Summary of Contents for Rockwell Automation Allen-Bradley POINT Guard

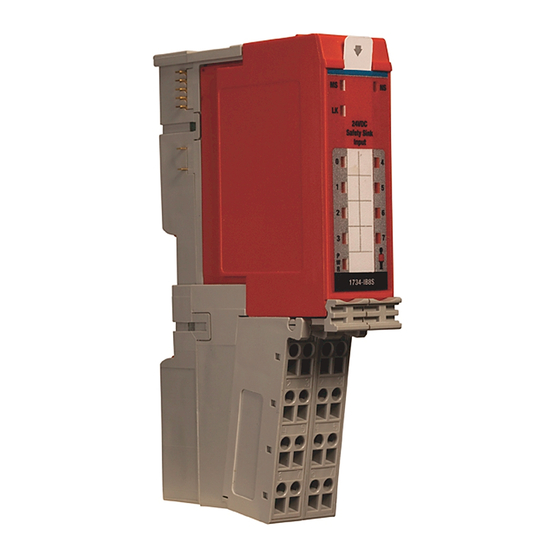

- Page 1 User Manual POINT Guard I/O Safety Modules Catalog Numbers 1734-IB8S, 1734-OB8S, 1734-IE4S...

- Page 2 Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE). Allen-Bradley, GuardLogix, Guardmaster, POINT Guard I/O, Rockwell Automation, Rockwell Software, RSNetWorx, SmartGuard, and Studio 5000 are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.

-

Page 3: Rockwell Automation Publication 1734-Um013J-En-P - July 2014

Corrected the Class ID in Table 15 Safety Analog Input Module (1734-IE4S) Updated Appendix C: Specifications Added specification for Sensor Supply Undercurrent Fault. Added Safety Data for Series B modules to Appendix C. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 4 Summary of Changes Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 5: Table Of Contents

Muting Lamp Operation (1734-IB8S) ......40 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 6 Configure the Safety Analog Inputs ......95 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 7 Controller on a DeviceNet Network......147 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 8 Configuration Assemblies ........194 Using Data from Modules Configured via the Generic Profile ..200 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 9 1734-UM013A-EN-P, February 2009 ......203 Index Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 10 Table of Contents Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 11: Preface

Rockwell Automation representative to confirm specifications of purchased product. Dimensions and weights are nominal and are not for manufacturing purposes, even when tolerances are shown. Consult your Rockwell Automation representative if you have any questions or comments. Also refer to the related documentation, listed in the page 13, as necessary. -

Page 12: Terminology

1. From the Quick Links list on http://www.ab.com, choose Product Compatibility and Download Center. 2. From the Compatibility Scenarios tab or the Get Downloads tab, search for and choose your product. 3. Click the download icon to access product release notes. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 13: Additional Resources

Describes the required media components and how to plan for and install these required components. Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system. Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details. - Page 14 Preface Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 15: Point Guard I/O Overview

Never use these products for an application involving serious risk to life or property without making sure that the system as a whole was designed to address the risks and that the Rockwell Automation products are properly rated and installed for the intended use within the overall equipment or system. - Page 16 24V DC, 3 mA. Other devices Evaluate whether devices used are appropriate to satisfy the requirements of safety category levels. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 17: Safety Precautions

EtherNet/IP or DeviceNet networks via these network adapters. Table 2 - Network Adapters Network System Adapter EtherNet/IP GuardLogix 1734-AENT (firmware revision 3 or later) 1734-AENTR DeviceNet SmartGuard or GuardLogix 1734-PDN (1) Not compatible with 1734-ADN, 1734-ADNX, 1734-APB, or 1734-ACNR adapters. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 18: 1734-Ib8S Digital Input Module Features

(channels), which allows use of the module for safety Category 3 and 4, and applications rated up to and including Performance Level e/ SIL CL3. • Safety outputs can be pulse-tested to detect field wiring short circuits to 24V DC. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 19: 1734-Ie4S Safety Analog Input Module Features

Studio 5000 environment. To find add-on profiles, go to http://www.rockwellautomation.com/support. (3) Dual-channel Analog (DCA) safety application instruction is available in RSLogix 5000 software, version 20 or later and Studio 5000 environment, version 21 and later. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 20: Cip Safety Architectures

POINT Guard I/O and POINT I/O Safety Communication Standard Communication Figure 2 - POINT Guard I/O Modules in DeviceNet Safety Architectures GuardLogix Controller SmartGuard Controller Guard I/O Safety Communication POINT Guard I/O and POINT I/O Standard Communication Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 21: Safety Application Requirements

SmartGuard 600 controller systems SmartGuard 600 Controllers Safety Reference Manual, publication 1752-RM001 You must read, understand, and fulfill the requirements detailed in these publications prior to operating a safety system that uses POINT Guard I/O modules. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 22 Chapter 1 POINT Guard I/O Overview Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 23: Safety Inputs, Safety Outputs, And Safety Data

(dual-channel complimentary) Figure 3 - Safety Status Networks Inputs to Network OFF Safety Status Input Output OFF 44076 The module is designed for use in applications where the safe state is the off state. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 24: Point Guard I/O Analog Input Module

Safety Input Terminal External Contact Where: T0 = Test Output 0 T1M = Test Output 1 with Muting T2 = Test Output 2 T3M = Test Output 3 with Muting I0…I7 = Safety Inputs Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 25 Figure 6 - Short-circuit between Input Signal Lines External Contact Short-circuit between Input Signal Lines and Power Supply (positive side) External Contact Short-circuit between Input Signal Lines 44079 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 26: Single-Channel Mode

Controller Safety Input 0 Status Test Output 0 Fault Detection External Device Input Terminal 0 Fault Detected Safety Safety Input 0 Data Network Data Sent to the Safety Input 0 Controller Status Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 27: Dual-Channel Mode And Discrepancy Time

