Rabe KORMORAN PL V 180 Operating Instructions Manual

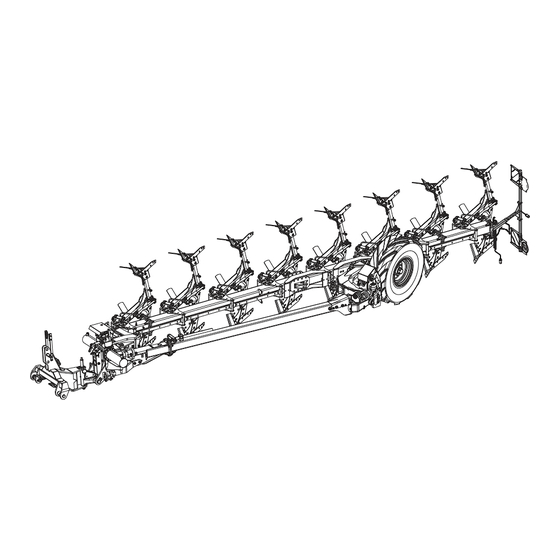

Semi mounted reversible plough with single wheel to plough on-land or in the furrow

Hide thumbs

Also See for KORMORAN PL V 180:

- Operating instructions manual (12 pages) ,

- Operating instructions manual (70 pages)

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rabe KORMORAN PL V 180

- Page 1 OPERATING INSTRUCTIONS (TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS FR) Serial no.: KORMORAN PL V 180 / PL VHA 180 Semi mounted reversible plough with single wheel to plough on-land or in the furrow...

- Page 3 KORMORAN PL V 180 / PL VHA 180 QUICK START Kormoran PL 180 / PL HA 180 Working position: quick start - Frame unlocked. - Offset setting jig open with cylinder positioned correctly. Preparing the tractor - Safety stop removed from the wheel block.

- Page 4 KORMORAN PL V 180 / PL VHA 180 QUICK START Check the side alignment (plumb line). 1st pass - The legs must be at right angles to the ground (adjust the Place the implement on the ground. inclination screws). Use the support bolt to adjust the working depth Close the offset again before you turn the implement.

-

Page 5: Table Of Contents

KORMORAN PL V 180 / PL VHA 180 TABLE OF CONTENTS 4.10 Plough body stone protection system ....19 INTRODUCTION ........7 4.10.1 Mechanical stone protection system ..19 4.10.2 "Hydro Avant" hydraulic stone protection system (additional equipment) ....19 Instructions ..........7 4.11 Lighting and signals (optional) ......19... - Page 6 KORMORAN PL V 180 / PL VHA 180 TABLE OF CONTENTS Removing and re-installing the front adjustment 10.11 Adjusting the Vari-Fix standard skimmers wheels .............35 (optional) ............50 10.11.1 Adjusting the Vari-Fix working depth ..50 Moving the subsoiler (additional equipment) into the working position ..........35...

-

Page 7: Introduction

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS INTRODUCTION 1.4.2 Position of the type plate NSTRUCTIONS Product documents The instructions are a vital component of the implement; if the implement is re-sold, these instructions must be enclosed in accordance with the applicable regulations. -

Page 8: Safety Information And Regulations

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS AFETY INFORMATION REGULATIONS 2.1.4 Hydraulic circuit and hydraulic connections Safety information CAUTION: 2.1.1 General instructions The hydraulic circuit is under high pressure. CAUTION: If there is a leak in the hydraulics, you must never come into The risk of accidents when using, maintaining or penetrate the skin and cause fatal injuries. -

Page 9: Transporting On Public Roads

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 2.1.6 Transporting on public roads 2.1.7 Maintenance Implements must always be used in accordance with the The maintenance area must be clean, dry, ventilated and well applicable directives and regulations regarding accident lit. -

Page 10: Safety Labels

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 2.1.9 Safety labels CAUTION: IMPORTANT: Ensure that the safety labels do not get damaged Replace damaged or missing labels. when cleaning your implement. Positions of the safety labels UI 1847... - Page 11 KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Explanation of the labels Item Label Description Item Label Description Read the operating instructions Read the manual and the safety instructions before starting up and also consider them when operating.

