised or unapproved additional equipment • Use of spare parts which are not KRONE original spare parts • Stationary operation of the machine Unauthorised modifications to the machine may affect the properties of the machine or disrupt proper operation. -

Page 13: Service Life Of The Machine

He has read the operating instructions and can implement the information in the operating instructions accordingly. • He is familiar with driving vehicles safely. • For road travel he has adequate knowledge of the highway code and has the stipulated driving licence. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 14: Personnel Qualification Of The Technicians

Additional equipment and spare parts that do not correspond to the requirements of the manufacturer may affect the operational safety of the machine and cause accidents. „ To ensure operational safety, use original parts or standard parts which correspond to the requirements of the manufacturer. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 15: Jobs On The Machine

„ Immediately eliminate potential causes of damage, for example heavy soiling, or tighten slack screws. „ In case of damage which may affect operational safety and cannot be repaired according to these operating instructions: Have damage repaired by a qualified service centre. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 16: Danger Zones

„ Ensure sufficient overlap of section tube and universal shaft guards. „ Make sure that the universal shaft guards are mounted and that they are fully functional. „ Allow the universal shaft locks to engage. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 17 „ In case of dangerous situations, immediately switch off drives and instruct persons to leave the danger zone. Danger zone due to trailing machine parts If machine parts are trailing, people may be seriously injured or killed. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 18: Ensuring Functionality Of Safety Devices

„ Make sure every time after cleaning the safety labels that they are complete and legible. „ Immediately replace missing, damaged and unrecognizable safety labels. „ Provide spare parts with intended safety labels. Descriptions, explanations and order numbers of safety labels,refer to page 25. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 19: Road Safety

„ Do not park the machine on slopes. „ Observe procedures for operating the machine on slopes, refer to page 54. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 20: Parking The Machine Safely

„ Check and clean the machine every day before using it for the first time. „ Check and clean the machine regularly during the working day. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 21: Sources Of Danger On The Machine

„ Specify rules for the use of hearing protection and for the working time. „ During operation keep windows and doors of cabin closed. „ Remove hearing protection for road travel. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 22 Transfer gearbox • Mower gearbox • Belt gearbox • Hydraulic system • Cutter bar „ Maintain a sufficient distance from hot surfaces. „ Leave machine parts to cool down and wear protective gloves. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 23: Dangers In Connection With Certain Activities: Working On The Machine

Frame or supporting components • Running gear „ Before carrying out welding work on the machine, obtain consent by KRONE customer service and, if required, identify alternatives. „ Before performing welding work on the machine, park the machine safely and disconnect it from the tractor. -

Page 24: Behaviour In Dangerous Situations And In Case Of Accidents

„ Before working on or under raised machine parts: Secure machine or machine parts against lowering by means of hydraulic shut-off device (e.g. stop cock) on machine side. „ Before working on or under raised machine parts: Safely support machine or machine parts. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 25: Carrying Out Oil Level Check And Oil And Filter Element Changes Safely

Safety Labels on the Machine Every safety label is provided with an order number and can be ordered directly from the authorised KRONE dealer. Immediately replace missing, damaged and unrecognisable safety labels. When attaching safety labels, the contact surface on the machine must be clean and free of dirt, oil and grease to ensure optimum adhesion of the labels. - Page 26 Safety Safety Labels on the Machine Position and meaning of safety labels KM000-176 EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 27 4. Ord. no. 27 002 056 0 (6x) DANGER Blade can cause serious injury or death. • Stay clear of machine while in operation. • Keep discharge chute and shields in place. EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 28 9. Order No. 27 004 598 1 (1x) CAUTION! The operating pressure of the hydraulic sys- tem must not exceed 200 bar. 10. Order No. 27 004 599 0 (1x) CAUTION! Max. PTO speed 1000 RPM EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 29 • Driveline guards that turn freely on driveline. 14. Order No. 27 021 593 0 (1x) WARNING Keep tractor hydraulic controls locked during road transport to prevent implement move- ment and possible personal injury. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 30: Safety Equipment