Dual-channel Resultant Resultant Safety Safety Safety Safety Data Input 0 Data Input 1 Data Input 0 Status Input 1 Status Dual-channels, Equivalent Normal Fault Fault Normal Dual-channels, Complementary OFF Fault Normal Normal Fault Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 28: Dual-Channel, Equivalent

Data Controller Safety Input 0, 1 Status Fault Detection Discrepancy Time Safety Input 0 Safety Data Network Data Sent Safety Input 1 to the Data Controller Fault Detected Safety Input 0, 1 Status Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 29: Dual-Channels, Complementary

Data Controller Safety Input 0, 1 Status Fault Detection Discrepancy Time Safety Input 0 Data Safety Network Data Sent Safety Input 1 to the Data Controller Fault Detected Safety Input 0, 1 Status Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 30: Safety Input Fault Recovery

The input turns off only if the input contact remains off after the off delay time has elapsed. This helps prevent rapid changes of the input data due to contact bounce. Figure 11 - Off-delay Input Signal Safety Input Network Data Off-delay 44095 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 31: Safety Analog Inputs (1734-Ie4S)

• Input Range = 0…10V • Low Engineering value = 0 • High Engineering value = 10,000 If the incoming signal is 1V, the data is 1000. If the incoming signal is 5.5V, the data is 5500. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 32: Digital Input Filter

At powerup or after a reconfiguration, each sensor power supply is tested by being turned on for 500 ms. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 33: Channel Offset

Process alarms alert you when an analog input value has exceeded the configured high or low limits for each channel. Process alarms are set at four configurable trigger points. • High High alarm • High alarm • Low alarm • Low Low alarm Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 34: Using A Single-Channel Sensor

• If you are using a 3-wire sensor, you must verify its behavior to make sure that if it loses its ground connection, the signal is 0 (safe state) at the module input when the fault occurs. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 35: Dual-Channel Equivalent Mode

High Alarm Channel A 250 ms 250 ms 250 ms Channel B Low Low Alarm Low Alarm Fault Present Input Status Deadband Difference between Channel A and Channel B Discrepancy Time = 250 ms Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 36: Tachometer Mode

For PNP-style sensors (sensor sources), use rising edge. Depending on your application, you may need to install an appropriately-sized pull-up resistor for falling-edge signal measurements or a pull-down resistor for rising-edge signal measurements. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 37 The module reports 0 Hz until 1 Hz is detected. For example, if a falling or rising edge is not detected for 1.02 seconds after the previous edge, the module reports 0 Hz. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 38 After C, the Overfrequency condition can be cleared, provided you have used an alternate method to verify that the actual frequency is below 1 kHz. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 39: Safety Outputs (1734-Ob8S)

Normal Operation OUT0 Safety OUT1 Network Data Sent Safety Output to the 0, 1 Controller Status Fault Detection OUT0 OUT1 Safety Network Error Data Sent Detected Safety Output to the 0, 1 Controller Status Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 40: Safety Output Fault Recovery

The lamp test may not run immediately after the test output is energized. It starts at the next 3-second interval. To allow time for two consecutive test intervals, program a minimum Test Output On Time of 6 seconds. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 41 Before checking the state of the corresponding muting status, be sure the test IMPORTANT output is commanded on. Once the test output is commanded on, a maximum time of 6 seconds is required for the module to detect a burned-out lamp. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 42: I/O Status Data

When all inputs or outputs are normal, the respective combined status is ON. When one or more of them has an error, the respective combined status is OFF. This is known as the combined safety input status or combined safety output status. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 43: Analog I/O Status Data

– High and Low Alarms Overrange or Underrange – Dual-channel Tachometer Dual Low Inputs Detected – Tachometer Frequency Overrange or Underrange The alarm status is reported in the Alarm Status attribute for each channel. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 44 Chapter 2 Safety Inputs, Safety Outputs, and Safety Data Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 45: Choosing A Power Supply

To comply with UL restrictions, field power and connected devices must be powered from a single Class 2-compliant power supply. The following Rockwell Automation 1606 power supplies are SELV- and PELV-compliant, and they meet the isolation and output hold-off time requirements of the SmartGuard 600 controller: •... -

Page 46: Power Supply Examples

• POINT Guard I/O does not require separate POINTBus (communication) power-supply usage, separating it from any other POINT I/O modules, except when additional POINTBus power is required. • Do not apply AC voltage to POINT Guard I/O modules. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 47: Example 1: Isolating Field Power Segments

Guard I/O modules, while creating a separate power group for AC I/O modules. Group 1 Group 2 Group 3 120V 5V and 24V Supply 5V and 24V Supply for 5V and 120V AC for Standard I/O Safety Inputs and Outputs Supply Modules Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 48: Placing Series A Digital And Analog Modules

Placing Series B Digital Always install modules in accordance with their specified operating temperature ratings, as listed in Appendix C, and provide a minimum of 5.08 cm (2 in.) Modules clearance above the modules. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 49 Figure 23 - Placing Series B Digital Modules for up to 55 °C (131 °F) Operation 5.08 cm (2 in.) ATTENTION: Vertical orientation requires careful attention to design details and panel layout so that all modules in the stack operate within their rated operating temperature range. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 50 Chapter 3 Guidelines for Placing Power Supplies and Modules in a System Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 51 Connect the Removable Terminal Block Remove a Mounting Base Wire Modules Connection Details Wiring Examples Figure 24 - POINT Guard I/O Modules Slide-in Writable Label Module Locking Mechanism Insertable I/O Module Mounting Base 31867-M Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 52: Precautions

140% of the rated voltage when applied in Zone 2 environments. • This device must be used only with ATEX-certified Rockwell Automation terminal bases. • Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous. -

Page 53: North American Hazardous Location Approval

In addition to this publication, see the following: • Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1, for additional installation requirements. • NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 54: Preventing Electrostatic Discharge

