Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Magnum Industrial MI-93050

- Page 1 MODEL NO.: MI-93050 SPECIFICATIONS Cutting Capacity (HxW) 90° ● 4" (100 mm) ▄ 4" x 6" (100 x 150 mm) 45° ● 3.25" (85 mm) ▍3 -1/4" x 4" (85 x 100 mm) Blade Speed 177 feet per minute (FPM) Blade Size 57.5"...

-

Page 2: Table Of Contents

Specifications Capacity: Round ................................4" Rectangle ............................4" x 6" Throat Depth..............................4" Vertical Worktable.........................6-1/4" x 15-3/4" Vise Tilts ..............................45º Blade Speed .......................... 60Hz 177FPM Motor ......................1/2HP 60Hz 1720RPM 4POLE Net Weight (approx.).......................... 50 lbs Packing..........................28.5" x 15" x 18" Table of Contents General Safety Rules........................ -

Page 3: General Safety Rules

11. Make certain the motor switch is in “off” 1. General Safety Rules position while connecting the machine into the power supply. WARNING 12. Pay your work undivided attention. 1. Read and understand instructions of this Looking around, and carrying on a manual entirely before operating the conversation, or “Horse-play”... -

Page 4: Electrical Schematic

Electrical Schematic Wiring Diagram Toggle Switch Single Phase - 2 -... -

Page 5: The Quick Vise And Work Set Up

BEFORE CUTTING Unhook the lock chain (A) in Fig.1 to release this saw. After service, must replace the chain, and hook it properly for your safety and carry. Failure to comply with the warning could result in personal injury and machine damage. 2. -

Page 6: Special Safety Rules For Metal Saw

available at stores. Use of glasses or 3. Special Safety Rules for Metal use of goggles not in compliance with DIN 58214 could result in severe injury from breakage of the eye protection. WARNING: For your own safety, do B. For dusty operations, wear a face not operate your metal saw until it is shield along with safety goggles. -

Page 7: Whenever Saw Is Running

․ Never cut freehand: G. To avoid an electrical shock, make a. Brace your workpiece solidly sure your fingers do not touch the metal prongs on the plug when against the fence and table top so it will not rock or twist during inserting or removing the plug to or from a live outlet. -

Page 8: Power Supply

4. Power Supply 6. Before freeing jammed material, turn the switch off and unplug the saw. Wait for all moving parts to stop. Motor Specifications 7. After finishing a cut, keep holding the The AC motor used in this saw is a power head down, release the switch, conduction, nonreversible type having the and wait for all moving parts to stop... -

Page 9: Earth

Ground 4. Fuses may “blow” or circuit breakers may trip frequently if: This metal saw is single insulated tool, so the Motor is overloaded-overloading can ground system is provided to protect you occur if you feed too rapidly or make from being shocked. -

Page 10: Unpacking And Checking Contents

5. Unpacking and Checking Tools Needed for Assembly Contents Note: The shown tools are not standard deliver with this saw. The Metal Saw is shipped complete in one carton. Separate all parts from packing material and check each item with illustration and “Table of Loose Part”... -

Page 11: Description And Characteristics

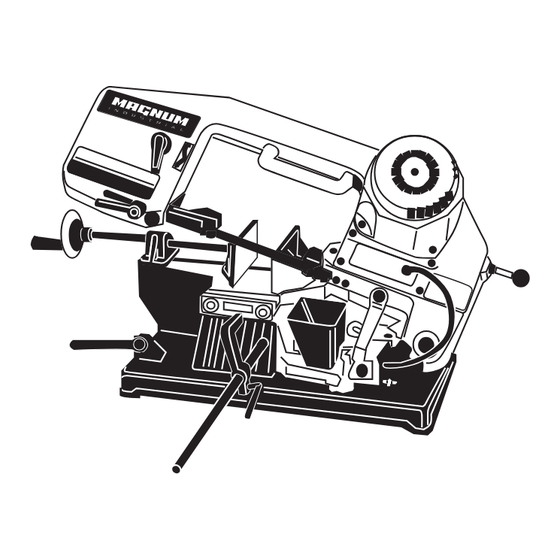

6. Description and Characteristics WARNING 1. This 4” portable band saw is made as light as 23 kgs by weight & equipped with SHUT OFF THE POWER SOURCE ALL an easy carrying handle for your fitness THE TIME, BEFORE THIS MACHINE IS to transport to any worksites. -

Page 12: Operating

7. Operating Blade Direction of Travel Be sure this blade is assembled to the Information Before Operation wheels so that the vertical edge can engage the work piece first. Be sure the blade isn’t in contact with the work when the motor is started. Run the motor, allow the saw to come to full speed. -

Page 13: Electrical Connections

Electrical Connections This band saw is designed for use on a circuit with an outlet that looks like (A) in Figure on the right hand side. This saw has a grounding prong as the right illustrated in (B). A temporary adapter (C) may be used to connect the plug to a two pole receptacle (D) if a properly grounded outlet is not available. -

Page 14: Changing Blade

WARNING Disconnect machine from the power source ! No matter when, where, or how. Pay extra attention to the saw during it in transportation, operation, maintenance. Or adjustment. Failure to comply may cause serious injury ! Changing Blade 1. Raise this saw head up-to 90 degree by lifting up knob (A) in Fig.6 a little bit to release the lock-pin, and slide it into the slot that is made for setting the saw arm... -

Page 15: Vertical Cutting

Vertical Cutting (optional) 1. Fasten the supporting bar (A) in Fig. 7 into the slot at the saw head. 2. Raise saw head to vertical position by lifting up the knob (B) a little to release the lock-pin and slide it into the slot which is set for 90 degree. -

Page 16: Adjustment

8. Adjustment Adjusting Blade Guide An unbounded handle is mounted on the unit for freely adjusting the position of blade guide to suit the workpiece size. It’s designed for your convenience to adjust blade guide easily and quickly at any time, and under any situation. -

Page 17: Maintain Gear Transmission

Maintain Gear Transmission WARNING The gears of the transmission system equipped with this machine are made of a SHUT OFF THE POWER SOURCE special kind of steel. BEFORE THIS MACHINE IS IN ADJUSTMENT, MAINTENANCE, OR The quality insures that the gears will be REPAIRMENT. -

Page 18: Adjusting Blade Tracking

Adjusting Blade Tracking WARNING Blade tracking adjustment requires running the saw with the back cover open. This adjustment must be completed by qualified persons only! Failure to comply may cause serious injury! Note: Before making any tracking adjustments, try a new blade. Warped blades will not track. -

Page 19: Part List & Explosion Drawings

PARTS LIST FOR MI-93050 PARTS # DESCRIPTION SPECIFICATION PARTS # DESCRIPTION SPECIFICATION MI-93050-4 Hex. Soc. Cap Screw M5x25 MI-93050-66 Self-Lubricated Bushing 1612 MI-93050-6 Hex. Cap Bolt M6x10 MI-93050-67-1 Flat Washer 23x50x3 4 ° L ° c t i r r i... - Page 20 PARTS LIST FOR MI-93050 PARTS # DESCRIPTION SPECIFICATION PARTS # DESCRIPTION SPECIFICATION MI-93050-126-2 Flat Washer 6x13x1 MI-93050-126-3 Button Head Socket Screw M6x8 ° 0 MI-93050-129 Hex. Soc. Cap Screw M5x16 MI-93050-130 Spring Washer t i c MI-93050-132 Cross Screw M5x6 MI-93050-134 Fiber Hex.

- Page 21 - 19 -...

- Page 22 - 20 -...

Need help?

Do you have a question about the MI-93050 and is the answer not in the manual?

Questions and answers