-

Page 12: Use

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS ESCRIPTION OF THE IMPLEMENT General views Coupling bar Locking handle Rotor Offset cylinder Front adjustment wheels Working elements Additional plough body (optional) Wheel Wheel block, lifting cylinder and reservoir 10 Wheel alignment arm... -

Page 13: Technical Data For Solid Sheet Body

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Technical data for solid sheet body* Body designation Description BP-351 O Single-part share with reversible points, Plasmabid hard coating or uncoated. BP-322 P Single-part share with reversible points or Plasmabid hard coating. -

Page 14: Dimensions And Weights

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Functional principle Dimensions and weights The pinion (item 1) is below the rack (item 4). The pistons (items 3 and 5) are screwed to the rack. The chambers (items 2 and 6) -

Page 15: Offset Setting Jig

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Offset setting jig Hydraulic control for transmission (optional) Uncoupled position Hydraulic cylinder Mounting outside the track Mounting inside the track The implement is equipped with a large setting jig to offset the 1st Hook plough body. -

Page 16: Front Adjustment Wheels

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS " " Functional principle COMPACT HOUSING When working with a semi-mounted plough, there is always a load on the top link (the bolt is never free). This pressure Z-shaped bar causes the front wheels to spin. -

Page 17: Wheel Block

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS One additional plough body at the front (item 1) between to the main chassis and requires the stabiliser to be changed. The wheel position remains unchanged. - 9 for implements with a pin retainer (B). -

Page 18: Mouldboard

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Mouldboard Trash board (additional equipment) Solid sheet body Slatted body Trash board The plough bodies come in solid sheet or slatted designs. The trash board improves soil turning. Slatted bodies are preferred on sticky soils. -

Page 19: Plough Body Stone Protection System

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 4.10 Plough body stone protection system The stone protection system is designed as a mechanical or hydraulic stone protection system. 4.10.1 Mechanical stone protection system Intermediate leg Link console In the hydraulic stone protection system, an intermediate leg (1) with a hydraulically supported lifting device is inserted. -

Page 20: Preparing The Tractor

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS REPARING THE TRACTOR Required tractive output The output required to drive your implement varies according to the soil conditions, working conditions and tractor equipment (tyres, front ballast, etc.). The following technical data is provided for information purposes. -

Page 21: Distance Between The Tyres

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 5.2.2 Distance between the tyres Ploughing outside the track Distance between the tyres Distance between the tyres and the plough furrow Distance between the traction and drag axles on the implement The unit that is coupled works best when the distance between possible. -

Page 22: Weighting The Tractor

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Ploughing inside the track We Tractor empty weight Front lifting capacity of the empty tractor Gap between front tyres Rear lifting capacity of the empty tractor Gap between rear tyres... -

Page 23: Length Of The Lifting Rods

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Length of the lifting rods Position of the stabilisers Top position Functional play Bottom position Axles Bolts The length of the lifting rods on the lifting arms determines the coupling's plumb line and the position of the lifting cylinders when working (guarantees left/right symmetry when working). -

Page 24: Bolt On The Top Link

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS OUPLING AND UNCOUPLING Bolt on the top link Coupling the implement to the tractor CAUTION: Ensure that coupling: - Neither causes overloading: Observe the highest permissible load on the coupling points. -

Page 25: Unlocking The Latch

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS CAUTION: As soon as the bottom links are coupled correctly, use the tractor's lifting function to lift the coupling head, in order to Before hooking the top link in, ensure that the space unlock the latch. -

Page 26: Position Of The Supports

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 6.1.7 Position of the supports Transport position Uncoupled position Supports Bolts Locking pins (x 2) The implement is equipped with two locking pins (item 1) on both sides of the rotating mechanism. -