POINT I/O one-piece mounting base (catalog number 1734-TOP, 1734-TOPS, 1734-TOP3, or 1734-TOP3S). You need two mounting base assemblies for each POINT Guard I/O module. Do IMPORTANT not use 1734-TB3 or 1734-TB3S mounting base assemblies. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 55: Connect The Module To The Mounting Base

Be sure that power is removed or the area is nonhazardous before proceeding. Repeated electrical arcing causes excessive wear to contacts on both the module and its mating connector. Worn contacts may create electrical resistance that can affect module operation. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 56: Connect The Removable Terminal Block

WARNING: When you connect or disconnect the removable terminal block (RTB) with field-side power applied, an electrical arc can occur. This could cause an explosion in hazardous location installations. Be sure that power is removed or the area is nonhazardous before proceeding. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 57: Remove A Mounting Base

3. Use a screwdriver to rotate the orange DIN-rail locking screw on the mounting base to a vertical position, noting this releases the locking mechanism. 4. Lift the mounting base off the DIN rail. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 58: Wire Modules

DIN rail materials (for example, aluminum or plastic) that can corrode, oxidize, or are poor conductors, can result in improper or intermittent grounding. Secure DIN rail to mounting surface approximately every 200 mm (7.8 in.) and use end-anchors appropriately. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 59: Terminal Layout

T3M = Test Output 3 with Muting I0…I7 = Inputs 0…7 COM = Supply Common Figure 26 - 1734-OB8S Field Connections 1734-TOP and 1734-TB Bases Shown Where: O0…O7 = Safety Outputs 0…7 COM = Supply Common Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 60: Connection Details

Schematic Diagram Safety Test Output Category Push Button Connect the push button between 24V DC and I0. 24V DC Connect the push button between I0 and T0. T0 must be configured as test pulse. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 61 I1 and T1. Light Curtain Connect the OSSD1 and OSSD2 to I0 and 3 or 4 based on I1, respectively. Connect the 24V power light curtain supply commons. being used In - Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 62: Wiring Examples

Pulse Test Output Test Output 1 Test Output 1 Mode Pulse Test Output Test Output 2 Test Output 2 Mode Power Supply Output Test Output 3 Test Output 3 Mode Power Supply Output Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 63: Single-Channel Safety Contactor

Figure 29 - POINT Guard I/O Module Wiring (single safety contact) Where: O0…O7 = Safety Outputs COM = Common Controller Parameter Name Configuration Setting Configuration Safety Output 0 Safety Output 0 Point Mode Safety Pulse Test Point Operation Type Single Channel Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 64: Dual-Channel Safety Contactors

COM = Common Controller Parameter Name Configuration Setting Configuration Safety Output 0 Safety Output 0 Point Mode Safety Pulse Test Point Operation Type Dual-channel Safety Output 1 Safety Output 1 Point Mode Safety Pulse Test Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 65: Safety Analog Input Wiring

When the module is configured as the source for sensor power, a short-circuit is detected at powerup (Cat. 2). However, when an external power supply is used, this fault must be detected by another means. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 66 For analog voltage-output sensors, the signal levels for operation for the application must be outside the signal level when the signal is not present, for example, when the wire is broken. Figure 43 Figure 44 on page 72 for tachometer wiring detail. Follow the Guidelines for Wiring Safety Analog Inputs on page Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 67 Common Cable Shield Signal Return and Common are at the same potential. Figure 43 Figure 44 on page 72 for tachometer wiring detail. Follow the Guidelines for Wiring Safety Analog Inputs on page Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 68 Field sensors are monitoring the same signal in a redundant configuration. You must configure a safety deadband between the two signals to achieve SIL 3. Follow the Guidelines for Wiring Safety Analog Inputs on page Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 69 Field sensors are monitoring the same signal in a redundant configuration. You must configure a safety discrepancy deadband between the two signals to achieve SIL 3. Follow the Guidelines for Wiring Safety Analog Inputs on page Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 70 Field sensors are monitoring the same signal in a redundant configuration. You must configure a safety discrepancy deadband between the two signals to achieve SIL 3. Follow the Guidelines for Wiring Safety Analog Inputs on page Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 71 Figure 42 - 4-wire Current Sensor (SIL 2) with External Power Supply 1734-TB Terminal Bases Signal (V) 4-wire Sensor Signal Return +24V Cable Shield Signal Return and Common are at the same potential. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 72 1734-TOP3 Terminal Bases (PNP-type) Metal Oxide or Carbon Composition Transistor Pull-up Resistor Pull- down Edge-to-edge Time Measured Here 1734-IE4S with Trigger = Rising Edge Follow the Guidelines for Wiring Safety Analog Inputs on page Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 73: Setting Up The Module

Add and Configure the Ethernet Bridge Module. Add and Configure the 1734 Ethernet Adapter. Add and Configure Safety Digital Input Modules. Add and Configure Safety Digital Output Modules. 5. Add and Configure Safety Analog Input Modules Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 74: Add And Configure The Ethernet Bridge Module

In the Name field of the New Module dialog box, type the name of the Ethernet bridge module. b. In the Description field, type an optional description. c. In the IP Address field, type the IP address. d. In the Slot field, choose the slot number. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 75: Add And Configure The 1734 Ethernet Adapter

1. Right-click the Ethernet connection and choose New Module. Ethernet Adapter 2. On the Select Module dialog box, check Communication and Allen-Bradley. 3. Choose an Ethernet adapter from the list and click Create. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 76 Compatible Module Controller will check module type and revision for compatibility. Compatible modules that match or are newer will be accepted. Disable Keying Controller will check module type, but will accept any version. Do not choose Disable Keying. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 77: Add And Configure Safety Digital Input Modules

