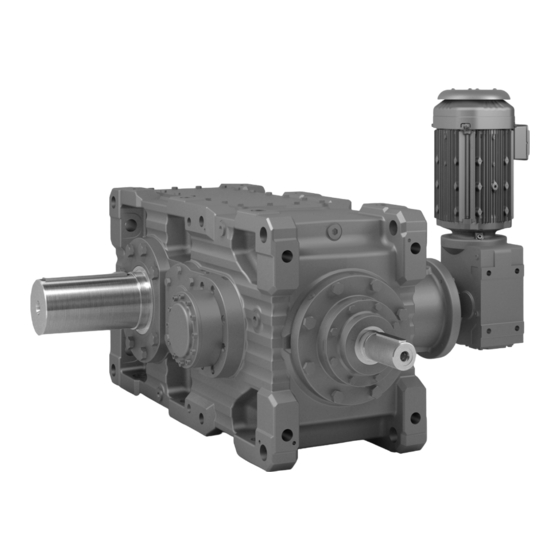

SEW-Eurodrive X Series Assembly And Operating Instructions Manual

Explosion-proof industrial gear units, bevel-helical gear units bucket elevator drives, torque classes from 6.8-270 knm

Hide thumbs

Also See for X Series:

- Assembly and operating instructions manual (380 pages) ,

- Assembling and operating instructions (348 pages) ,

- Addendum to the assembly and operating instructions (24 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for SEW-Eurodrive X Series

- Page 1 *24817333_0518* Drive Technology \ Drive Automation \ System Integration \ Services Assembly and Operating Instructions Explosion-Proof Industrial Gear Units X.. Series Bevel-Helical Gear Units Bucket Elevator Drives Torque Classes from 6.8 – 270 kNm Edition 05/2018 24817333/EN...

- Page 2 SEW-EURODRIVE—Driving the world...

-

Page 3: Table Of Contents

Table of contents Table of contents General information........................ 7 About this documentation .................... 7 Structure of the safety notes ................... 7 Rights to claim under limited warranty ................ 8 Copyright notice ...................... 9 Safety notes .......................... 10 Preliminary remark...................... 10 EAC marking......................... 10 General information ...................... 10 Target group ......................... 11 Designated use ...................... 11 Other applicable documentation ................... 12... - Page 4 Table of contents Backstop /BS ........................ 66 Motor adapter /MA ...................... 67 Drive packages on a steel frame .................. 68 Cooling types ........................ 70 Fan /FAN........................ 70 Water cooling cover /CCV..................... 73 4.10 Water cooling cartridge /CCT.................. 74 4.11 Oil-water cooler for splash lubrication /OWC .............. 77 4.12 Oil-air cooler for splash lubrication /OAC.............. 77 4.13 Oil-water cooler for pressure lubrication /OWP............. 77...

- Page 5 Table of contents 6.23 Fan /FAN........................ 157 6.24 Water cooling cover /CCV................... 158 6.25 Water cooling cartridge /CCT.................. 160 6.26 Oil-water cooler for splash lubrication /OWC .............. 165 6.27 Oil-air cooler for splash lubrication /OAC.............. 165 6.28 Oil-water cooler for pressure lubrication /OWP............ 165 6.29 Oil-air cooler for pressure lubrication /OAP .............. 165 6.30 Motor pump /ONP1L .................... 166 6.31...

- Page 6 Table of contents Refilling grease ...................... 215 Fan /FAN........................ 215 8.10 Axial fan ........................ 216 8.11 Water cooling cover /CCV................... 222 8.12 Water cooling cartridge /CCT.................. 224 8.13 Oil-water cooler for splash lubrication /OWC .............. 227 8.14 Oil-air cooler for splash lubrication /OAC.............. 227 8.15 Oil-water cooler for pressure lubrication /OWP............ 227 8.16 Oil-air cooler for pressure lubrication /OAP .............. 228 8.17...

-

Page 7: General Information

General information About this documentation General information About this documentation The current version of the documentation is the original. This documentation is an integral part of the product. The documentation is written for all employees who assemble, install, start up, and service this product. Make sure this documentation is accessible and legible. -

Page 8: Rights To Claim Under Limited Warranty

General information Rights to claim under limited warranty Meaning of the hazard symbols The hazard symbols in the safety notes have the following meaning: Hazard symbol Meaning General hazard Warning of dangerous electrical voltage Warning of hot surfaces Warning of risk of crushing Warning of suspended load Warning of automatic restart 1.2.3... -

Page 9: Copyright Notice

General information Copyright notice Copyright notice © 2018 SEW‑EURODRIVE. All rights reserved. Unauthorized reproduction, modifica- tion, distribution or any other use of the whole or any part of this documentation is strictly prohibited. Assembly and Operating Instructions – X.. Series Bevel-Helical Gear Units Bucket Elevator Drives... -

Page 10: Safety Notes

Safety notes Preliminary remark Safety notes The following basic safety notes must be read carefully to prevent injury to persons and damage to property. The user must ensure that the basic safety notes are read and observed. Ensure that persons responsible for the machinery and its operation as well as persons who work on the unit independently have read through the document- ation carefully and understood it. -

Page 11: Target Group

Safety notes Target group Refer to the documentation for more information. Target group Specialist for Any mechanical work may only be performed by adequately qualified specialists. Spe- mechanical work cialists in the context of this documentation are persons familiar with the design, mechanical installation, troubleshooting, and maintenance of the product who possess the following qualifications: •... -

Page 12: Other Applicable Documentation

Safety notes Other applicable documentation INFORMATION It is essential that you observe the following information on explosion protection: • A drive motor connected to the gear unit may only be operated under the condi- tions described in the chapter "Starting up gear units in potentially explosive atmo- spheres" (→ 2 187). - Page 13 Safety notes Safety symbols on the gear unit Safety symbol Meaning Indicates the oil drain. Indicates the position of the breather. Serves to avoid mistaking the oil measuring position for the venting position. Helps avoid errors caused by lack of understanding. Read the in- formation in the operating instructions.

- Page 14 Safety notes Safety symbols on the gear unit Safety symbol Meaning Caution: Removing the oil dipstick during operation may result in damage to the gear unit. STOP Caution: Risk of burns due to hot gear oil. After startup, you may remove the following labels from the gear unit. Meaning The brake is not set at the factory.

- Page 15 Safety notes Safety symbols on the gear unit Meaning The coupling is supplied without oil. VORSICHT NOTICE ATTENTION PRECAUCIÓN VOORZICHTIG OSTROŻNIE Kupplung wird ohne Öl geliefert. Coupling delivered without oil Mögliche Sachschäden! Possible damage to property. • Vor der Inbetriebnahme Kupplung •...

-

Page 16: Symbols On The Dimension Sheet

Safety notes Symbols on the dimension sheet Meaning The gear unit is supplied without oil. VORSICHT NOTICE ATTENTION PRECAUCIÓN VOORZICHTIG OSTROŻNIE Getriebe wird ohne Öl geliefert. Gear unit is delivered without oil. Mögliche Sachschäden! Potential damage to property! • Vor der Inbetriebnahme Ölbefüllung •... -

Page 17: Symbols On The Packaging

Safety notes Symbols on the packaging Symbol Meaning G 1/4" Indicates the water inflow with connection dimensions. H 2 O G 1/4" Indicates the water return with connection dimensions. H 2 O Indicates the oil inflow. Indicates the oil return. Indicates the position of the magnetic screw plug. -

Page 18: Transport

Safety notes Transport 2.10 Transport 2.10.1 General information WARNING Suspended loads can fall. Severe or fatal injuries. • Do not stand under the suspended load. • Secure the danger zone. • Use suitable, sufficiently rated and undamaged handling equipment. • Consider the gear unit dimensions, the center of gravity and the weight that has to be moved when selecting lifting equipment or crane (see dimension drawing). - Page 19 Safety notes Transport NOTICE Improper transport can damage the gear unit. Possible damage to property. • Note the following information. • Inspect the shipment for damage as soon as you receive the delivery. Inform the shipping company immediately about any damage. It may be necessary to sus- pend startup.

- Page 20 Safety notes Transport The following figure shows an example of how the gear unit can be transported. 9007203196587531 Assembly and Operating Instructions – X.. Series Bevel-Helical Gear Units Bucket Elevator Drives...

- Page 21 Safety notes Transport 2.10.2 Gear units on swing base/base frame Gear units on a swing base/base frame may only be transported using vertically ten- sioned lifting cables [1] or chains. The following figures show a transportation example. 9007199436455563 Assembly and Operating Instructions – X.. Series Bevel-Helical Gear Units Bucket Elevator Drives...

