fadini APROLI 280 Batt Instruction Manual

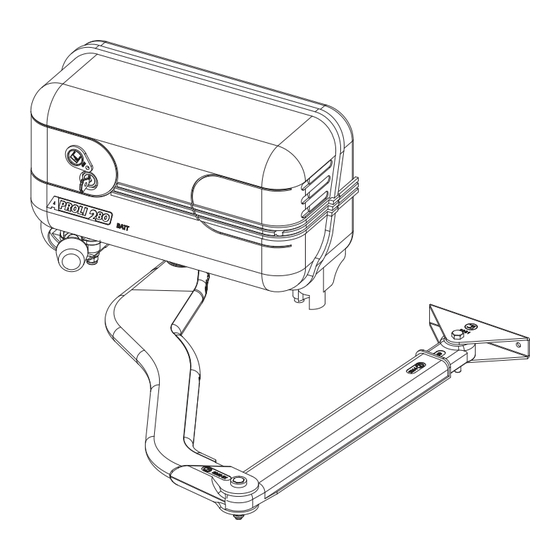

External oil-hydraulic operator with articulated arm for swinging gates mounted on large pillars

Hide thumbs

Also See for APROLI 280 Batt:

- Installation manual (12 pages) ,

- Instruction manual (12 pages)

Advertisement

Quick Links

Download this manual

See also:

Installation Manual

Advertisement

Summary of Contents for fadini APROLI 280 Batt

- Page 1 GB Instructions manual 1 - 12 pages APROLI 280 Batt External oil-hydraulic operator with articulated arm for swinging gates mounted on large pillars EN 13241 EN 12453 EN 12445 the gate opener...

-

Page 2: Installation

Meccanica Fadini snc (Via Mantova, 177/A - 37053 Cerea - VR - Italy) declares under own responsibility that: APROLI 280 Batt complies with the 2006/42/CE Machinery Directive, and also that it is sold to be installed in an “automatic system”, along with original accessories and components as indicated by the manufacturing company. An automatic gate operator is, by law, a “machinery”... - Page 3 For Aproli 280 Batt to work as an automatic system it is required that an electronic control box type Elpro be tted externally in a sheltered place. Operations can be selected to be either fully automatic or semiautomatic (closing by pulse), depending on the user’s requirements.

- Page 4 ELECTRICAL WIRING DIAGRAM AND LAYOUT OF THE ACCESSORIES Before installing Aproli 280 Batt it is advisable that preparatory work be carried out for all of the accessories required at least to ensure safety and proper control of the system.

- Page 5 APROLI 280 BATT SAME VERSION FOR BOTH RIGHT AND LEFT INSTALLATIONS Aproli 280 Batt is not designed as a handed ie. left- or right-hand unit; it comes in a single version factory pre-set to be installed to the left handside of the gate (gate closed, view from inside). For those installations where the operator is on the right handside, it is required that the rotation shaft be set accordingly (Pic.

- Page 6 PRELIMINARY ASSESSMENTS BEFORE INSTALLATION Since Aproli 280 Batt comes with an arm whose gate xing end can be adjusted into three lengths (460, 520 and 580 mm), it is required that the most suitable length be assessed in relation to the gate width (and inertia) and, also, in consideration of the space that the arm is allowed to take in the most critical position when the gate is fully open (Pic.

- Page 7 Once satis ed that voltage is properly supplied to the motors, operator setting is to be attended. Aproli 280 Batt installed on the left is factory pre-set, gate in closed position. Whereas with Aproli 280 Batt installed on the right, it is required that the motor shaft be turned to the end of the permitted rotation.

- Page 8 IMPORTANT: the hole in the attened surface of the square shaft is a reference point. Aproli 280 Batt is factory pre-set to be installed on the left. If installed on the right, the shaft is to be rotated 205° to get it in the correct position.

- Page 9 (Pic. 13). NOTE WELL: Depending on which side of the gate Aproli 280 Batt is mounted, on the left or on the right, The function of the red and green adjusting screws changes in relation to open and close control.

-

Page 10: Ordinary Maintenance

Pic. 15 RELEASING FOR MANUAL OPERATIONS With Aproli 280 Batt non locking (reversible version) it is rst required that the electric lock be released by the coded key and the gate pushed open by hand. With the locking version, releasing is by opening the ap in the front cover by the coded key and lowering the inner lever. -

Page 11: Maintenance Record

NOTE WELL: this document must record any ordinary and extraordinary services including installation, maintenance, repairs and replacements to be made only by using Fadini original spare parts. This document, for the data included in it, must be made available to authorized inspectors/o cers, and a copy of it must be handed over the end user/s. - Page 12 Working temperature -20 °C +80 °C (*) Max. gate width per leaf Working torque 220-300 Nm Oil type Oil Fadini - Item 708L VERSIONS Shaft rotation angle 205° - Non locking (reversible): an electric lock is needed Weight with arm...

Need help?

Do you have a question about the APROLI 280 Batt and is the answer not in the manual?

Questions and answers