Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

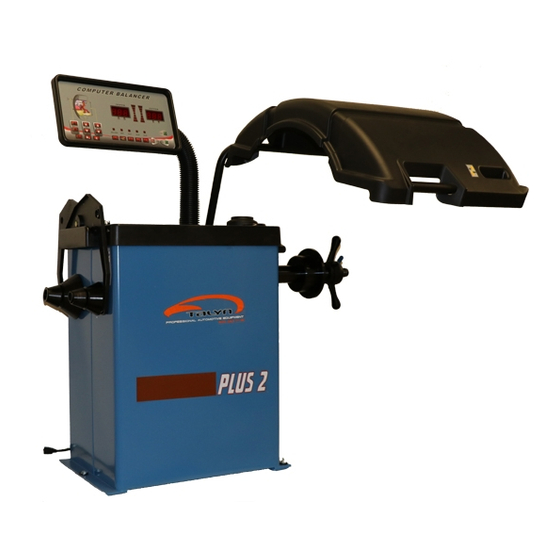

Summary of Contents for Talyn Plus 2

-

Page 2: Table Of Contents

CONTENT 1. Preface -----------------------------------------------------------------------------------------------------------------------------------1 WARNING CLAUSE ---------------------------------------------------------------------------------------------------------------------------1 INTRODUCTION--------------------------------------------------------------------------------------------------------------------------------1 INSTALLATION ---------------------------------------------------------------------------------------------------------------------------------1 SAFETY REGULATION-----------------------------------------------------------------------------------------------------------------------2 2. INSTALLATION & OPERATION --------------------------------------------------------------------------------------4 2.1 INSTALLATION OF THE PROTECTIVE COVER--------------------------------------------------------------------------------4 2.2 INSTALLATION OF THE MAINSHAFT---------------------------------------------------------------------------------------------4 2.3 EQUIPPING POWER SOURCE-----------------------------------------------------------------------------------------------------4 3. TECHNICAL PERFORMANCE ----------------------------------------------------------------------------------------4 3.1 PERFORMANCE & CHARACTERISTICS-----------------------------------------------------------------------------------------4 3.2 MAIN TECHNICAL SPECIFICATION-----------------------------------------------------------------------------------------------5 3.3 WORKING PRINCIPLE-----------------------------------------------------------------------------------------------------------------5 4. - Page 3 7.2 ERROR-----------------------------------------------------------------------------------------------------------------------------13 7.3 RESSURE SENSOR INSTALLATION & WIRING-----------------------------------------------------------------------------14 7.4 GENERAL TROUBLESHOOTING & SOLUTION-------------------------------------------------------------------------------14 7.5 ACCESSORIES---------------------------------------------------------------------------------------------------------------------------15 8. MAINTENANCE ---------------------------------------------------------------------------------------------------------------16 9. OPERATION DETAILED DESCRIPTION ---------------------------------------------------------------------18 9.1 HOW TO BALANCE A WHEEL------------------------------------------------------------------------------------------------------18 9.2 PARAMETER SETUP -----------------------------------------------------------------------------------------------------------------19 9.3 CUSTOMER SELF-CALIBRATION-------------------------------------------------------------------------------------------------20 APPENDIX 1---------------------------------------------------------------------------------------------------------------------- APPENDIX 2----------------------------------------------------------------------------------------------------------------------...

-

Page 4: Preface

1. PREFACE WARNING ATTENTION: Dangers or unsafe procedures that can There will be one year of warranty period on the cause minor injuries or damage to property. condition that the machine including the operation system, tools and accessories are used properly and/or Read these instructions carefully before using the without damage. -

Page 5: Safety Regulation

Failure to observe these instructions can damage the warnings can cause serious injuries to the operator or machine and compromise the operator's safety. other persons. Do not operate the machine until you have read and Remove the original packing materials after positioning understood all the danger/warning notices in this them as indicated on the packaging. - Page 6 serviced. indicates where to connect the ground wire. - Any unauthorized changes or modifications made to DECAL LOCATION DIAGRAM the machine automatically release the manufacturer from any liability in the case of damage or accidents resulting from such changes or modifications. WEAR PROTECTIVE GLOVE Nameplate READ OPERATION MANUAL...

-

Page 7: Installation & Operation

such as voltage、 frequency、 power、 phase number & full parameter marked on the nameplate of the machine. load current, and the weight and manufacture date of The wiring of the machine must have the fuse and the the machine. perfect ground protection. And install the electrical Leakage automatic controls switch in the power source. -

Page 8: Main Technical Specification

-Place, carry and store the machine according to the driven, wear-resistant, low noise -press stop key to realize the emergency stop indication of the label on the package carton. -full automatic dynamic/static balance check - Store environment: RH20%-95% temperature -balance 3 ALU rim and 1 motorcycle tire -10℃-+60℃... -

Page 9: Installation

the sunlight for long time and the moisture. 5. SAFETY AND PREVENTION 5.1.1 Before operation, please confirm that you have read the entire warning label and the instruction manual. Not according with the safety instruction can cause the injuries to the operators & bystanders. 5.1.2 Keep your hands and the other parts of your body from the location with the potential danger. -

Page 10: Configuration & Use

The wheel balancers described in this manual must be used exclusively to measure the extent and position of car wheel unbalances, within the limits specified in the technical data section. Furthermore, models equipped The machine must be installed properly, operated with motors must be provided with a suitable guard. -