-

Page 22: Storage And Transport Conditions

Safety notes Storage and transport conditions 2.11 Storage and transport conditions The gear units can be provided with the following protection and packaging types de- pending on the storage and transport conditions. 2.11.1 Internal conservation Standard corrosion protection After the test run, the test oil fill is drained out of the gear unit. The remaining oil film protects the gear unit against corrosion for a limited period of time. - Page 23 Safety notes Storage and transport conditions 2.11.4 Storage conditions NOTICE Improper storage may result in damages to the gear unit. Possible damage to property. • During storage up to startup, the gear unit must be stored in a shock-free manner to prevent damage to the rolling bearing raceways.

-

Page 24: Structure

Structure Bucket elevator drive Structure Bucket elevator drive Bucket elevators are conveyor systems that vertically lift large quantities of bulk mater- ial. Depending on the volume of the buckets and on the needed conveyor height, high drive powers may be required. Especially during maintenance, the bucket elevator drive may only be operated at a reduced speed. -

Page 25: Auxiliary Drive / Iec Motor Standard Ie1 And Ie3

Structure Auxiliary drive / IEC motor standard IE1 and IE3 Auxiliary drive / IEC motor standard IE1 and IE3 21958623243 The auxiliary drive [1] is available in "empty buckets" design (solely for maintenance purposes) or "full buckets" design. The auxiliary drive is mounted to the bevel-helical gear unit [3] via an auxiliary drive adapter [2]. - Page 26 Structure Auxiliary drive / IEC motor standard IE1 and IE3 3.2.1 IEC motor standard IE1 and IE3 DR.. motors comply with all international standards and meet the currently valid IEC motor standard. The auxiliary drive is equipped with DRN.. (IE3) design motors by SEW‑EURODRIVE as standard.

-

Page 27: Overrunning Clutch

Structure Overrunning clutch Overrunning clutch The overrunning clutch [1] is a part of the auxiliary drive adapter [2] and allows for operation in one direction of rotation via the auxiliary drive [3]. The gear unit can be operated in 2 ways: •... -

Page 28: Speed Monitoring

Structure Speed monitoring Speed monitoring NOTICE In case of a malfunction of the overrunning clutch, the auxiliary drive can be des- troyed due to overspeed. Possible damage to property. • The overrunning clutch must be equipped with a speed monitoring function for safety reasons. -

Page 29: Torque-Limited Backstop

Structure Torque-limited backstop Torque-limited backstop 539377931 Housing Freewheel cage Compression springs Outer ring Inner ring Friction lining Torque-controlled backstops are used in dual drives where both drives are equipped with a backstop. The torque limitation prevents the restoring torque from being unevenly distributed to the individual backstops. -

Page 30: Gear Ratio Of The Backstop

Structure Gear ratio of the backstop Gear ratio of the backstop 6144189579 X3K.. X3K.. X3K.100 14 – 80 X3K.200 12.5 – 71 X3K.110 16 – 90 X3K.210 14 – 80 X3K.120 12.5 – 71 X3K.220 12.5 – 71 X3K.130 16 – 90 X3K.230 14 – 80 X3K.140 12.5 – 71 X3K.240 12.5 – 71 X3K.150 16 – 90 X3K.250 14 – 80 X3K.160 12.5 – 71 X3K.260 12.5 – 71 X3K.170... -

Page 31: Position Of Motor Terminal Box And Cable Entry

Structure Position of motor terminal box and cable entry Position of motor terminal box and cable entry The position of the motor terminal box has so far been indicated with 0°, 90°, 180° or 270° as viewed onto the fan guard (see figure below). A change in the product stand- ard EN 60034 specifies that the following designations will have to be used for ter- minal box positions for foot-mounted motors in the future: •... -

Page 32: Series Nameplate

Structure X.. series nameplate X.. series nameplate The following example shows the structure of the nameplate. The oil quantity specified on the nameplate refers only to the basic unit. SEW-EURODRIVE 76646 Bruchsal/Germany X3FS190/B Type 01.1234567812.0001.06 -39.06 min. nom. max. PK1 [kW] 43300 43300 43300... -

Page 33: Type Designations

Structure Type designations Type designations 3.9.1 Gear units The following example shows the structure of the type designation: X3KS250 /HU /B Industrial gear unit series Number of gear unit stages • 2 = 2-stage • 3 = 3-stage • 4 = 4-stage Gear unit design •... - Page 34 Structure Type designations 3.9.2 Oil supply systems The gear unit can be equipped with an oil supply system for cooling and lubrication purposes. The following example shows the structure of the type designation: OWC020-00/M Oil supply system Cooling medium • W = Water •...

- Page 35 Structure Type designations 3.9.4 Abbreviations for optional accessories The table shows the abbreviations used and what they mean. Abbreviation Meaning Base frame Backstop Torque-limited backstop Breather Water cooling cover Water cooling cartridge Flange coupling FAN-ADV Fan, Advanced design Horizontal housing Universal housing Thermal housing HSST...

-

Page 36: Mounting Positions

Structure Mounting positions 3.10 Mounting positions The mounting position defines the spatial orientation of the gear unit housing and is designated M1...M6. With the alternative mounting positions, there might be limitations regarding certain options. Consult SEW‑EURODRIVE in this case. 6068016395 3.10.1 Deviating mounting positions Note that the following deviating mounting positions are permitted for X3K.. -

Page 37: Mounting Positions And Standard Mounting Surfaces

Structure Mounting positions and standard mounting surfaces 3.11 Mounting positions and standard mounting surfaces A certain standard mounting surface is assigned to each mounting position. INFORMATION • The mounting position and/or mounting surface must not differ from the order. • Other mounting surfaces are possible in combination with a certain mounting posi- tion. -

Page 38: Fixed And Variable Pivoted Mounting Positions

Structure Fixed and variable pivoted mounting positions 3.12 Fixed and variable pivoted mounting positions Mounting positions deviating from the standard are differentiated between fixed and variable pivoted mounting positions. INFORMATION • Fixed and variable pivoted mounting positions are only possible after consultation with SEW‑EURODRIVE. - Page 39 Structure Fixed and variable pivoted mounting positions 3.12.1 Fixed pivoted mounting position Definition: Gear units with fixed pivoted mounting position have a fixed mounting position that dif- fers from the standard. This means the gear unit does not change its mounting posi- tion during operation.

- Page 40 Structure Fixed and variable pivoted mounting positions 3.12.2 Variable pivoted mounting position Definition: Gear units with variable pivoted mounting position can change the mounting position variably during operation within the specified max./min. range. Example: The gear unit is operated in variable pivoted mounting position M1 to M6 = 9° and M1 to M5 = 12°.

- Page 41 Structure Fixed and variable pivoted mounting positions The type designation for this example is: M1-M5/–9°...12° = Initial mounting position = Pivoting direction 12° = Pivoted from M1 to M5 by 12 ° -9° = Pivoted from M1 to M5 by -9° (= Pivoted from M1 to M6 by 9°) The variable pivoted mounting position is shown on the nameplate as follows: X3FS190/B...

- Page 42 Structure Fixed and variable pivoted mounting positions 3.12.3 Combination of variable and fixed pivoted mounting positions Fixed and variable pivoted mounting positions can be combined. Example: The following example shows a combination of fixed and variable pivoted mounting position. The type designation is set up as follows: M1-M5/–9°...12°...

-

Page 43: Direction Of Rotation Dependencies

Structure Direction of rotation dependencies 3.13 Direction of rotation dependencies 3.13.1 X.K.. Standard Shaft position Position of final gear X3K.. = Position of the backstop = Alternative backstop position (depending on size and gear ratio) = Contact SEW‑EURODRIVE when using a backstop Note the restrictions regarding external forces on the LSS INFORMATION: For more information and a 3D view of the gear unit, refer to chapter Shaft positions. -

Page 44: Housing Types

Structure Housing types 3.14 Housing types SEW‑EURODRIVE distinguishes between the following housing types: 3.14.1 Horizontal housing /HH The horizontal housing is designed for mounting position M1. This housing design is non-reversible. The following figure shows an example of a single-piece housing for sizes 100 – 210: 9007208285647499 The following figure shows an example of a two-piece housing for sizes 220 – 280: 9453596299... - Page 45 Structure Housing types 3.14.2 Universal housing /HU The universal housing can be installed in any mounting position (M1 to M6). The hous- ings can be reversible if required. The following figure shows an example of a single-piece housing for sizes 100 – 210: 9007207839154827 The following figure shows an example of a two-piece housing for sizes 220 – 280: 9007207839156491...

- Page 46 Structure Housing types 3.14.3 Thermal housing /HT The thermal housing is designed for mounting position M1. This housing design is non-reversible. Various measures make this gear unit suitable for increased thermal requirements. The following figure shows an example of a thermal housing for size 220: 9007208902548235 Assembly and Operating Instructions –...

