Table of Contents

Advertisement

Quick Links

Instructions- -Parts List

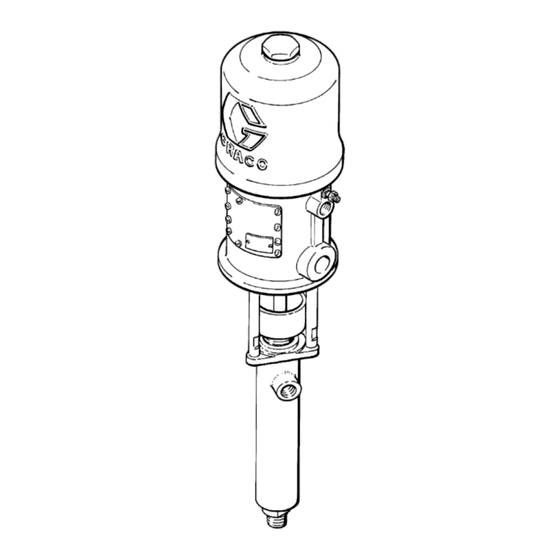

SEVERE- -DUTY

Stainless Steel Pumps

For airless and air- -assisted spraying of finishing materials.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for Table of Contents.

Part No. 223843, Series A

30:1 Ratio Presidentr Pump

3600 psi (25.0 MPa, 250 bar) Maximum Fluid Working Pressure

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

II 2 G T3

Part No. 223844, Series A

15:1 Ratio Monarkr Pump

2700 psi (18.5 MPa, 185 bar) Maximum Fluid Working Pressure

180 psi (1.25 MPa, 12.5 bar) Maximum Air Input Pressure

II 1/2 G T3

ITS03ATEX11228

MODEL 223843 SHOWN

308106H

EN

2575

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Graco 223843

- Page 1 Read all warnings and instructions in this manual. Save these instructions. See page 2 for Table of Contents. Part No. 223843, Series A 30:1 Ratio Presidentr Pump 3600 psi (25.0 MPa, 250 bar) Maximum Fluid Working Pressure 120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure II 2 G T3 Part No.

-

Page 2: Table Of Contents

......Caution Symbol Graco Standard Warranty ..... . -

Page 3: Warnings

D This equipment is for professional use only. D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 4 Permanently coupled hoses cannot be repaired; replace the entire hose. D Use only Graco approved hoses. Do not remove any spring guard that is used to help protect the hose from rupture caused by kinks or bends near the couplings.

- Page 5 Notes 308106...

-

Page 6: Installation

Installation Grounding 5. Object being sprayed: according to your local code. WARNING 6. Fluid supply container: according to your local code. FIRE AND EXPLOSION HAZARD Before operating the pump, ground the system as explained below. Also read 7. All solvent pails used when flushing, according to the section FIRE AND EXPLOSION your local code. - Page 7 Installation Typical Installation Pump Pump Runaway Valve Air Line Lubricator Bleed--Type Master Air Valve (required, for pump) Pump Air Regulator Air Line Filter Bleed--Type Master Air Valve (for accessories) Air Supply Hose Fluid Drain Valve (required) Fluid Filter Fluid Supply Hose Spray Gun Fluid Suction Hose Wall Bracket...

- Page 8 Air Line Accessories Contact your Graco distributor for available accesso- ries. If you supply your own accessories, be sure they Install the following accessories in the order shown in are adequately sized and pressure--rated to meet the the Typical Installation, using adapters as necessary: system’s requirements.

-

Page 9: Operation

Operation Pressure Relief Procedure 3. Close the bleed-type master air valve (required in your system). WARNING 4. Unlock the spray gun trigger safety. 5. Hold a metal part of the gun firmly to the side of a SKIN INJECTION HAZARD grounded metal pail, and trigger the gun to relieve Fluid under high pressure can be in- pressure. - Page 10 AND EXPLOSION HAZARD on page ing Air Pressure given on your pump or in the Technical Data on pages 20 and 21. Keep the packing nut/wet--cup (4) filled with Graco Starting and Adjusting the Pump Throat Seal Liquid (TSL) or compatible solvent, to help prolong the packing life.