Overload protection • The overload protection protects the tractor and the machine from load peaks „ To avoid damaging the machine, switch off the PTO shaft if the overload clutch engages continuously. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 31: Smv Emblem

When driving the machine on public highways, the SMV emblem must be mounted. If the machine is transported on transport vehicles (for example lorry or train), the SMV emblem must be covered or dismounted. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 32: Machine Description

Impact damage protection system 16 Locking safety device front Universally-jointed drive shaft 17 Side guard Coupling rod Labelling INFORMATION The entire identification plate represents a legal document and should not be altered or rendered illegible! EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 33: Lighting

(3). Intermediate universal shaft To ensure the functionality and to increase the lifetime, the friction clutch must be vented once a year before the beginning of the season, refer to page 70. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 34: Pole Protection Mechanism

After the impact damage protection system has been triggered, the mowing unit swivels back. Reversing the mowing unit causes the impact damage protection system to engage again. The trigger moment has been set at the factory. Dimension X=85 mm EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 35: Technical Data

NOTICE Complying with change intervals for biooils To ensure high life expectancy of the machine, it is absolutely necessary to comply with change intervals for biooils due to the ageing of the oils. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 36: Oils

Lubricating grease to DIN 51818 of NLGI class 2, Li soap with EP additives Lubricate the manual lubrication point until grease escapes at the bearing position. After lubricating, remove the grease escaping from the bearing position. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 37: Control And Display Elements

Double-acting control unit (2+/2-) (2-) Lowers both mowers from transport position to head- land position. (2+) Raises both mowers from headland position to trans- port position. Bottom Activates the lower toggle switch (3). EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 38 Raises the left mower from working position to head- land position. Middle Single-acting control unit (1+): Lowers both mowers from headland position to work- ing position. Raises both mowers from working position to head- land position. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 39: Initial Operation

ü The blades have been inserted, refer to page 79. ü The hydraulic system has been vented. ü The friction clutch has been vented, refer to page 70. ü The coupling points have been adapted, refer to page 40. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 40: Adapting Coupling Points

The thicker journal of the top link pin (1) is facing outwards. „ Secure the top link pin with the linch pin (3). „ Make sure that the anti-twist lock (4) of the top link pin is in the recess. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 41: Setting The Coupling Rod

„ Shut down and safeguard the machine, refer to page 24. „ Disassemble the universal shaft. „ Install each half (1, 2) on the tractor and machine side respectively. „ Shorten section tubes and guard tubes. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 42 (shift length) of the profile tubes and guard tubes of at least 200 mm, refer to the operating instructions of the universal shaft manufacturer. „ Check the overlap of profile tubes and guard tubes. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 43: Start-Up

This may result in serious accidents. „ Only connect the machine to the three-point hitch of the tractor. „ Never mount the machine on U-frame coupler. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 44: Connecting Hydraulic Hoses

Use a control unit on the tractor which can be locked in the neutral position against unintentional operation. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 45: Connecting Operation Panel

Connection operation panel to tractor „ Connect 2-pole plug (2) to 2-pole socket (1) of the tractor. Connection operation panel to machine „ Connect 14-pole plug (3) with 14-pole socket (4) of the machine. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 46: Connecting Road Travel Lighting

The machine could be damaged if the universal shaft length is not checked when changing the tractor. „ In order to avoid damage to the machine, check universal shaft length every time the tractor is changed and correct it, if necessary, refer to page 41. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 47 ü The machine is shut down and safeguarded, refer to page 24. „ Slide universal shaft (1) on PTO shaft end of tractor and secure it. „ Secure universal shaft guard by means of supporting chain (2) against turning. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 48: Operation

If the front guard is folded up during work, objects can be ejected. As a result, people may be seriously injured. „ Fold down the front guard. „ Connect the guard cloths of the front guard and the side guard using the turnlock fasteners. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 49: Folding Up The Front Guard