-

Page 47: Combination Overview Of Housing Designs And Options

Structure Combination overview of housing designs and options 3.15 Combination overview of housing designs and options 3.15.1 Horizontal housing /HH and universal housing /HU Single-piece and split gear unit housings for horizontal applications (HH) as well as universal housings (HU) offer a wide range of possible variants. The following table shows the options that can be combined with horizontal housings (HH) and the op- tions that can be combined with universal housings (HU). - Page 48 Structure Combination overview of housing designs and options 3.15.2 Thermal housing /HT The thermal housing (HT) allows for a wide range of possible variants. The following table shows the options that can be combined with the thermal housing (HT). Options Base frame Backstop Torque-limiting backstop...

-

Page 49: Input And Output Shaft

Structure Input and output shaft 3.16 Input and output shaft There are two types of shafts: • High-speed shaft (HSS) • Low-speed shaft (LSS) 6065865995 3.16.1 Input shaft The input shaft is provided with a closed keyway according to DIN 6885/T1 and a cen- tering bore according to DIN ... - Page 50 Structure Input and output shaft 3.16.2 Output shaft as a solid shaft with key /..S The output shaft is provided with a closed keyway according to DIN 6885/T1 and a centering bore (according to DIN 332). The delivery includes a key according to DIN ...

- Page 51 Structure Input and output shaft 3.16.4 Output shaft as a splined solid shaft/..L The output shaft is a splined shaft according to DIN 5480. There is a centering in front of and behind the splined shaft to improve the guide of the output element. Two threads are available on the front end of the shaft for mounting an end plate.

- Page 52 Structure Input and output shaft 3.16.5 Output shaft as a hollow shaft with keyway /..A The hollow shaft is equipped with a keyway according to DIN 6885/T1. Included in the delivery: • Protection cover [2] • Retaining screws [1] or • 2 retaining rings 9007199579038987 The protection cover is dust-tight.

- Page 53 Structure Input and output shaft 3.16.7 Output shaft as a splined hollow shaft /..V The output shaft is splined according to DIN 5480. Included in the delivery: • Protection cover [2] • Endplate with screws [1] or • 2 retaining rings 744271627 3.16.8 Gear unit mounting for hollow shaft gear units...

-

Page 54: Shaft Positions, Directions Of Rotation, Backstops, Auxiliary Drives

Structure Shaft positions, directions of rotation, backstops, auxiliary drives 3.17 Shaft positions, directions of rotation, backstops, auxiliary drives The following figures show the standard variants of the bucket elevator gear units. The auxiliary drives are mounted in mounting position M4A with motor terminal box posi- tion 0°. -

Page 55: Sealing Systems

Structure Sealing systems 3.18 Sealing systems 3.18.1 Input shaft Designation Property Environment Illustration Standard Single oil seal with dust protec- Normal environment tion lip Dust-protected Single oil seal with Medium dust dust protection cover load with abrasive particles Protected against dust, Double lip seal with High dust load regreasable... - Page 56 Structure Sealing systems 3.18.2 Output shaft Designation Property Environment Illustration Standard Single oil seal with dust protec- Normal environment tion lip Dust-protected Single oil seal with Medium dust dust protection cover load with abrasive particles Protected against dust, Double lip seal with High dust load regreasable dust protection cover...

- Page 57 Structure Sealing systems INFORMATION Make sure the gear unit shaft is rotating during regreasing. 3.18.3 Position of lubrication points Universal housing HU / horizontal housing HH / thermal housing HT Grease nipple on gear unit cover Regreasable sealing systems are usually equipped with taper greasing nipples ac- cording to DIN ...

-

Page 58: Coating And Surface Protection Systems

Structure Coating and surface protection systems 3.19 Coating and surface protection systems The following tables give an overview of coating and surface protection systems. Used as surface protection under typical ambient conditions, corrosivity category DIN EN ISO 12944-2. OS 1 low environmental pollution Suited for environments prone to condensation and atmospheres with low humidity or contamination, such as outdoor applications under roof or with pro-... - Page 59 Structure Coating and surface protection systems OS 3 high environmental pollution Salt spray test ISO 7253 480 h OS 4 high environmental pollution Suitable for environments with permanent humidity or severe atmospheric or chemical contamination. Regular acidic and caustic wet cleaning also with chemical cleaning agents.

-

Page 60: Lubrication

Structure Lubrication 3.20 Lubrication 3.20.1 Lubrication types Splash lubrication The oil level is low; gearing and bearing parts that are not immersed in the oil bath are lubricated by splashing oil. Standard lubrication type for horizontal mounting positions (M1 or M3). Bath lubrication The gear unit is (almost) completely filled with oil;... -

Page 61: Accessories

Structure Accessories 3.21 Accessories The following section describes the accessories for the several lubrication types. INFORMATION The position of the accessories may vary depending on gear unit design and gear unit size. 3.21.1 General accessories The following figure shows the general accessories. 9007205325104011 Oil dipstick (optional) Oil level glass... - Page 62 Structure Accessories Gear unit venting A breather serves to prevent non-permitted pressure generated by heating during operation. The gear units are equipped with a breather as standard. Oil drain The gear unit is equipped with an oil drain plug as standard. An oil drain valve may be provided as option.

-

Page 63: Design Of Options And Accessories

Design of options and accessories Torque arm /T Design of options and accessories Torque arm /T A torque arm is available as option for shaft-mounted gear units to support the reac- tion torque. The torque arm can bear tensile stress as well as thrust loads. The length of the torque arm can be adjusted within a certain range. -

Page 64: Flange Coupling With Cylindrical Interference Fit /Fc-S

Design of options and accessories Flange coupling with cylindrical interference fit /FC-S Flange coupling with cylindrical interference fit /FC-S NOTICE Improper installation and mounting may result in damage to the gear unit. Possible damage to the gear unit. • Gear units with flange couplings cannot be additionally secured on the floor with a rigid connection. -

Page 65: Flange Coupling With Keyway /Fc-K

Design of options and accessories Flange coupling with keyway /FC-K Flange coupling with keyway /FC-K NOTICE Improper installation and mounting may result in damage to the gear unit. Possible damage to the gear unit. • Gear units with flange couplings cannot be additionally secured on the floor with a rigid connection. -

Page 66: Backstop /Bs

Design of options and accessories Backstop /BS Backstop /BS The purpose of a backstop is to prevent undesirable reverse rotation. During opera- tion, the backstop permits rotation in only one specified direction of rotation. The backstop functions by using centrifugal lift-off sprags. Once the lift-off speed is reached, the sprags completely lift off from the contact surface of the outer ring. -

Page 67: Motor Adapter /Ma

Design of options and accessories Motor adapter /MA Motor adapter /MA Motor adapters [1] are available for mounting: • IEC (B5) motors of sizes 100 to 355 • NEMA ("C" face) motors of sizes 182 to 449 INFORMATION • The gear unit must be installed in such a way that liquids cannot enter the motor adapter (HSS end) and accumulate there. -

Page 68: Drive Packages On A Steel Frame

Design of options and accessories Drive packages on a steel frame Drive packages on a steel frame For gear units in a horizontal mounting position, complete pre-assembled drive pack- ages on a steel frame (swing base or base frame) are available. 4.6.1 Swing base /SB A swing base is a steel frame [1] that accommodates the gear unit, (hydro) coupling... - Page 69 Design of options and accessories Drive packages on a steel frame 4.6.2 Base frame /BF For gear units in a horizontal mounting position, complete pre-assembled drive pack- ages on a base frame are available. A base frame is a steel frame [1] that accommodates the gear unit, (hydro) coupling and motor (and brake, if required), including protection devices, such as guards, etc.

-

Page 70: Cooling Types

Design of options and accessories Cooling types Cooling types 4.7.1 Fan cooling A fan is installed on the gear unit input shaft. Its airflow improves the transmission of heat from the gear unit surface to the environment. Refer to chapter "Fan" for further information. - Page 71 Design of options and accessories Fan /FAN 4.8.2 X3K.. Advanced (option) /FAN-ADV When the type X3K.. Advanced is used, the connection element (e.g. hydraulic centri- fugal coupling) can be mounted flush to the fan guard. The air intake clearance is integrated into the fan guard. 18014399183937419 Air intake clearance INFORMATION...

- Page 72 Design of options and accessories Fan /FAN 4.8.3 Axial fan An axial fan [1] is integrated to increase the thermal rating. The fan depends on the direction of rotation. This is the reason why fans are available for CW or CCW rotation. Refer to the information on the order documents.

-

Page 73: Water Cooling Cover /Ccv

Design of options and accessories Water cooling cover /CCV Water cooling cover /CCV The water cooling cover is located on the assembly opening of the gear unit, and is provided with cooling water through a water connection. The customer is to provide for the water connection. -

Page 74: Water Cooling Cartridge /Cct

Design of options and accessories Water cooling cartridge /CCT 4.9.2 Notes on connection and operation A cooling water volume flow (water inflow temperature 15 °C) depending on the gear unit size is necessary according to the following table to achieve the thermal rating given in the catalog. - Page 75 Design of options and accessories Water cooling cartridge /CCT 4.10.1 Structure [4] [3] 313751819 Cooling pipes Tube plate with connection piece Return Supply The water cooling cartridge consists of 3 main parts: • Cooling pipes (CuNi alloy) • Tube plate (brass) •...

