Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Zonestar P802QS

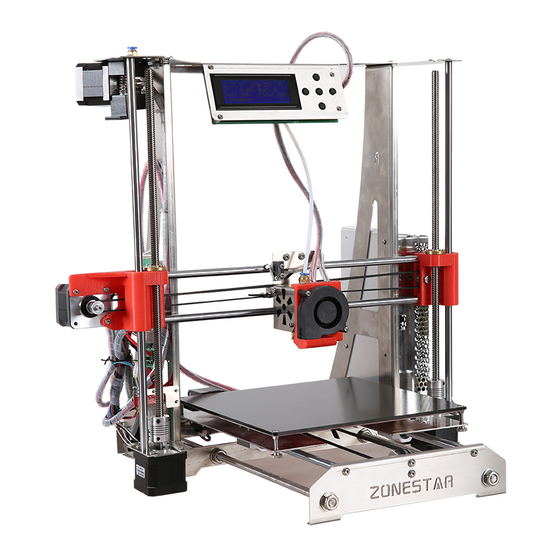

- Page 1 Installation Guide Model:P802QS/P802QSU Ver 3.0 www.zonestar3d.com Youtube Channle Facebook Group...

-

Page 2: Version Record

Version Record Version Date Author Check Remark V1.0 2016-06-25 Chris Hally 1st Version V1.1 2016-09-02 Chris Hally Add Detail Z-axis installation V2.0 2017-01-20 Alien Hally Fix some bugs V3.0 2017-05-12 Alien Hally New package and upgrade If you have any problems with the installation, please feel free to contact us, we will reply to you ASAP! Email: Support@zonestar3d.com... - Page 3 Picture of the whole parts...

- Page 4 Parts - package Option for P802QSU...

-

Page 5: Screws And Nuts

Screws and nuts M3x10 M4x6 Screw (x45) M3x6 Screw (x36) M3 Nut (x30 ) Screw(x10) M3x25 Screw (x4) M3x12 pole (x4) M3X20 Screw(x20) Φ4.5*22 spring (x4) M3 shim (x12) M3 Hand Nut (x4) - Page 6 Viode turorial English Spanish Russian Electronic Parts Wiring Guide Filament Run-out Check Detector Note 1: The video tutorial may be a little different from your kit! Note 2: We suggest you check the electronic parts before installed.

- Page 7 Pre-Assembled Assemble Y-axis belt pulley shim 5x22x1.2 *3 shim 5x12x0.6 *2 ball bearing 625zz M5x14 Note:smooth surface of the shims towards ball bearings.

- Page 8 Pre-Assembled Assemble LCD display module pole Note:there are two type poles and M3x8 two type screws. LCD 2004 pole PCBA M3x8 M3x10 pole M3x12 pole M3x10 M3x12 M3x6...

- Page 9 Pre-Assembled Assemble slider module left 1. Put two linear bearings on slider module left, through the two bearings by sliding rod, then push bearings into slot, check concentricity of the bearings. 2. Mount copper nut,lock with three M3x20 screws and M3 nuts. M3x20 *3 copper nut slider module left...

- Page 10 Pre-Assembled Assemble slider module right 1.mount screw M5x25,shim M5, linear bearing shim M5,lock with nut M5. 2.mount copper nut, lock with three screws M3. M3x20 *3 copper nut slider M5x20 module right shim M5 *3 M3 Nut *3 ball bearing 625zz...

- Page 11 Pre-Assembled Hotend X ENDSTOP HotEnd Cooler FAN Tube Fitting: PC04-M6 Extruder FAN...

- Page 12 • Assemble Extruder Engine(EM4) clamp mechanism M3x6 motor holder shim M4 U-bearing jbckscrew M3x3 *2 Adapter M4x10 Video Tutorial...

- Page 13 Install X-axis Motor to slider left 1. Install a stepper motor (23mm shaft lenght) to silder left , lock with 3 pcs M3x6 screws. 2. Mount one pulley to the stepper motor, lock the jbckscrew on the pulley. silder left M3x6 *3 Note: Please pay attention to the installation direction of the...

