Summary of Contents for Danfoss PVE Series 4

- Page 1 MAKING MODERN LIVING POSSIBLE Technical Information Proportional Valve Group PVE, Series 4 for PVG 32/100/120 and PVHC powersolutions.danfoss.com...

- Page 2 PVE, Series 4 for PVG 32/100/120 and PVHC Revision History Table of Revisions Date Changed Jan 2014 Converted to Danfoss layout – DITA CMS March 2013 Back page matter change Aug 2012 Various changes, new articles about NP May 2012 Major update 520L0553 •...

-

Page 3: Table Of Contents

General Information List of abbreviations for PVG/PVE...............................5 Literature reference for PVG products............................6 Standards for PVE..................................... 7 PVE with connector variants.................................7 Warnings......................................7 PVE series 4 introduction................................7 PVE stands for PVE actuator .................................8 Overview......................................9 Functionality PVG functionality....................................10 PVE functionality.................................... 10 Hydraulic subsystems................................ - Page 4 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Contents PVE dimensions for PVG 32 and PVG 100..........................38 PVE dimensions for PVG 120..............................40 PVEO pinout.....................................41 PVEO connection....................................42 PVE standard connection data / pinout ..........................42 PVE standard connections..............................43 Standard PVE with DI................................43 Standard PVE with SP................................

-

Page 5: General Information

Normally Open solenoid valve in PVE Programmable Logical Circuit ® PLUS+1 Trademark for Danfoss controllers and programming tool POST Power On Self Test. Boot up evaluation for PVED Pilot Pressure. The oil gallery for PVE actuation Proportional Valve Basic module - valve slice... -

Page 6: Literature Reference For Pvg Products

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC General Information Abbreviation Description PVEP PVE variant PWM controled PVES PVE variant with 0-2% hysteresis PVEU PVE variant with US 0-10V Proportional multi-section Valve Group PVHC PV variant with Current controlled valve actuator Proportional Valve Manual control with handle Proportional Valve Pump side module.Inlet Proportional Valve end plate... -

Page 7: Standards For Pve

PVE series 4 introduction PVE Series 4 is the common name for the Danfoss PVG electrical actuator. This technical information covers our voltage controlled PVE and our current controlled PVHC actuator. For the PVHC please see in the PVHC sectionl. -

Page 8: Pve Stands For Pve Actuator

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC General Information PVE controlled PVG with PVSK PVE stands for PVE actuator The Danofss PVE is built on more than thirty years experience of electrical valve control and is the perfect fit for our high performance proportional valves PVG 32, PVG 100 and PVG 120, as it is for our EH steering. -

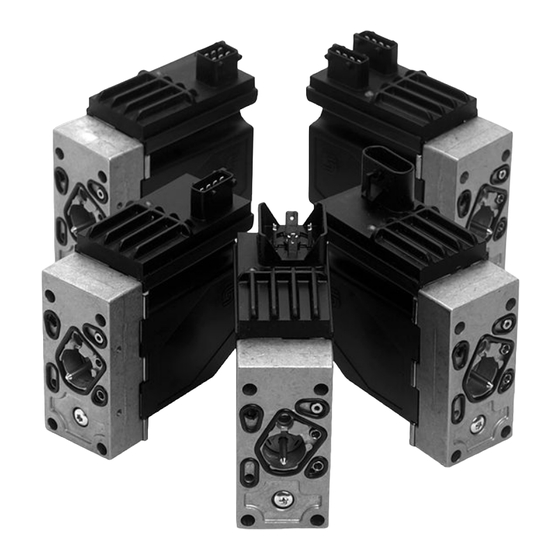

Page 9: Overview

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC General Information Overview The PVG is a sectional spool valve stack with up to 12 individually controlled proportional valves. The PVG with the PVE can be operated as single valves or several valves in cooperation. The oil flow out of the work section (A- or B-port) can be controlled by a combination of the following: •... -

Page 10: Functionality

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Functionality PVG functionality The PVG valve distributes oil from pump flow to a particular work function in the application via a specific valve section. This is done by moving the spool (PVBS). Depending on the choice of components the oil work flow enters the PVG through the PVP (proportional valve pump side module), a PVSK, a mid inlet or other system interface and enters the PVB (proportional valve basic module) via the P gallery and leaves through the T gallery. - Page 11 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Functionality Pilot oil diagram Set point Electronics Spool LVDT 1.0 [0.039] Tank V310073.A The hydraulic subsystem moves the spool and thereby opens the valve for work flow. The heart in the hydraulic subsystem is the solenoid valve bridge which controls the Pilot Pressure (Pp) on spool ends.