- Page 76 Design of options and accessories Water cooling cartridge /CCT 4.10.2 Notes on connection and operation To achieve the thermal rating specified in the selection tables of the X.. Series Indus- trial Gear Units catalog, different cooling water flow rates are required depending on the size, mounting position, and type of lubrication.

-

Page 77: Oil-Water Cooler For Splash Lubrication /Owc

Design of options and accessories Oil-water cooler for splash lubrication /OWC 4.11 Oil-water cooler for splash lubrication /OWC INFORMATION For descriptions on the unit structure, refer to the addendum to the operating instruc- tions "Oil-Water Cooler for Splash Lubrication /OWC". 4.12 Oil-air cooler for splash lubrication /OAC INFORMATION For descriptions on the unit structure, refer to the addendum to the operating instruc-... -

Page 78: Motor Pump /Onp1

Design of options and accessories Motor pump /ONP1 4.16 Motor pump /ONP1 INFORMATION For a description of the unit structure, refer to the addendum to the operating instruc- tions "Motor pump /ONP1". 4.17 Oil heater /OH An oil heater may be required to ensure lubrication during a cold gear unit startup when the ambient temperature is low. -

Page 79: Pressure Switch /Ps

Design of options and accessories Pressure switch /PS 4.18 Pressure switch /PS The pressure switch signals the correct oil pressure in the pressure pipe und in this way indicates that the pressure lubrication is ready for operation. The pressure switch must be monitored by the operator. -

Page 80: Temperature Switch /Tsk

Design of options and accessories Temperature switch /TSK 4.21 Temperature switch /TSK A temperature switch with preset switching temperatures is available for monitoring the gear unit's oil temperature. The temperature switch is designed with 2 fixed switching points for controlling and monitoring the system function. - Page 81 Design of options and accessories Breather /BPG 4.22.2 Desiccant breather filter /DC INFORMATION For explosion-proof drives, the desiccant breather filter is protected by a guard plate. The gear unit leaves the factory with the guard plate already mounted. 22880088843 The breather has the following characteristics: •...

-

Page 82: Checklist

Checklist Before startup Checklist Before startup This checklist provides an overview of the points that must be checked before start- ing up a gear unit in a potentially explosive area in accordance with Direct- ive 2014/34/EU. Check the following points before starting up a gear unit in a potentially explos- Check ive atmosphere: chapter... -

Page 83: During Startup

Checklist During startup During startup This checklist includes all activities that have to be performed during startup of a gear unit in a potentially explosive atmosphere according to Directive 2014/34/EU. Check the following points during gear unit startup in a potentially explosive Check area: chapter... -

Page 84: Installation/Assembly

Installation/assembly Required tools/resources Installation/assembly Required tools/resources Not included in the delivery: • Set of wrenches • Torque wrench • Mounting device • Compensation elements (washers, spacer rings), if necessary • Fasteners for input and output elements ® • Lubricant, e.g. NOCO fluid from SEW‑EURODRIVE →... -

Page 85: Important Information

Installation/assembly Important information Important information Read the following notes prior to installation/mounting. WARNING Risk of crushing if the drive starts up unintentionally. Severe or fatal injuries. • Work on the gear unit only when the machine is not in use. Secure the drive unit against unintentional power-up. - Page 86 Installation/assembly Important information WARNING Danger due to installing impermissible components. Severe or fatal injuries. • Do not mount any impermissible components to the gear unit. • Additional installation of invalid components or assemblies that impact on the functioning of the gear unit can invalidate the conformity. •...

- Page 87 Installation/assembly Important information NOTICE Improper installation and assembly can damage the gear unit. Possible damage to property. • Observe the following notes. • Make sure that the customer components are designed for the load. • The most important technical data is provided on the nameplate. Additional data relevant for operation is available in drawings, on the order con- firmation or in an order-specific documentation.

- Page 88 Installation/assembly Important information INFORMATION • Depending on the order, the gear unit can be delivered with or without oil. Ob- serve the information on the nameplate. • The electrical installation must comply with the standard EN 60079-14. • The gear unit must be mounted in such a way that liquids cannot enter the motor adapter (HSS end) or the mounting flange (LSS end) and accumulate there.

-

Page 89: Prerequisites For Installation

Installation/assembly Prerequisites for installation Prerequisites for installation Check that the following conditions have been met: • The information on the motor's nameplate must match the voltage supply system. • The drive has not been damaged during transportation or storage. • Ambient temperature according to the order documents and the nameplate. -

Page 90: Installing The Gear Unit

Installation/assembly Installing the gear unit Installing the gear unit WARNING Danger due to insufficient attachment options on the part of the operator. Severe or fatal injuries. • Make sure that there are sufficient and suitable attachment options for the gear unit at the operator's machine before mounting the gear unit to the operator's ma- chine. - Page 91 Installation/assembly Installing the gear unit 6.5.1 Tightening torques: Gear unit mounting of foot-mounted design The following table shows the thread sizes and the tightening torques for mounting the individual gear unit sizes. Tightening torque Size Screw/nut Strength class 8.8 X100 – 110 X120 –...

- Page 92 Installation/assembly Installing the gear unit 6.5.3 Aligning the shaft axis WARNING Shafts can break if the shaft axis is not aligned accurately. Severe or fatal injuries. • Refer to the separate operation instructions regarding the requirements of the couplings. The service life of the shafts, bearings and couplings depends on the precision of the alignment of the shaft axes with each other.

-

Page 93: Gear Unit Mounting In Potentially Explosive Atmospheres

Installation/assembly Gear unit mounting in potentially explosive atmospheres Gear unit mounting in potentially explosive atmospheres INFORMATION Make sure to observe the safety notes in chapter 2 when installing the gear unit in a potentially explosive atmosphere. Gear units and gearmotor in equipment groups I and II INFORMATION Explosion-proof X.. - Page 94 Installation/assembly Gear units and gearmotor in equipment groups I and II Determine the lowest and highest limit value from the temperature ranges for surface and oil bath temperatures. Make sure that the gear unit is only operated within this temperature range. Do the following to determine the temperature range permitted for operating the gear unit: Choose the lower value from the upper limits of surface temperature and oil bath tem-...

- Page 95 Installation/assembly Gear units and gearmotor in equipment groups I and II The maximum surface temperature results from the division into temperature classes. The temperature classes indicate the maximum surface temperature for potentially ex- plosive gas atmospheres. The maximum surface temperature for potentially explosive dust atmospheres is indicated in the separate dust labeling.

-

Page 96: Speed Monitoring

Installation/assembly Speed monitoring The maximum permitted surface temperature results from the Ex classification on the nameplate. Other temperatures are only permitted after consultation with SEW- EURODRIVE. To determine the temperature range for the drive at which the gear unit may be oper- ated, you have to compare the information for the surface temperature (Ex classifica- tion) and the information for the oil bath temperature (lubricant table). -

Page 97: Filling The Gear Unit And Auxiliary Drive Adapter With Oil

Installation/assembly Filling the gear unit and auxiliary drive adapter with oil Filling the gear unit and auxiliary drive adapter with oil 6.9.1 Notes Observe the notes in chapter "Important information" (→ 2 85). The gear unit is delivered without oil fill as standard. Observe the following information for gear units: WARNING Risk of crushing if the drive starts up unintentionally. -

Page 98: Gear Units Delivered With Oil Fill (Option)

Installation/assembly Gear units delivered with oil fill (option) 6.10 Gear units delivered with oil fill (option) Observe the notes in chapter "Important information" (→ 2 85). NOTICE Improper startup can result in damage to the gear unit. Possible damage to property. • It is important that gear units with shaft end pump, motor pump or customer-in- stalled cooling system are vented before taking them into operation the first time. -

Page 99: Gear Units With Solid Shaft

Installation/assembly Gear units with solid shaft 6.11 Gear units with solid shaft 6.11.1 Mounting input and output components Observe the notes in chapter "Important information" (→ 2 85). NOTICE The bearing, housing, or shaft may be damaged due to improper assembly. Possible damage to property. •... -

Page 100: Flange Coupling With Cylindrical Interference Fit /Fc-S

Installation/assembly Flange coupling with cylindrical interference fit /FC-S 6.12 Flange coupling with cylindrical interference fit /FC-S Observe the notes in chapter "Important information" (→ 2 85). INFORMATION Before installation/assembly, first read the addendum to the operating instructions "Flange Coupling with Cylindrical Interference Fit /FC-S". 6.13 Flange coupling with keyway /FC-K Observe the notes in chapter "Important information" (→ 2 85). - Page 101 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 6.15.2 Dimensions of the machine shaft DIN 33 ø D2 ø D14 ø D15 Rmax. DR.M.. X..A100 47.5 80.4 X..A110 312.5 90.4 X..A120 244.5 190.5 100.4 X..A130 111.4 X..A140 122.4 X..A150 308.5 224.5 132.4...