Add the Safety Digital Input Module Follow these steps to add the POINT Guard I/O safety digital input module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 78 3. Select an input module and click Create. 4. Specify the module’s general properties. a. In the Name field of the New Module dialog box, type a unique name for the input module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 79 This selection directs the controller to configure the module. External Means This selection directs the controller to establish a safety input connection only, and the controller will not configure the module or control the Test Outputs. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 80 (1) To have this choice from the pull-down menu, you must choose ‘This Controller’ from the Configured By pull-down menu. When test outputs are configured as standard outputs, they IMPORTANT must not be used for safety purposes. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 81 • Status tags for each of the test outputs. (1) When using combined status, use explicit messaging to read individual point status for diagnostic purposes. h. From the Data Format pull-down menu, use the default ‘Integer’ . Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 82: Configure The Safety Digital Inputs

The I/O Configuration tree displays the module. Configure the Safety Digital Inputs Follow this procedure to configure the safety digital inputs. 1. From the Module Properties dialog box, click the Input Configuration tab. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 83 Configuring discrepancy time on safety I/O modules masks input IMPORTANT discrepancies detected by the controller safety instructions. Status can be read by the controller to obtain this fault information. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 84 Filter time is ON to OFF transition. Input must be low after input delay has elapsed before it is set logic 0. This delay time is configured per channel with each channel specifically tuned to match the characteristics of the field device, for maximum performance. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 85: Configure The Test Outputs

If communication to the module times out, you can set the test outputs to Clear OFF (default) or Hold Last State. For more information, see Appendix 3. Click Apply. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 86: Add And Configure Safety Digital Output Modules

Follow these steps to add and configure POINT Guard I/O safety modules. 1. Right-click the POINT I/O Chassis and choose New Module. 2. On the Select Module dialog box, select a safety output module and click OK. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 87 4. Under Module Definition, click Change to edit the module’s settings. a. In the Series field, choose the output module’s series letter. b. In the Revision fields, choose the output module’s revision numbers. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 88 Selecting Safety creates output tags and enables these outputs for use in the Safety Task. None Automatically selected when Configured By = External. Selecting None results in an input only connection to the module. Status is read, but no outputs are written. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 89 (1) When using combined status, use explicit messaging to read individual point status for diagnostic purposes. h. From the Data Format pull-down menu, use the default ‘Integer’ . 5. Click OK to return to the Module Properties dialog box. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 90: Configure The Safety Digital Outputs

The output point is enabled and performs a pulse test on the output. When the output is Test energized, the output pulses low briefly. The pulse test detects whether the output is functioning properly. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 91: Add And Configure Safety Analog Input Modules

Follow these steps to add the POINT Guard I/O safety analog input module. 1. Right-click the POINT I/O Chassis and choose New Module. 2. From the Select Module dialog box, select an analog input module and click Create. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 92 SNN of the lowest safety node on the network. 4. Click Change to open the Module Definition dialog box. a. In the Series field, choose the analog input module’s series letter. b. In the Revision fields, choose the module’s revision numbers. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 93 From the Data Format pull-down menu, use the default ‘Integer’ . 5. Click OK to return to the Module Properties dialog box. 6. Click OK again to apply your changes. The I/O Configuration tree displays the 1734-IE4S module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 94: Configure The Safety Analog Input Channel Operation

Configure a deadband value for applications that use two sensors to measure the same variable; otherwise, spurious trips may occur. 5. If desired, configure a Channel Offset for the paired safety analog inputs. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 95: Configure The Safety Analog Inputs

When you click Apply, channel 1 is set to the same value as channel 0 and channel 3 is set to the same value as channel 2 if the channel operation is configured as dual-channel equivalent. 3. Configure the module for current, voltage, or tachometer inputs. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 96: Configure Safety Analog Input Alarms (Optional)

Instead, to facilitate troubleshooting, use the application program to check for high and low alarm values via the Dual Channel Analog Input instruction or other data comparison instructions. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 97 These values are based on the Engineering units configured on page For more information on this feature, see Process Alarms on page 33 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 98: Configure Tachometer Operation

To use this feature, you must use Channels 0 and 1 together, and Channels 2 and 3 together. Channels 0 and 1 have the same setting and channels 2 and 3 have the same setting. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 99 When the module is configured as dual-channel Equivalent, channels 0 and 1 have the same setting and channels 2 and 3 have the same setting. The tachometer On Level must be greater than the tachometer Off Level. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 100: Values And States Of Tags

Controls the safety output. SAFETY • ON: 1 OFF: 0 Digital Output Data Standard Output Data Controls the test output when Test Output mode is set to a standard output. STANDARD • ON: 1 OFF: 0 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 101 ‘STANDARD’ denotes additional information that must not be directly used for safety functions. ATTENTION: Do not rely on data readback to detect faults. You must monitor status bits to detect faults. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 102: Configure Safety Connections

50…100 ms. An input module with a light curtain guarding a hazard may need the fastest response possible. Selecting appropriate RPIs results in a system with maximum (best) performance. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 103: Configuration Ownership

If any differences are detected, the connection between the GuardLogix controller and the POINT Guard I/O module is lost, and the yellow yield icon appears in the controller project tree. For more information, see Chapter Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 104: Saving And Downloading The Module Configuration

The module receives it's field power from the 24V DC connection to the power supply feeding it, for example a 1734-AENT, 1734-FPD, or 1734-EP24DC module. Make sure that 24V DC power is connected to these modules before performing a flash update of the 1734-IE4S. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 105: Before You Begin

• Personal computer with a Microsoft Windows 2000, Microsoft Windows 2000 Terminal Server, or Microsoft Windows XP operating system • 1734-PDN adapter • SmartGuard controller and POINT Guard I/O module EDS files Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 106: Set The Node Address

SNN. Follow these steps to set the node address with the node commissioning tool. 1. Choose Start>Programs>Rockwell Software>RSNetWorx>DeviceNet Node Commissioning Tool. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 107 5. Enter the current address for the device. An out-of-box device uses address 63. 6. Click OK 7. Enter the new address for the device. 8. Click Apply. 9. Look for confirmation in the messages section. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 108: Auto-Addressing With A 1734-Pdn Adapter