Page 27: Locking And Unlocking The Turning Gear

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Locking and unlocking the turning Uncoupling the implement from gear the tractor CAUTION: CAUTION: The implement has a locking mechanism for the Ensure that nobody is standing close to the turning gear. The mechanism may only be unlocked implement before lowering it. -

Page 28: Hydraulic Connections

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Hydraulic connections Clean the coupler on the implement and the tractor before connecting the hydraulic circuits. Check that the implement's hydraulic connections are compatible with the tractor's connection. Make logical connections: - The functions that are used most to the lever that is most accessible. -

Page 29: Function Selection Switch (Optional)

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Function selection switch (optional) 7.4.1 Installing the function selection switch on off Suction device with mechanical lock Cab power supply cable Electric valve connector Extension Black cable IMPORTANT: IMPORTANT: If the implement is parked outside, store the housing Check the cable lengths: They must not be too short in a clean, dry place. -

Page 30: Electrical Connections For Solenoid Valves

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 7.4.2 Electrical connections for solenoid valves 7.4.4 Using the function selection switch 0 1 2 3 4 5 6 7 8 9 Changeover switch Terminal on off Solenoid valve for the offset... -

Page 31: Special Attributes Of The Selection Switch

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 7.4.5 Special attributes of the selection switch Deactivating a function Press the relevant button for deactivation. Switch the function selection switch off by pressing button A (section 7.4.3). Reactivating a function Switch the function selection switch on by pressing button A (section 7.4.3). -

Page 32: Adjusting The Working Width

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Adjusting the working width Adjusting the wheel angle The wheel angle is adjusted automatically according to the plough body's working width. Display Working width label Reduce the cylinder stroke (item 1): - The wheel comes closer to the implement frame (item 2). -

Page 33: Adjusting The Restoring Force Of The Hydraulic Stone Protection System

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Adjusting the angle lever stop Adjusting the restoring force of the hydraulic stone protection system Adjustment instructions Minimum pressure: 120 bar (factory setting) pressure gradually. Adjustment 3000 2000 4000 1000... -

Page 34: Adjusting The Height Of The Front Adjustment Wheels

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Adjusting the height of the front adjustment wheels Remove the pins (item 3). Remove the bolts (item 2). Adjustment wheels Blades on the plough body The front adjustment wheels must be aligned with the plough body's blades on the implement to ensure it works properly. -

Page 35: Adjusting The Offset (Width Of The 1St Track)

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS The offset cylinder (item 1) must be in one of the two positions Adjusting the offset (width of the for "inside the track" at the end of the offset setting jig (item 2). -

Page 36: Combined Transport And Supporting Wheel

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Torque - shear bolt Quality grade 4.6 Size (DIN ISO 272) Ib/ft M 16 Torque - fastening screw Quality grade 8.8 Size (DIN ISO 272) Ib/ft M 16 Combined transport and supporting... -

Page 37: Adjusting The Transport/Working Position

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS DJUSTING THE TRANSPORT WORKING POSITION DANGER: Risk of an electric shock. clearance between live power systems and the implement, there is a risk of severe or even fatal injuries. - Never use the implement in close proximity to power systems or live devices. -

Page 38: Adjusting The Working Position

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Adjusting the working position Raise the implement. Bolts Safety latch Implement frame Use the handle to unscrew the locking bolt (item 1) and allow the implement to rotate one quarter turn. -

Page 39: Travelling By Road

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10 F IELD ADJUSTMENT Travelling by road CAUTION: CAUTION: Read this chapter in its entirety before starting to Be aware of the overhang when driving on public work, in order to understand all adjustments, their roads. -

Page 40: First Pass

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Ploughing on-land Adjusting the wheel height The wheel's height can be adjusted in the 1st pass. A check and/ 10.2 First pass 10.2.1 Opening the offset setting jig Adjustment screw... -

Page 41: Second Pass

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.3 Second pass Before completing the adjustments, ensure that the mouldboards are polished and that the earth slides without clumping. Otherwise, clean the device. speed up the smoothing process for the mouldboards. -

Page 42: Adjusting The Offset (Width Of The 1St Track)

