Table of Contents

Advertisement

Installation Guide

EUROPE

VITRONICS SOLTEC BV

Karolusstraat 20

4903 RJ Oosterhout

the Netherlands

Tel. +31-162-483000

Fax +31-162-483269

ASIA PACIFIC

VITRONICS SOLTEC PTE LTD.

135 Joo Seng Road

#02-01 PM Industrial Building

Singapore 368363

Tel. +65-484-3010

Fax +65-484-1910

VITRONICS SOLTEC GmbH

An der Köhlerei 7

97828 Marktheidenfeld

Germany

Tel. +49-9391-98820

Fax +49-9391-988228

VITRONICS SOLTEC MID ASIA

Room 1616, Hansuh Bldg.

11-11, Yeouido-Dong, Youngdeungpo-Ku

Seoul, Korea 150010

Tel. +82-2-782-4790

Fax +82-2-782-4792

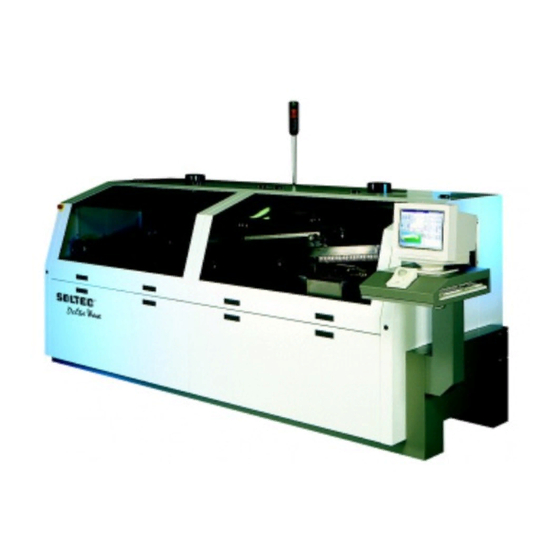

DeltaWave

Version 22.5.0.000

AMERICAS

VITRONICS SOLTEC Inc.

2 Marin Way

Stratham, New Hamphire 03885

USA

Tel. +1-603-772-7778

Fax +1-603-772-7776

VITRONICS SOLTEC SH REPR. OFFICE

Room G, 14th Floor, Huadu Mansion

828-838 ZhangYang Road

Shanghai, China 200122

Tel. +86-21-6876-4885

Fax +86-21-6876-5335

Advertisement

Table of Contents

Summary of Contents for Dover Vitronics Soltec DeltaWave 6622cc

- Page 1 Installation Guide DeltaWave Version 22.5.0.000 EUROPE AMERICAS VITRONICS SOLTEC BV VITRONICS SOLTEC GmbH VITRONICS SOLTEC Inc. Karolusstraat 20 An der Köhlerei 7 2 Marin Way 4903 RJ Oosterhout 97828 Marktheidenfeld Stratham, New Hamphire 03885 the Netherlands Germany Tel. +31-162-483000 Tel. +49-9391-98820 Tel.

- Page 2 Rights COPYRIGHT 2003 VITRONICS SOLTEC BV All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Vitronics Soltec BV. This publication remains the property of Vitronics Soltec BV and may not be passed, loaned or given to any third party.

- Page 3 Preface During the composition of this manual much attention is given to avoid errors and mistakes. Also we aimed to give the contents a clear structure. If during the use of this manual errors or incomplete descriptions are found, or the reader considers that improvements are necessary to overcome any in- accuracies, please inform us.

-

Page 5: Table Of Contents

Table of Contents Preface Table of Contents Installation 1.1 General . 1.2 Transport 1.2.1 Symbols used . 1.2.2 Dimensions & weight . 1.2.3 Centre of gravity . 1.2.4 Unpacking . 1.2.5 Lifting with forklift 1.2.6 Adjust leveling pads . 1.3 Installation info 1.3.1 Carrying capacity floor per leveling pad . - Page 6 1.7 Mechanical adjustments. . 1-15 1.7.1 Solderwave setting: Smartwave and Mainwave . . 1-15 1.7.2 Backplate setting . . 1-16 1.7.3 Chipwave setting . . 1-17 1.7.4 Setting the solderlevel sensor . . 1-18 1.7.5 Foamfluxer . . 1-18 1.7.6 Spray drumfluxer .

- Page 7 SAFETY RULES GENERAL INFORMATION ICON DESCRIPTION ICON DESCRIPTION Only Qualified personnel is allowed to work on the High voltages are present on various parts of the sys- equipment. tem. Never eat, drink or smoke while working on the machine. Before working on the electrical circuit, turn main Wash thoroughly before eating, drinking or smoking.