„ Pull the spring cotter pin (3) and pull the locking (2) off the bolt. „ Fold down the front guard (1), place the locking (2) onto the bolt and secure it with the spring cotter pin (3). „ Close the turnlock fasteners (4). EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 50: Side Guard

ü The machine is shut down and safeguarded, refer to page 24. „ Fold down the side guard (1). „ Ensure that the side guard (1) is secured by the locking, refer to page 63. „ Close the turnlock fasteners (2). EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 51: Operate The Support Jack

„ Pull the bolt (1), push the front support jack (2) downwards and lock it by using the bolt (1). „ Pull the tension bar (4), swivel the rear support jack (3) downwards and lock it by using the tension bar (4). EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 52: Locking / Releasing Stop Cocks

„ Move the toggle switch (3) to the “centre” position. „ Move the control unit (1+) to the float position until both mowers are lowered to the working position. „ To mow, move the control unit (1+) to the float position. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 53: Mowing

ü The front guards are folded down, refer to page 49. ü The side guards are folded down, refer to page 50. ü The rear linkage is blocked. ü The parking jacks are in the transport position, refer to page 51. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 54: Field Mode On Slopes

„ To avoid accidents, the relevant safety instructions must be read and observed, refer to page 13. KMG000-094 „ Do not move the machine from transport into working position or from working into transport position as long as the machine is operated diagonal to the slope. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 55: Driving And Transport

Even with a fitted rear-mounted device, the front axle of the tractor must always be loaded with a minimum 20% tare weight of the tractor. „ Make sure before starting to move that these requirements have been met. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 56: Prepare The Machine For Road Travel

The mowers are secured against unintentional lowering by folding them up as far as the limit stop (2). „ Make certain after swivelling the mowers up that the outrigger arms (1) right and left are fully lowered and that they rest on the end stops (2). EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 57: Switching Off The Machine

„ Detach the top link. „ Unlock the lower link hooks of the tractor. „ Continue to lower the rear linkage until the lower link pins are free. „ Move tractor away carefully. Parking KMG000-020 EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 58 ü The side mounted mowers are in the transport position. The outrigger arms (1) are fully retracted and rest on the end stops (2). „ Only park the machine on level ground capable of bearing the load such as concrete or asphalt. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 59: Settings

ð Top link longer = greater cutting height ð Top link shorter = smaller cutting height „ Swivel the support jack/(s) up, refer to page 51. For version with "high-cut skids" The cutting height can be increased using high-cut skids. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 60: Setting The Lateral Links

The setting is made by raising the machine. „ Raise the machine until the lateral suspension arms (3) are set to X = approx. 0 mm. 10.3 Setting Overcut KM000-165 EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 61: Adjusting The Relief Spring(S)

If the dimension a is changed, the nuts (3) may come into contact with the rocker arm (4). This may damage the machine. The dimension a is set in the factory to 3-5 mm. „ Never change dimension a. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 62: Setting The Lifting Speed / Lowering Speed Of The Hydraulic Cylinders

(4). ü The machine is in the working position, refer to page 52. ü The machine is shut down and safeguarded, refer to page 24. „ Loosen hexagon nut (1). EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 63: Checking/Setting Locking Of Side Guards

„ To reduce the ground pressure, reduce the dimension X. „ Tighten the counter nut (5). „ Set the dimension X in the same way on all relief springs. 10.7 Checking/setting locking of side guards KMG000-042 EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 64 ü The machine is shut down and safeguarded, refer to page 24. „ Loosen the screw connection (3). „ Readjust the locking (2) in the oblong hole. „ Tighten the screw connection (3). „ Check the locking (2). EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 65: Maintenance - General Information

Check/change blade carrier (blade quick refer to page 83 fastener) Check/replace abutting edge on the cutterbar refer to page 86 Vent friction clutch refer to page 70 Check/replace locking of the side guards refer to page 63 EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 66: Maintenance - After The Season

Check guard cloths refer to page 72 Check the hydraulic hoses for leaks and, if ne- refer to page 73 cessary, have them replaced by a KRONE service partner. Check the electrical connection cables and, if necessary, have them repaired or changed by... -