- Page 14 Assemble heat bed bracket Install 4 bearings (SCS8UU) on heat bed bracket, lock with M4x6mm screws. M4x6 *12 heat bed bracket SCS8UU linear bearing *4 Note: In order to let the bearin is on the same line, please insert a lead rod to the linear bearing before tightend the M4 screws.

- Page 15 Assemble base frame front Y-axis belt pulley M4x6 *2 base frame front...

- Page 16 Assemble base frame back Note 1: Y Endstop install on the down of the metal frame M3x20 *2 Base frame back M4x6 *2 Note 2: the lower position of the motor, the better. Y-axis limit M3 nut *2 switch Note 3: lock the jbckscrew on the pulley after intstalled...

- Page 17 Assemble base frame bottom base frame bottom M3x6 *8 Coupling 5x7 *2 shim *8 Connect toward back Note 1: Don’t tighten the motor in this step. Note 2: Don’t lock the jbckscrew on the coupling in this step.

- Page 18 Assemble base frame left and right base frame left base frame right base frame bottom M4x6 *4 Notice: base frame left and base frame right are different!

- Page 19 Assemble base frame back M4x6 *4 base frame back...

- Page 20 Install LCD display module base frame top LCD display module M3x6 *4...

- Page 21 Install base frame top M4x6 *4 base frame top base frame right...

- Page 22 Assemble Y-axis bracing piece M4X6 *6 base frame back bracing piece *2...

- Page 23 Install Y-axis sliding rod and heat bed bracket NOTE Please insert slowly and carefully to prevent damage to the linear bearings!! Lead rod M8x380mm *2 PS: Using the lead rod with hole in the end. heat bed bracket M4x6 *4...

- Page 24 Install Y-axis timing belt tie-wrap *2 timing belt Note: Tighten the belt before locked it.

- Page 25 Assemble Heat Bed MK3 heat bed M3 nut *4 KM3x25 *4 Note: Don’t tighten the screw in this step.

- Page 26 Install Heat Bed MK3 Heat Bed Spring *4 Hand nut *4...

- Page 27 Install Z-endstop 1. Lock the Z endstop PCBA to the Z endstop frame with 2 M3x6 screws. 2. Install the Z endstop module to base frame left Z endstop M3x6 *2 M3x6 *2...

- Page 28 Install slider module left and rods 1. Through base frame top and Lead screw fix module and Lead screw 345mm slider module left by lead rod, its bottom entering the hole on KA3x10 *2 Z-axis motor(left),its top locked with M4x6. M4x6 2.

- Page 29 Install slider module right and rods 1. Through base frame top and Lead screw fix module and Lead screw 345mm slider module right by lead rod, its bottom entering the hole on Z-axis motor(left),its KA3x10 *2 top locked with M4x6. M4x6 2.

- Page 30 Detail for how to assemble slider module Step 1.Loosen the screws that fix the cooper a little. Step 2.Insert the lead rod through the “Z-axis lead screw fix module” and “X- slider” Step 3.Fix the lead rod to the top metal frame...

- Page 31 Detail for how to assemble slider module Step 4.Fix the “z-axis lead screw fixed module” to the top metal frame. Step 5.Insert the lead screw to the cooper nut. If the lead screw hard to insert to to the bearing, please take out the bearing from the “z-axis lead screw fixed module”...

- Page 32 Detail for how to assemble slider module Step 7.Insert the lead screw and bearing to “Z-axis lead screw fixed module” Step 8. Insert the lead screw to the bottom of coupling. the lead screw center with the coupling is not concentric, please move the Z-axis motor a little.

- Page 33 Detail for how to assemble slider module Step 10. Rotate the coupling and move down the “x-slider” to the lowest positon, then fixed the Z-axis motor. Step 11. Rotate the coupling and move up the “x-slider” to the middle positon, then fixed the copper nut.

- Page 34 Detail for how to assemble slider module...

- Page 35 Install hot end Through hole of slider module right and hole of extruder and hole of slider module left,its right end leveled with hole edge of slider module right. slider module left slider module right extruder sliding rod 380mm X2 NOTE Please insert slowly and carefully to...

- Page 36 Install X-axis timing belt Fixed one end of the timing belt on one clasp of the hotend by cable tie, through pulley of slider module left and ball bearing of slider module right,then fixed on the other clasp of the hotend by tie-wrap. clasp tie-wrap *2 timing...