-

Page 9: Installation

Installation ENERAL Installing only by trained Vitronics Soltec / Agent personnel. At the end of this chapter an installation sheet is located. RANSPORT 1.2.1 S YMBOLS USED Position pallet/box for transport Breakable Keep dry Lift here (labels are placed on position where forklift should lift) IGURE YMBOLS ON PACKAGING... -

Page 10: Centre Of Gravity

NSTALLATION 1.2.2 D & IMENSIONS WEIGHT ABLE ACKING ON ALLET WEIGHT TOTAL WEIGHT TOTAL L X W X H WITH SOLDERPOT WITH SOLDERPOT EMPTY FILLED 420 x 150 x 188 1800 2550 ABLE ACKING IN RATE WEIGHT TOTAL WEIGHT TOTAL WITH SOLDERPOT WITH SOLDERPOT L X W X H... -

Page 11: Unpacking

1.2 - T RANSPORT 1.2.4 U NPACKING The Vitronics Soltec DeltaWave is packed on a wooden pallet. When necessary, the machine is packed in crates (e.g. when shipped). If packed in crates the fol- lowing procedure should followed. IGURE RATE Use the above figure order A,B,C to uncrate. - Page 12 NSTALLATION 1.2.5 L IFTING WITH FORKLIFT When the transporting straps are removed, the DeltaWave can be placed on the place the cus- tomer has planned it. To lift and transport the DeltaWave use the figure below. The points where the forks from the forklift can be placed are shown.

-

Page 13: Installation Info

1.3 - I NSTALLATION INFO NSTALLATION INFO 1.3.1 C ARRYING CAPACITY FLOOR PER LEVELING PAD IGURE ARRYING CAPACITY Weight per leveling pad maximum 450 kg. 1.3.2 C & LEARANCE FOR OPERATE MAINTENANCE IGURE LEARANCE ABLE LEARANCE CLEARANCE FOR CLEARANCE FOR POSITION OPERATE MAINTENANCE... -

Page 14: Installation Requirement

NSTALLATION 1.3.3 I NSTALLATION REQUIREMENT 1.8 "Installation sheet", on page 1–22. 1.3.4 P UTTING IN POSITION IGURE ELTA 1.3.5 M ECHANICAL ADJUSTMENTS After carefully positioning the machine and allowing for sufficient working space, follow the list below in setting the machine into its correct attitude. 1. - Page 15 1.3 - I NSTALLATION INFO 3. The solderpot and fluxer units are levelled in relation to the underframe prior to the machine leaving the factory. The solderpot is set in the basic work position (wave height 7 mm). trapezium nut 2 mm bolt safety nut...

-

Page 16: Electrical Connection

NSTALLATION 1.3.6 E LECTRICAL CONNECTION Only qualified electricians should work on the electrical circuits of the machine. 1. Feed the mains-cable for the whole machine trough the top side of the infeed section. 2. Connect the mains leads in accordance with the diagrams. Check the current rotation of the phases. - Page 17 1.3 - I NSTALLATION INFO 1.3.9 E XHAUST SYSTEM Two exhaust gauges of 160 mm (6.3”) are provided. One for the flux unit and one for the solder fumes. These should be connected with the customer’s exhaust system (not supplied by Vitronics Soltec).

- Page 18 NSTALLATION 1.12 S IGURE OLDERLEVEL MIN MAX AND MAX 2. Filling with solderbars. When filled with bars, its impossible to melt them on the heated sides of the solderpot. There- fore the sumps must be removed. When a nitrowave is on the solderpot also the nitrowave covers must be removed. ONLY FOR CHIPWAVE 1.

- Page 19 1.3 - I NSTALLATION INFO 1.15 R IGURE EMOVING BOLTS SUMPS 4. Remove sumps. 5. Fill solderpot with bars. Make sure the bars are placed against the heated sides of the solderpot. Installation Guide DeltaWave HAPTER...