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Adjustments 10.3.3 Adjusting the offset (width of the 1st track) adjustment wheel must run in the track from the previous pass. always ploughs to the same width as the other plough bodies. -

Page 43: First Pass

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Ploughing in the furrow Adjusting the wheel height The working depth on the wheel is adjusted using a screw. The implement can be used inside the track with the tractor. -

Page 44: Longitudinal Alignment

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.5.1 Longitudinal alignment As of the 2nd pass, the tractor is in the track. The implement must be aligned longitudinally (front/rear) so that all plough bodies work at the same depth. -

Page 45: Adjusting The Tractor's Power Control

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS Adjustments 10.6 Adjusting the hydraulic compensating cylinder (optional) Adjustment screw Counter nut Bolts Valve The front adjustment wheel cannot control side alignment Manometer on its own. In this case, turn the adjustment screws (item 1) Hydraulic cylinder below the turning cylinders. -

Page 46: Working In The Field - Adjusting Settings

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.7 Working in the field - adjusting 10.8 Adjust disc coulter (additional settings equipment) 10.7.1 Safety during operation 10.8.1 Adjusting the disc coulter's working depth Danger: Adjustment instructions General risk of accident while working with the implement. -

Page 47: Adjusting The Disc Coulter Side Overlap

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.9.2 Adjusting the round rod 10.9 Adjusting the disc coulter side overlap Adjustment Adjustment instructions After adjusting the overlap, check that the disc coulter is able to turn to the direction of travel, see chapter "10.9.3 Adjusting the stop of the swing arm on the disc coulter", page 48. -

Page 48: Adjusting The Stop Of The Swing Arm On The Disc Coulter

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.9.3 Adjusting the stop of the swing arm on the 10.10 Adjusting the round rod for the disc coulter standard skimmers (additional equipment) Adjustment instructions The side swing of the disc coulter (1) is limited by the adjusting 10.10.1... -

Page 49: Adjusting The Round Rod Side Overlap

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.10.2 Adjusting the round rod side overlap Torque (observe the quality grade) Quality grade 8.8 Size Adjustment instructions (DIN ISO 272) Ib/ft M 20 Quality grade 10.9 Size Ib/ft M 20 10.10.3... -

Page 50: Adjusting The Vari-Fix Standard Skimmers (Optional)

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.11 Adjusting the Vari-Fix standard skimmers (optional) 10.11.1 Adjusting the Vari-Fix working depth Adjustment instructions blade tip (H) Retaining ring Adjust H so that the cutting edge (a) works in the soil across Locking pin the entirety of its width. -

Page 51: Adjusting The Vari Heavy Duty Skimmers (Optional)

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.12 Adjusting the Vari Heavy Duty skimmers (optional) 10.12.1 Vari Heavy Duty - adjusting the working depth Adjustment instructions H = factory setting: • The Vari Heavy Duty working depth is 1.) Remove the retaining ring. -

Page 52: Adjust Trash Boards (Additional Equipment)

KORMORAN PL V 180 / PL VHA 180 OPERATING INSTRUCTIONS 10.13 Adjust trash boards (additional 10.14 Adjust subsoiler (additional equipment) equipment) Adjustment instructions Adjustment instructions Do not adjust trash boards too deep to avoid slowing down the Adjustable working depth If the soil is crumbling, the trash boards are only needed to scrape off the upper furrow crown. -

Page 53: Adding Additional Plough Bodies

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE 10.15 Adding additional plough bodies 11.2 Used tyres You can add additional plough bodies to the front and rear of CAUTION: Storing, leaving or disposing of used tyres in nature information please contact your dealer. -

Page 54: Identification On A Hydraulic Hose

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE CAUTION: 13.1.1 When you work on the hydraulic circuit, lower the implement to the ground and discharge the pressure from the hydraulic circuit. CAUTION: Never carry out curing, welding, cutting, grinding elements. -

Page 55: Lubrication And Greasing

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE 13.2 Lubrication and greasing 1 + 2 Lubrication point on the cardan joint Lubrication points on the rotary housing Lubrication points on the cardan shaft housing Lubrication points on the pinion support... - Page 56 KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Marking Group Position Quantity 12 hours Rotary housing Lubrication points on the 12 hours Cardan shaft turning gear 12 hours Pinion support 12 hours Hydraulic cylinder Lubrication device on the offset arm...

