Table of Contents

Advertisement

Quick Links

Instruction and service manual

Roots vacuum pumps

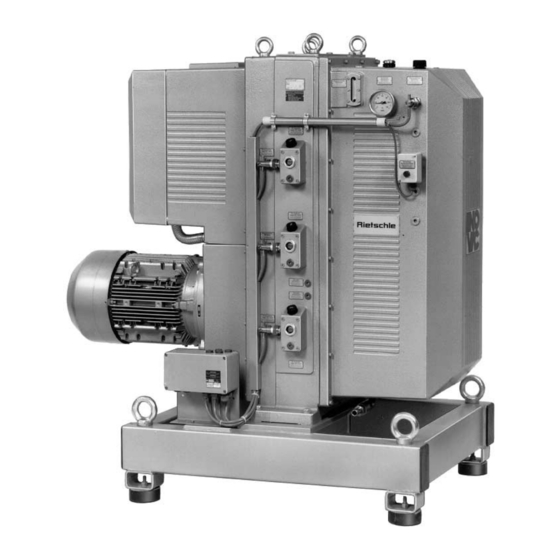

VWP-3

VWP 160-3

VWP 160-3 / 250-3

VWP 250-3

VWP 400-3

BE 221

2.4.99

Werner Rietschle

GmbH + Co. KG

Postfach 1260

79642 SCHOPFHEIM

GERMANY

Fax 0 76 22 / 39 23 00

E-Mail: info@rietschle.com

http://www.rietschle.com

Rietschle (UK) Ltd.

Bellingham Way

NEW HYTHE

KENT ME20 6XS

UNITED KINGDOM

Fax 0 16 22 / 71 51 15

E-Mail: info@rietschle.co.uk

VWP 400-3

http://www.rietschle.co.uk

0 76 22 / 3 92-0

0 16 22 / 71 68 16

Advertisement

Table of Contents

Summary of Contents for Rietschle INOVAC VWP-3 Series

- Page 1 79642 SCHOPFHEIM GERMANY 0 76 22 / 3 92-0 Fax 0 76 22 / 39 23 00 E-Mail: info@rietschle.com http://www.rietschle.com Rietschle (UK) Ltd. Bellingham Way NEW HYTHE KENT ME20 6XS UNITED KINGDOM 0 16 22 / 71 68 16 Fax 0 16 22 / 71 51 15 E-Mail: info@rietschle.co.uk...

-

Page 2: Table Of Contents

Table of contents: Page: Introduction Application Design Construction INOVAC sectional drawings 3.2.1 Cross section through compressor stages 3.2.2 Longitudinal section INOVAC Principle of operation INOVAC individual components 3.4.1 Drive 3.4.2 Power transmission 3.4.3 Compressor stages 3.4.4 Lubrication 3.4.5 By-pass system 3.4.6 Sealing gas 3.4.7... -

Page 3: Introduction

1. Introduction To prevent contamination from possible dangerous sub- stances contained in the process, the exhaust outlet must always be connected to an appropriate emission control system. All units being returned to our works for mainte- nance or any other reason must be free of harmful and dangerous material. -

Page 4: Inovac Sectional Drawings

VWP 160-3 / 250-3 3.2 INOVAC sectional drawings 3.2.1 Cross section through compressor stages 1 Bearing lubrication LP 2 Bearing lubrication MP 3 Bypass system 4 Bearing lubrication HP 5 Vacuum connection 6 Outlet valves 7 Exhaust air connection 3.2.2 Longitudinal section INOVAC 8 Sealing 9 Service temperature sensor (VWP 400-3) 10 LP stage... -

Page 5: Inovac Individual Components

3.4 INOVAC individual components VWP 160-3 / 250-3 VWP 400-3 3.4.1 Drive The INOVAC vacuum pump is driven by a flanged electric motor, normally the stand- ard drive supplied with a basic design is 400/690 V, 50 Hz, IP 54, 1450 rpm, B 5 LP stage flange: LP stage... -

Page 6: Lubrication

3.4.4 Lubrication The INOVAC vacuum pump is a dry running pump and consequently the only lubrication to the stages is to the bearing and gear drive areas. This is by means of splash discs (see picture 7). Depending upon stage size the total oil fill quantity, including pipelines and storage reservoir is approxi- mately 1.31 l. -

Page 7: Cooling System

3.4.7 Cooling system The INOVAC vacuum pumps are liquid-cooled. There are two cooling variants. 3.4.7.1 Radiator cooling (pict. 9) With the radiator cooling the medium is circulated, unpressurized in a closed circuit via a small rotary pump, independent of the coolant tempera- ture. -

Page 8: Electrical Installation

Electrical installation 5.2.1 General (see data sheet D 221) The electrical data can be found on the data plate (N) or the motor data plate. The motors correspond to DIN / VDE 0530 and have IP 54 protection and insulation class B or F. The connection diagram can be found in the terminal box on the motor. Check the electrical data of the motor and the control gear for compatibility with your available supply (voltage, frequency, permissible current etc.). -

Page 9: Coolant

Yoo can see the quantity of coolant in the data (9.7). For other coolants please contact Rietschle. The coolant can be drained by opening the drain valve (K ) near the base of the water jacket (Y... -

Page 10: Initial Operation

7. Initial Operation (see data sheet D 221) Warning –> Start-up with pipework At start-up, severe damage may occur if there is debris in the pipework. We therefore recommend a vacuum tight inlet filter of 5 micron rating is installed for start-up. The pump will normally be delivered with the bearing oil reservoirs filled but these should be checked before first start up. -

Page 11: Exchanging Stages

7 and 9.5) check all connections for possible leak- age. Mount the cooler housing (see chapter 8.3.1). The stages themselves can be checked and repaired at an authorised Rietschle service centre, therefore they should be returned with the appropriate Health and Safety certifi- cate. -

Page 12: Lager

8.5 Bearings (see pos. 48 and 541 E 220/1 VWP 400-3 resp. E 221/1 VWP 160-3/ 250-3) Check bearings for wear after 15,000 operating hours, however exchange the bearings at the latest after 20,000 operating hours. 8.6 Valves (see pos. 4 E 220/1 VWP 400-3 resp.

Need help?

Do you have a question about the INOVAC VWP-3 Series and is the answer not in the manual?

Questions and answers