- Page 102 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 6.15.3 Mounting the gear unit onto the machine shaft Sizes X100 – 160 Observe the notes in chapter "Important information" (→ 2 85). INFORMATION • Included in the delivery: – 2× retaining rings [8]/[9] and end plate [4] •...

- Page 103 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A INFORMATION Applying lubricant to the threaded rod and nut prior to assembly makes the job easier. 9007202143065995 Machine shaft Hollow shaft Threaded rod Retaining ring, inside End plate Retaining ring, outside 5.

- Page 104 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 6. Loosen the nut [5]. Screw out the threaded rod [2]. 9007202142726155 Threaded rod 7. Secure the machine shaft [1] with the retaining screw [6]. The retaining screw should also be locked with a suitable threadlocker. Observe the following informa- tion on the retaining screw [6].

- Page 105 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A INFORMATION When mounting protection cover (see chapter "Input output shafts" (→ 2 52)), make sure it entirely covers the gasket to guarantee it is dust- proof. If the gear unit is subject to increased vibrations during operation, secure the screws ®...

- Page 106 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A Observe the following information on the retaining screws [3]. Thread size for Tightening torque 6 x retaining screws Assembly/ Size Disassembly strength class 10.9 operating state X..A170 – 190 M10×30 Apply hand pressure X..A200 –...

- Page 107 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 4. Loosen the nut [5]. Screw out the threaded rod [2]. 9007202142726155 Threaded rod 5. Secure the machine shaft [1] with the retaining screw [6]. The retaining screw should also be locked with a suitable threadlocker. Observe the following informa- tion on the retaining screw [6].

- Page 108 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A INFORMATION When mounting protection cover (see chapter "Input output shafts" (→ 2 52)), make sure it entirely covers the gasket to guarantee it is dust- proof. If the gear unit is subject to increased vibrations during operation, secure the screws ®...

- Page 109 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 2. To protect the centering bore, screw the retaining screw [6] into the machine shaft [1]. 9007202105921291 Machine shaft Retaining screw 3. Turn the end plate [4] and remount it with the outer retaining ring [8]. 9007202105924619 End plate Retaining ring...

- Page 110 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 36028799870151563 Machine shaft End plate Ejector screw Assembly and Operating Instructions – X.. Series Bevel-Helical Gear Units Bucket Elevator Drives...

- Page 111 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A Size X170 – 280 Observe the notes in chapter "Important information" (→ 2 85). 1. Loosen the retaining screw [6]. 310460043 Retaining screw 2. Remove the retaining screws [3] and the end plate [4]. 310464523 Retaining screw End plate...

- Page 112 Installation/assembly Output shaft as a hollow shaft with keyed connection /..A 4. To disassemble the gear unit, flip the end plate [4] over and use the retaining screws [3] to reattach it centrically to the hollow shaft [7]. The retaining screws [3] should be tightened hand-tight.

-

Page 113: Output Shaft As A Hollow Shaft With Shrink Disk /..H

Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 6.16 Output shaft as a hollow shaft with shrink disk /..H INFORMATION Only drive components with corresponding ATEX approval are permitted, assuming that these components are covered by Directive 2014/34/EU. 6.16.1 General information The material of the machine shaft should be dimensioned by the customer according... - Page 114 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 6.16.2 Dimensions of the machine shaft 9007199906389771 X.F.. ø D5 ø D6 ø D17 ø D18 ø D19 ø D20 DIN 33 X.K.. X.T.. DR.M.. X..H100 394.5 X..H110 400.5 X..H120 286.5 190.5 X..H130...

- Page 115 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 6.16.3 Mounting the gear unit onto the machine shaft INFORMATION • Make sure the dimensions of the machine shaft correspond to SEW‑EURODRIVE specifications → see previous page. • Observe the manufacturer's shrink disk documentation. Sizes X100 –...

- Page 116 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H Observe the following information on the retaining rings [8][9]. 2 x retaining ring Size (bore) DIN 472 X..H100 80×2.5 X..H110 90×2.5 X..H120 100x3 X..H130 110x4 X..H140 120x4 X..H150 130x4 X..H160 140x4 INFORMATION Applying lubricant to the threaded rod and nut prior to assembly makes the job...

- Page 117 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 6. Loosen the nut [5]. Screw out the threaded rod [2]. 9007202134044427 Threaded rod 7. Secure the machine shaft [1] with the retaining screw [6]. The retaining screw [6] should also be locked with a suitable threadlocker.

- Page 118 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H CAUTION! The loose shrink disk could slip. Potential risk of crushing due to falling parts. Secure the shrink disk against slipping. 10. NOTICE! Tightening the screws without installed shaft might deform the hollow shaft.

- Page 119 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H [9a] [9b] [10] 18014401395749259 [9a] Taper (outer ring) [9b] Taper bushing (inner ring) [10] Locking screws 12. Work around the ring in several stages, evenly tighten the locking screws [10] by ¼...

- Page 120 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H CAUTION Improper assembly of the protection cover may result in risk of injury due to rotating parts. Possible injury to persons. • After assembly, check to see that the protection cover is properly attached. NOTICE Dust and dirt may damage the sealing system of the gear unit.

- Page 121 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H Size X170 – 280 Observe the notes in chapter "Important information" (→ 2 85). INFORMATION • Included in the delivery: – Retaining screws [3] and end plate [4]. • Not included in the delivery: –...

- Page 122 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 310497035 Machine shaft End plate Threaded rod Hollow shaft Retaining screws 5. Screw the nut [5] onto the threaded rod up to the end plate [4]. Tighten the nut [5] until the shoulders of the machine shaft [1] and the hollow shaft meet.

- Page 123 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H Size Strength class 8.8 Tightening torque in Nm Strength class 8.8 X..H170 – 230 1597 X..H240 – 280 2778 310510731 Machine shaft Retaining screw 8. Slide the shrink disk [9] with untightened screws onto the hollow shaft [7] and posi- tion the inner ring of the shrink disk [9b] with dimension A.

- Page 124 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 11. Tighten the locking screws [10] by hand. In doing so, align the bevel (outer ring) [9a] parallel to the taper bushing (inner ring) [9b] of the shrink disk. Successively tighten the locking screws [10] in a clockwise direction (not in a diametrically op- posite sequence), each with a quarter turn.

- Page 125 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H INFORMATION If the taper (outer ring) and the taper bushing (inner ring) cannot be aligned on the face that holds the screws, disassemble the shrink disk again and carefully clean/lub- ricate it as shown in the next chapter.

- Page 126 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 6.16.4 Disassembling the gear unit from the machine shaft Sizes X100 – 160 Observe the notes in chapter "Important information" (→ 2 85). NOTICE Removing the gear unit incorrectly from the machine shaft may damage bearings and other components.

- Page 127 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 3. Loosen the retaining screw [6]. Remove the outer retaining ring [8] and the end plate [4]. 9007202105918859 [4] End plate [6] Retaining screws [8] Retaining ring 4. To protect the centering bore, screw the retaining screw [6] into the machine shaft [1].

- Page 128 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 6. Thread the ejector screw [8] into the end plate [4] to remove the gear unit from the machine shaft [1]. Applying lubricant to the ejector screw [8] and the thread in the end plate [4] prior to disassembly makes the job easier.

- Page 129 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H Size X170 – 280 Observe the notes in chapter "Important information" (→ 2 85). NOTICE Removing the gear unit incorrectly from the machine shaft may damage bearings and other components. Possible damage to property. •...

- Page 130 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 2. Loosen the retaining screw [6]. 310460043 Retaining screw 3. Remove the retaining screws [3] and the end plate [4]. 310464523 [3] Retaining screw [4] End plate 4. To protect the centering bore, screw the retaining screw [6] into the machine shaft [1].

- Page 131 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H 5. To disassemble the gear unit, flip the end plate [4] over and use the retaining screws [3] to reattach it centrically to the hollow shaft [7]. The retaining screws [3] should be tightened hand-tight.

- Page 132 Installation/assembly Output shaft as a hollow shaft with shrink disk /..H Cleaning and lubricating the shrink disk Observe the notes in chapter "Important information" (→ 2 85). Clean and lubricate the shrink disk before installing it again. INFORMATION • You must perform the following steps carefully to ensure proper functioning of the shrink disk.

-

Page 133: Output Shaft As A Splined Hollow Shaft /..V

Installation/assembly Output shaft as a splined hollow shaft /..V 6.17 Output shaft as a splined hollow shaft /..V INFORMATION Only drive components with corresponding ATEX approval are permitted, assuming that these components are covered by Directive 2014/34/EU. 6.17.1 General information The material of the machine shaft should be dimensioned by the customer according to the loads that will occur (e.g. - Page 134 Installation/assembly Output shaft as a splined hollow shaft /..V 6.17.2 Dimensions of the machine shaft DIN 332 C1 C2 ø D25 ø D26 ø D27 ø D28 ø D29 Dm FA DIN 5480 DR.M.. -0.069 X..100 30 14 74.4 3 M24 W 75x3x30x24x8f 81.326 N 75x3x30x24x9H...