Page 11: Control Panel

Fig 5 5. Unit conversion key can convert the unit of the 1- Power &plug 2- Side Panel unbalance value and size. 3- Return Spring 4- main switch 5- Scale 6- control panel 7- Weight Tray 8- Hood 9- Quick Nut 10- Balance Shaft 6. -

Page 12: Value Input

6.3.2 MOUNT WHEEL Preparation before test:Check and clean the dust and mud and if there are foreign bodies, such as metal and stone, clipped on the surface of the tire. And also check the air pressure of the tire is according with the specified value. -

Page 13: Residual Unbalance Value Display

display[DIS]:[XXX],And the default system is mm. automatically stops. The machine can also start by 6.4.2 Input Br (RIM Breadth) Value lowering down the protective hood which can be set by Use the Br measurement caliper to measure the Br of the program. -

Page 14: Balance Mode & Alu Balance Mode Select

value, you should press and the display will immediately display the inside or outside unbalance value of less than 5g. The maximum residual unbalance value is 4 g. 6.6 BALANCE MODE SELECT Press the corresponding ALU1 key to choose the balance mode. If all the lights not Dis1=Dis+ 3/4”... -

Page 15: Supplementary Explanation

Press program key to enter the program setup ALU3-clip the weight inside and the position to add menu. weight outside is same to ALU2. -p- (protective cover setup) and then press ” to confirm the entrance. Select to set the on/off of the protective cover function. Then press key to return to the upper level. -

Page 16: Error

error of stop Press the start key or rise up the protective cover. factory set-up fault Correct factory set-up If you cannot solute by the above-mentioned method, customer set-up fault Customer set-up please contact with the professional persons. 7.2 ERROR INDICATION Reverse rotates is Troubleshooting of not correct... -

Page 17: Ressure Sensor Installation & Wiring

7.3 PRESS SENSOR INSTALLATION AND WIRING After change the computer board, phase sensor or the press sensor, you must execute the self-calibration. In the process to change the computer board, you should setup the parameter according to the parameter marked in the machine or the original board. You must self-calibrate after changing :... - Page 18 the change wheel STANDARD ACCESSORY foreign body on the of the value Oven, DESCRIP QUANT DESCRIP QUANTI ACCESSORY ACCESSORY will not rim or the assemble recalibrate the TION TION exceed 5g sensor. surface in the rim Fix the anchor center deformation bolt.

-

Page 19: Accessories

where they are suitably protected from dust and 8. MAINTENANCE dirt. If necessary, use ethyl alcohol to clean the display panel. Perform the calibration procedure at least once every six months. WARNING LUBRICATION The manufacturer will not bear any responsibility The only rotating parts of the wheel balancer are in the event of claims resulting from the use of the motor and balance shaft. - Page 20 4 spheres test, welding load, the product must be disposed of properly at the ASTM D 2509, kg end of its life. Test Timken OK load, ASTM D 2509, lb Thus, hazardous consequences that treatments substances Stability of oxidization bomb non-specific method, ASTM D 942, pressure contained in these products, or improper use of...

-

Page 21: Operation Detailed Description

Consult the following table to choose the most suitable fire extinguisher. Dry materials Water YES Foam YES Powder YES* CO2 YES* YES* Use only if more appropriate extinguishers 3.1 Pull out the scale of the balancer to measure are not at hand or when the fire is small. the Di value which means the distance from the insider of the tire to the body. -

Page 22: Parameter Setup

indication lamps light. Pls add the weight corresponding to the value displayed in the APP(minimum unbalance setup), In the window. Once again, start the machine to test. upper state, press to enter the APP setup. The window will display the unbalance value. The balance process will be completed until reaching Press to enter the setup... -

Page 23: Customer Self-Calibration

installation of the sensor is correct Press key to test static sensor In the condition of DYN, press the pizeo sensor “ ”— “ ” Press to enter the special function setup program 2 option:“ ”– “ ”和 “ ” –“ ”... - Page 24 Press to span the machine. The window will display “ ”-“ ”,then Use your hand to rotate the tire until all the right side lamp light up. At this moment clip the weight of 100g at the 12 clock position outside of the tire. Press span the machine.

- Page 25 : Factory Self-Calibration If the customer self-calibration will not be helping to maintain the machine to have satisfactory balancing stability, we recommend that you proceed Factory Self-Calibration procedure. Below you would find the detailed instruction: Press “Home button” one time ,and it displays “DIS + button”...

-

Page 26: Appendix

When the machine stops, it displays “100—ADD “, at this moment please remove that 100g standard weight from the outside rim edge firstly, then pull the wheel by hand until the inner indicating lights are all illuminating, clamp that 100g standard weight on the inside rim at 12 o’clock position,... -

Page 27: Appendix

APPENDIX 1 POWER DOARD LAYOUT... - Page 28 APPENDIX 2 CIRCUIT SCHEME...

- Page 30 Appendix Protective cover installation I...

- Page 31 Appendix Protective cover installation II Hex. Screw M10X30 Flat washer 10 Spring washer Spring Screw M10X20 The manufacturer has the right to modify the products without notification to the buyer in advance...

Need help?

Do you have a question about the Plus 2 and is the answer not in the manual?

Questions and answers