- Page 57 KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Marking Group Position Quantity 12 hours Front wheel set Wheel hub 60 hours Pivot point Console 60 hours Width adjustment 60 hours Hydraulic stone protection 60 hours Intermediate leg system 60 hours...

- Page 58 KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Marking Group Position Quantity 12 hours on the supporting frame 12 hours Central chassis 12 hours on the supporting frame 12 hours on the supporting frame 12 hours 12 hours on the supporting frame 9901.00.23EN00 - 01/2016...

- Page 59 KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Marking Group Position Quantity Lubrication devices 12 hours on the wheel set 12 hours Cylinder Disc coulter Disc bearing hours 1) Lubricating grease = standard lubricating grease 2) Also lubricate after cleaning Regular lubrication of moving parts ensures that the implement functions in an optimum manner and increases its service life.

-

Page 60: Rectify Faults

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE 14 R Repair ECTIFY FAULTS Warning: 14.1 Replacing the shear bolt on the Risk of accident when undoing the pivot bolt. There is a risk of accident when the plough mechanical stone protection system body swivels back. -

Page 61: Replacing The Vari Heavy Duty (Vhd) Skimmer Shear Bolt

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Shear bolt torques Repair instructions • Always insert the shear bolt (3) from the rod Shear bolt side. dimension Size Strength Torque • Always use original shear bolts. 190 Nm 140 lb-ft •... -

Page 62: Replacing The Subsoiler Shear Bolt (Additional Equipment)

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE - 1. Undo the pivot bolt (1). Shear bolt torques - 2. Pivot the subsoiler in. Quality grade 10.9 Width across Size - 3. Insert the new shear bolt from the subsoiler side. - Page 63 KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Dismantling procedure Wheel Hydraulic jack Remove the wheel (item 1). Wheel support Position the hydraulic jack (item 1). Installation procedure Re-attach the wheel. Nuts x 8 Remove the wheel nuts (item 1).

-

Page 64: Spare Parts

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE 16 S Screw the nuts on again. PARE PARTS In order to guarantee operational safety and a long service life for the implement, use only manufacturer's original spare parts. Installing any parts other than those from the manufacturer causes the implement's warranty to become invalid. -

Page 65: Tightening Torques

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE 16.2 Tightening torques Adhere to the tightening torques for the components. The tightening torque for each element varies according to the soil conditions and the lubrication. All values in the following table are for guidance only. -

Page 66: Moving The Subsoiler (Additional Equipment) Into The Storage Position

KORMORAN PL V 180 / PL VHA 180 MAINTENANCE Discharge the pressure from the hydraulic circuits by moving 16.4 Starting up again and inspecting the tractor's control lever (tractor engine switched off). After storing, carry out a complete and visual inspection Store the implement away from human activity. -

Page 67: Ce Declaration Of Conformity

CE D ECLARATION OF ONFORMITY 17 CE D ECLARATION OF ONFORMITY Semimounted-reversible plough (Aufsattel-Drehpflug) Designation: Type: Kormoran PL VHA Serial no.: 9901.00.23EN00 - 01/2016 - 67 -... - Page 70 RABE ZI Nord Les Gaudères 37130 Langeais France Tel: (+33) 2 47 96 72 61 Fax (+33) 2 47 96 71 85 info@rabe-gb.fr www.rabe-gb.fr RABE Am Rabewerk 1 49152 Bad Essen Germany Tel: +49 (0) 54 72 771 - 0 Fax +49 (0) 54 72 771 -195 info@rabe-gb.de...

Need help?

Do you have a question about the KORMORAN PL V 180 and is the answer not in the manual?

Questions and answers