- Page 135 Installation/assembly Output shaft as a splined hollow shaft /..V 6.17.3 Mounting the gear unit onto the machine shaft INFORMATION Make sure the dimensions of the machine shaft correspond to SEW‑EURODRIVE specifications → see previous page. Size X100 – 160 Observe the notes in chapter "Important information" (→ 2 85). INFORMATION •...

- Page 136 Installation/assembly Output shaft as a splined hollow shaft /..V NOTICE Dust and dirt may damage the sealing system of the gear unit. Possible damage to property. • Make sure to attach the protection cover correctly and dust-tight after completing assembly. INFORMATION When mounting...

- Page 137 Installation/assembly Output shaft as a splined hollow shaft /..V Size X170 – 320 Observe the notes in chapter "Important information" (→ 2 85). INFORMATION • Included in the delivery: – Retaining screws [3] and end plate [4]. • Not included in the delivery: –...

- Page 138 Installation/assembly Output shaft as a splined hollow shaft /..V 9007200026433547 Machine shaft End plate Threaded rod Hollow shaft Retaining screws 4. Tighten the machine shaft [1] with the nut [5] until the shoulders of the machine shaft and the hollow shaft [7] meet. 771696651 Machine shaft Hollow shaft...

- Page 139 Installation/assembly Output shaft as a splined hollow shaft /..V 5. Loosen the nut [5]. Screw out the threaded rod [2]. 771752587 Threaded rod 6. Secure the machine shaft [1] with the retaining screw [6]. The retaining screw should also be locked with a suitable thread locker. Observe the following informa- tion on the retaining screw [6].

- Page 140 Installation/assembly Output shaft as a splined hollow shaft /..V NOTICE Dust and dirt may damage the sealing system of the gear unit. Possible damage to property. • Make sure to attach the protection cover correctly and dust-tight after completing assembly. INFORMATION When mounting...

- Page 141 Installation/assembly Output shaft as a splined hollow shaft /..V 6.17.4 Disassembling the gear unit from the machine shaft NOTICE Improper disassembly of the gear unit and machine shaft may damage bearings and other components. Possible damage to property. • You may only use the hollow shaft as a support for disassembly. Note that sup- porting on any other parts of the gear unit may damage the material.

- Page 142 Installation/assembly Output shaft as a splined hollow shaft /..V 3. Turn the end plate [4] and reinstall the end plate [4] and the outer retaining ring [8]. 3241265291 End plate Retaining ring 4. Thread the ejector screw [9] into the end plate [4] to remove the gear unit from the machine shaft [1].

- Page 143 Installation/assembly Output shaft as a splined hollow shaft /..V Sizes X170 – 320 1. Loosen the retaining screw [6]. 3241268619 [6] Retaining screw 2. Remove the retaining screws [3] and the end plate [4]. 3241279627 [3] Retaining screw [4] End plate 3.

- Page 144 Installation/assembly Output shaft as a splined hollow shaft /..V 4. To disassemble the gear unit, flip the end plate [4] over and use the retaining screws [3] to reattach it centrically to the hollow shaft [7]. The retaining screws [3] should be tightened hand-tight.

-

Page 145: Torque Arm /T

Installation/assembly Torque arm /T 6.18 Torque arm /T Observe the notes in chapter "Important information" (→ 2 85). WARNING Insufficiently secured gear units can fall down during disassembly and assembly. Severe or fatal injuries. • Secure the gear unit during assembly and disassembly. Support the gear unit us- ing appropriate tools. - Page 146 Installation/assembly Torque arm /T 2. NOTICE! Make sure that the stud bolt [2] is screwed simultaneously into the yoke [1] and the joint head [3]. Possible damage to property. The stud bolt [2] must be screwed evenly into the yoke [1] and the joint head [3], covering a length of at least 1 x the bolt's diameter.

-

Page 147: Couplings

Installation/assembly Couplings 6.19 Couplings INFORMATION The couplings must be marked for the use in potentially explosive areas. Also adhere to the special operating instructions given by the respective coupling manufacturer. 6.19.1 Mounting tolerances Adjust the following misalignments according to the coupling manufacturer's specifica- tions when mounting couplings. - Page 148 Installation/assembly Couplings Measuring in- Angular offset Axis offset struments Micrometer dial A prerequisite for this measuring method is The following figure shows the how to that there is no axial play in the shaft bear- measure axial offset using a more accurate ings when the shafts rotate.

- Page 149 Installation/assembly Motor adapter /MA 6.20 Motor adapter /MA 6.20.1 Maximum permitted motor weight Two criteria are to be checked when mounting a motor onto the gear unit: 1. Maximum motor weight depends on gear unit design and mounting type 2. Maximum motor weight depends on motor adapter size INFORMATION The motor weight may not exceed either one of these criteria.

- Page 150 Installation/assembly Motor adapter /MA 2. Maximum motor weight depends on motor adapter size The following maximum loads on the motor adapter must not be exceeded. 9007199611271819 [1] Center of gravity of the motor X = Distance from the center of gravity [2] Motor adapter = Weight of the mounted motor INFORMATION...

- Page 151 Installation/assembly Motor adapter /MA 6.20.2 Claw coupling INFORMATION Observe the operating instructions of the respective coupling manufacturer. ROTEX® coupling Observe the notes in chapter "Important information" (→ 2 85). Mounting the coupling 9007205071635979 1. NOTICE! Improper assembly can damage the coupling halves [1][2]. Possible damage to property.

- Page 152 Installation/assembly Motor adapter /MA 3. NOTICE! Improper mounting may result in damage to the coupling. Possible dam- age to property. During assembly, it is essential to observe dimension E so that the spider remains axially flexible during operation. The dimension E is listed in the following table.

- Page 153 Installation/assembly Motor adapter /MA Displacement – Aligning the coupling NOTICE Improper mounting of the coupling may result in damage. Possible damage to property. • The shaft ends must be aligned accurately to ensure a long service life of the coupling. Strictly adhere to the displacement values specified in the following chapter.

- Page 154 Installation/assembly Motor adapter /MA 100% 20% 30% 40% 50% 60% 70% 80% 90% 100% Radial offset ∆K 5989508747 Displacement values The following table shows the displacement values: Coupling Max. axial displacement Max. radial misalignment Angular displacement ΔK Angular displacement ΔK size ΔK in mm...

-

Page 155: Motor Adapter /Ma

Installation/assembly Base frame /BF 6.20.3 Attaching the motor to the motor adapter Observe the notes in chapter "Important information" (→ 2 85). 1. Clean the motor shaft and flange surfaces of the motor and the motor adapter. They must be dry and free of grease. INFORMATION ®... - Page 156 Installation/assembly Base frame /BF NOTICE Improper assembly may result in damage to the gear unit. Possible damage to property. • Check to see that the support structure of the foot mounting is adequately dimen- sioned and rigid. • Fasten the frame to the gear unit foundation using only the mounting holes provided for this purpose.

-

Page 157: Swing Base /Sb

Installation/assembly Swing base /SB 6.22 Swing base /SB Observe the following notes: NOTICE Improper assembly may result in damage to the gear unit. Possible damage to property. • The system frame must be sufficiently dimensioned to absorb the torque of the torque arm. - Page 158 Installation/assembly Water cooling cover /CCV 6.24 Water cooling cover /CCV INFORMATION A water cooling cover can only be used in connection with a temperature monitoring device on the gear unit. 6.24.1 Notes on connection/installation INFORMATION Make sure that the connection to the cooling circuit complies with ATEX require- ments.

- Page 159 Installation/assembly Water cooling cover /CCV • Install filters in the cooling water inlet to prevent the heat exchanger from dirt and mud in particular if the cooling water is obtained from sources other than the public water supply system. • Install an automatic throttle valve in the respective inlet to compensate pressure.

- Page 160 Installation/assembly Water cooling cartridge /CCT 6.25 Water cooling cartridge /CCT INFORMATION Water cooling cartridges may only be used in connection with a temperature monitor- ing device on the gear unit. 6.25.1 Notes on connection/installation INFORMATION Make sure that the connection to the cooling circuit complies with ATEX require- ments.

- Page 161 Installation/assembly Water cooling cartridge /CCT 370075915 Supply (cold water) Return (warm water discharge) The following measures can be taken to ensure proper functioning in different sys- tems: • Install a safety valve in the cooling water inlet to prevent fluctuations in pressure and volume.

- Page 162 Installation/assembly Water cooling cartridge /CCT 0 – 5 °dH Very soft water 5 – 10 °dH Soft water 10 – 20 °dH Medium hard water 20 – 30 °dH Hard water > 30 °dH Very hard water 1) 10 mg/l of hardener corresponds to 1 °dH pH value •...