-

Page 20: Starting Up

NSTALLATION TARTING UP 1.4.1 I NSTRUCTIONS STARTING UP IS ONLY ALLOWED BY QUALIFIED PERSONNEL BEFORE STARTING UP, START UP THE FOLLOWING PROCEDURE: 1. Open the N /Air valve. Adjust the pressure on 6 bar maximum for air and 5 bar for N 2. -

Page 21: Start Process

1.5 - S TART PROCESS TART PROCESS 1.5.1 P REPARATIONS TO START CHECKLIST: • / Air is present. • Power is present. • All circuit breakers ON. • PC program is on. 1.5.2 S WITCH ON 1. Choose recipe (ALT C). If not present edit recipe. 2. -

Page 22: End Process

NSTALLATION ND PROCESS 1.6.1 P REPARATIONS TO STOP Before stopping the machine must be complete empty. 1.6.2 S TOP PROCEDURES The machine can manually stopped or by timer. To work with the timer see chapter PC program. To stop manually follow the following procedure: 1. - Page 23 1.7 - M ECHANICAL ADJUSTMENTS ECHANICAL ADJUSTMENTS 1.7.1 S OLDERWAVE SETTING MARTWAVE AND AINWAVE 1.16 S IGURE OLDERWAVE SETTING 1. Check the smart or mainwave nozzle is correctly levelled. Easy to do by reducing the pumpspeed to the point that the solderflow is breaking from the nozzle rim. The solder must break over the total width.

-

Page 24: Backplate Setting

NSTALLATION 1.17 C IGURE ONTACT GLASSPLATE SOLDER 1.7.2 B ACKPLATE SETTING 1. Nitrowave: Using the nitrowave the solder has to overflow the backplate during soldering. Adjust the backplate in such a way that using the glassplate and raising the waveheight as described above the solder is just overflowing at the backside. -

Page 25: Chipwave Setting

1.7 - M ECHANICAL ADJUSTMENTS 1.7.3 C HIPWAVE SETTING 1. When the mainwave and the backplate are adjusted set the chipwave. Place the glassplate (partnr. 627.3785) above the chipwave. 1.19 G IGURE LASSPLATE ON HIPWAVE 2. Adjust the pumpspeed such that the wave touches the glassplate over the full width in an unbroken line off about 10 mm. -

Page 26: Setting The Solderlevel Sensor

NSTALLATION 1.7.4 S ETTING THE SOLDERLEVEL SENSOR 1.21 S IGURE OLDERLEVEL SENSOR 1. Check if the solderlevel is 15 mm from the top of the bath rim (without pumping). 2. Turn on both solderwaves. 3. Adjust the ring of the float so that it sensor is on. 1.7.5 F OAMFLUXER 1. -

Page 27: Spray Drumfluxer

1.7 - M ECHANICAL ADJUSTMENTS 1.7.6 S PRAY DRUMFLUXER 1. Check if the fluxer is level. If necessary correct the threaded ends. 2. Check if the drain is closed. 3. Fill the fluxer up to the top of the overflow pipe with flux of the desired density. 4. -

Page 28: Nozzlefluxer

NSTALLATION 1.7.7 N OZZLEFLUXER 1.22 C IGURE HECK AIRCAP 1. Check if the nozzle aircap is set correct. 2. Fill the fluxsupply container or place the vessel of the fluxsupplier in the machine. 3. Place the suctionpipe on the vessel/container. 4. -

Page 29: Density Control Unit

1.7 - M ECHANICAL ADJUSTMENTS 6. Set the pump-frequency and start/stop position in the PC program. 7. Test options: move once to check if the nozzle move and spray correctly. 8. Place the glassplate (or an empty PCB) in the conveyor to check if the underside is wetted well with flux. -

Page 30: Installation Sheet

NSTALLATION NSTALLATION SHEET See next pages. HAPTER... - Page 31 Installation sheet DeltaWave 6622cc UNITS IN MM LIFTING POINTS. STRIP FRAME FRAME DISTANCE BETWEEN FORKS LEVELING SCREW UNPACK LIFT PLACE MINIMUM 800MM-1000MM MACHINE MACHINE MACHINE REMOVE INSERT...

- Page 32 Installation sheet DeltaWave 6622cc DESCRIPTION UNITS 3x400 or 3x415 Input Voltage Power Minimum Power Maximum I largest Load kg / lb 2450 / 5400 Weight Machine with solderpot filled kg / lb 2650 / 5840 Shipping Weight with solderpot filled Carrying capacity floor per leveling feet kg / lb 450 / 992...

- Page 33 Index Leveling pad . . 1-4 Weight . Mainwave . 1-15 Aircap . .1-20 Nozzlefluxer . . 1-20 Backplate . .1-16 Procedures . . 1-14 Checklist . .1-13 Clearence . . 1-5 Re-start . . 1-14 Rights . . 1-ii Density control .

Need help?

Do you have a question about the Vitronics Soltec DeltaWave 6622cc and is the answer not in the manual?

Questions and answers