Emerson Rosemount 3051S Technical Note

Rising to new levels with electronic remote sensor ers systems and tuned-system assemblies, dp level

Hide thumbs

Also See for Rosemount 3051S:

- Reference manual (240 pages) ,

- Manual (96 pages) ,

- Manual supplement (60 pages)

Advertisement

Quick Links

Download this manual

See also:

Reference Manual

Technical Note

00840-1400-4801, Rev BB

Rising to new levels with Rosemount 3051S

Electronic Remote Sensor (ERS) Systems and

Tuned-System Assemblies

1.0

Executive summary

Differential Pressure (DP) technology has been used for many years to measure tank level. Internal tank

architecture, agitation, corrosive or viscous processes that may cause challenges for alternative level

technologies are ideal applications for DP level technology, which delivers a repeatable, stable and

accurate measurement when utilized correctly.

Traditional DP technologies, such as wet leg and dry leg systems, which utilize impulse piping as well as

capillary based solutions, are well understood and reliable technologies. Impulse lines benefit from clean

processes as they are prone to plugging and may freeze in extreme cold ambient temperatures. Capillary

solutions continue to give excellent measurements when capillary lengths can be minimized. However,

these traditional DP level systems can be difficult to use in areas and applications with wide ambient and

process temperature shifts.

Improvements to traditional measurement technology, such as Tuned-System

developed to increase response time and reduce measurement error and are considered best practices

for indoor applications and shorter spans and tanks with high pressure vessels.

Another DP level instrumentation innovation is the Rosemount

System. This technology builds upon the proven DP technology and is suited to distillation towers, tall

vessels and other applications with long spans or widely varying temperature. The Rosemount 3051S

ERS System

pressure transmitters that are linked together electronically. Differential pressure is calculated in one of

the two sensors and is transmitted to the DCS or PLC using a standard two-wire 4–20 mA HART

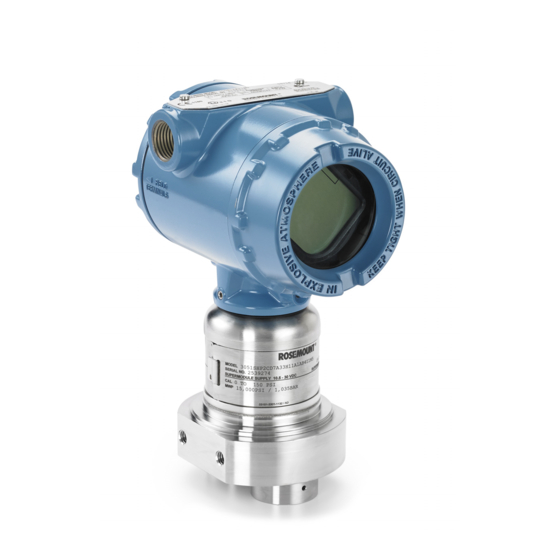

Figure 1. Rosemount 3051S ERS System

Rosemount DP Level

(Figure

1) replaces mechanical impulse piping and long lengths of capillary with two

With a Rosemount 3051S ERS System, a digital signal replaces impulse lines and capillary to increase measurement

reliability and performance on tall towers and vessels.

Rosemount DP Level

™

Assemblies, have been

™

3051S Electronic Remote Sensor (ERS)

April 2019

™

®

signal.

1

Advertisement

Summary of Contents for Emerson Rosemount 3051S

- Page 1 DCS or PLC using a standard two-wire 4–20 mA HART signal. Figure 1. Rosemount 3051S ERS System With a Rosemount 3051S ERS System, a digital signal replaces impulse lines and capillary to increase measurement reliability and performance on tall towers and vessels. Rosemount DP Level...

- Page 2 Technical Note Rosemount DP Level 00840-1400-4801, Rev BB April 2019 Overview of traditional DP Level technology Vapor pressure (vessel static pressure) is subtracted in DP measurement Conventional DP transmitters are used in level applications by measuring the amount of pressure exerted by the liquid level in a vessel.

- Page 3 Figure 3. Rosemount 3051S Balanced System A balanced system has identical diaphragm seals and equal lengths of capillary on both the high and low side of the DP transmitter.

- Page 4 In addition, balanced systems result in excess capillary on the high side of the transmitter that is often coiled up and adds unnecessary costs. Figure 5. Rosemount 3051S Tuned-System Assembly A Tuned-System Assembly minimizes fill-fluid volume on the high pressure side of the transmitter to increase performance and response time.

- Page 5 DP measurement on tall vessels or towers. Rather than using a single DP transmitter with mechanical impulse piping or capillary, the Rosemount 3051S ERS System uses two direct mount gage or absolute sensors that are connected with a non-proprietary electrical wire. One of the two sensors calculates the DP and transmits it back to the host system/DCS using a standard two 4–20 mA HART...

- Page 6 Technical Note Rosemount DP Level 00840-1400-4801, Rev BB April 2019 to a 5 m (16.4 ft.) balanced system and more than 3000 percent when compared with a 30 m (98.4 ft.) balanced system. Figure 6. Time Response Impact The time response of 1.092 mm (0.040-in.) capillary with Silicone 200 fill-fluid at 24 °C (75 °F) ambient. System is balanced with equal lengths of capillary on the low and high reference connection of the transmitter.

- Page 7 The evaporator consequently needed to be taken off line so maintenance staff could remove the salt buildup. A Rosemount 3051S ERS System was installed with a tank spud remote seal eliminating all the headaches that Solvay was previously experiencing. In fact, because Solvay has not lost measurement due to plugging, a higher level of efficiency has resulted by reducing operations and maintenance costs.

- Page 8 Technical Note Rosemount DP Level 00840-1400-4801, Rev BB April 2019 Figure 7. Easily Accessible Process Information Gain access to more process variables such as PHI, PLO, DP, mass, density, and interface. In addition, because the operator has access to the PLO measurement point as well as the system DP, vapor pressure can be actively monitored.

- Page 9 I/O points, doubling the cost in wiring. Complimentary technologies While the Rosemount 3051S ERS System is great for tall vessels and towers, there are applications where a Tuned-System assembly will continue to be the preferred technology. The sensors in a Rosemount 3051S ERS System are specified and sized based on the combined static pressure and the DP column from the liquid level, whereas a Tuned-System assembly is sized just on the DP column.

- Page 10 The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount +971 4 8118100 is a mark of one of the Emerson family of companies. All other marks are the property of their respective owners. +971 4 8865465 ©...

Need help?

Do you have a question about the Rosemount 3051S and is the answer not in the manual?

Questions and answers