- Page 163 Installation/assembly Water cooling cartridge /CCT Cooling water assessment based on water substances The following table provides an overview of the resistance of copper-nickel pipes against substances in non-potable water. Assessment criterion Approximate concentration Evaluation mg/l CuNi10Fe1Mn < 6 pH value 6 to 9 >...

- Page 164 Installation/assembly Water cooling cartridge /CCT Types of cooling water/characteristics Note the following conditions: Industrial water • Usually untreated water (no drinking water) • Often very contaminated • A water analysis is necessary for assessment • Copper, brass and steel are very resistant against industrial water Stream water and river water •...

- Page 165 Installation/assembly Oil-water cooler for splash lubrication /OWC 6.26 Oil-water cooler for splash lubrication /OWC Observe the notes in chapter "Important information" (→ 2 85). INFORMATION Before installation/assembly, first read the addendum to the operating instructions "Oil-Water Cooler with Motor Pump for Splash Lubricaton /OWC". 6.27 Oil-air cooler for splash lubrication /OAC Observe the notes in chapter "Important information" (→ 2 85).

- Page 166 Installation/assembly Motor pump /ONP1L 6.30 Motor pump /ONP1L Observe the notes in chapter "Important information" (→ 2 85). INFORMATION Before installation/assembly, first read the addendum to the operating instructions "Motor Pump /ONP1L". 6.31 Motor pump /ONP1 Observe the notes in chapter "Important information" (→ 2 85). INFORMATION Before installation/assembly, first read the addendum to the operating instructions "Motor Pump /ONP1".

- Page 167 Installation/assembly Oil heater /OH 6.33 Oil heater /OH WARNING Danger of electric shock. Severe or fatal injuries. • De-energize the oil heater before you start working on the unit. • Secure the oil heater against unintended power-up. NOTICE Improper installation of the oil heater may result in damage to the gear unit. Possible damage to property.

- Page 168 Installation/assembly Oil heater /OH 6.33.1 Notes regarding the function of the oil heater • The heater is screwed into the gear unit housing at the factory and is controlled by a thermostat. The trip temperature of the heater is set at the factory depending on the lubricant used.

- Page 169 Installation/assembly Oil heater /OH ϑ Thermostat Explosive atmosphere Non-explosive atmosphere Isolation amplifier 24153214219 Electrical connection WARNING Risk of injury due to electric shock. Severe or fatal injuries. • Disconnect the unit from the supply system if live parts can be touched during work on the unit.

- Page 170 Installation/assembly Oil heater /OH Maximum switching capacity: Nominal impulse voltage: 2500 V Overvoltage category II (via the switching contacts 400 V) Required fusing: See maximum switching current • Permitted ambient temperature: -40˚ C to +80° C • Permitted storage temperature: min. -50° C, max. +50° C •...

- Page 171 Installation/assembly Oil heater /OH 6.33.3 Oil level monitoring INFORMATION • Observe the manufacturer's operating instructions. • If the oil level is too low, switch off the drive and the oil heater. 6.33.4 Temperature sensors in heating elements The operator's control evaluates the temperature sensor and controls the operator's switching devices.

- Page 172 Installation/assembly Oil heater /OH 6.33.6 Connection power and electrical connection of resistor element The gear unit heater comes equipped with cable glands and jumpers. They are in- cluded in the scope of delivery of the screw-in heaters and are already preassembled. The gear unit heater is connected to the current supply via terminal studs.

- Page 173 Installation/assembly Oil heater /OH AC voltage/1‑phase/230 V/3 heating resistors The oil heaters described in this chapter are equipped with 3 heating resistors per heating element. For connecting the oil heater, refer to the manufacturer's documenta- tion included in the delivery. The following table shows the connected load of the installed heater. inst inst Gear unit...

- Page 174 Installation/assembly Incremental encoder with speed monitor 6.34 Incremental encoder with speed monitor 6.34.1 Notes INFORMATION • The incremental encoder must be used with an isolation amplifier that enables in- trinsically safe switching operations. The isolation amplifier must be located out- side the potentially explosive atmosphere.

- Page 175 Installation/assembly Pressure switch /PS 6.35 Pressure switch /PS INFORMATION All gear units with pressure lubrication are equipped with a pressure switch for func- tion monitoring. The pressure switch is to be connected and integrated into the system in such a way that the gear unit can only be operated when the oil pump is building up pressure.

- Page 176 Installation/assembly Pressure switch /PS 6.35.2 Dimensions G 1/4" 721994635 6.35.3 Electrical connection 722003723 [1][2] NC contact [1][4] NO contact 6.35.4 Technical data • Switching pressure 0.5 ± 0.2 bars • Maximum switching capacity 4 A - 250 V ; 4 A - 24 V •...

- Page 177 Installation/assembly Temperature sensor /PT100 6.36 Temperature sensor /PT100 6.36.1 Information INFORMATION • To ensure intrinsically safe wiring, the temperature sensor must be used with a Zener barrier whose current consumption enables correct measuring operation. • The Zener barrier must be located outside the potentially explosive atmosphere. •...

- Page 178 Installation/assembly Temperature sensor /PT100 6.36.3 Electrical connection 359158539 [1] [2] Resistor element connection 6.36.4 Technical data • Design with thermowell and changeable measuring insert • Sensor tolerance [K] ± (0.3 + 0.005 x T), (corresponds to DIN IEC 751 class B), T = Oil temperature [°C] •...

- Page 179 Installation/assembly Temperature sensor /PT100 (metallic) 6.37 Temperature sensor /PT100 (metallic) INFORMATION • To ensure intrinsically safe wiring, the temperature sensor must be used with a Zener barrier whose current consumption enables correct measuring operation. • The Zener barrier must be located outside the potentially explosive atmosphere. •...

- Page 180 Installation/assembly Temperature sensor /PT100 (metallic) 6.37.1 Technical data 44.5 4401813899 Area of application For monitoring the oil temperature Operating temperature -50 °C to 400 °C Thermowell diameter Ø 7 mm Installation length 100 mm Process connection G1/2 screw fitting Measuring insert 1 x PT100 in double-wire circuit Tolerance class in accordance with Class B (standard) EN 60751...

- Page 181 Installation/assembly Temperature switch /NTB 6.38 Temperature switch /NTB 6.38.1 Notes INFORMATION • The temperature switch must be used with an isolation amplifier that enables in- trinsically safe switching operations. The isolation amplifier must be located out- side the potentially explosive atmosphere. •...

- Page 182 Installation/assembly Temperature switch /NTB 6.38.2 Dimensions G1/2" 9007199621265931 6.38.3 Electrical connection To guarantee a long service life and trouble-free functioning, we recommend that you use a relay in the power circuit instead of a direct connection through the temperature switch. 366532491 [1][3] NC contact (without vacuum) Grounding terminal 6.3 x 0.8...

- Page 183 Installation/assembly Temperature switch /TSK 6.39 Temperature switch /TSK 6.39.1 Notes INFORMATION • The temperature switch must be used with an isolation amplifier that enables in- trinsically safe switching operations. The isolation amplifier must be located out- side the potentially explosive atmosphere. •...

-

Page 184: Brake

Installation/assembly Brake 6.39.2 Dimensions L=80 SW36 893872779 6.39.3 Electrical connection To guarantee a long service life and trouble-free functioning, we recommend that you use a relay in the power circuit instead of a direct connection through the temperature switch. TKS 60 °C TKS 90 °C 36028797912842123 [1][2]... -

Page 185: Startup

Startup Important information Startup Important information Read the following notes prior to startup. WARNING Risk of crushing if the drive starts up unintentionally. Severe or fatal injuries. • Work on the gear unit only when the machine is not in use. Secure the drive unit against unintentional power-up. - Page 186 Startup Important information • Fill the gear unit with the oil grade specified on the nameplate. The oil quantity specified on the nameplate is an approximate quantity. The markings on the oil dipstick are the decisive indicators for the oil quantity to be filled into the unit. For additional information, refer to chapter "Checking the oil level" ...

-

Page 187: Starting Up Gear Units In Potentially Explosive Atmospheres

Startup Starting up gear units in potentially explosive atmospheres 7.1.1 Permitted external loads During project planning, the drives are dimensioned according to the radial and axial loads described in the order confirmation. INFORMATION If the configured loads are exceeded during operation, the drive may be damaged and impermissibly high temperatures may occur. -

Page 188: Startup Of Gear Units With Long-Term Protection

Startup Startup of gear units with long-term protection Startup of gear units with long-term protection Adhere to the following points for gear units with long-term protection: 7.3.1 Anti-corrosion agent Clean the output shafts and flange surfaces thoroughly to ensure they are free of anti- corrosion agents, contamination or similar. -

Page 189: Startup Sequence

Startup Startup sequence Startup sequence NOTICE Improper startup may result in damage to the gear unit. Possible damage to property. • Observe the following sequence for startup. 1. Startup of the auxiliary drive 2. Startup of the speed monitor 3. Startup of the main drive 7.4.1 Starting up the auxiliary drive Make sure that the rotary motion of the input shaft of the main gear unit is not obstruc-... - Page 190 Startup Startup sequence Functional test of the speed monitoring 1. Switch on the auxiliary drive of the bucket elevator drive. 2. Briefly set the switching speed to a lower value than the output speed of the auxili- ary drive. 3. The speed monitor detects overspeed and the output relay becomes operative. The functional test is successful when the current supply to the main and auxiliary drives is interrupted.

