Upright AB38 Operator's Manual

Hide thumbs

Also See for AB38:

- Operator's manual (84 pages) ,

- Operation and parts manual (24 pages) ,

- Service & parts manual (133 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Upright AB38

- Page 1 Manual part number 500426-007-EN for serial numbers 04244 to current JULY 09...

- Page 3 Serial Numbers 04244 – Current NGLISH When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of the chassis above the front axle pivot.

-

Page 5: Safety Rules

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas. Modifications to the aerial work platform are prohibited or permissible only at the approval by UpRight. AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key. -

Page 6: Table Of Contents

ONTENTS Safety Rules ..............Page 1 Introduction &... -

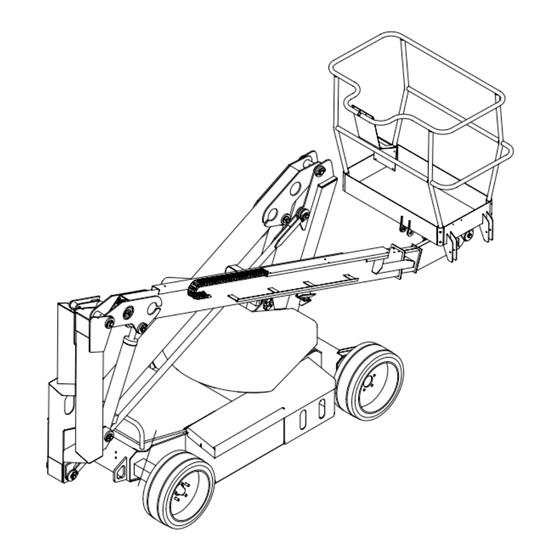

Page 7: Introduction & General Description

ENERAL ESCRIPTION W A R N I N G DO NOT use the maintenance platform without guardrails properly assembled and in place. Figure 1: AB38 1. Platform 2. Entry Bar 3. Elevating Assembly 4. Platform Controls 5. Manual Case 6. -

Page 8: Special Limitations

V E R L O A D L A R M The AB38 is fitted with a load sensing system designed to comply with the requirements of BS EN 280: 2001 If a load equivalent to 90% of safe working load is lifted a fault code “03” will be displayed on the digital display on the platform control box. -

Page 9: Controls & Indicators

Controls and Indicators ONTROLS AND NDICATORS The operator shall know the location of each control and indicator and have a thorough knowledge of the function and operation of each before attempting to operate the unit. Figure 2: Controls and Indicators Upper Controls 1. -

Page 10: System Functions

System Function Inspection YSTEM UNCTION NSPECTION Refer to Figure 1 and Figure 2 for the locations of various controls and indicators. W A R N I N G STAND CLEAR of the work platform while performing the following checks. Before operating the machine, survey the work area for surface hazards such as holes, drop-offs, bumps and debris. -

Page 11: Emergency Lowering

Operation O T A T I N G T H E L A T F O R M 1. Select the rotate function button (the button will illuminate to confirm selection). 2. While engaging the Interlock Switch, move the Control Handle forwards or backwards to achieve clockwise or counter clockwise rotation. -

Page 12: Transporting The Machine

Transporting the Machine RANSPORTING THE ACHINE R A N E Secure the straps to chassis lifting/tie down points only. O R K L I F T D A N G E R Forklifting and Lifting by Crane are for transport only. See specifications for weight of machine and be certain that forklift is of adequate capacity to lift the machine. -

Page 13: Maintenance

Maintenance AINTENANCE W A R N I N G Never perform service while the platform is elevated. Y D R A U L I C L U I D The hydraulic fluid reservoir is located in the chassis door. Figure 5: Hydraulic Fluid Reservoir and Dipstick NOTE: Never add fluid if the platform is elevated. -

Page 14: Battery Maintenance

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water. Always replace batteries with UpRight batteries or manufacturer approved replacements weighing 26,3 kg (58 lbs.) each. • Check the battery fluid level daily, especially if the machine is being used in a warm, dry climate. -

Page 15: Inspection & Maintenance Schedule

Inspection and Maintenance Schedule NSPECTION AND AINTENANCE CHEDULE The Complete Inspection consists of periodic visual and operational checks, along with periodic minor adjustments that assure proper performance. Daily inspection will prevent abnormal wear and prolong the life of all systems. The inspection and maintenance schedule should be performed at the specified intervals. -

Page 16: Daily Preventative Maintenance Checklist

Daily Preventative Maintenance Checklist AILY REVENTATIVE AINTENANCE HECKLIST AINTENANCE ABLE REVENTATIVE AINTENANCE EPORT Y = Yes/Acceptable Date: _______________________________________ N = No/Not Acceptable Owner: ______________________________________ R = Repaired/Acceptable Model No: ___________________________________ Serial No:____________________________________ Serviced By: _________________________________ ___________________________________________ COMPONENT INSPECTION OR SERVICES Check electrolyte level. -

Page 17: Decal Location

Decal Location ECAL OCATION ITEM PART NO. DESCRIPTION QTY. 500264-000 DECAL - UpRight AB38 BOOM 501870-000 DECAL - LOWER CONTROL BOX 500257-000 DECAL - AB38 LOGO 057695-000 DECAL - BALLAST STRIP 502480-000 DECAL - EMERGENCY LOWERING 057696-000 DECAL - ‘UpRight’ LOGO... -

Page 18: 1.2 Specifications

Introduction & Specifications Section 1.2 Specifications Table 1-1: Specifications ITEM METRIC IMPERIAL (ANSI) Duty Cycle 45% of 8 hour shift 45% of 8 hour shift Platform Size 0.7 m x 1.3 m (inside gaurdrails) 2.3 ft x 4.3 ft (inside gaurdrails) Max. - Page 20 Local Distributor: Lokaler Vertiebshändler: Distributeur local: El Distribuidor local: Il Distributore locale: Europe TEL: +1 (559) 443 6600 TEL: +44 (0) 845 1550 058 FAX: +1 (559) 268 2433 FAX: +44 (0) 195 2299 948 www.upright.com PN - 500423-006...

Need help?

Do you have a question about the AB38 and is the answer not in the manual?

Questions and answers