A. Set the address of the leftmost I/O module. B. When you configure the leftmost module, set Sequential AutoAddress to ‘Sequential Address’ . The module sequences the rest of the modules to its right in the group. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 109: Set Up Your Devicenet Network

If RSLinx software finds the nodes on the DeviceNet network, RSNetWorx for DeviceNet software also finds the nodes. 2. Open RSNetWorx for DeviceNet software. 3. From the Networks menu, choose Online. 4. Select the SmartGuard driver and click OK. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 110: Configure The Point Guard I/O Modules

From the Safety Configuration tab, you can configure the module’s safety inputs and outputs. I/O Modules Configure Digital Safety Inputs and Test Outputs 1. Double-click the POINT Guard I/O digital input module to open the Properties dialog box. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 111 (positive side) and short-circuits between input signal lines can be detected. Safety A solid-state output safety sensor is connected. Standard A standard device, such as a reset switch, is connected. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 112 4. If you are pulse-testing the module, edit the parameters so that the channels are pulse tested by Test sources 0 and 1, respectively. 5. Double-click General to edit the Input Error Latch Time, if desired. The default value is 1000 ms. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 113: Configure Digital Safety Outputs

Safety Output Error Latch 0…65,530 ms Safety output errors are latched for this time. 1000 ms Time (in 10 ms increments) 2. Double-click Output Error Latch Time to change from the default value (1000ms), if desired. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 114: Configure Safety Analog Inputs

Configure Safety Analog Inputs Follow these steps to configure a 1734-IE4S module. 1. Double-click the POINT Guard I/O analog module to open the Properties dialog box. 2. Click the Safety Configuration tab. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 115 Channel Offset -32768…32767 Offset value for dual channel mode only. Configure an offset when differences in the sensors (in engineering units) nominal input signals would otherwise exceed the desired deadband. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 116 Guard Analog Input module. This allows the module to detect a loss of sensor power. (1) For more information on the filter frequencies and step response, see the technical specifications for the 1734-IE4S module, beginning on page 164. (2) 1000 for Tachometer mode. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 117 • These values are based on the Engineering units Low Alarm -32768…32767 High High/Low Low Alarm 0…32767 Deadband on the High High and Low Low alarms. Deadband High/Low Alarm Deadband 0…32767 Deadband on the High and Low alarms. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 118 This is the voltage at which the module considers the tachometer sensor to be ON for tachometer (in 1 V increments) speed calculation purposes. The Tachometer On Level must be greater than the Tachometer Off Level. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 119: Configure The Smartguard Controller

Set Up the Input and Output Connections 1. In RSNetWorx for DeviceNet software, right-click the SmartGuard controller and choose Properties. 2. Click the Safety Connection tab to see a list of all Safety I/O modules currently in your project. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 120 3. Right-click the POINT Guard I/O module and choose Add Connection. The Add Safety Connection dialog box appears. You can add individual safety connections for the inputs and outputs. The SmartGuard 600 controller can have up to 32 connections. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 121 6. From the Configuration pull-down menu, for this example choose Configuration signature must match. 7. In the Requested Packet Interval (RPI) box, enter 10 ms. 8. In the Connection Reaction Time Limit (CRTL), enter 40.1 ms. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 122 5 bytes. 11. Click Apply. For further details, see the SmartGuard 600 Controllers User Manual, publication 1752-UM001, and SmartGuard 600 Controllers Safety Reference Manual, publication 1752-RM001. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 123: Complete The Set Up Of The Smartguard Controller

2. Place RSNetWorx from DeviceNet software back into Online mode. a. If you see this dialog box, click Yes to save changes. b. Click OK to upload or download device information. You see the following nodes after the browse. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 124: Save And Download Module Configuration

If any of these change, the connection between the SmartGuard controller and the POINT Guard I/O module is lost, and a yellow yield icon appears in the RSNetWorx for DeviceNet tree. For more information, see Chapter Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 125: Configure The Module In Rsnetworx For Devicenet Software

2. Configure the module’s inputs and outputs. See the following sections: • Configure Digital Safety Inputs and Test Outputs on page 110 Configure Digital Safety Outputs on page 113 • • Configure Safety Analog Inputs on page 114 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 126: Add The Point Guard I/O Module To The Controller Project

New Module. 2. In the Select Module Type dialog box, check Safety and Allen-Bradley. 3. Select the Generic DeviceNet Safety Module and click Create. 4. On the New Module dialog box, click Change. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 127 5. On the Module Definition dialog box, set these parameters for your module. Cat. No. Product Type Product Code 1734-IB8S 1734-OB8S 1734-IE4S 1734-IB8S Module 1734-IE4S Module 6. Click the Connection tab. 7. Set the Configuration Assembly Instance to 864 for all POINT Guard modules. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 128 Table 10 - 1734-IE4S Output Assemblies Safety Output Connection Output Assembly Safety Output Assembly Safety Size Input Number Output Number Safety Tachometer 199 (C7h) 770 (302h) Individual members of each assembly are listed in Appendix Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 129: Complete The Safety Configuration

1. In RSNetWorx for DeviceNet software, double-click the module. 2. On the Safety tab, click Copy Signature. 3. In the Logix Designer application, right-click the DEVICENET- SAFETYMODULE and choose Properties. 4. On the Safety tab, check the Configuration Signature checkbox. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 130 5. Click Paste. 6. In RSNetWorx for DeviceNet software, click Copy to copy the safety network number. 7. On the General tab in the Logix Designer application, click next to the safety network number field. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 131: Download The Devicenet Network Configuration

You must fully test your application prior to safety-locking your devices. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 132: Determine If Devices Can Be Verified

Safety Locked The device is already locked. To return to RSNetWorx for DeviceNet software so that you can correct the status of the indicated devices, close the Safety Device Verification Wizard by clicking Cancel. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 133: Select Devices To Verify

