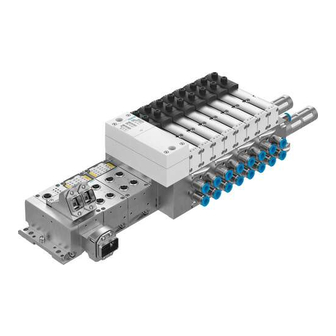

Festo VTSA Series Description Pneumatics

Valve terminal

Hide thumbs

Also See for VTSA Series:

- Description (267 pages) ,

- Manual (176 pages) ,

- Brief description (16 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Festo VTSA Series

- Page 1 Valve terminal VTSA/VTSA-F VTSA… Description Pneumatics 538923 1312 h [8025774]...

- Page 3 ........538923 © (Festo AG & Co., 73726 Esslingen, Germany, 2013) Internet: http://www.festo.com E-Mail: service_international@festo.com...

- Page 4 Contents and general safety instructions ® CAGE CLAMP is a registered trademark of the respective owner in certain countries. Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 5: Table Of Contents

........... 1-45 Festo P.BE-VTSA-44-EN en 1312h English... - Page 6 ........3-37 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 7 ..... . . 5-20 5.5.7 Replacing the manifold sub-base or right end plate, size 65 mm 5-24 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 8 ............Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 9: Intended Use

CE marking. Standards and test values, which the product must comply with and fulfill, can be found in the section “Technical data”. The product-relevant EU directives can be found in the declar- ation of conformity. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 10: Target Group

– The technical data in this documentation may show val- ues deviating from this. Target group This manual is directed exclusively toward technicians trained in control and automation technology. Service Please consult your local Festo repair service if you have any technical problems. VIII Festo P.BE-VTSA-44-EN en 1312h English... -

Page 11: Notes On This Description

M23 round plug, IC): Information about the electric/electronic components is included in the documentation supplied with the product. – Valve terminal with AS-interface: Information about the electric/electronic components is included in the documentation supplied with the product. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 12: Important User Information

... means that failure to observe this instruction may result in material damage. In addition, the following pictogram marks passages in the text which describe activities with electrostatically sensitive devices: Electrostatically sensitive devices: Incorrect handling may cause damage to devices. Festo P.BE-VTSA-44-EN en 1312h English... - Page 13 Festo. Text designations Bullets denote activities that may be carried out in any • desired order. 1. Numerals denote activities that must be carried out in the sequence specified. – Arrowheads indicate general lists. Festo P.BE-VTSA-44-EN en 1312h English...

- Page 14 – with two valve positions for 18 mm and 26 mm widths – with one valve position for 42 mm (ISO 1), 52 mm (ISO 2) and 65 mm (ISO 3) widths – Per valve position with working lines (2) and (4). – Manual override Festo P.BE-VTSA-44-EN en 1312h English...

- Page 15 – Solenoid valve with monostable, impulse or mid-position valve Valve terminal – Valve terminal VTSA/VTSA-F VTSA/VTSA-F – With CPX terminal – AS-interface – or with multi-pin node (cage clamp, M23 round plug, Sub-D or IC). XIII Festo P.BE-VTSA-44-EN en 1312h English...

- Page 16 Vertical pressure shut-off – Plate on a valve position for isolating the valve pressure supply plate Vertical pressure supply – Plate on a valve position for individual compressed air supply plate Tab. 0/1: Product-specific terms and abbreviations Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 17: Overview Of Components

Overview of components Chapter 1 Overview of components Festo P.BE-VTSA-44-EN en 1312h English... - Page 18 VTSA/VTSA-F valve terminal with multi-pin plug ....1-49 Connection and display components of the electrical components ..1-52 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 19 Information about the electronics of the VTSA/VTSA-F valve terminal with multi-pin node can be found in the corres- ponding package insert. Information about the electronics of the VTSA/VTSA-F valve terminal with AS-interface can be found in the correspond- ing package insert. Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 20: The Vtsa/Vtsa-F Valve Terminal

1. Overview of components The VTSA/VTSA-F valve terminal Festo supports your automation tasks at machine level with the VTSA/VTSA-F valve terminals. The modular structure of the valve terminal enables you to optimally customise it to your machine or system. The valve terminal pneumatics establish the following con- nection: –... - Page 21 The maximum number of valve positions does not apply in the case of mixed components of a valve terminal with manifold sub-bases T1 and T2 or VIGM and VIGI. Tab. 1/2: Number of valve positions for the VTSA/VTSA-F with CPX terminal Festo P.BE-VTSA-44-EN en 1312h English...

- Page 22 The maximum number of valve positions does not apply in the case of mixed components of a valve terminal with manifold sub-bases T1 and T2 or VIGM and VIGI. Tab. 1/3: Number of valve positions for the VTSA/VTSA-F with multi-pin plug connec- tion Festo P.BE-VTSA-44-EN en 1312h English...

- Page 23 The maximum number of valve positions does not apply in the case of mixed components of a valve terminal with manifold sub-bases T1 and T2. Tab. 1/4: Number of valve positions for the VTSA/VTSA-F with AS-interface Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 24: Components, Width 18

The essential components of width 18 ... 52 mm are shown in Fig. 1/1 and Fig. 1/2. right end plate 90°-connection plate (optional) Pneumatic supply plates (optional) Manifold sub-base Fig. 1/1: Pneumatic base components of the VTSA/VTSA-F valve terminal (1st level) Festo P.BE-VTSA-44-EN en 1312h English... - Page 25 Blanking plate for valve position Vertical pressure shut-off plate (optional) (optional) Valves Vertical pressure supply plate (optional) Exhaust port cover Flow control plate (optional) Fig. 1/2: Pneumatic components of the VTSA/VTSA-F valve terminal (2nd level) Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 26: Main And Additional Supply

The pneumatic supply plate can also be used for additional supply. This is necessary, for example, if the valve terminal is operated with several pressure zones or if many valves simul- taneously are switched to flow or exhausted on the valve ter- minal. 1-10 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 27: Valves

VTSA… is provided via ports (3) and (5). The exhaust procedure is effected via port (1) also see section 3.8 and 3.8.1). All 5/2-way valves and 5/3-way mid-position valves can be used in all operating modes. 1-11 Festo P.BE-VTSA-44-EN en 1312h English... - Page 28 5/3-way valve, normally open 1 2, switching position 14 latching 5/3-way valve, normally exhausted, switching position 12 latching 5/3-way valve, normally open 1 2, closed 4 Tab. 1/5: Identification of the valve function in type code (part 1) 1-12 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 29 26 mm) have a piston position sensing. An inductive sensor (N/C contact) monitors the neutral position of the piston spool. The sensor has a PNP or an NPN output. The valve is actuated via a multi-pin or fieldbus connection. 1-13 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 30: Manifold Sub-Bases

If, on the other hand, only manifold sub-bases that control only one solenoid coil per valve position are used, the valve terminal can only be equipped with monostable 5/2-way valves (Ident. Code M, O, SO or SQ). 1-14 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 31: Pilot Control

– you can choose whether the valve terminal should be supplied with internal or external pilot air via the corres- ponding right end plate variants. 1-15 Festo P.BE-VTSA-44-EN en 1312h English... - Page 32 You can ascertain the end plate with which your VTSA/VTSA-F valve terminal is fitted by means of the following table. Con- version between internal and external pilot air supply is de- scribed in section 5.6.2. 1-16 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 33 Tab. 1/8: Variants of the right end plate for widths 18 ... 52 mm Note Instructions for combining the soft-start valve and the right end plate can be found in the assembly instructions VABV-S6-1Q-... 1-17 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 34: Pressure Zone Separation

( Fig. 1/4). Inscription on the manifold sub-bases Closed ducts Supply duct (1) Supply duct (1) Exhaust channels (3) and Exhaust channels (3) and Tab. 1/9: Identification of pressure zones on manifold sub-bases 1-18 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 35: Vertical Stacking

This vertical stacking will enable you to implement certain addi- tional effects as desired. Tab. 1/10 shows the basic design and possible components of vertical stacking. 1-19 Festo P.BE-VTSA-44-EN en 1312h English... - Page 36 Manifold sub-base VABF...A1G2... Working ports (2) VABV...T1 or VABV...T2 and (4) turned 90° Instructions on installing the vertical stacking components Section 3 Tab. 1/10: Components of the pneumatic module of the VTSA/VTSA-F valve terminal 1-20 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 37 10 means the control range of the pressure regulator extends to 10 bar. In the sales documentation and in the Festo Configurator, the components are marked with an ID code. You can identify the vertical stacking components with the aid of the following table.