-

Page 12: Variant Of Hydraulic Subsystem: Pvea

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Functionality Variant of hydraulic subsystem: PVEA Hydraulic variant: PVEA NO2 and NO4 are replaced with orifices. Warning PVEA is not for use on PVG 100. Variant of hydraulic subsystem: PVHC The PVHC does not work as a PVE and does not have transducer, anti cavitation nor protection against tank pressure spikes. -

Page 13: Mechanical Subsystem

The standard PVE has an aluminum block for distributing pilot oil. PVE with anodized block are available. The connector gives the electrical interface to power and control system. Danfoss have a variety of connectors. We know that tradition and the aspects of serviceability are important when our customers choose. - Page 14 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Functionality The PVE features Closed Loop Control (CLC). This is made possible by on board electronics and an integrated feedback transducer that measures spool movement. The integrated electronics compensate for flow forces on the spool, internal leakage, changes in oil viscosity, pilot pressure, etc. This results in lower hysteresis and better resolution.

-

Page 15: Safety And Monitoring

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety and monitoring The choice of PVE also decides the level of feedback and safety. PVE are available with fault monitoring, spool direction indication, spool position feedback and separate float control. The fault monitoring is available in PVEA/H/S/P/U and is a utilization of the ASIC. -

Page 16: The Solenoid Valves Are Disabled When

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety and monitoring Warning Error pins from more PVEs may not be interconnected. Not activated error pins are connected to ground and will disable any active signal. Error pins are signal pins and can only supply very limited power consumption. -

Page 17: Direction Indication Feedback (-Di)

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety and monitoring Spool position feedback (-SP) 75% U 4.5V 2.5V 50% U 25% U 0.5V Spool travel Spool travel 7 mm 0 mm 7 mm Neutral 100% 100% A port B port Direction indication feedback (-DI) PVE with build in indication for spool movement direction are available. -

Page 18: Solenoid Disabling Function (-Np)

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety and monitoring Solenoid disabling function (-NP) PVEH-NP and PVEA-NP have a build in feature that disables the solenoids by US at 50% and gives a feedback on the solenoid status. This is done to facilitate application monitoring. The fault monitoring is still activated but the closed loop will remain passive until the control signal shifts. -

Page 19: Safety In Application

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety in application Building in safety All brands and all types of control valves (incl. proportional valves) can fail. Thus the necessary protection against the serious consequences of function failure should always be built into the system. For each application an assessment should be made for the consequences of pressure failure and uncontrolled or blocked movements. - Page 20 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety in application Control system example A Main power supply B Emergency stop/man present switch C HMI/Joystick control D Movement detection sensors E Main controller F PVG 32 control valve G Hydraulic deactivation 520L0553 •...

-

Page 21: Typical Wiring Block Diagram Example

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety in application Electrical block diagram for above illustration Main power supply Emergency stop and Motion detection sensor (battery) Man present switch Main control valve Supply Main controller Supply Neutral Signal HMI / Joystick Detection... - Page 22 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety in application Typical wiring block diagram example Man present Emergency stop switch PVE 1 Neutral detection / Supply control PVEH with AMP connector signal ≠ Delay neutral Error PVE 2 PVEH Neutral detection / Supply control with AMP...

-

Page 23: Example Of Fault Monitoring

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety in application Example of fault monitoring Similar to previous example using fault monitoring for deactivation of the hydraulic system with extra fault inputs using the PVE’s with DI (Direction Indication) function. Example of fault monitoring for deactivation of the hydraulic system Emergency Man present... -

Page 24: Pvg100 - Alternative Ls Dump Or Pilot Supply Disconnect

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Safety in application PVG100 – Alternative LS dump or pilot supply disconnect • PVPP, pilot oil supply shut off • External cartridge valve connecting LS Pressure to Tank • External cartridge valve connecting main Pressure to Tank PVG120 –... -

Page 25: Pve Control

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control PVE control by voltage • The PVE is controlled with a low current voltage signal. • The spool stroke is proportional to the control voltage (US). • The power is supplied via the supply wire (U or U •... -

