Table of Contents

Advertisement

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE

SAFETY INFORMATION

WARNING

!

If the information in these instructions

are not followed exactly, a fi re or

explosion may result causing property

damage, personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use

any phone in your building.

•

Immediately call your gas supplier from a

neighbour' s phone. Follow the gas supplier' s

instructions.

•

If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certifi ed kit is used.

$10.00

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

OPERATING INSTRUCTIONS

INSTALLATION AND

GD80NT-1ME

GD80PT-1ME

WARNING

!

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

1.28C

Advertisement

Table of Contents

Summary of Contents for Napoleon GD80NT-1ME

- Page 1 INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE. CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE. NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE INSTALLATION AND OPERATING INSTRUCTIONS GD80NT-1ME SAFETY INFORMATION GD80PT-1ME WARNING If the information in these instructions are not followed exactly, a fi...

-

Page 2: Table Of Contents

TABLE OF CONTENTS INSTALLATION OVERVIEW INTRODUCTION VENTING INSTALLATION FRAMING FINISHING OPERATION ELECTRICAL INFORMATION OPERATING INSTRUCTIONS 10.0 ADJUSTMENT 11.0 MAINTENANCE 12.0 REPLACEMENTS 13.0 TROUBLESHOOTING 14.0 WARRANTY 15.0 SERVICE HISTORY NOTE: Changes other than editorial are denoted by a vertical line in the margin. -

Page 3: Installation Overview

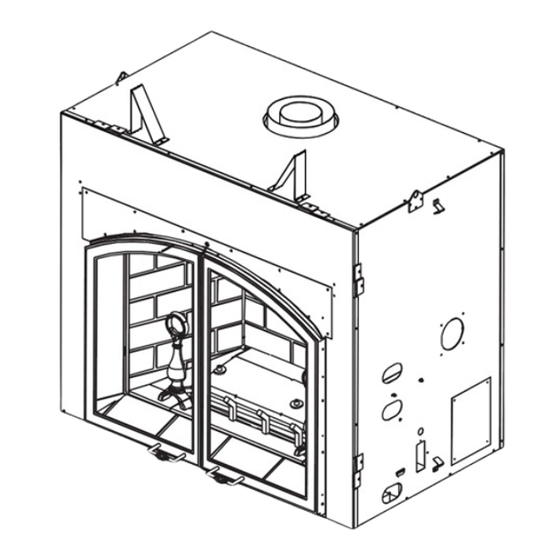

1.0 INSTALLATION OVERVIEW See the sections “ MINIMUM ENCLOSURE CLEARANCES” for drywall See the sections “ MINIMUM (or other combustible ENCLOSURE material) CLEARANCES” for non-combustible material See the section “ MINIMUM See the section MANTEL AND ENCLOSURE “ VENTING” and CLEARANCES”... -

Page 4: Introduction

2.0 INTRODUCTION WARNING • THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED. • ANY CHANGES OR ALTERATIONS TO THIS APPLIANCE OR ITS CONTROLS CAN BE DANGEROUS AND IS PROHIBITED. 3.2B... - Page 5 DIMENSIONS GENERAL INSTRUCTIONS WARNING ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT, WITH THE GLASS DOOR OPENED OR REMOVED. PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE. PROVIDE ADEQUATE VENTILATION. NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

- Page 6 4.1A GENERAL INFORMATION FOR YOUR SATISFACTION, THIS APPLIANCE HAS BEEN TEST-FIRED TO ASSURE ITS OPERATION AND QUALITY! APPLIANCE...

- Page 7 RÉFÉRER AU MANUEL D'INSTRUCTION POUR DES ELECTRICAL RATING: 115V 0.82AMP, 60HZ EXTENSIONS PLUS GRANDES. RÉFÉRER AU MANUEL SERIAL NUMBER/ D'INSTALLATIONDE PROPRIÉTAIRE. WOLF STEEL LTD. GD80 CLASSIFICATION: 115V 0.82AMP, 60HZ NO. DE SÉRIE: 24 NAPOLEON ROAD, BARRI E, ON, L4M 0G8 CANADA W385-0294 W385-0294 / G...