-

Page 191: Torque-Limited Backstop

Startup Torque-limited backstop Torque-limited backstop NOTICE The slipping torque may not be changed by any means for safety reasons. Possible damage to property. • There is a risk that the load cannot be kept safely in its position after the motor is switched off and that it can accelerate in the opposite direction. -

Page 192: Water Cooling Cartridge /Cct

Startup Water cooling cartridge /CCT Water cooling cartridge /CCT NOTICE Risk of damage to the system due to performance loss. Possible damage to property. • A loss of performance may result from the formation of scale on the inside of the pipe. -

Page 193: Oil-Water Cooler For Pressure Lubrication /Owp

Startup Oil-water cooler for pressure lubrication /OWP 7.10 Oil-water cooler for pressure lubrication /OWP INFORMATION Before startup, first read the addendum to the operating instructions "Oil-Water Cooler for Pressure Lubrication /OWP". 7.11 Oil-air cooler for pressure lubrication /OAP INFORMATION Before startup, first read the addendum to the operating instructions "Oil-Air Cooler for Pressure Lubrication /OAP". -

Page 194: Oil Heater /Oh

Startup Oil heater /OH 7.14 Oil heater /OH WARNING Risk of explosion due to an incorrect oil level. Severe or fatal injuries. • If the heater is operated with insufficient oil level, surfaces might heat up and turn into an ignition source. •... -

Page 195: Backstop /Bs

Startup Backstop /BS 7.15 Backstop /BS INFORMATION Regular operation of the backstop below the lift-off speed is not permitted, except during temporary starting and braking and in auxiliary drive mode. The permitted min- imum speed rating is listed on the nameplate. NOTICE Operating the motor in blocking direction could destroy the backstop. -

Page 196: Measuring The Surface And Oil Temperatures

Startup Measuring the surface and oil temperatures 7.16 Measuring the surface and oil temperatures INFORMATION Even slight changes in the ambient conditions (such as limited installation space) can have a significant impact on the temperature profile. For more information, refer to chapters "Temperature information" (→ 2 93) and "Permitted lubricants" (→ 2 232). -

Page 197: Gear Unit Shutdown / Gear Unit Conservation

Startup Gear unit shutdown / gear unit conservation 7.18 Gear unit shutdown / gear unit conservation WARNING Risk of crushing if the drive starts up unintentionally. Severe or fatal injuries. • Work on the gear unit only when the machine is not in use. Secure the drive unit against unintentional power-up. - Page 198 Startup Gear unit shutdown / gear unit conservation 7.18.2 External corrosion protection • Clean the respective surfaces. • Grease the shaft near the sealing lip to separate the sealing lip of the oil seal and the anti-corrosion agent. • Apply a wax-based protective coating to shaft ends and unpainted surfaces as ex- ternal corrosion protection...

-

Page 199: Inspection/Maintenance

Inspection/maintenance Preliminary work for inspection and maintenance Inspection/maintenance Preliminary work for inspection and maintenance Observe the following notes before you start with inspection/maintenance work. WARNING Risk of crushing if the drive starts up unintentionally. Severe or fatal injuries. • Work on the gear unit only when the machine is not in use. Secure the drive unit against unintentional power-up. - Page 200 Inspection/maintenance Preliminary work for inspection and maintenance CAUTION Danger due to leakage of lubricant. Injuries. • Remove any dripping oil immediately with oil binding agent. NOTICE Filling in the wrong oil may result in significantly different lubricant characteristics. Possible damage to property. •...

-

Page 201: Inspection And Maintenance Intervals

Inspection/maintenance Inspection and maintenance intervals • For third-party parts, such as cooling systems, observe the separate inspection and maintenance intervals of the manufacturer's documentation. • Strictly observe the safety notes in the individual chapters. Inspection and maintenance intervals Adhere to the following inspection and maintenance intervals: Time interval What to do? Daily... - Page 202 Inspection/maintenance Inspection and maintenance intervals Time interval What to do? At least every 3 years depending on the • Change mineral oil. operating conditions (see figure on next page) At least every 5 years depending on the • Change synthetic oil. operating conditions (see figure on next page) •...

-

Page 203: Lubricant Change Intervals

Inspection/maintenance Lubricant change intervals Lubricant change intervals It might be necessary to change the oil more frequently when using special designs or under more severe/aggressive ambient conditions. INFORMATION Mineral CLP lubricants and synthetic polyalphaolefin-based (PAO) lubricants are used for lubrication. The synthetic lubricant CLP HC (according to DIN 51502) shown in the following illustration corresponds to the PAO oils. -

Page 204: Checking The Oil Level

Inspection/maintenance Checking the oil level Checking the oil level 8.4.1 General information Note the following when checking the oil level. NOTICE Improper checking of the oil level may result in damage to the gear unit. Possible damage to property. • Check the oil level only when the gear unit is at idle state. - Page 205 Inspection/maintenance Checking the oil level 6. Screw in the oil fill plug. 7. Insert the oil dipstick. Oil sight glass Observe the notes in chapter "Preliminary work regarding inspection and mainten- ance" (→ 2 199). The oil sight glass only shows the oil level. The oil level is determined using the oil dipstick.

- Page 206 Inspection/maintenance Checking the oil level 8.4.3 Notes on the procedure for fixed and variabel pivoted mounting positions Observe the information on the nameplate and in the order documents. Fixed pivoted mounting positions Procedure Check the oil level in the fixed, intended position. Observe the notes in chapter "Standard procedure" (→ 2 204).

- Page 207 Inspection/maintenance Checking the oil level The following figure shows an example of the information sign for check mounting po- sition 0°. 01.1234567812.0001.06 M1-M2 [0°] 1897 737 5 9007204944147979 The following figure shows an example of the information sign for check mounting po- sition 20°.

- Page 208 Inspection/maintenance Checking the oil level Combination of fixed and variable pivoted mounting positions Procedure Observe the following procedure when combining fixed and variable pivoted mount- ing positions. Before checking the oil level of gear units with variable/fixed pivoted mounting posi- tion, position the gear unit in the mounting position defined in the order documents.

- Page 209 Inspection/maintenance Checking the oil level Following an example of the information sign for checking the mounting position at 30°. 01.1234567812.0001.06 M1-M5 [30°] 1897 737 5 9007204944186379 Following an example of the information sign for checking the mounting position at 30°. 01.1234567812.0001.06 M1-M2 [20°] M1-M5 [30°]...

-

Page 210: Checking The Oil Consistency

Inspection/maintenance Checking the oil consistency Checking the oil consistency Observe the notes in chapter "Preliminary work regarding inspection and mainten- ance" (→ 2 199). Proceed as follows to check the oil consistency: 1. Start the gear unit for a short time for the oil to mix with suspended particles. 2. - Page 211 Inspection/maintenance Changing the oil • The oil grade and oil viscosity are listed on the nameplate of the gear unit. The oil quantity specified on the nameplate is an approximate quantity. The mark on the oil dipstick or the oil level glass is the decisive indicator of the correct oil quantity. When additional attachments, e.g.

- Page 212 Inspection/maintenance Changing the oil 8.6.2 Procedure 27021598273932171 Oil drain plug bevel-helical gear units Oil drain plug auxiliary drive adapter Oil filling plug bevel-helical gear unit Oil filling plug of the auxiliary drive adapter Observe the notes in chapter "Preliminary work regarding inspection and mainten- ance" (→ 2 199).

-

Page 213: Breather /Bpg

Inspection/maintenance Breather /BPG Size Oil quantity in liters Size Oil quantity in liters X3K130 X3K230 X3K140 X3K240 X3K150 X3K250 X3K160 X3K260 X3K170 X3K270 X3K180 X3K280 X3K190 • Use a filling filter to fill the oil into the gear unit (max. filter mesh 25 µm). •... - Page 214 Inspection/maintenance Breather /BPG 8.7.2 Desiccant breather filter /DC Proper operation: If possible, use desiccant breather filters only for gear units filled with new oil that do not contain water. Only then can the maximum service life of the filter be ensured. The service life of the filters usually is 12 months, after that time the filters must be re- placed.

-

Page 215: Refilling Grease

Inspection/maintenance Refilling grease Refilling grease WARNING Risk of crushing due to rotating parts. Severe or fatal injuries. • Make sure to provide for sufficient safety measures for relubrication. INFORMATION Make sure that the old grease cannot escape uncontrolled (preventing explosions, e.g. -