Page 67: Maintenance - Every 50 Hours

Metric thread screws with control thread INFORMATION The table does not apply to countersunk screws with hexagon socket in case the countersunk screw is tightened via hexagon socket. DV000-001 Thread size Strength class on screw head EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 68 Tightening torque (Nm) M12 x 1.5 M14 x 1.5 M16 x 1.5 M18 x 1.5 M20 x 1.5 M24 x 2 1,121 1,312 M27 x 2 1,148 1,635 1,914 M30 x 1.5 2,100 2,650 EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 69 The term “locking screw” includes the drain plug, the inspection screw as well as the ventilation and breather filters. This table applies only to locking screws with external hexagon in connection with copper seal ring and for bleed valves made of brass with shaped seal ring. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 70: Deviating Tightening Torques

„ Never intervene in the overload protection. „ Only use KRONE original spare parts. The friction clutch protects the tractor and the machine from damage. The friction clutch must be vented before starting up for the first time and once a year. The friction clutch is designed with a permanently adjusted turning torque M . - Page 71 „ Remove the universal shaft. „ Loosen the cap nuts (1) uniformly but do not remove them. ð The friction discs are relieved. „ Turn the friction clutch (2). „ Screw in the cap nuts (1) completely. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 72: Checking Guard Cloths

„ Do not aim the water jet from high-pressure cleaner at bearings and electrics/electronic components. ü The machine is shut down and safeguarded, refer to page 24. „ After each use, remove husk and dust from the machine. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 73: Maintenance - Hydraulic System

When checking hydraulic hoses, the state-specific conditions (e.g., BGVU) must be observed. Performing a visual inspection „ Visually inspect all hydraulic hoses for damage and leaks and have them replaced by an authorised specialist if necessary. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 74: Maintenance - Gearbox

„ Refill with fresh oil up to the inspection hole (1) via the filling hole (3). „ Screw on the locking screw of the inspection hole (1) and the locking screw of the filling hole (3), tightening torque refer to page 69. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 75: Main Gearbox

„ Refill with fresh oil up to the inspection hole (1) via the filling hole (3). „ Screw on the locking screw of the inspection hole (1) and the locking screw of the filling hole (3), tightening torque refer to page 69. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 76 „ Top up new oil via the filling hole (3) up to the inspection hole (1). „ Mount the locking screw of the inspection hole (1) and the locking screw of the filling hole (3), Anziehdrehmoment refer to page 69. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 77: Maintenance - Cutterbar

(a, b). • The nuts (2) with left-handed thread (LH) have distinctive grooves (a) on the bevel. • The pinion shafts (4) with left-handed thread (LH) have a distinctive groove (b) on the face. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 78: Replacing The Shear Bolt At The Rotary Hub

„ Dismount the nut (2) by using the special key (10) included with delivery. „ Dismount the hub (1). „ Remove the damaged shear pins (3). „ Check the nut and the hub for damage. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 79: Check/Change Blades

Maintenance - Cutterbar Check/change blades 14.3 INFO : Replace damaged parts by KRONE original spare parts. „ Fill the space above the bearing with grease (c). „ Place the hub on the pinion shaft. INFO : Observe the position of the shear pins. The slots of the shear pins (3) must be mounted facing each other horizontally, see detail (I). -

Page 80: Changing Blades For The "Blade Screw Connection" Version

„ Clean the area around the blades, cutting discs and mower drums. „ Remove the damaged or worn blade. „ Check the fastening elements of the blade, refer to page 82. Also replace worn or damaged fastening parts. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 81: Changing Blades For The "Blade Quick Fastener" Version

„ Guide the blade (2) onto the retaining bolt (5) and release the blade key (1) in a controlled manner with your hand. „ Repeat the process for all blades. „ Fold down the front guard, refer to page 49. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 82: Checking/Replacing Retaining Bolts