-

Page 8: Venting

3.0 VENTING WARNING RISK OF FIRE, MAINTAIN SPECIFIED AIR SPACE CLEARANCES TO VENT PIPE AND APPLIANCE. IF VENTING IS INCLUDED WITH SPACERS THE VENT SYSTEM MUST BE SUPPORTED EVERY 3 FEET FOR BOTH VERTICAL AND HORIZONTAL RUNS. USE SUPPORTS OR EQUIVALENT NON-COMBUSTIBLE STRAPPING TO MAINTAIN THE REQUIRED CLEARANCE FROM COMBUSTIBLES. - Page 9 VENTING LENGTHS AND COMPONENTS PART 5” /8” SUPPLIER WEBSITE For Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent and Metal-Fab follow the installation procedure found on the website for your venting supplier. GD422-1 GD422R-1 GD410 GD411 GD412 GD401 GD420 GD430 For optimum fl...

- Page 10 TYPICAL VENT INSTALLATION 16” MINIMUM 3 FEET MINIMUM 40 FEET MAXIMUM 24” MAXIMUM 13” MINIMUM 53 3/4” MINIMUM PLUS RISE* 40 3/4” 40 3/4” * See “ VENTING” section...

- Page 11 SPECIAL VENT INSTALLATION 3.3.1 PERISCOPE TERMINATION 12” MINIMUM TO GRADE 30” MINIMUM 40 3/4” 9.1A...

- Page 12 MINIMUM AIR TERMINAL LOCATION CLEARANCES COVERED BALCONY APPLICATIONS INSTALLATIONS CANADA U.S.A. 12.3B...

- Page 13 VENTING APPLICATION FLOW CHART TOP EXIT Horizontal Termination Vertical Termination Vertical rise is equal Vertical rise is equal Vertical rise is less Vertical rise is less to or greater than to or greater than than horizontal run than horizontal run the horizontal run the horizontal run Horizontal run +...

- Page 14 TOP EXIT HORIZONTAL TERMINATION ) < (V Simple venting confi guration (only one 90° elbow) REQUIRED VERTICAL RISE IN FEET V 12.5 17.5 HORIZONTAL VENT RUN PLUS OFFSET IN FEET H For vent confi gurations requiring more than one 90° elbow, the following formulas apply: Formula 1: H <...

- Page 15 ) > (V Simple venting configuration (only one 90° elbow) See graph to determine the required vertical rise V for the required horizontal run H 147” REQUIRED VERTICAL RISE IN INCHES V 57” 19 1/2” 2’ 19.5’ 12.5’ HORIZONTAL VENT RUN PLUS OFFSET IN FEET H The shaded area within the lines represents acceptable values for H and V...

- Page 16 VERTICAL TERMINATION ) < (V Simple venting configurations. See graph to determine the required vertical rise V for the required horizontal run H REQUIRED VERTICAL RISE IN FEET V HORIZONTAL VENT RUN PLUS OFFSET IN FEET H The shaded area within the lines represents acceptable values for H and V For vent configurations requiring one or more 90°...

- Page 17 ) > (V Simple venting configurations. See graph to determine the required vertical rise V for the required horizontal run H REQUIRED VERTICAL RISE IN FEET V HORIZONTAL VENT RUN PLUS OFFSET IN FEET H The shaded area within the lines represents acceptable values for H and V For vent configurations requiring more than two 90°...