- Page 11 Operation Shutdown and Care of the Pump WARNING For overnight shutdown, relieve the pressure. Always stop the pump at the bottom of the stroke to prevent To reduce the risk of serious injury whenever you the fluid from drying on the exposed displacement rod are instructed to relieve pressure, always follow the and damaging the throat packings.

-

Page 12: Troubleshooting

Troubleshooting 1. Relieve the pressure. WARNING To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the 2. Check all possible causes and problems before Pressure Relief Procedure on page 9. disassembling the pump. PROBLEM CAUSE SOLUTION... - Page 13 Torque the packing nut/wet--cup (4) to 18--20 ft--lb (24--27 N.m). Fill the wet--cup with Graco Throat Seal Liquid or compatible solvent. 4. Tighten the tie rod locknuts (106) evenly, and torque to 25--30 ft--lb (34--41 N.m).

- Page 14 Replace any worn or damaged parts. NOTE: If the sleeve (10) needs replacement and is 7. Reconnect the displacement pump to the air motor hard to remove, contact your Graco distributor. as explained on page 13. 308106...

- Page 15 Service Torque to 18--20 ft-lb (24--27 N.m) Torque to 25--30 ft-lb (34--41 N.m) Torque President to 25--30 ft-lb (34--41 N.m); Monark to 15--20 ft-lb (20--27 N.m) 101(REF) Torque to 65--75 ft-lb (88--102 NSm) Torque to 75--100 ft-lb (102--136 N.m) Lips of v-packings must face down Lips of v-packings must face up Fig.

-

Page 16: Parts

Parts Model 223843, Series A 30:1 Ratio Presidentr Pump Includes items 101--110 REF PART NO. NO. DESCRIPTION 207352 AIR MOTOR See 306982 for parts 223842 DISPLACEMENT PUMP ASSY See pages 18 and 19 for parts 105† 101946 PIN, cotter; stainless steel;... - Page 17 Parts Model 223844, Series A 15:1 Ratio Monarkr Pump Includes items 101--110 REF PART NO. NO. DESCRIPTION 215363 AIR MOTOR See 307043 for parts 223842 DISPLACEMENT PUMP ASSY See pages 18 and 19 for parts 105† 101946 PIN, cotter; stainless steel; 0.12”...

- Page 18 Parts Model 223842, Series B Severe- -Duty, Stainless Steel Displacement Pump Includes items 1--22 12** 308106...

- Page 19 Parts Model 223842, Series B Severe- -Duty, Stainless Steel Displacement Pump Includes items 1--22 REF PART REF PART NO. NO. DESCRIPTION NO. NO. DESCRIPTION 186179 PIN, ball stop; stainless steel 223593 HOUSING, valve, intake; 165052 SEAL, o--ring; PTFE stainless steel with 186183 RETAINER, o--ring;...

-

Page 20: Technical Data

Technical Data Maximum fluid working pressure ......3600 psi (25.0 MPa, 250 bar) Maximum air input pressure . - Page 21 Technical Data Maximum fluid working pressure ......2700 psi (18.5 MPa, 185 bar) Maximum air input pressure .

-

Page 22: Mounting Hole Layout

Dimensions Mounting Hole Layout Model 223843 Shown USE GASKET 166392 (ORDER SEPARATELY) 1/2 npt(f) 0.28” (7.1 mm) DIA. 4.38” AIR INLET (111.3 mm) DIA. 2.5” (64 mm) 5.0” (127 mm) 3/8 npt(f) FLUID OUTLET 3/4 npt(m) FLUID INTAKE Pump Model 223843 30 in. - Page 23 Notes 308106...

-

Page 24: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 223843 and is the answer not in the manual?

Questions and answers