Section (1.1) of the gauge (1) is used to check the material thickness of the retaining bolts. Section (1.2) of the gauge (1) is used to check the contour of the blade carriers. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 83: Checking/Replacing Blade Carrier

„ The blade carriers must be replaced at the latest when the application seam (1) is worn at one point. „ The blade carriers must only be replaced by KRONE original spare parts. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 84 „ Remove the blades. „ Clean the area to be checked. „ Slide the gauge (1) with the section (1.2) as far as it will go over the retaining bolt of the blade carrier (2). EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 85: Checking/Replacing Cutting Discs/Mower Drums

„ The cutting discs/mower drums must be checked at least once a day or after contact with foreign objects. „ If cutting discs/mower drums are deformed, the dimension X=48 mm must not be exceeded. „ The cutting discs/mower drums must only be replaced by KRONE original spare parts. KM000-042 EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 86: Checking The Wear Limit On Cutting Discs/Mower Drums

„ The cutting discs/mower drums must be replaced at the latest when the material thickness is below the minimum material thickness of 3 mm. „ The cutting discs/mower drums must only be replaced by KRONE original spare parts. KM000-043 14.7... -

Page 87: Checking Oil Level

Checking oil level INFORMATION There is no need to change the oil on the cutterbar. Before checking the oil level on the cutterbar, the cutterbar must be aligned levelly by means of a spirit level. EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 88 If the oil does not reach the inspection hole (1): „ Top up new oil via the inspection hole (1) up to the inspection hole (1). „ Mount the locking screw of the inspection hole (1),refer to page 69. EasyCut B 970 Original Operating Instructions 150000711_01_en...

-

Page 89: Maintenance - Lubrication

ü The machine is shut down and safeguarded, refer to page 24. „ Observe operating instructions of the universal shaft manufacturer. „ Lubricate the universal shaft with multi-purpose grease at the intervals indicated in the figure. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 90: Lubrication Chart - Machine

Type of lubrication Lubricant Comment Grease Multi-purpose grease „ Apply two strokes of lubricating grease from the grease gun per grease nipple. „ Remove excess lubricating grease at the grease nipple. KMG000-023 Every 20 operating hours EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 91: Waste Disposal

All synthetic materials must be brought to a recycling centre for synthetic materials. Rubber • Rubber parts (hoses, tyres, …) must be brought to a rubber recycling centre. Electronic scrap • All electronic parts must be brought to a disposal point for electronic scrap. EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 92: Appendix

Appendix Appendix EasyCut B 970 Original Operating Instructions 150000711_01_en... -

Page 93: Index

Connecting the machine to the tractor ....43 Consumables ..........20, 35 Contact ..............2 Contact data of your dealer ........2 Control and Display Elements ......37 Conversion table ..........9 Cross references ..........6 EasyCut B 970 Original Operating Instructions 150000711_01_en... - Page 94 Folding down side guard (working position) ..50 Lubrication chart - Machine ........ 90 Folding up side guard (transport position) ..50 Folding up the front guard ........49 From headland to transport position....53 Front guard ............48 EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 95 Only perform work when the machine is at standstill ............. 23 Operate the support jack ........51 Operation............48 Operation is only allowed after proper start-up .. 15 Operation panel ..........37 Operational safety: Technically sound condition 15 EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 96 Technical data ............ 35 Technical limit values ......... 16 Technically sound state of the machine ..... 15 Term “machine” ............ 7 Tightening torques..........67 Top link pin ............40 Unsuitable consumables ........20 EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 97 This page has been left blank deliberately. EasyCut B 970 Original Operating Instructions 150000711_01_en...

- Page 98 Maschinenfabrik Bernard Krone GmbH & Co. KG * Heinrich-Krone-Straße 10 D-48480 Spelle * Postfach 11 63 D-48478 Spelle ' +49 (0) 59 77 / 935-0 6 +49 (0) 59 77 / 935-339 ü www.landmaschinen.krone.de...

Need help?

Do you have a question about the EasyCut B 970 and is the answer not in the manual?

Questions and answers