Advertisement

Quick Links

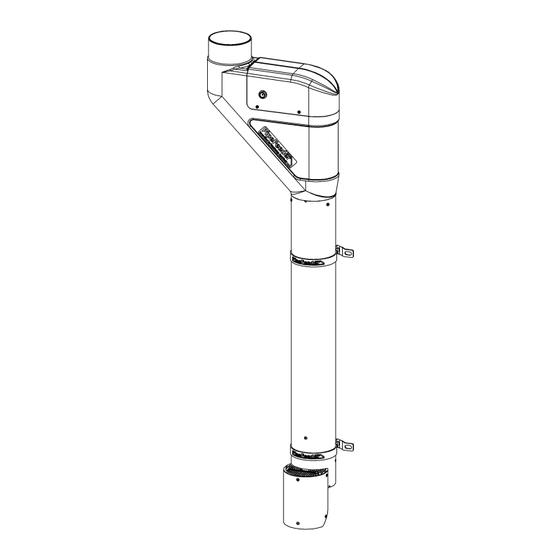

PipeFeeder HighSpeed

Benefit of carrousel

24VDC

EN

Installation and operating instruction

Article number: 010-107-000

Date: February 2017

Doetinchem,

Version 2.0 - Translation of original instructions for use

The Netherlands

According to Annex 1 Chapter 1.7.4 Machine guideline 2006/42/EG

www.hanskamp.nl/en

Advertisement

Summary of Contents for Hanskamp PipeFeeder HighSpeed

- Page 1 PipeFeeder HighSpeed Benefit of carrousel 24VDC Installation and operating instruction Article number: 010-107-000 Date: February 2017 Doetinchem, Version 2.0 - Translation of original instructions for use The Netherlands According to Annex 1 Chapter 1.7.4 Machine guideline 2006/42/EG www.hanskamp.nl/en...

- Page 2 All information in this manual has been compiled with care. Hanskamp shall not be liable for errors or faults in this manual. The recommendations are meant to serve as guidelines.

- Page 3 24VDC Introduction The PipeFeeder HighSpeed suits all types of milking or feeding carousels and can be linked to any brand or type of feed computer. The stainless steel pipe holds the stock of concen- trate. As a feed trough of the carousel comes under the PipeFeeder the electric motor of the dosator gets a signal via the sensor.

- Page 4 Only use approved spare parts, and make sure they are only installed by author- ized technicians. The PipeFeeder HighSpeed should be shielded, so that the dosing system is un- reachable. This separation should meet European standards and guidelines. With- out this separation the PipeFeeder HighSpeed doesn’t meet the safety require- ments of Hanskamp.

- Page 5 Review safety related items with all operators frequently (annually). The PipeFeeder HighSpeed should be shielded, so that the dosing system is un- reachable. This separation should meet European standards and guidelines. With- out this separation the PipeFeeder HighSpeed doesn’t meet the safety require- ments of Hanskamp.

- Page 6 General safety messages appear in this safety messages section. Specific safety messages are in applicable parts of this manual when potential hazards may occur if the instructions or procedures are not followed. 6 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

- Page 7 Do not use any solvents or abrasives that could damage the safety stickers. Replace missing or illegible safety stickers. Safety stickers are available by Hanskamp. Always use the article numbers in your corre- spondence. 001-755-000 Warning sticker: The PipeFeeder can start automa- tically.

- Page 8 Please read the whole installation instructions and keep the safety instructions in mind. If the PipeFeeder is controlled by an MotorController from Hanskamp, see also installa- tion instructions Art. No. 010-105-000. This can be requested from the manufacturer. If the PipeFeeder is not controlled by the MotorController, always consult the manual for the relevant control unit.

- Page 9 The PipeFeeder is designed to hang directly above the feed trough so that the fall height remains low so noise and dust are reduced. Also the PipeFeeder HighSpeed can be mounted, above a hop- per.

- Page 10 End assembly After the assembly the PipeFeeder HighSpeed has to be covered by shields. Be- cause all the different situations, the Installer has to take care of this. When the covers aren’t installed, the machine isn’t safe and doesn’t meet the issued declaration of conformity.

- Page 11 (pic. 5).The size of the exit point is limited by a bar to prevent cuts. The PipeFeeder HighSpeed should be shielded, so that the dosing sys- tem is unreachable. This separation should meet European standards and guidelines.

- Page 12 No part of this publication may be reproduced or made public without prior permission in writing from Hanskamp AgroTech BV. Although this publication was put together with the utmost care, Hanskamp AgroTech is not liable for any damage that might arise due to errors or gaps in this publication.

- Page 13 The Netherlands, Doetinchem 26-10-2015 H.J. Hanskamp 13 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

- Page 14 Calibrate the controller. (see page 11, step plastic. ke it empty. The rotor can be rotated by hand proper amount. when it is empty. PipeFeeder doesn’t distribute Calibration is incorrect. Calibrate the controller. the proper amount. 14 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

- Page 15 (35 gr. per rotation) 029 = PipeFeeder HighSpeed Example : Art.No.: 029-320-010 = A 1440mm normal blue PipeFeeder HighSpeed with motor 001-631-000 24VDC 120 Rpm, turned right, with extension tube Technical data 24VDC Motor Input & Supply voltage 24VDC...

- Page 16 It is possible to reorder loose components from your supplier for maintenance, or for any other reason. Please use the item numbers shown below on the drawing. Multiple colors possible. See page Multiple dosing lengths possible. See page 17 16 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

- Page 17 Black 001-924-000 LLDPE/MDPE plastic element 45° with lid, Blue 001-925-000 LLDPE/MDPE plastic element 45° with lid, Red 002-024-000 LLDPE/MDPE plastic element 45° with lid, Orange With extension Without extension 17 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

- Page 18 PipeFeeder HighSpeed t.b.v carrousel 24VDC Installation dimensions: 18 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

- Page 19 PipeFeeder HighSpeed t.b.v carrousel 24VDC Hanskamp AgroTech B.V. Broekstraat 17 7009 ZB Doetinchem The Netherlands Visit us on: Tel: +31 (0)314 - 393 797 Fax: +31 (0)314 - 393 826 www.hanskamp.nl/en 19 - 19 Hanskamp AgroTech B.V. (the Netherlands) www.hanskamp.nl/en...

Need help?

Do you have a question about the PipeFeeder HighSpeed and is the answer not in the manual?

Questions and answers