-

Page 18: Installation

4.0 INSTALLATION WARNING FOR SAFE AND PROPER OPERATION OF THE APPLIANCE, FOLLOW THE VENTING INSTRUCTIONS EXACTLY. ALL INNER EXHAUST AND OUTER INTAKE VENT PIPE JOINTS MAY BE SEALED USING EITHER RED RTV HIGH TEMP SILICONE SEALANT W573-0002 (NOT SUPPLIED) OR BLACK HIGH TEMP MILL PAC W573-0007 (NOT SUPPLIED) WITH THE EXCEPTION OF THE APPLIANCE EXHAUST FLUE COLLAR WHICH MUST BE SEALED USING MILL PAC. - Page 19 4.1.1 HORIZONTAL INSTALLATION WARNING THE FIRESTOP ASSEMBLY MUST BE INSTALLED WITH THE VENT SHIELD TO THE TOP. TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE RETURN FLANGE OF THE MOUNTING PLATE. VENT SHIELD CAULKING FIRESTOP...

- Page 20 USING FLEXIBLE VENT COMPONENTS WARNING DO NOT ALLOW THE INNER FLEX PIPE TO BUNCH UP ON HORIZONTAL OR VERTICAL RUNS AND ELBOWS. KEEP IT PULLED TIGHT. SPACERS ARE ATTACHED TO THE INNER FLEX PIPE AT PREDETERMINED INTERVALS TO MAINTAIN AN EVEN AIR GAP TO THE OUTER FLEX PIPE.

- Page 21 4.2.2 VERTICAL AIR TERMINAL INSTALLATION WARNING MAINTAIN A MINIMUM 2” SPACE BETWEEN THE AIR INLET BASE AND THE STORM COLLAR. ROOF SUPPORT INNER PIPE TERMINAL CONNECTOR HIGH TEMPERATURE SEALANT INNER FLEX PIPE OUTER FLEX PIPE AIR INLET 2” BASE CAULKING STORM COLLAR WEATHER SEALANT...

- Page 22 4.2.3 APPLIANCE VENT CONNECTION #8 X 1/2” SELF DRILLING SCREWS 2” OVERLAP HIGH TEMP SEALANT 28.1 MOBILE HOME INSTALLATION 29.1...

- Page 23 GAS INSTALLATION WARNING RISK OF FIRE, EXPLOSION OR ASPHYXIATION. ENSURE THERE ARE NO IGNITION SOURCES SUCH AS SPARKS OR OPEN FLAMES. SUPPORT GAS CONTROL WHEN ATTACHING GAS SUPPLY PIPE TO PREVENT DAMAGING GAS LINE. ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT WITH THE GLASS DOOR OPENED OR REMOVED.

-

Page 24: Framing

5.0 FRAMING WARNING RISK OF FIRE! IN ORDER TO AVOID THE POSSIBILITY OF EXPOSED INSULATION OR VAPOUR BARRIER COMING IN CONTACT WITH THE APPLIANCE BODY, IT IS RECOMMENDED THAT THE WALLS OF THE APPLIANCE ENCLOSURE BE “ FINISHED” (IE: DRYWALL / SHEETROCK), AS YOU WOULD FINISH ANY OTHER OUTSIDE WALL OF A HOME. - Page 25 WARNING DO NOT BUILD INTO THIS AREA - IT MUST BE LEFT CLEAR TO PROVIDE ADEQUATE CLEAR- ANCE FOR THE VENT IN THIS 14” WIDE AREA CENTERED ALONG THE FRONT OF THE FIRE- PLACE. NO COMBUSTIBLES ARE ALLOWED. 5 1/2” MAX 72”...

- Page 26 MINIMUM CLEARANCE TO COMBUSTIBLES Minimum clearance to combustible construction from appliance and vent surfaces: Non combustible framing: Combustible framing: Non combustible fi nishing: Combustible fi nishing: **HORIZONTAL VENT SECTIONS: **VERTICAL VENT SECTIONS: 1" 29 1/4" 1" 74" 48 3 /4" 29 1/4"...

- Page 27 MINIMUM CLEARANCE TO COMBUSTIBLE ENCLOSURES WARNING USE ONLY NON-COMBUSTIBLE MATERIAL SUCH AS CEMENT BOARD, CERAMIC TILE, MARBLE, ETC. WHEN FINISHING TO THE APPLIANCE. DO NOT USE WOOD OR DRYWALL. FACING AND/OR FINISHING MATERIAL MUST NEVER OVERHANG INTO THE APPLIANCE OPENING DO NOT DISTORT OR FORCE THE FRAME KIT COMPONENTS.