The device is not safety-locked, but the device does not support verification via the Safety Device Verification Wizard. Consult your user documentation for information on how to verify this device. Once the device has been verified, it can be safety-locked by the wizard. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 134: Review The Safety Device Verification Reports

No devices are ready to be the Finish dialog box. safety-locked Review the Safety Device Verification Reports The Review page displays safety devices with status of either Verify FAILED or Ready to be Safety Locked. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 135: Lock Safety Devices

3. Click Next. The wizard performs a final comparison of the configuration signature in each safety device to its configuration signature in RSNetWorx for DeviceNet software before locking the device. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 136 5. Click Finish to close the wizard. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 137: The Safety Network Number

(SNN). The module number and SNN make up the safety module’s DeviceID. Safety devices require this more complex identifier to make sure that duplicate module numbers do not compromise communication between the correct safety devices. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 138: Manually Setting The Safety Network Number

And to keep integrity, the setting of the module’s SNN is required to be a manual action. This manual action is to use the ‘set’ function on an out-of-box POINT Guard I/O module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 139: Resetting A Module To Out-Of-Box Condition

Local is displayed. When a second device owns the configuration, Remote is displayed, along with the safety network number (SNN), and node address or slot number of the configuration owner. Communication error is displayed if the module read fails. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 140: By Using Rsnetworx For Devicenet Software

3. Click Reset Ownership. By Using RSNetWorx for DeviceNet Software Follow these steps to reset the module to an out-of-box condition. 1. Right-click the module and choose Reset Safety Device. 2. Check all of the options. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 141: Replacing A Module In A Guardlogix System On An Ethernet/Ip

Table 11 to replace a POINT Guard I/O module based on your scenario. Once you have completed the steps in the scenario correctly, the DeviceID will match the original, enabling the safety Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 142 1. Remove the old I/O module and install the new module. 2. Right-click the replacement POINT Guard I/O module and choose Properties. 3. Click to the right of the safety network number to open the Safety Network Number dialog box. 4. Click Set. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 143 1. Remove the old I/O module and install the new module. 2. Right-click your POINT Guard I/O module and choose Properties. 3. Click the Safety tab. 4. Click Reset Ownership. 5. Click OK. 6. Right-click your module and choose Properties. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 144 Scenario 3 - Replacement Module SNN Is Different from Original and No Safety Signature Exists 1. Remove the old I/O module and install the new module. 2. Right-click your POINT Guard I/O module and choose Properties. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 145: Replacement With 'Configure Always' Enabled

• The module is in out-of-box condition or has an SNN that matches the configuration. If the project is configured for ‘Configure Always’ , follow the appropriate steps to replace a POINT Guard I/O module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 146 3. Click the Safety tab. 4. Click Reset Ownership. 5. Click OK. 6. Follow your company-prescribed procedures to functionally test the replaced I/O module and system and to authorize the system for use. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 147: Replacing A Module When Using A Smartguard Or Guardlogix

3. Right-click the module and choose Download to Device. 4. Click Yes to confirm. 5. Click Download on the Safety Network Number Mismatch dialog box to set the SNN on the replacement module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 148 SNN and configuration signature now match that of the original. If you are already connected to the controller, a connection is made. The controller does not need to be taken out of Run mode to download to the replacement module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 149 After the download is complete, place the controller back in Run mode and the connection to the replacement module is established. 9. Follow your company-prescribed procedures to functionally test the replaced I/O module and system and to authorize the system for use. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 150 Chapter 8 Replacing POINT Guard I/O Modules Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 151 Input 0 Input 2 Input/Output 1 Input/Output 5 Input 1 Input 3 Input/Output 2 Input/Output 6 Sensor 0 Sensor 2 Input/Output 3 Input/Output 7 Sensor 1 Sensor 3 Power Power 1734-IB8S or 1734-OB8S 1734-IE4S Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 152: Module

Valid configuration, locked by a network configuration tool, such as RSNetWorx software. Flashing yellow Not locked. None. Valid configuration by a network configuration tool, such as RSNetWorx software. (1) Not applicable when used with GuardLogix controllers. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 153: Power

Flashing red A fault in the partner input circuit of a dual-input configuration has been Check the field wiring and verify your configuration for the partner detected. circuit. If no problem found, replace module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 154: 1734-Ob8S Safety Output Status

Flashing red A fault in the partner output circuit of a dual-output configuration Check the circuit wiring and end device of the partner. If no problem has been detected. found, replace module. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 155: Message Instructions

• If any status bit goes to a value of 0 (0 = error, 1 = no error), use the status bit to condition your message instruction as follows. • Place these rungs in the standard task. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 156: Configure The Message Instruction

This example illustrates values you enter to determine the reason for the fault on Output 3. Figure 48 - Message Instruction Configuration Example When entering the Instance value, enter the input/output point plus 1 In this example, Output Point 3 is Instance 4. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 157: Class, Instance, And Attribute Data For I/O Modules

02: Over current detected 03: Short circuit detected 04: Output ON error 05: Error in the other dual channel output 06: N/A 07: N/A 08: Dual channel violation 09: Short circuit detected at safety output Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 158 (1) See the fault code definitions in Table 16 for details. (2) Missing clock, watchdog timeout. (3) For this instance, specify the Destination Tag to be a SINT[6]. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 159 Check field power supply and wiring Startup 3.3V over/under OV-UV detector failed startup test If the problem persists, replace module error Sensor power/input wiring Sensor power to input signal violation detected Check field wiring error Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 160 Appendix B Get I/O Diagnostic Status from Modules in Logix Systems Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 161: Technical Specifications For Series A Modules