- Page 38 (1) and (14) for a valve position L1D1 Vertical pressure shut-off plate for shutting off individual operating pressure for ports (1) and (14) for a valve position Tab. 1/11: Identification of the vertical stacking components (part 1) 1-22 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 39: Pressure Regulator Plates

(1) (P). This provides the same regulated working air pressure in channels (2) and (4). Exhaust process: The exhaust flow in the valve is from channel (2) to chan- nel (3) and from channel (4) to channel (5). 1-23 Festo P.BE-VTSA-44-EN en 1312h English... - Page 40 For example, the pressure regulator for duct (4) cannot be adjusted when the valve is pressurised in the switching position from duct (1) to duct (2) and vented from duct (4) to duct (5). 1-24 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 41 (2) of the manifold sub- base. The exhaust is passed via duct (4) to pressure regulat- ing valve A and then via the valve to duct (5). 1-25 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 42 (3) and (5) on the valve. The valve is thus operated in reversible mode Fig. 1/6). This means: – duct (3) routes the working pressure to port (2) – duct (5) routes the working pressure to port (4). 1-26 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 43 Operating pressure is always present at the pressure reg- ulator, as the pressure is regulated upstream of the valve. In other words, the regulator can always be adjusted. In the case of the AB-pressure regulator, the valve must switch for this. 1-27 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 44 When, instead of the operating pressure of the valve ter- minal, two further different pressures are required in ducts (2) and (4). – When fast venting is required. – When the pressure regulator must always be adjustable. 1-28 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 45 B-pressure regulator Manifold sub-base Valve Duct (5) (exhaust) A-pressure regulator Duct (1) (air) Intermediate plate Duct (3) (exhaust) Fig. 1/6: Reversible AB-pressure regulator For instructions on how to install this pressure regulator Section 3.8.2 1-29 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 46: Components For Protective Functions

Vertical pressure shut-off plate Note The vertical pressure shut-off plates are only intended in combination with VSVA valves from Festo. Duct 12 is not blocked in the vertical pressure shut-off plate. This plate can be used to cut off the corresponding valve in vertical stacking from the terminal's operating and pilot pres- sure. - Page 47 When the valve terminal is supplied with internal pilot air via the soft-start valve, the full operating pressure is always present at duct (14). This pressure causes the valves on the valve terminal to immediately move to the required switching 1-31 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 48 VABV-S6-1Q-..Note When using “Protection against unexpected start-up”: protection against unintentional operation of the MO is to be ensured for all operating modes. 1-32 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 49 Optional: 90°-connection plate VABF...A1G2... Working ports (2) and (4) turned 90°. Tab. 1/13: Control block The detailed description of the control block can be found in the operating instructions VOFA-..., which accompany the product. 1-33 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 50: Vacuum Block Vabf-S4-1-V2B1

The strength of the ejector pulse is influenced by the adjustable flow control valve. Fig. 1/8: Vacuum block Further important information about the vacuum block can be found in the operating instructions for VABF-S4-1-V2B1... 1-34 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 51: Pilot Air Switching Function (Manifold Sub-Base Vabf-S4

SPBA-B11R-G18-P-M12--0.25X Optional: 90°-connection plate VABF...A1G2... Working ports (2) and (4) turned 90°. Tab. 1/14: Components for switching the pilot air supply Further information appears in the assembly instructions for the vertical stacking plate. 1-35 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 52: Components, Width 65 Mm

65 mm (ISO 3) consists of the following components: Adapter plate Pressure regulator plate Blanking plate right end plate Flow control plate Intermediate solenoid plate MUH Valve Manifold sub-base Fig. 1/9: Components of the VTSA/VTSA-F valve terminal, width 65 mm 1-36 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 53: Valves

5/2-way valve with mechanical spring. You can identify the valve function with the aid of the following table. In the sales documentation and in the Festo Configurator the valves are marked with an Ident. Code. 1-37... -

Page 54: Manifold Sub-Bases

If, on the other hand, only manifold sub-bases that control only one solenoid coil per valve position are used, the valve terminal can only be equipped with monostable 5/2-way valves (Ident. Code M or O) or cover plates. 1-38 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 55: Pressure Zones

You can mount further components at each valve position between the manifold sub-base and the valve. These vertical stackings enable you to implement certain additional func- tions as desired. Tab. 1/17 shows the basic design and possible components of vertical stacking. 1-39 Festo P.BE-VTSA-44-EN en 1312h English... - Page 56 Manifold sub-base VIGI-04-D-3 which supports the actuation of two solenoid coils Instructions on installing the vertical stacking components Chapter 3 Tab. 1/17: Components of the pneumatic module of the VTSA/VTSA-F valve terminal, width 65 mm 1-40 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 57: Connection And Control Elements Of The Pneu. Components, Width 18

LR-ZP-A-D-3 indicates that this component is an A-pres- sure regulator. You can identify the vertical stacking compon- ents with the aid of the following table. In the sales docu- mentation and in the Festo Configurator, the components are marked with an ID code. Identification in Ident.-... - Page 58 Working ports (2) and (4), per valve Optional manual override cover cap, position for non-detenting function of manual override Inscription fields Fig. 1/10: Pneumatic connection, display and control elements of the components and base components, widths 18 ... 52 mm 1-42 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 59 18 mm and 26 mm, with free-wheel unit) Port (1) (individual operating pressure for one valve position) Fig. 1/11: Connection and control elements of the vertical stacking components, width 18 ... 52 mm 1-43 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 60 Fig. 1/12: Connection and control elements of the soft-start valve Description of the connection and control elements for the control block VOFA-... operating instructions Description of the connection and control elements for the vacuum block VABF-S4... operating instructions 1-44 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 61: Connection, Display And Control Elements Of The Pneumatic Components, Width 65 Mm

65 mm Pilot port (14) for supplying the valves of width 18 … 52 mm Fig. 1/13: Pneumatic connection, display and control elements of the components, widths 65 mm 1-45 Festo P.BE-VTSA-44-EN en 1312h English... - Page 62 Adjusting screw for throttle flow (3) adjustment: pull knob out of locking Adjusting screw for throttle flow (5) position and turn) Connection for pressure gauge Fig. 1/14: Connection and control elements of the vertical stacking components, width 65 mm 1-46 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 63: Electrical Components

Per valve position, one or two solenoid coils (dependent on the manifold sub-base) and within the valve terminal, a maximum of 26 or 32 solenoid coils are con- trolled via the CPX terminal ( Tab. 1/2). 1-47 Festo P.BE-VTSA-44-EN en 1312h English... - Page 64 CPX bus node Pneumatic interface Further optional CPX modules Fig. 1/15: Electric components of the VTSA/VTSA-F valve terminal with CPX terminal AS-interface Multi-pin node Fig. 1/16: Electric components of the VTSA/VTSA-F valve terminal with AS-interface 1-48 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 65: Vtsa/Vtsa-F Valve Terminal With Multi-Pin Plug