- Page 28 0” IF NON- 3 1/2” ** COMBUSTIBLE 2” FINISHING IS USED SUCH AS BRICK AND STONE. 7” ** 2” STAND OFF 72” SPACER MINIMUM ENCLOSURE 53 3/4” HEIGHT NON-COMBUSTIBLE MINIMUM PLUS RISE* 1”...

- Page 29 ALCOVE FRAMING RECESS OR ALCOVE AREA ENCLOSURE AREA APPLIANCE NOTE: Recesses or alcoves above the appliance can be made as deep as desired provided the minimum clearances to combustibles are maintained. Non-combustible material can be used, provided the minimum clearances to combustible materials are applied.

- Page 30 MINIMUM MANTEL CLEARANCES WARNING RISK OF FIRE, MAINTAIN ALL SPECIFIED AIR SPACE CLEARANCES TO COMBUSTIBLES. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY CAUSE A FIRE OR CAUSE THE APPLIANCE TO OVERHEAT. ENSURE ALL CLEARANCES (I.E. BACK, SIDE, TOP, VENT, MANTEL, FRONT, ETC.) ARE CLEARLY MAINTAINED.

-

Page 31: Finishing

6.0 FINISHING WARNING RISK OF FIRE! NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE. THE FRONT OF THE APPLIANCE MUST BE FINISHED WITH ANY NON-COMBUSTIBLE MATERIALS SUCH AS BRICK, MARBLE, GRANITE, ETC., PROVIDED THAT THESE MATERIALS DO NOT GO BELOW THE SPECIFIED DIMENSION AS ILLUSTRATED. DO NOT STRIKE, SLAM OR SCRATCH GLASS. - Page 32 LOG SHIPPING BRACKET LOG SHIPPING BRACKET...

- Page 33 DECORATIVE BRICK PANEL INSTALLATION SECURING SCREW BRACKET ANDIRON / GRATE MOUNTING SCREW ( RETAINER...

- Page 34 LOG PLACEMENT WARNING FAILURE TO POSITION THE LOGS IN ACCORDANCE WITH THESE DIAGRAMS OR FAILURE TO USE ONLY LOGS SPECIFICALLY APPROVED WITH THIS APPLIANCE MAY RESULT IN PROPERTY DAMAGE OR PERSONAL INJURY. LOGS MUST BE PLACED IN THEIR EXACT LOCATION IN THE APPLIANCE. DO NOT MODIFY THE PROPER LOG POSITIONS, SINCE APPLIANCE MAY NOT FUNCTION PROPERLY AND DELAYED IGNITION MAY OCCUR.

- Page 35 NOTE: For propane, remove the screw from the #3 log support bracket. Move the bracket to the right most location, then install the log. BRACKET GLOWING EMBERS CHARCOAL EMBERS Fine dust found in the bottom of the bag should not be used. NOTE: Charcoal embers are not to be placed on the burner.

-

Page 36: Operation

7.0 OPERATION WARNING IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT WITH THE GLASS DOOR OPENED OR REMOVED. - Page 37 HAND HELD REMOTE OPERATIONS BLUE LCD DISPLAY ON/OFF KEY THERMOSTAT KEY UP/DOWN ARROW KEY MODE KEY 35.4 TEMPERATURE DISPLAY ROOM THERMOSTAT ROOM TEMPERATURE SET TEMPERATURE 35.6 SMART THERMOSTAT 35.7...

- Page 38 FLAME HEIGHT 35.8 FAN SPEED 35.9 CHILD PROOF FUNCTION...

- Page 39 7.10 NIGHT LIGHTS 35.12 7.11 LOW BATTERY / MANUAL BYPASS 35.13 7.12 IN THE EVENT OF A POWER FAILURE 35.14...

