Table of Contents

Advertisement

Quick Links

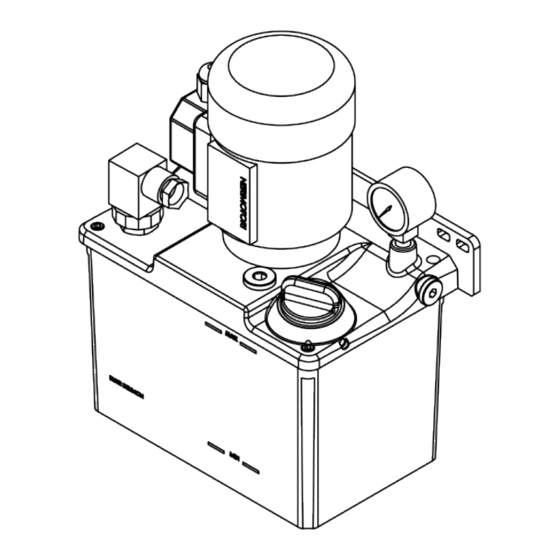

SureFire II Lubricator

Three Phase - Quick Start Manual

Safety

General safety instructions

Electrical safety instructions

Safety instructions which promote safe operation

of the lubricator

Electrical connections made to Earth ground are

identified by this symbol

Conditions and actions that pose potential

hazards to the user are marked by this sign.

All safety and/or warning labels affixed to the SureFire II

lubricator must be maintained in a completely legible condition.

Also, any modifications made to the SureFire II Lubricator (or

to any of its components) must be approved by Bijur Delimon.

prior to its use, otherwise the warranty and any liability by Bijur

Delimon will be null and void.

PDI Operation

The SureFire II PDI Lubricator has a motor-driven pump that

pulls lubricant in from the reservoir and delivers pressurised

lubricant to the distribution network through the outlet(s) in

the top plate. Pressurising the distribution network forces all of

the positive displacement injectors (PDIs) in the system to fire,

discharging the lubricant that was stored in each of their

discharge chambers during the last pump cycle.

The pressure in the main line continues to rise activating the

pressure switch until relief pressure is reached, at which stage,

the relief valve opens and discharges the pressurised lubricant

back into the reservoir. A pressure switch can be used to

trigger the motor to stop, and momentary pressure in the main

line becomes greater than the pressure at the outlet side of

the gear pump. This pressure differential actuates a quick

dump valve which relieves the main line pressure back into the

reservoir.

SLR Operation

The SureFire II SLR Lubricator has a motor-driven pump that

pulls oil in from the reservoir and delivers pressurised oil to the

distribution network through the outlet(s) in the top plate.

Pressurising the distribution network forces all of the

resistance fittings in the system to discharge the oil in

proportioned quantities to the friction points. The resistance

fittings continue to flow and the pump builds pressure until

pressure relief valve setting is reached (130 psi/9 bar). Once

the motor is shut off, pressure in the distribution network

returns to near 0 psi via a quick dump valve.

Installation & Commissioning

Install the SureFire II Lubricator in the horizontal

position ONLY. Attach the lubricator in the desired location and

to the desired equipment by means of an appropriately sized

bolt through each of the (2) mounting holes in the top plate.

(3L=M6, 6L/12L=M8, 30L=M10) The lubricator should be

installed in a location that is easy to access, for purposes of

viewing the front panels, for ease of reservoir filling, for ease of

service and for ease of attachment to the distribution network

plumbing.

Remember the SureFire II lubricator allows attachment of

distribution plumbing to either (or both) sides of the top plate.

If only one side is used, be sure to plug the unused outlet with a

G1/4 BSPP plug (two plugs are included with each lubricator).

The retrun line is G3/8BSPP (Retrun Port not present with

Pressure or Flow Bypass).

One liquid tight fitting is supplied on the motor. Use the liquid

tight fitting to secure the electrical wiring for the motor and to

prevent ingress of fluids or dirt into the motor electrical

enclosure compartment.

All tubing, flexible hoses and fittings must be compatible with

the lubricant, operating pressure and surrounding

1.

environment. In general, try to install the lubricator in the

lowest position (vertically) with relation to the rest of the

distribution network and do not allow the tubing to rise and fall

when avoiding obstacles. This is in case air enters the

distribution lines, the bubbles will tend to rise towards the end

of the distribution lines and not get caught anywhere along the

way. Any air bubbles trapped in the distribution network

plumbing may prevent the PDI injectors from working properly.