Tab. 1/3). Each solenoid coil occupies a pin/ter- minal of the multi-pin plug connection. Cover Protective conduit with strain relief Multi-pin node Cage clamp Fig. 1/17: Electric components of the VTSA/VTSA-F valve terminal with multi-pin node cage clamp 1-49 Festo P.BE-VTSA-44-EN en 1312h English... - Page 66 Fig. 1/18: Electric components of the VTSA/VTSA-F valve terminal with multi-pin node M23 round plug Multi-pin plug cover with cable Multi-pin node Sub-D multi-pin plug connection Fig. 1/19: Electric components of the VTSA/VTSA-F valve terminal with multi-pin node Sub-D 1-50 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 67 1. Overview of components IC connections Multi-pin node Fig. 1/20: Electric components of the VTSA/VTSA-F valve terminal with multi-pin node IC 1-51 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 68: Connection And Display Components Of The Electrical Components

Service interface for handheld, etc. the pilot solenoid coils red LED: common error display of the Power supply connection valves Earth terminal Fig. 1/21: Electrical connecting, display and control elements of the VTSA/VTSA-F valve terminal with CPX terminal 1-52 Festo P.BE-VTSA-44-EN en 1312h English... - Page 69 Service interface for handheld, etc. horizontal output of the power supply DIL switch (under the cover) connection (continuing) Fig. 1/22: Electrical connection, display and control elements of the VTSA/VTSA-F valve terminal with CPX-M-FB20 or FB21 1-53 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 70 (AS-i In) Inputs External earth connection yellow LEDs: signal status display of the pilot solenoid coils Inscription field Fig. 1/23: Electrical connection and display components of the VTSA/VTSA-F valve ter- minal with AS-interface 1-54 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 71 Internal earth terminal for the the pilot solenoid coils connecting cable Cable routing Terminal strip Inscription field Fig. 1/24: Electrical connection and display components of the VTSA/VTSA-F valve ter- minal with multi-pin node cage clamp 1-55 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 72 LEDs: signal status display of Inscription field the pilot solenoid coils M23 round plug as per CNOMO E03.62.530.N Fig. 1/25: Electrical connection and display components of the VTSA/VTSA-F valve ter- minal with multi-pin node M23 round plug 1-56 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 73 Sub-D multi-pin plug connection cable Yellow LEDs: signal status display of Inscription field the pilot solenoid coils Earth terminal Fig. 1/26: Electrical connection and display components of the VTSA/VTSA-F valve ter- minal with multi-pin node Sub-D 1-57 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 74 M12 individual connections (IC) External earth connection Yellow LEDs: signal status display of the pilot solenoid coils Fig. 1/27: Electrical connection and display components of the VTSA/VTSA-F valve ter- minal with multi-pin node IC 1-58 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 75: Assembly

Assembly Chapter 2 Assembly Festo P.BE-VTSA-44-EN en 1312h English... - Page 76 ..........Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 77: Assembly

Information on dismantling and mounting the I/O mod- ules can be found in the description for the CPX I/O mod- ules. – Information on mounting modules and components ordered at a later stage can be found in the package in- sert. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 78: General Instructions On Mounting And Dismantling

Pay particular attention to the following: Do not touch the plug connectors or contact surfaces. • For valve terminals with multi-pin node Sub-D: Protect the multi-pin node against humidity, dirt and • dust etc. before the connecting cable is mounted. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 79: Mounting Variants

Information for mounting the VTSA/VTSA-F valve terminal and the CPX terminal can be found in the corresponding assembly instructions. www.festo.com/sp enter search term: “CPX terminal with VTSA valve terminal” or “VTSA valve terminal” user documentation Festo P.BE-VTSA-44-EN en 1312h English... -

Page 80: Mounting/Dismantling The Optional Inscription Label Holder, Width 18

( Fig. 2/1) Dismantling Pull the inscription label holder from the manifold sub-base. Fixture for in- scription label holder on the manifold sub- base Inscription label holder Fig. 2/1: Mounting the inscription label holder Festo P.BE-VTSA-44-EN en 1312h English... -

Page 81: Mounting/Dismantling The Optional Manual Override Cover Caps, Width 18

2. make sure the cover cap is aligned in such a way that the snap hooks engage in the designated slots. 3. Clip the cover caps into the recesses in the manual over- rides ( Fig. 2/2): Festo P.BE-VTSA-44-EN en 1312h English... - Page 82 If you wish to remove the cover caps, note that the snap hook of the cover caps may become damaged when the hooks are dismantled. Dismantling Proceed as follows: Pry the caps from the manual override by using a suitable • screwdriver ( Fig. 2/3): Festo P.BE-VTSA-44-EN en 1312h English...

- Page 83 2. Assembly Fig. 2/3: Dismantling the manual override caps Festo P.BE-VTSA-44-EN en 1312h English...

- Page 84 2. Assembly 2-10 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 85: Installation

Installation Chapter 3 Installation Festo P.BE-VTSA-44-EN en 1312h English... - Page 86 ........3-51 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 87: Installation

VTSA/VTSA-F valve terminal with CPX terminal can be found in the CPX system description, chapter 3. Detailed instructions on connecting the CPX modules (bus nodes, I/O modules etc.) can be found in the corresponding descriptions for the CPX module. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 88: Compressed Air Preparation

( ISO 8573-1 class 4). This avoids operative malfunctions of the valves. Excessive residual oil content is not permissible, independent of the compressor oil, as otherwise the basic lubrication will be washed out with time. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 89: Operation With Lubricated Compressed Air

3.1.2 Operation with lubricated compressed air Operate system equipment with unlubricated compressed air, if possible. In this way, you protect the environment. Festo pneumatic valves and actuators have been designed so that, if used as intended, they will not require additional lubrica- tion and will still achieve a long service life. - Page 90 Incorrect supplemental oil and an oil rate in the com- pressed air that is too high will reduce the service life of the valve terminal. Use Festo special oil OFSW-32 or the alternatives listed • in the Festo catalogue (as per DIN 51524-HLP32, basic viscosity 32 CST at 40 °C).

- Page 91 – droplets of oil on the silencer indicate that the lubricator setting is too high. 7. Correct any incorrect lubricator settings. If applicable, take comprehensive maintenance measures of the com- pressed air supply into consideration. Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 92: General Notes On Connecting The Tubing

The back pressures can lead to pneumatic actuation of other valves, especially with un- switched 3/2-directional control valves that are normally closed. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 93: Installing The Tubing

First mount the tubing at port (1) and then at ports (3) and (5). Secure the tubing with a hose clamp 3. 3. For better system clarity, bundle together the installed tubes with: – tubing straps or – multiple hose holders. Festo P.BE-VTSA-44-EN en 1312h English... - Page 94 3. Installation Fig. 3/1: Mounting the tubing connections 3-10 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 95 – nector. – Press down the locking ring of the threaded connect- or 2, e.g. with a Festo QSO releasing tool. Loosen the hose clamp screw 3. – 3. Remove the tubing from the fitting. 4. Seal non-required fittings with blanking plugs 4.

- Page 96 3. Installation Fig. 3/2: Removing the tubing connection 3-12 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 97: Connecting The Vtsa/Vtsa-F Valve Terminal

This operating pressure must correspond to the pilot pressure. All other valves from Festo which are operated so they comply with the ISO standard work independently of duct (12). The pilot exhaust air is vented directly at each valve in an unduc- ted manner. - Page 98 The seals between the manifold sub-bases and the valves must be mounted in the corresponding position Section 5.6.1). – Valve terminals with a selector end plate must be oper- ated in positions 3 or 4 of the selector plate ( Tab. 3/3). 3-14 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 99: Pilot Air Supply

( Appendix A, Tab. A/5 and Fig. A/1), the pilot control must be supplied with external pilot air. The pilot air is to be supplied via pilot port (14). 3-15 Festo P.BE-VTSA-44-EN en 1312h English... - Page 100 The valve terminal may only be operated in positions 3 • and 4 of the selector plate. Otherwise, pilot air 12 may escape at the interface to the valve when the valve is replaced and the pilot pressure could break down. 3-16 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 101 14 to control side 12. This is guaran- teed with Festo valves. Valves from other manufacturers might have to be additionally supplied with external pilot air via port (12).