25 mA (to avoid fault when used as a muted lamp output) Current, min (when used to control muting lamp) 5 mA (at which fault indication is generated when used as a muted lamp output) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 162 (2) Input off-to-on filter time is the time from a valid input signal to recognition by the module. Input on-to-off time is the time from a valid input signal to recognition by the module. (3) Use this conductor category information for planning conductor routing. Refer to the Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 163: Safety Digital Output Module Specifications

0…126 ms (in 6 ms increments) Input filter time, ON to OFF Terminal base screw torque See terminal base specifications Indicators 1 yellow lock status indicator 1 green/yellow power status indicator 8 I/O channel status indicators Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 164: Safety Analog Input Module Specifications

12 bits Filter Single-pole anti-aliasing filter: • Filter frequency = 10 Hz followed by four-pole digital filter Available corner frequencies, approx. • 1 Hz • 10 Hz • 5 Hz • 50 Hz Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 165 Shielded on signal ports Wire size Determined by installed terminal block Weight, approx. 68 g (2.4 oz) Dimensions (HxWxD), approx. 77 x 25 x 55 mm (3.03 x 0.98 x 2.17 in.) (without terminal block) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 166 (2) Use this conductor category information for planning conductor routing. Refer to the Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1. (3) For more information, see Figure Accuracy Drift vs Temperature (Current mode) on page 172. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 167 50 Hz 10 Hz 1 Hz 5 Hz 0 ->1= ~25 ms 0 ->2= ~72 ms 0 ->3= ~125 ms 0 ->4= ~450 ms 400 ms 800 ms 1200 ms 0 1 2 3 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 168 10000.00 ADC resolution = -72.2 dB Figure 51 - Frequency Response of Current Input with Filter = 5 Hz Frequency (Hz) 0.01 0.10 1.00 10.00 100.00 1000.00 10000.00 ADC resolution = -72.2 dB Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 169 Figure 53 - Frequency Response of Current Input with Filter = 50 Hz Frequency (Hz) 0.01 0.10 1.00 10.00 100.00 1000.00 10000.00 0.01 0.10 1.00 10.00 100.00 1000.00 10000.00 ADC resolution = -72.2 dB ADC resolution = -72.2 dB Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 170 10000.00 ADC resolution = -72.2 dB Figure 55 - Frequency Response of Voltage Input with Filter = 5 Hz Frequency (Hz) 0.01 0.10 1.00 10.00 100.00 1000.00 10000.00 ADC resolution = -72.2 dB Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 171 10000.00 ADC resolution = -72.2 dB Figure 57 - Frequency Response of Voltage Input with Filter = 50 Hz Frequency (Hz) 0.01 0.10 1.00 10.00 100.00 1000.00 10000.00 ADC resolution = -72.2 dB Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 172 Current mode, choose a sensor for your application that can operate in the middle of its range and not at the outer limits. Figure 58 - Accuracy Drift vs Temperature (Current mode) Drift (%/°C) Temperature (°C) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 173: Technical Specifications For Series B Modules

-20 °C 40 °C 55 °C (-4 °F) (104 °F) (131 °F) Aggregate current of test outputs per module 2.8 A @ 40 °C (104 °F) 0.55 A @ 55 °C (131 °F) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 174 Type tested at 500V AC for 60 s. Power bus, operating supply voltage 24V DC nom, Class 2 Power bus, operating voltage range 19.2…28.8V DC, Class 2 Power bus current (no load), max 25 mA Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 175 (3) Input off-to-on filter time is the time from a valid input signal to recognition by the module. Input on-to-off time is the time from a valid input signal to recognition by the module. (4) Use this conductor category information for planning conductor routing. Refer to the Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 176: Safety Digital Output Module Specifications

50V (continuous), Basic Insulation Type between field side and system No isolation between individual channels Type tested at 860V AC DC for 60 s Power bus, operating supply voltage 24V DC nom, Class 2 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 177: Environmental Specifications

5 g @ 10…500 Hz Shock, operating IEC 60068-2-27 (Test Ea, Unpackaged Shock) 30 g Shock, nonoperating IEC 60068-2-27 (Test Ea, Unpackaged Shock) 50 g Corrosives 1734-IB8S and 1734-OB8S Series B only: G2 (ISA S71.04) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 178 Figure 59 - System Temperature Derating When a 1734-IE4S Module Is Used 1.2 W/cm (3 W /in.) 0.8W/cm (2 W /in.) -20°C 40°C 55°C (-4 °F) (104 °F) (131°F) Placing Series A Digital and Analog Modules on page 48 for examples. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 179: Certifications

Legislations and Standards Familiarize yourself with related legislation and standards information. Relevant international standards include the following: • IEC 61508 (SIL 1-3) • IEC 61131-6 • IEC 60204-1 • IEC 62061 • ISO 13849-1 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 180 Appendix C Specifications Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 181 5570 controllers in Studio 5000 Logix Designer projects. 1756-RM099 GuardLogix Controller Systems Safety Provides information on safety application requirements for GuardLogix Reference Manual, publication 5560 and 5570 controllers in RSLogix 5000 projects. 1756-RM093 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 182: Series A Safety Data

1% of SIL 3 Limit 1.00E-05 10% of SIL 3 Limit 1.00E-04 1.00E-03 1.00E-02 Proof Test Interval (years) Figure 61 - PFD vs. Proof Test Interval 1734-IB8S Series A Proof Test Interval [years] Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 183 3.3E-06 3.9E-11 (1) This data is for dual channel mode of operation. (2) Calculated based on ISA TR-84 method. (3) Mean Time to Failure (Spurious). Mission Time for all modules is 20 years. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 184: Series B Safety Data

Appendix D Safety Data Series B Safety Data Figure 63 - PFD vs Proof Test Interval 1734-IB8S Series B Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 185 (1) Data for this module is for both single channel and dual channel modes of operation. (2) Calculated based on ISA TR-84 method. (3) Mean Time to Failure (Spurious). Mission Time for all modules is 20 years. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 186 Appendix D Safety Data Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 187 Safety input or test output errors are latched for this time. 1000 ms (in increments of 10 ms) (1) Parameters directly related to safety are marked with an x in the left column. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 188: Appendix E