- Page 37 Install AC power connector (Optional) Base Frame right Power Connector(Optional)

- Page 38 Assemble power supply power supply base frame right M3x6 *3...

- Page 39 Install control board Metal Frame left Pole M3x12 *4 Control board M3x6 *8...

- Page 40 Install Extruder Motor base frame top M3X10 *2 Extruder Motor...

- Page 41 Assemble Filament Feeder (FF3) If there is one set filament feeder in the parcel, please refer to the below picture to assemble it, otherwise please skip this step. filament filament feeder pipe filament feeder pier *2 filament feeder frame X2 M3x20 M3x20 *8 filament feeder arm X2...

- Page 42 Intall Filament Feeder (FF4) If there is one set filament feeder in the parcel, please refer to the below picture to assemble it, otherwise please skip this step. Extruder motor Base Frame Top M3x10 *2 Base Frame Left Feeder pipe Copper pole M3x45 Filament feeder (FF4)

- Page 43 Install Filament Run Out Detector If there is one set filament run out deteector in the parcel, please refer to the below picture to assemble it, otherwise please skip this step. M3X10 *2 Filament run out detector...

- Page 44 To know your printer LCD and Keypad Extruder Fan Hotend X-Motor Z Endstop Heat Bed Power Supply (PSU) Z-Motor(right)

- Page 45 To know your printer Extruder Motor Filament Run out Detection Z-Motor(left) Y Limit switch Control Board Y Motor...

- Page 46 Install PTFE tube Push the plastic ring on the Tube Fitting and then insert PTFE tube into fitting, to connect the extruder and hotend by PTFE tube. PTFE tube Tube Fitting Extruder Motor Filament Roll Filament Run Out Detector Filament Hotend...

- Page 47 Appendix I : Assemble silder module Slider module left linear bearing Note:proper position that spring can produce compressive force. M3x20 X3 copper nut M3x30 M3 Nut x3 motor linear bearing spring M3x8 *3 Pole Slider module right M3x20 X3 linear bearing X2 copper nut M5x20 slider module right...

- Page 48 Appendix II : Assemble Hotend (HE2) PTFE tube: OD:4mm ID:2mm length: 27mm heat sink tube throat M6x26 heater block 16x16x12 Temperature sensor nozzle heater...

-

Page 49: Wiring Guide

Wiring Guide Attention. P802QS/P802QSU Wiring Diagram Power Supply Wiring Motor wire and How to change the direction of stepper motor How to adjust the current of motor Wiring Guide Video Toturial Link: https://youtu.be/4i7aiA3zrBU... - Page 50 !Attention! The picture in this file may not match the actual machine, just for reference only. Take care when installation, to avoid electrical shock hazards! Once the connection is completed, please confirm again. WRONG WIRING MAY DAMAGED THE ELECTRONIC DEVICE! Operating current of some parts of are larger, please make sure the contact is good .

- Page 51 P802Q/P802QSU Wiring Diagram Assembled on hotend Swapping DC+ and DC- will damage the control board!!

-

Page 52: Power Supply Wiring

Power Supply Wiring The voltage of power supply is different depending on the country. Before wiring, please make sure this setting is right. AC power L, N, G must be correctly distinguished, or may endanger personal safety ! Attention! Note: Exposure wire is dangerous! “V-”... - Page 53 Motor wire and How to change the direction of Stepper motor Default motor wire sequence as below, please check before connect. Motor wire color Motor wire connect to control color and board and motor sequence exchange the sequence of the motor line, the motor direction will be reversed 1.use tweezers pull out 2.pull out the wire 3.

- Page 54 How to adjust the current of motor 1.Rotate the potentiometer using a screwdriver, clockwise rotating the potentiometer will incerease the VREF, otherwise the VREF will be decreased. 2.Use a voltage meter to measure the value of Vref 3. Imotor = Vref*1.25 (A) e.g.

- Page 55 Level the heatbed Refer to the below video to level the heat bed. Video Tutorial Link: https://youtu.be/QWsYR8NIGpc P802 Bed Level...

- Page 56 Congratulations!

Need help?

Do you have a question about the P802QS and is the answer not in the manual?

Questions and answers