- Page 102 Supply the external pilot air via port (14) 3. • NOTE: Valve terminal with soft-start valve: Observe the information in the as- sembly instructions VABV-S6-1Q-..Tab. 3/2: Variants of the right end plate (part 2) 3-18 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 103 – Pilot air supply branched from duct (1) – Port (14) sealed – Pilot exhaust air (82/84) via port (12) Reversible 2x3/2-way valves from Festo (Ident. Code P, Q and R) require operating pressure at port (12) to ensure the functionality of the pneumatic spring. Note: The VTSA valve terminal must not be equipped with reversible 2x3/2-way valves from Festo, as these require operating pressure in duct 12 for the pneumatic spring.

-

Page 104: Pilot Control, Width 65 Mm

If the operating pressure of the valve terminal lies between 3 ... 10 bar, pilot control can be operated with internally branched pilot air. The pilot air is branched here from supply duct P1. 3-20 Festo P.BE-VTSA-44-EN en 1312h English... - Page 105 If the valve terminal is prepared for external pilot air, – a plug pin is located in duct 1 on the underside of each intermediate solenoid plate ( Fig. 3/4); the flow from 1 to the pilot control ducts is therefore blocked 3-21 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 106 Plug pin duct 1 Fig. 3/4: Intermediate solenoid plate, positions of the plug pin in air duct P1 Note For valves with pneumatic spring: turn the code seal on • the pneumatic spring side of the valve. 3-22 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 107: Pressure Zone Separation, Width 18

• of the right end plate must be operated with a pressure that corresponds to the required pilot pressure for the valve terminal at the very least ( Appendix A, Tab. A/5, Fig. A/1). 3-23 Festo P.BE-VTSA-44-EN en 1312h English... - Page 108 Ports (12) or (14) on the right end plate are for valve termin- als with pilot control by means of external pilot air supply. By mounting an additional supply plate within a pressure zone you can provide additional supply air or extract exhaust air. 3-24 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 109 Supply plate of pressure zone 1 Right end plate with port (14) for external pilot air supply Fig. 3/5: Example of a VTSA/VTSA-F valve terminal with 3 pressure zones and pilot con- trol with external pilot air supply 3-25 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 110: Pressure Zone Separation, Width 65 Mm

(3 or 5) as well. Pressure zone 1 Pressure zone 2 External pilot air Supply air Fig. 3/6: Terminal with pilot control through external pilot air and two pressure zones 3-26 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 111: Reversibly Operated Vtsa/Vtsa-F Valve Terminal

(12) (venting of pilot exhaust air via port (12)). Note If the valve terminal is equipped with reversible 3/2-way • valves (Ident. Code P, Q and R), you operate the valve terminal exclusively in position 1 of the selector plate. 3-27 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 112: Operating The Vtsa/Vtsa-F Valve Terminal With Reversible Valves

1 or 2 of the selector plate Tab. 3/3). If this pressure zone is operated in a revers- ible manner, however, the valve terminal should only be operated in position 1 of the selector plate ( Tab. 3/3). 3-28 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 113: Operating The Vtsa/Vtsa-F Valve Terminal With Reversible Pressure Regulators

Code P, Q and R) on reversible pressure regulators (iden- tifier R5) must not be operated in a separate pressure zone. The reversible pressure regulators supply pres- sure via duct (1) and vent the exhaust air via ducts (3) and (5). 3-29 Festo P.BE-VTSA-44-EN en 1312h English... - Page 114 If the rotary knob cannot be used for setting the pressure regulator because it is encapsulated by the adjacent rotary knobs, the rotary knobs of the adjacent pressure regulator can be removed temporarily. This results in sufficient space to operate the rotary knob. 3-30 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 115 In this case, turn the rotary knob clockwise or anti-clockwise a few degrees until it can be noticeably pressed down some millimetres. If required: 8. Pull the key out. 3-31 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 116 Rotary knob in safety level Rotary knob in setting level Rotary knob Rotary knob in free-running level Fig. 3/7: Setting the pressure regulator plates (widths 18 mm and 26 mm) using the rotary knob 3-32 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 117 This prevents accidental adjustment of the con- trolled variable. When the locking element has been pulled out, a padlock can be applied to secure its position. 3-33 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 118 “Flow diagrams of the pressure regulator plates” in Appendix A). Adjusting screw, internal hexagon socket (spanner size 2.0) Fig. 3/9: Setting the pressure regulator plates (widths 18 mm and 26 mm) using the adjusting screw 3-34 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 119: Vacuum / Low-Pressure Operation

–0.9 ... 3 bar: – the pilot control is operated with an external pilot air sup- – the valve terminal is fitted with the following valve sub- bases and sometimes has additional pressure zones: 3-35 Festo P.BE-VTSA-44-EN en 1312h English... - Page 120 – To enable the ejector pulse during vacuum operation a connection is to be established between the suction line and the pressure line via a T-piece. 3-36 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 121: Connecting The Pneumatic Lines

It is possible to mount the 90°-connection plate with the exit for the working ports in the direction of the valve base level, but this is not supported by Festo because the desig- nation of the ports no longer applies in this direction of mounting. - Page 122 65 mm: For external pilot air supply connect the pilot air as • follows: – for widths up to 52 mm in the adapter plate – for width 65 mm in the right end plate. 3-38 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 123 Important information about this can be found in the assembly instructions VABV-S6-1Q-... First mount the seals and then the fittings and/or silencer (position of the ports Fig. 3/10, Fig. 3/11 and Fig. 3/12. Port size following tables). Then lay the tubing lines. 3-39 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 124 – G1”, 1” NPT – in the adapter plate Depending on what you have ordered, the valve terminal will already be equipped with ports. Tab. 3/5: Supply and disposal ports, standard operation 3-40 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 125 – GÅ”, Å” NPT Width 52 mm: – G½”, ½” NPT Depending on what you have ordered, the valve terminal will already be equipped with ports. Tab. 3/6: Supply and disposal ports, reversible operation 3-41 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 126 Depending on what you have ordered, the valve terminal will already be equipped with ports. The external pilot air is supplied as standard via port (14). Requirement: the valve terminal must be fitted with Festo valves (except reversible 2x3/2-way valves). Observe the correct position of the seals below the valves Section 5.6.1, also observe...

- Page 127 – GÅ”, Å” NPT Width 52 mm: – G½”, ½” NPT Width 65 mm: – G½”, ½” NPT Depending on what you have ordered, the valve terminal will already be equipped with ports. Tab. 3/8: Working ports 3-43 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 128 Working ports of the valve terminal and supply ports for the valve terminal with selector end plate (3/5) (12) (14) Fig. 3/10: Position of the pneumatic ports, part 1 (width 18 … 52 mm) 3-44 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 129 (12) Fig. 3/11: Position of the pneumatic ports, part 2 (width 18 … 52 mm) Width 65 mm (14) (14) (12) (12) Fig. 3/12: Position of the pneumatic ports, part 3 (width 65 mm) 3-45 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 130 Valve terminal 1 Exhaust tubing 3/5 Central pilot exhaust tubing Central exhaust line 3/5 Valve terminal 2 Pilot air exhaust tubing Fig. 3/13: Centrally ducted exhaust air with non-return valves 3-46 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 131: Connecting The Electric Cables

OFF procedures, are necessary for putting your ma- chine/system into a safe state in the event of an EMER- GENCY OFF (e.g. switching off the operating voltage for the valves and output modules, switching off or pres- sure). 3-47 Festo P.BE-VTSA-44-EN en 1312h English... - Page 132 30 m. Note For valves with Ident. Code SO, SQ, SP and SN (valves with switching position sensing via sensor), Festo recommends using lines with straight plugs. VTSA/VTSA-F valve terminal with CPX terminal: Instructions on connecting the operating voltage can be found in the CPX system description, chapter 3.