Page 26: Atex Pve

Warning PVEM is not PLUS+1 compliant. ATEX PVE The Danfoss PVE ATEX portfolio has the same monitoring and control characteristics as the equivalent standard PVE. PVEU–PVE with fixed control signal range The PVEU (PVE 0-10V) is designed for PLC/ microcontroller(uC) control hence the U. The control signal U... -

Page 27: Pvep

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control Recommended PWM frequency for PVE (continued) PVE type PWM frequency PVEA/H/S/U > 1 kHz Warning The PWM is not evaluated by the PVE so variance/failure in period (T) will not be detected. PVEP The PVEP is designed for PWM control signals only. -

Page 28: Pveo

The solenoids might be activated by voltage down to 6 V. PVE for float spool Danfoss has developed two PVE variants to support the float spool. The float spool is a 4/4 spool, where as the standard is a 4/3 spool giving another characteristic and maximum stroke. These variations are covered by the built-in electronics. - Page 29 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control Variants of the float spool PVBS Float PVBS Progressive control Float control PVEH-F (6 pin) Dead band 0.8 mm : 25% -> 75% U to float pin Max float at 5.5 mm Has priority PVEH-F (4 pin) Dead band 1.5 mm...

- Page 30 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control PVE characteristic – Float B PVBS maximum float is 4.8 mm [0.19 in]. PVE has four pins. Float at U = 0.75 520L0553 • Rev GD • Jan 2014...

-

Page 31: Pvhc Control

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control PVHC control PVHC characteristic Spool stroke, mm Ideal curve Hysteresis Current in mA @ 12V @ 24V 500/1000 mA 280/560 mA 280/560 mA 500/1000 mA V310 000.A PVHC current response and hysteresis @ 25 bar Pp, 21 ctS, 25 °C. The PVHC control is done by dual Pulse Width Modulated (PVM) high current supply 100-400 Hz PWM control signals. -

Page 32: Example Of Pve Use

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control PVES Series 4 PVEA Series 4 PVEH Series 4 The PVES has an ASIC closed loop The PVEA has an ASIC closed loop The PVEH has an ASIC closed circuit and the NC-S solenoids. - Page 33 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE control 25 pin SUB-D connector with M3 screws (MIL-DTL-24308) PVEH/A/S PVEM PVEO V310116.A E – Emergency stop F – Signal output, fault monitoring NC – Not connected 520L0553 • Rev GD • Jan 2014...

-

Page 34: Technical Data

PVE operating parameters Declaration of conformity The PVEA/H/P/S/U have CE marking according to the EU directive EMC Directive 2004/108/EC. The declarations are available at Danfoss. The PVEO/M and PVHC are not subject to this directive. Warning The PVE is designed for use with pilot oil supply. Use without oil supply can harm the system. The PVE is designed for use with pilot pressure range 10 to 15 bar [145 to 220 psi]. -

Page 35: Pvhc Control Specification

10˚C [50˚F] 30˚C [86˚F] Filtering in the hydraulic system Required operating cleanliness level 18/16/13 (ISO 4406, 1999 version) For further information see Danfoss documentation Hydraulic Fluids and Lubricants, Technical Information 520L0463. Enclosure and connector versions Version of connector Hirschmann connector... -

Page 36: Pveo And Pvem Control Specification

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVHC reaction time (continued) From max. spool travel to neutral position at power off max. 0.175s rated 0.090s min. 0.065s PVEO and PVEM control specification PVEO and PVEM control specification Supply voltage U rated 12 V... -

Page 37: Pvep Control Specification

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVEA, PVEH, PVES and PVEU reaction time in sec. (minus PVG 120) Supply voltage Function PVEA PVEH, PVEP, Prop. fine PVES, PVEU Disconnected by Reaction time from neutral position max. -

Page 38: Pve Dimensions For Pvg 32 And Pvg 100

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVE dimensions for PVG 32 and PVG 100 PVE with Hirschmann connector PVE with AMP connector 520L0553 • Rev GD • Jan 2014... - Page 39 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVE with Deutsch connector PVHC with Deutsch connector PVHC with AMP connector 92.2 [3.63] 92.2 [3.63] V310 388 V310 387 520L0553 • Rev GD • Jan 2014...