All electrical connections are to be made by

a qualified technician and all local electrical codes are to be

followed. When electrical connections are being made, do so

before the power leads are connected and before the power is

supplied.

Consult the wiring diagram on page 4 for the correct wiring for

your SureFire II lubricator.

The installation should include a means of

disconnecting the power supply for servicing. Such means shall

allow for switching off the power during normal operation and/

or in an emergency. Also, a residual current device is required

to automatically disconnect the power supply in the event of a

failure in basic insulation.

This emergency disconnecting switch shall be located in close

proximity to the equipment and be within easy reach. The switch

should be marked as the disconnecting device of the equipment,

shall have ON/OFF positions clearly identified and should meet

the requirements of IEC60947-1 or IEC60947-3.

Be sure that all plumbing distribution lines are clean, are not

kinked and are free from any chips or any other impurities.

Fill the reservoir through the fill cap and/or fill

cap strainer with clean lubricant specified by the Original

Equipment Manufacturer and that meets all of the lubricant

specifications to the right.

Do not overfill the reservoir. Never fill past the

"MAX" level as noted on the reservoir. Overfilling could cause

damage to your Surefire II.

Pump Priming

Filling the reservoir and turning on the lubricator is usually

enough to prime the pump. However, in the case of a very thick

lubricant, sometimes it's necessary to assist priming the pump.

Upon initial startup, if no lubricant is being delivered to the

pump outlet, make sure the pump is primed.

Avoid all kinds of impurities as dirt particles are the most

common cause of gear pump failure. If you wish to determine

whether the lubricant you plan on using is approved for use

with Bijur Delimon International Systems, you can consult the

Customer Service Department.

To prime the distribution network, plumb the entire system

(mainline tubing, manifolds, junctions, air/oil blocks, injectors,

injector outlet tubing to bearing points, meter units etc.). Then,

remove a plug or injector at the point furthest away from the

pump. Now, run the pump until bubble-free lubricant flows from

this point. Replace the plug or last injector.

Motor Duty Cycle:

3 Phase motor: S1, Continuous Duty

3 Litre Three Phase

30 Litre Three Phase

Lubrication Specifications:

Standard Oil version:

20 to 1500 cSt @ operating temperature

Light Oil version:

5-40 cSt @ operating temperature

Grease version(PDI only):

NLGI grade 000 - 00 (40,000 cSt max)

BIJUR DELIMON INTERNATIONAL

TEL

(+44) 01432 365000

WWW.BIJURDELIMON.COM

WWW.BDICOOLING.COM

Denco Lubrication Ltd,

Ramsden Court, Ramsden Road,

Rotherwas Industrial Estate,

Hereford, Herefordshire, HR2 6LR

36711 • R1 04/17

Advertisement

Table of Contents

Summary of Contents for Bijur Delimon SureFire II

- Page 1 When electrical connections are being made, do so All safety and/or warning labels affixed to the SureFire II before the power leads are connected and before the power is lubricator must be maintained in a completely legible condition.

- Page 2 Filler Cap Assy necessary c) If filling with a fluid grease, due to the fact that SureFire II PDI fluid grease models omit the filter screens, be sure the grease is fresh, clean, and is not higher than 40,000 cSt viscosity.

- Page 3 SureFire II Lubricator Three Phase - Quick Start Manual Dimensional Schematics Measurements shown in millimeters. SureFire II 3, 6 & 12 Litre Three Phase 3 Litre 7.40 7.40 (2)G1/4BSPP G3/8BSPP female outlets return port 1 each side 6.40 6.50 299.50 148.50...

- Page 4 SureFire II Lubricator Three Phase - Quick Start Manual Dimensional Schematics Measurements shown in millimeters. SureFire II 30 Litre Three Phase 30 Litre Surefire II Three Phase Technical Specifications Output Volume – Three Phase: G3/8BSPP return port 500cc/min @ 60 Hz (416cc/min @ 50 Hz) 250cc/min @ 60 Hz (167cc/min @ 50 Hz) Output Pressure (max.):...

Need help?

Do you have a question about the SureFire II and is the answer not in the manual?

Questions and answers