- Page 133 VTSA/VTSA-F valve terminal with CPX terminal: • Please note the supplementary earthing instructions in the CPX system description, chapter 3. This prevents interference from electromagnetic sources and ensures electromagnetic compatibility in accordance with EMC directives. 3-49 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 134 Valve terminal with M23 round Valve terminal with multi-pin multi-pin node plug multi-pin node node IC Earth terminal Internal earth terminal in the cage clamp multi-pin node Fig. 3/14: Earth terminals of the VTSA/VTSA-F valve terminal 3-50 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 135: Address Assignment Of The Valves

The following assignment applies: – solenoid coil 14 occupies the less significant address – solenoid coil 12 occupies the higher-value address Identification features: – colour of the solenoid coil contact housing in the man- ifold sub-base: black 3-51 Festo P.BE-VTSA-44-EN en 1312h English... - Page 136 (identifier: rating plate with black dot) Manifold sub-base (width 42 mm or 52 mm) which occupies two addresses Fig. 3/15: Example: address assignment of VTSA/VTSA-F valve terminal with 8 valve posi- tions, width 18 ... 52 mm (top view) 3-52 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 137 VIGM-...) or two addresses (manifold sub-base VIGI-...), irrespective of whether it is fitted with a valve or a blanking plate. The following allocation applies in this case: – coil 14: lower-value address – coil 12: higher-value address 3-53 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 138 Fig. 3/16: Example: address assignment of VTSA/VTSA-F valve terminal, width 65 mm, 8 valve positions (top view) Further instructions on addressing the VTSA/VTSA-F valve terminal with CPX terminal can be found in the description for the CPX I/O modules. 3-54 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 139: Commissioning

Commissioning Chapter 4 Commissioning Festo P.BE-VTSA-44-EN en 1312h English... - Page 140 ........4-18 4.5.2 Operating states of the pneumatic system ....4-19 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 141: Commissioning

LEDs and manual overrides to the solenoid coils – function impairments – operating states of the pneumatic system. Further information The commissioning procedure for the CPX terminal is de- scribed in the corresponding manual for the CPX bus node. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 142: General Instructions

Fig. 4/1). Pay attention to any electric signals present (e.g. after • EMERGENCY STOP). Exercise care and attention when switching on the com- • pressed air via the soft-start valve for gradual pressure build-up. Festo P.BE-VTSA-44-EN en 1312h English... - Page 143 82/84 12/14 12/14 Externally supplied pilot air, branched in front of the soft-start valve Soft-start valve of complete supply Fig. 4/1: Example of valve-cylinder combination with slow pressure build-up of the complete system Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 144: Manual Override (Mo)

By actuating the manual override, you can switch the valve without an electric signal. You only need to switch on the compressed air supply. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 145: Manual Override, Width 65 Mm

4.2.1 Manual override, width 18 ... 52mm Note If the VTSA/VTSA-F valve terminal is used in a dusty envir- onment, Festo recommends that you protect the manual overrides with cover caps VAMC-S6-CS against dirt and dust when the valve terminal has been commissioned. At the same time the manual overrides are protected against incorrect use. -

Page 146: Manual Override, Width 65 Mm

The position of the manual overrides on the intermediate plate and the valve terminal can be seen in the following im- ages: non-detenting manual override Fig. 4/3: Position of the manual overrides on the intermediate plate Festo P.BE-VTSA-44-EN en 1312h English... - Page 147 4. Commissioning LED and manual override for valve LED and manual override for valve solenoid coil 14 solenoid coil 12 Fig. 4/4: Position of the solenoid coils and manual overrides on the valve terminal Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 148: Checking The Valves And The Valve/Actuator Combination

Commissioning variants Commissioning the pneumatic components by means of the manual override is described below. The commissioning procedure for the CPX terminal is de- scribed in the corresponding manual for the CPX bus node. 4-10 Festo P.BE-VTSA-44-EN en 1312h English... - Page 149 A valve that has been switched by an electric signal cannot be reset by the manual override. The electric signal is dom- inant in this case. Reset the electric signal before actuating the manual • override. 4-11 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 150 If the manual override is in the actuated state, it is not pos- sible to reset the valve to its neutral position with an elec- tric signal. The manual override is dominant in this case. 4. Switch off the compressed air supply after testing the valves. 4-12 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 151 – returns to the rest spring resets the plun- position (not for ger of the manual over- bistable 5/2-way ride to the initial posi- valves (Ident. Code J, D) tion). Tab. 4/4: Non-detenting operation of the manual override 4-13 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 152 – returns to the rest position (not counter-clockwise through 90° for bistable 5/2-way valves as far as its stop. (Ident. Code J, D) • Then release the plunger. Tab. 4/5: Detenting operation of the manual override 4-14 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 153: Led Display Of The Valves

LED for solenoid coil 12 Valve width 26 mm LED for solenoid coil 14 Valve width 42 mm Valve width 18 mm Valve width 52 mm Fig. 4/5: Position of the LEDs (width 18 ... 52 mm) 4-15 Festo P.BE-VTSA-44-EN en 1312h English... - Page 154 – the pilot exhaust is blocked or – Servicing required With double-solenoid valves the LED lights up only when the electric pulse is present. Tab. 4/6: LED display of the solenoid coil (width 18 ... 52 mm) 4-16 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 155: Valves, Widths 65 Mm

– the pilot exhaust is blocked or – Servicing required With double-solenoid valves the LED lights up only when the electric pulse is present. Tab. 4/7: LED display for the switching status of the solenoid coil (width 65 mm) 4-17 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 156: Fault Finding

For valve terminals that are operated with external pilot air: • after switching on again, check the pilot pres- sure (set in accordance with the operating pres- sure if necessary, Chapter 3). Tab. 4/8: Function impairment of the pneumatic system 4-18 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 157: Operating States Of The Pneumatic System

Width 65 mm: Section 5.6.5) through isolating discs. Vacuum or external pilot air, pressure range Please observe the requirements for low-pressure Tab. A/5. operating the valve terminal with operation vacuum or low pressure Section 3.9). 4-19 Festo P.BE-VTSA-44-EN en 1312h English... - Page 158 Slow start-up after if control signals are applied, the EMERGENCY STOP pilot air must be present immediately after activation with the pilot pressure specified in Tab. A/5 at the very least Tab. 4/9: Pneumatic operating states 4-20 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 159: Conversion And Maintenance

Conversion and maintenance Chapter 5 Conversion and maintenance Festo P.BE-VTSA-44-EN en 1312h English... - Page 160 ........5-43 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 161: Conversion And Maintenance

Information for mounting/dismounting and connecting the electric components can be found in the CPX system descrip- tion. VTSA/VTSA-F valve terminals with multi-pin plug: Instructions on connecting the electric components can be found in the information supplied with the product. Festo P.BE-VTSA-44-EN en 1312h English... -

Page 162: General Preventive Action

Apply screws accurately to avoid damaging the thread. • Observe the specified tightening torques. • Check seals for damage (IP 65). • Make sure that the connecting surfaces are clean (avoid • contact errors and leakage). Festo P.BE-VTSA-44-EN en 1312h English... -