-

Page 40: Pve Dimensions For Pvg 120

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVE dimensions for PVG 120 PVE with AMP connector for PVG 120 65 [2.56] 120 [4.72] V310320A PVE with Deutsch connector for PVG 120 65 [2.56] 120 [4.72] V310380A Please notice that connector needs extra space for mounting. -

Page 41: Pveo Pinout

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVG 120 and PVG 32 combo with Deutsch connector 362 [14.25] V310 383 PVEO pinout PVEO with direction indication (DI) connection Connector 1 AMP (grey) Connector 2 DI-B DI-A AMP (black) PVEO standard connection... -

Page 42: Pveo Connection

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data PVEO connection AMP version of PVEO–DI AMP version of PVEO/PVEO–R PVEO-DI DI-B Pin no. DI-A Grey connector Black connector P301 104 Hirschmann/DIN version of PVEO / PVEO–R Deutsch version of PVEO PVEO/PVEO-R 157-502.11 PVE standard connection data / pinout... -

Page 43: Pve Standard Connections

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data Control (U ) for standard mounted PVEH /PVEM float B, 4–pin version Function Voltage relative Neutral 0,5 • U Q: P → A 0,5 → 0,34 • U 50% →... -

Page 44: Standard Pve With Sp

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data • Ground pins are internally connected. • only supplies electronics for feedback signal and error pin on PVEA-DI / PVEH-DI. Two separate power sources can be used. AMP version: PVEA–DI/PVEH–DI Deutsch version: PVEA–DI/PVEH–DI PVEA-DI/PVEH-DI PVEA-DI/PVEH-DI... -

Page 45: Pvhc Connection

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data Deutsch version: PVES–NP PVES-SP connected Error PVHC connection • 100-400 Hz PWM control signals. • Each connector controls one direction and must have U and ground • No constraints on pin for U and ground. -

Page 46: Pvep With Controled Pwm

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC Technical Data AMP with separate float pin Deutsch version with separate float pin PVEH-F Not con- No con- nected Float nection Error Float Error 157-779 PVEP with controled PWM PVEP connection Connector PWM A Error... -

Page 47: Pve Warnings

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE warnings PVE warnings Warning Not applying to the Operational Conditions can compromise safety. All brands and all types of directional control valves – including proportional valves – can fail and cause serious damage. -

Page 48: Pve Code Numbers

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE code numbers PVE code numbers for PVG 32 and PVG 100 use Deutsch connector code numbers Feature std. float A float B Fast-no ramp memory Connector PVEA* active – 157B4792 157B4796 11105542... -

Page 49: Pve Code Numbers For Use On Pvg 120

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE code numbers Hirschmann/DIN connector code numbers (continued) Feature std. float B anodized ramp Connector passive 157B4833 PVEM 12 V 157B4116 157B4416 157B4516 24 V 157B4128 157B4428 157B4528 PVEO 12 V 157B4216 157B4266 157B4217... -

Page 50: Pve Accessories

Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE code numbers Hirschmann/DIN code numbers (continued) Feature anodized Connector 1x4 = one plug x four pins PVEO 12 V 155G4272 24 V 155G4274 Deutsch code numbers Feature anodized Connector 1x4 = one plug x four pins PVEH passive... -

Page 51: Connector Code Numbers At Other Suppliers

— AMP crim tool 169400-1 AMP die set for crimp tool 734253-0 These connector code numbers are not Danfoss numbers. PVED code numbers for use on PVG 32 and PVG 100 Cables code numbers for PVED-CC Feature Wire colors Description... - Page 52 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC PVE code numbers Cables code numbers for PVED-CC (continued) (continued) Feature Description Code number Connector AMP/black Terminator 157B4988 Deutsch 0.1m loop cable 11007531 Deutsch Terminator 11007561 Deutsch Terminator dummy 11007563 CAN Interface 10104136 CG 150 CAN USB interface...

- Page 53 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC 520L0553 • Rev GD • Jan 2014...

- Page 54 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC 520L0553 • Rev GD • Jan 2014...

- Page 55 Technical Information PVE, Series 4 for PVG 32/100/120 and PVHC 520L0553 • Rev GD • Jan 2014...

- Page 56 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

Need help?

Do you have a question about the PVE Series 4 and is the answer not in the manual?

Questions and answers