Standard A device that is not used in the safety loop is connected. Range ±10V 0…5V Input voltage range. 0…10V ±5V 4…20 mA 4…20 mA Input current range. 0…20 mA Tachometer Tachometer mode. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 189: Appendix E

Channel Offset -32768…32767 Offset value for dual channel mode only (in engineering units). (1) Parameters directly related to safety are marked with an x in the left column. (2) 1000 for Tachometer mode. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 190: Appendix E

Appendix E Configuration Parameters Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 191: Input Assemblies

Error 899 (383h) Standard Reserved Input Power Error Reserved Test Output 3 Test Output 2 Test Output 1 Test Output 0 (1) This data is diagnostic only and does not have safety integrity. Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 192: Output Assemblies

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Reserved Reserved Reserved Reserved Ch 3 Input Ch 2 Input Ch 1 Input Ch 0 Input Status Status Status Status Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 193 Ch 2 Combined Ch 1 Combined Ch 0 Combined Ch 3 Input Ch 2 Input Ch 1 Input Ch 0 Input Standard Alarm Status Alarm Status Alarm Status Alarm Status Status Status Status Status Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 194: Configuration Assemblies

Safety Output 5 Channel Mode Safety Output 6 Channel Mode Safety Output 7 Channel Mode Dual-channel Safety Output 0 Mode Dual-channel Safety Output 1 Mode Dual-channel Safety Output 2 Mode Dual-channel Safety Output 3 Mode Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 195 Dual-channel Safety Input 1…2 Configuration … … … Dual-channel Safety Input 3 Mode Pad Byte (0x00) … … … Dual-channel Safety Input 3 Discrepancy Time (low byte) Dual-channel Safety Input 3 Discrepancy Time (high byte) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 196 High/Low Alarm Trip Low (Low Byte) High/Low Alarm Trip Low (High Byte) High/Low Alarm Deadband (Low Byte) High/Low Alarm Deadband High Byte) Pad Byte 1 … … … Pad Byte 2 … … … Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 197 High/Low Alarm Trip Low (Low Byte) High/Low Alarm Trip Low (High Byte) High/Low Alarm Deadband (Low Byte) High/Low Alarm Deadband High Byte) Pad Byte 1 … … … Pad Byte 2 … … … Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 198 High/Low Alarm Trip Low (Low Byte) High/Low Alarm Trip Low (High Byte) High/Low Alarm Deadband (Low Byte) High/Low Alarm Deadband High Byte) Pad Byte 1 … … … Pad Byte 2 … … … Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 199 Ch 2_3 Discrepancy Time (High Byte) Ch 2_3 Discrepancy Deadband (Low Byte) Dual Channel Safety Input 2_3 Configuration Ch 2_3 Discrepancy Deadband (High Byte) Ch 2_3 Channel Offset (Low Byte) Ch 2_3 Channel Offset (High Byte) Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

-

Page 200: Using Data From Modules Configured Via The Generic Profile

193. • POINTGuardAnalogMod.I.Data[0] = Channel 0 Low Byte (SINT) • POINTGuardAnalogMod.I.Data[1] = Channel 0 High Byte (SINT) • CH0_Data = Combined Channel 0 data (INT) that can be used in an application program Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 201: 1734-Um013I-En-P, May 2013

Added Analog I/O Status Data New Chapter: Guidelines for Placing Power Supplies and Modules in a System Identified key positions for 1734-IE4S modules Updated information on wiring POINT Guard I/O modules including 1734-IE4S modules Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... -

Page 202: 1734-Um013E-En-P, March 2012

History of Changes Change Illustrated 1734-IE4S field connections Safety analog-input-module wiring guidelines and examples List of Rockwell Automation Bulletin 1606 PELV/SELV- compliant power supplies Revised power supply considerations and examples Updated Ethernet adapter configuration procedures Clarified information on ‘cycle inputs’ condition... -

Page 203: 1734-Um013B-En-P, June 2009

Setting the node address of a POINT Guard I/O module Resetting POINT Guard I/O modules to out-of-box condition Auto-addressing with a 1734-PDN adapter IEC Temperature Code c-UL-us certification Ex certification ODVA certification 1734-UM013A-EN-P, Initial release February 2009 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014... - Page 204 Appendix G History of Changes Notes: Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 205 12 data 101 example 138 status indicator 153 lost 42 wiring 58 removable terminal block 56 architectures 20 safety input 102 auto-addressing 108 connection faulted tags 100 connection reaction time limit 121 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 206 23 glossary 12 discrepancy error 43 grounding 58 discrepancy fault 35 GuardLogix controller 125 equivalent 23 SNN 139 mode 18 Guardmaster product 16 safety contactors 64 wiring 62 Dual-channel Analog safety instruction 94 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 207 106 NPN-style sensors 36 keyswitches 56 NS status indicator 104 legislations and standards 179 ODVA 12 light curtain 61 off-delay 18 limit switches 16 off-level 37 listen only 77 on-delay 18 on-level 37 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 208 19 backplane 45 RSNetWorx for DeviceNet software 15 Pollution Degree 2 53 power reset module 140 field 46 version 19 status 121 RSWho 109 status indicator 153 RTB 56 See removable terminal block Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 209 16 icon 132 door monitoring 61 save 104 emergency stop 102 scaling gate monitoring 62 analog inputs 31 limit 16 schematic diagrams 60 system reaction time 21 security 18 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 210 Safety Device Verification Wizard 134 USB 105 verification reports failure report 135 Safety Device Verification Wizard 135 verify DeviceNet Safety configuration 132 FAILED 134 select devices 133 verify failed 133 verify not supported 133 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014...

- Page 212 New Product Satisfaction Return Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

Need help?

Do you have a question about the Allen-Bradley POINT Guard and is the answer not in the manual?

Questions and answers