Page 163: Service And Maintenance Measures To Be Executed Regularly

Observe the tightening torque every six months system – of all housing screws – of all mounting screws. Electrical components Check every six months – the tightening torque of the cable connector (present with some plug connectors). Festo P.BE-VTSA-44-EN en 1312h English... -

Page 164: Dismantling The Valve Terminal

– Valves – Pressure regulators – Exhaust plates – Cover plates – Flow control valves – Exhaust port cover – Soft-start valve – Vertical pressure shut-off plates – Vertical supply plates Tab. 5/1: Pneumatic components Festo P.BE-VTSA-44-EN en 1312h English... - Page 165 Dismantling the valve terminal The procedure for dismantling the valve terminal is described in the corresponding assembly instructions. corresponding assembly instructions www.festo.com/sp enter search term: “CPX terminal with VTSA valve terminal” or “VTSA valve terminal” user documentation Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 166: Replacing The Solenoid Coil Fuse, Width 65 Mm

Fig. 5/1). – right: fuse for solenoid coil 14 – left: fuse for solenoid coil 12. 4. Insert the new fuse. 5. Close the cover. 6. To replace additional fuses repeat procedure 1 to 5. Festo P.BE-VTSA-44-EN en 1312h English... - Page 167 5. Conversion and maintenance Loosen the fastening screws in the Carefully remove the fuse from its cover base. Right fuse for solenoid coil 14 Left fuse for solenoid coil 12 Fig. 5/1: Replacing a solenoid coil fuse Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 168: Replacing Valve Terminal Components

Dismounting Proceed as follows: Use a screwdriver with a narrow blade to loosen the • mounting screws and remove the component from the manifold sub-base ( Fig. 5/2). 5-10 Festo P.BE-VTSA-44-EN en 1312h English... - Page 169 18 mm (VSVA-...-A2): 1.0 Nm (± 10 %) – valve width 26 mm (VSVA-...-A1): 2.0 Nm (± 10 %) – valve width 42 mm (VSVA-...-D1): 3.0 Nm (± 20 %) – valve width 52 mm (VSVA-...-D2): 6.5 Nm (± 20 %) 5-11 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 170: Replacing The Cover Plate With A Valve, Width 65 Mm

3. Place the intermediate solenoid plate on the manifold sub-base. 4. If applicable, place additional components on the inter- mediate solenoid plate and screw these components tight. 5. Fasten the valve. 5-12 Festo P.BE-VTSA-44-EN en 1312h English... - Page 171 5. Conversion and maintenance ISO valve If applicable components for vertical stacking Intermediate solenoid plate Manifold sub-base Fig. 5/3: Fitting the valve 5-13 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 172: Replacing/Adding Components For Vertical Stacking, Width 18

The printed part number on the regulator plate only refers to the standard configuration. When reordering pressure regu- lators with additional features, such as a lockable rotary knob, extended design etc., only use the VABF configurator. 5-14 Festo P.BE-VTSA-44-EN en 1312h English... - Page 173 The following component sequence is recommended for valve positions with vertical stacking: Manifold sub-base Optional Vertical supply plate Optional vertical pressure shut-off plate Optional flow control plate Optional pressure regulator plate Valve Fig. 5/4: Assembly sequence for vertical stacking 5-15 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 174 Note – Valve position with vertical pressure shut-off plate: vertical pressure shut-off plates are only intended in combination with VSVA valves from Festo. In the vertical pressure shut-off plate only duct 1 and 14 are blocked (not duct 12). The pilot air supply for the valve is branched internally...

- Page 175 1. Check the seals for damage. Replace any damaged seals. 2. Place the new component at the valve position, or, if applicable, onto a component already fitted. 3. Fasten the new component. Width across flats for the Allen key Tab. 5/3. 5-17 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 176 Item Width across flats of the Allen key Valve width 18 mm 26 mm 42 mm 52 mm Tab. 5/3: Vertical stacking 4. Fit the removed components in the same manner as be- fore. 5-18 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 177: Replacing/Adding Components For Vertical Stacking, Widths 65 Mm

1. Check the seals for damage. Replace damaged seals. 2. Place the new component on the intermediate solenoid plate or, if applicable, onto a component already fitted. 3. Fasten the new component. 4. Re-assemble the dismantled components in reverse or- der. 5-19 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 178: Replacing The Exhaust Plate Or Exhaust Port Cover, Widths 18

An overview is provided by table Tab. 1/3. Dismounting Proceed as follows: 1. Disconnect the electrical and pneumatic connections and then remove the valve terminal from its mounting surface Section 5.3). 5-20 Festo P.BE-VTSA-44-EN en 1312h English... - Page 179 Fig. 5/6: Position of the screw connectors with example of the right end plate 5. Pull the corresponding base component away from the adjacent base component. Mounting Proceed as follows: 1. Check the exposed seals for damage. Replace damaged seals. 5-21 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 180 2. Place the sealing plate on the guide pins of the manifold sub-base or pneumatic supply plate (sealing plates with duct separation Section 3.6). Manifold sub-base Guide pins Sealing plate (optionally with duct separation) Fig. 5/7: Mounting manifold sub-bases 5-22 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 181 4. Mount the valve terminal on the mounting surface corresponding assembly instructions www.festo.com/sp enter search term: “CPX terminal with VTSA valve terminal” or “VTSA valve terminal” user documentation). 5. Then install the electrical and pneumatic connections Section 3.10 and 3.11). 5-23 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 182: Replacing The Manifold Sub-Base Or Right End Plate, Size 65 Mm

3. Loosen the fuse covers for all of the manifold sub-bases that are to be dismantled. Doing this will create more space to dismantle the fittings. Tilt the covers downwards. 5-24 Festo P.BE-VTSA-44-EN en 1312h English... - Page 183 5. Conversion and maintenance Fig. 5/9: Loosening the fuse cover 4. Loosen the screws from the corresponding base compon- ents ( Fig. 5/10). 5-25 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 184 1. Make sure the seals are not damaged. Replace damaged seals. 2. Insert the seals into the grooves of supply ducts 1, 3, 5, 12, and 14 in the manifold sub-bases ( Fig. 5/11 and Fig. 5/12). 5-26 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 185 5. Conversion and maintenance Manifold sub-base Seals Groove for seal (duct 3 here) Fig. 5/11: Mounting manifold sub-bases Manifold sub-base Seals Right end plate Groove for seal (duct 3 here) Fig. 5/12: Mounting the right end plate 5-27 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 186 When doing this use the original socket head screws and spring washers. Tighten the screws lightly in turn to begin with and then tighten with 9 Nm ± 10 % (po- sition Fig. 5/14). 5-28 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 187 End plate Fig. 5/14: Fitting the end plate 5. Tilt all loosened fuse covers upwards: tighten the screws of the covers using 1 Nm ± 20 %. (Position Fig. 5/9). Fig. 5/15: Mounting manifold sub-bases 5-29 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 188 6. Mount the valve terminal on the mounting surface corresponding assembly instructions www.festo.com/sp enter search term: “CPX terminal with VTSA valve terminal” or “VTSA valve terminal” user documentation). 7. Then install the electrical and pneumatic connections Section 3.10 and 3.11). 5-30 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 189: Converting The Vtsa/Vtsa-F Valve Terminal

1. Please observe the general safety measures in sec- tion 5.1. 2. Use a screwdriver with a narrow blade to loosen the mounting screws for all the valves. Remove the valves from the manifold sub-bases ( Fig. 5/2). 5-31 Festo P.BE-VTSA-44-EN en 1312h English... - Page 190 4. If necessary, turn all of the valve seals according to the desired exhaust air variant ( Fig. 5/16). Identification label The seal is visible in the inspection window on control side 14 Inspection window on control side 12 Fig. 5/16: Turning the valve seal 5-32 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 191: Conversion, Internal Or External Pilot Air Supply, Width 18

In addition, you can also specify whether the pilot exhaust air should be vented via port (12) (deviating from the ISO stand- ard). End plates with axial supply ports VABE...R-... or VABE-...RZ-... The procedure for replacing the end plates is described in section 5.5.6. 5-33 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 192: Conversion, Internal Or External Pilot Air Supply, Widths 65 Mm

Feed the pilot air supply via port 12 or 14 on the right end plate. For internal pilot air supply: • Seal the ports 12 and 14 on the right end plate with blanking plugs (these need to be ordered separately). 5-34 Festo P.BE-VTSA-44-EN en 1312h English... - Page 193 8. Assemble the components in reverse order. Plug pin connection 14 Plug pin port P1 Plug pin connection 12 Fig. 5/17: Intermediate solenoid plate with the positions of the plug pins in air ducts 12, 14 and P1 5-35 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 194: Conversion, Vtsa/Vtsa-F Valve Terminal With Two Or More Pressure Zones, Width 18

– seal plate with duct separation VABD-...-10-P...-C – a pneumatic supply plate with exhaust plate or exhaust cover for each pressure zone VABF-...-1P1A... 5-36 Festo P.BE-VTSA-44-EN en 1312h English... - Page 195 3. Mount the valve terminal on the mounting surface corresponding assembly instructions www.festo.com/sp enter search term: “CPX terminal with VTSA valve terminal” or “VTSA valve terminal” user documentation). 4. Then install the electrical and pneumatic connections Section 3.3). 5-37 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 196 Supply plate with port (1) for supplying compressed air to the 2nd pressure zone Supply plate with port (1) for supplying compressed air to the 1st pressure zone Fig. 5/18: Example of a VTSA/VTSA-F valve terminal with 3 pressure zones 5-38 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 197: Conversion, Valve Terminal With 2 Pressure Zones, Widths 65 Mm

Exhaust duct 3 Fig. 5/19: Mounting the isolating disc for pressure zone separation (width 65 mm) The supply and exhaust is effected on the left-hand side via the adapter plate and via the right end plate. 5-39 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 198: Adding Valve Positions, Widths 18

VABB...-WT Tab. 5/5: Valve position extension Note If a manifold sub-base is inserted between existing mani- fold sub-bases, the address assignment of all the valves to the right of the inserted manifold sub-base changes. 5-40 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 199: Adding Valve Positions, Widths 65 Mm

5.6.7 Adding valve positions, widths 65 mm You can easily adapt the VTSA/VTSA-F valve terminal to the requirements of your machine or system by adding valve pos- itions. The smallest expansion unit is a manifold sub-base with one valve position. 5-41 Festo P.BE-VTSA-44-EN en 1312h English... - Page 200 Section 5.5.7). 2. Mount the corresponding components, such as vertical stacking components, valve or cover plate to the added valve position (mounting vertical stacking components Section 5.5.4, mounting the valve or cover plate Section 5.5.2). 5-42 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 201: Adding A Soft-Start Valve

5. Conversion and maintenance 5.6.8 Adding a soft-start valve The procedure for adding a soft-start valve is described in the assembly instructions VABV-S6-1Q-… 5-43 Festo P.BE-VTSA-44-EN en 1312h English... - Page 202 5. Conversion and maintenance 5-44 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 203: A. Technical Appendix

Technical appendix Appendix A Technical appendix Festo P.BE-VTSA-44-EN en 1312h English... - Page 204 ........... . A-26 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 205: A.1 Technical Data

The valves can be operated up to a temperature of –5 °C. In order to prevent the condensate and humidity from freezing, we recommend installation of a dryer, with which condensate and humidity can be removed. Festo P.BE-VTSA-44-EN en 1312h English... - Page 206 … + – Medium –5 50 °C Degree of protection IP 65 per DIN 60 529 (with cable from Festo accessories) Type 4 in accordance with NEMA Relative air humidity 90 % at 40 ºC Corrosion protection CRC 0 (per FN940070)

- Page 207 18 mm and 26 mm for two valve positions; width 42 mm, 52 mm and 65 mm for one valve position Tab. A/2: General technical data for the VTSA/VTSA-F valve terminal (continued) Festo P.BE-VTSA-44-EN en 1312h English...

- Page 208 ± 30 g at 11 ms duration; 5 shocks per direction 5 shocks per direction Continuous shock ± 15 g at 6 ms duration; 1000 shocks per direction Tab. A/4: Values for vibration and shock as per DIN/IEC68 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 209 (14) – reversible 2x3/2-way valves (Ident. Code P, Q, R): Port (3) or (5): –0.9 ... 10 Port (14): diagram Fig. A/1 Port (12): same pressure as at port (14) Festo P.BE-VTSA-44-EN en 1312h English...

- Page 210 – all pressure regulators: 0 ... 10 Manual override – Width 18 ... 52 mm – Non-detenting or turning with detent – 65 mm – Non-detenting Tab. A/5: Medium and pressure range of the VTSA/VTSA-F valve terminal Festo P.BE-VTSA-44-EN en 1312h English...

- Page 211 Fig. A/1: Required pilot pressure of the external pilot air supply for 2x2/2- and 2x3/2-way valves (Ident. Code VC, VV, K, H, N, P, Q and R) Note The fittings of the pneumatic ports cause a reduction in the nominal flow rate of the valves. Festo P.BE-VTSA-44-EN en 1312h English...

- Page 212 – Exhausted (E, SA, SE), pressurised (B) 1000 (700) 1350 (700) – exhausted/pressurised (SB) 700 (700) 700 (700) Ident. Code = Identification code Mid-position values are indicated in parenthesis Tab. A/6: Nominal flow rates of the valves VSVA-B-...(part1) A-10 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 213 2800 (1700) – pressurised 1 } 2, closed 4 } 5 (VG) 2300 (900) Ident. Code = Identification code Mid-position values are indicated in parenthesis Tab. A/7: Nominal flow rates of the valves VSVA-B-...(part2) A-11 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 214 Tab. A/8: Nominal flow rates of valves 65 mm wide Standard nominal flow rates [I/min], valves VSVA-B-... Soft-start valve Exhaust Pressurisation VABF-S6-1-... 3000 3300 Tab. A/9: Nominal flow rate of the soft-start valve VABF-S6-1-… A-12 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 215 12 / 40 — Measuring method 0 - 10 %, according to FN 942032 Tab. A/10: Valve switching times, valves VSVA-B-..., width 18 mm and 26 mm, nominal voltage 24 V DC and 110 V AC A-13 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 216 — / 8 — 5/3-way, closed 17 / 5/3-way, exhausted 18 / 5/3-way, pressurised 16 / Measuring method according to FN 942032 Tab. A/12: Valve switching times, valves 65 mm wide, nominal voltage 24 V A-14 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 217 Tab. A/13: Valve switching times, valves VSVA-B-..., width 42 mm and 52 mm, nominal voltage 110 V AC Soft-start valve Switching times [ms] Identifier in the type code VABF-S6-1-P5A4-... Valve Sensor Tab. A/14: Valve switching times, soft-start valve A-15 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 218 R7-...-6 ZN, ZNY reversible A-pressure regulator plate for port (4) 0.5 ... 6 bar R7-...-10 reversible A-pressure regulator plate for port (4) 0.5 ... 10 bar Tab. A/15: Pressure ranges of the pressure regulators A-16 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 219 10 bar P-pressure regulator, 18 mm wide Fig. A/3: Diagram: flow rate as a function of the output pressure of the 10 bar P-pres- sure regulator, 18 mm and 26 mm wide (identifier R1-...-10) A-17 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 220 10 bar P-pressure regulator, 52 mm wide Flow rate Fig. A/5: Diagram: flow rate as a function of the output pressure of the 6 bar and 10 bar P-pressure regulator, 52 mm wide (identifier R1-...) A-18 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 221 18 mm wide Fig. A/7: Diagram: flow rate as a function of the output pressure of the 10 bar A-, B- and AB-pressure regulator, 18 mm and 26 mm wide (identifier R2-...-10, R3-...-10, R4-...-10) A-19 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 222 Flow rate Fig. A/9: Diagram: flow rate as a function of the output pressure of the 6 bar and 10 bar A-, B- and AB pressure regulator, 52 mm wide (identifier R2-..., R3-... and R4-...) A-20 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 223 18 mm wide Fig. A/11: Diagram: flow rate as a function of the output pressure for the reversible 10 bar A-, B- and AB-pressure regulator, 18 mm and 26 mm wide (identifier R7-...-10, R6-...-10 and R5-...-10) A-21 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 224 Flow rate Fig. A/13: Diagram: flow rate as a function of the output pressure of the reversible 6 bar and 10 bar A-, B- and AB-pressure regulator, 52 mm wide (identifier R7-..., R6-... and R5-...) A-22 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 225 4 to 5 Rotations of the adjusting screw Fig. A/15: Diagram: flow rate as a function of flow control, width 42 mm (flow control plate identifier F1B1) A-23 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 226 F1B1) Flow Characteristic curve of the flow control plate Rotations of the adjusting screw Fig. A/17: Diagram: flow rate as a function of flow control, 65 mm wide (flow control plate GRO-ZP-3) A-24 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 227 The maximum length of the signal cable for VTSA/VTSA-F valve terminals with CPX terminal is 30 m. Tab. A/16: Technical data for the electric components A-25 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 228: A.2 Accessories

A. Technical appendix Note Information regarding the maximum expansion of the VTSA/VTSA-F valve terminal with CPX terminal can be found in chapter 1, Tab. 1/2, Tab. 1/3 and Tab. 1/4 Accessories Accessories www.festo.com/catalogue A-26 Festo P.BE-VTSA-44-EN en 1312h English... -

Page 229: B. Supplementary Component Overview

Supplementary component overview Appendix B Supplementary component overview Festo P.BE-VTSA-44-EN en 1312h English... - Page 230 ......Separating the VTSA/VTSA-F valve terminal from the CPX terminal ..B-14 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 231: B.1 Overview Of Valve Position Components

Ident. Code: M Design: – single solenoid 5/2-way valve – Pneumatic spring return. NOTE: The number of addresses assigned to this valve depends on the type of manifold sub-base Section 3.4). Tab. B/1: 5/2-way valves (part 1) Festo P.BE-VTSA-44-EN en 1312h English... - Page 232 – Valve with Ident. Code: SQ: Switching position sensing via inductive sensor with NPN output. NOTE: The number of addresses assigned to this valve depends on the type of manifold sub-base Section 3.4). Tab. B/1: 5/2-way valves (part 2) Festo P.BE-VTSA-44-EN en 1312h English...

- Page 233 – 5/3-way valve 12/14 – Normally exhausted (14) – Switching position 14 with memory function Ident. Code: SB (12) Version: – 5/3-way valve – Normally open from 1 12/14 (14) – Switching position 14 with memory function. Festo P.BE-VTSA-44-EN en 1312h English...

- Page 234 3/2-directional control valve (normally open) 12/14 – Pneumatic spring return. (14) Ident. Code: N Version: (14) (12) – Two monostable 3/2-directional control valves – Normally open – Pneumatic spring return. 12/14 (14) Tab. B/3: 2x3/2-way valves Festo P.BE-VTSA-44-EN en 1312h English...

- Page 235 – On control side 14, one reversible monostable 3/2-way valve (normally closed) – On control side 12, one reversible monostable 3/2-way valve (normally open) 33/55 110/114 (12) – Pneumatic spring return. (14) Tab. B/4: Reversible 2x3/2-way valves Festo P.BE-VTSA-44-EN en 1312h English...

- Page 236 The 2/2-way valves with Ident. Code VV are to be operated in a separate pressure zone with separate exhaust ducts (3) and (5) if the VTSA/VTSA-F valve terminal is equipped with other valve functions. Tab. B/5: 2x2/2-way valve Festo P.BE-VTSA-44-EN en 1312h English...

- Page 237 – with external pilot air supply (Ident. Code PM) Design: VABF-S6-1-P5A4-…12-4-1-N – Sensor with NPN output – with internal pilot air supply (Ident. Code PO) – with external pilot air supply (Ident. Code PK) Tab. B/6: Soft-start valves Festo P.BE-VTSA-44-EN en 1312h English...

- Page 238 H, K, N) is not permitted. Reversible 2x3/2-way valves (Ident. Code: P, Q, R) do not need a separate pressure zone in combination with these pressure regulators. Tab. B/7: Pressure regulator plates for regulating outputs (2) and (4) B-10 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 239 Ident. Code: ZV Function: – Plate with port (11) for supplying individual operating pressure and individual pilot air for 14 5 a valve position, duct 1 and 14 Tab. B/9: Vertical pressure supply plate B-11 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 240 B. Supplementary component overview Note The vertical pressure shut-off plates are only intended in combination with VSVA valves from Festo. In the vertical pressure shut-off plate only duct 1 and 14 are blocked (not duct 12). Vertical pressure shut-off plate...

- Page 241 – Vertical stacking consisting of component VABF-S4…-S and 5/2-way monostable valve with spring return – Optionally with switching position sensing in the valve via inductive sensor with PNP output Tab. B/12: Vertical stacking for pilot air disconnection B-13 Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 242: B.2 Separating The Vtsa/Vtsa-F Valve Terminal From The Cpx Terminal

2. Slacken the fittings between the pneumatic interface and manifold sub-base or pneumatic supply plate of the VTSA/VTSA-F valve terminal in a crosswise direction (pos- ition of the fittings Fig. B/2). 3. Then loosen the fittings. B-14 Festo P.BE-VTSA-44-EN en 1312h English... - Page 243 CPX system description. Mounting Proceed as follows: 1. Make sure the seals are not damaged. Replace damaged seals. 2. Place the seal onto the guide pins of the pneumatic inter- face. B-15 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 244 Fig. B/3: Mounting the VTSA/VTSA-F valve terminal on the pneumatic interface 3. Push the pneumatic interface together with the pneumatic manifold sub-bases, or the pneumatic supply plate. Make sure that the seal and the components are correctly posi- tioned. B-16 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 245 VTSA/VTSA-F valve terminal with CPX terminal. Informa- tion regarding the connection can be found: – in section 3.10 for the pneumatics – in the CPX system description for the electric compon- ents of the VTSA valve terminal with CPX terminal. B-17 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 246 B. Supplementary component overview B-18 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 247 Index Appendix C Index Festo P.BE-VTSA-44-EN en 1312h English...

-

Page 248: C. Index

............Festo P.BE-VTSA-44-EN en 1312h English... - Page 249 ........1-52 Current consumption ......A-25 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 250 ........A-25 Low-pressure operation ..... . 3-35, 4-19 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 251 ......A-25 Optimisation, Flow rate ......Festo P.BE-VTSA-44-EN en 1312h English...

- Page 252 Protection class ....... . . Festo P.BE-VTSA-44-EN en 1312h English...

- Page 253 ......Tubing connection ......3-40 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 254 ........1-57 Festo P.BE-VTSA-44-EN en 1312h English...

- Page 255 ......... . Festo P.BE-VTSA-44-EN en 1312h English...

- Page 256 C. Index C-10 Festo P.BE-VTSA-44-EN en 1312h English...

Need help?

Do you have a question about the VTSA Series and is the answer not in the manual?

Questions and answers