- Page 40 7.13 CONTROL MODULE MAINS VOLTAGE SUPPLY CORD MODULE ON/OFF SWITCH (SHOWN IN NOTE: Control module ON/OFF switch should always THE ON POSITION) be in the “ ON” position. If for any reason the module COMMUNICATION BUS (3 P IN) is turned “ OFF” , the components plugged into the 120V AUX OUTLET FAN OUTLET module won’...

-

Page 41: Electrical Information

8.0 ELECTRICAL INFORMATION WARNING DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER WATER. CALL A QUALIFIED SERVICE TECHNICIAN IMMEDIATELY TO HAVE THE APPLIANCE INSPECTED FOR DAMAGE TO THE ELECTRICAL CIRCUIT. RISK OF ELECTRICAL SHOCK OR EXPLOSION. DO NOT WIRE 110V TO THE VALVE OR TO THE APPLIANCE WALL SWITCH. -

Page 42: Operating Instructions

9.0 OPERATING INSTRUCTIONS WARNING IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE. ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT WITH THE GLASS DOOR OPENED OR REMOVED. -

Page 43: Adjustment

10.0 ADJUSTMENT 10.1 PILOT BURNER ADJUSTMENT Check Pressure Readings: PILOT PILOT SCREW BURNER ELECTRODE FLAME SENSOR AFTER TAKING PRESSURE READINGS, BE SURE TO TURN SCREWS CLOCKWISE FIRMLY TO RESEAL. DO FLAME MUST ENVELOP NOT OVERTORQUE. UPPER 3/8” TO 1/2” OF FLAME SENSOR 39.1A 10.2 VENTURI ADJUSTMENT... - Page 44 10.3 FLAME CHARACTERISTICS PILOT BURNER ELECTRODE FLAME SENSOR FLAME MUST ENVELOP UPPER 3/8” TO 1/2” OF FLAME SENSOR 54.1A 10.4 AIR CONTROL ROD ACCESS...

-

Page 45: Maintenance

11.0 MAINTENANCE MAINTENANCE WARNING MAINTENANCE MAINTENANCE TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE. APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED. DO NOT USE ABRASIVE CLEANERS. CAUTION: 40.1 11.1 INNER ACCESS PANEL NOTE: A new gasket will be required, when re-installing the access panel, see “ REPLACEMENTS” section. - Page 46 11.2 NIGHT LIGHT REPLACEMENT LENSE FRAME SCREWS FIREBOX TOP NOTE: Do not handle the lamp (bulb) with bare fi ngers, protect with a clean dry cloth. GASKET LENSE FRAME THE FIREBOX MUST BE SEALED. 11.3 BLOWER REPLACEMENT...

- Page 47 HANDLE HOUSING MAINS VOLTAGE SUPPLY CORD VALVE WING NUT MODULE ON/OFF SWITCH COMMUNICATION BUS (3 PIN VALVE RECEIVER PLATE 120V AUX OUTLET SLOT FAN OUTLET CONSTANTLY POWERED 120V OUTLET SPARK MODULE 11.4 REMOTE RECEIVER REMOVAL (4) AA Batteries 11.5 VALVE REMOVAL HANDLE HOUSING VALVE...

- Page 48 11.6 CARE OF GLASS DO NOT CLEAN GLASS WHEN HOT! DO NOT USE WARNING ABRASIVE CLEANERS TO CLEAN GLASS. HOT GLASS WILL CAUSE BURNS. DO NOT TOUCH GLASS UNTIL COOLED. NEVER ALLOW CHILDREN TO TOUCH GLASS. 11.7 RESTRICTING VERTICAL VENTS 77.3...

-

Page 49: Replacements

12.0 REPLACEMENTS WARNING FAILURE TO POSITION THE PARTS IN ACCORDANCE WITH THIS MANUAL OR FAILURE TO USE ONLY PARTS SPECIFICALLY APPROVED WITH THIS APPLIANCE MAY RESULT IN PROPERTY DAMAGE OR PERSONAL INJURY. ** THIS IS A FAST ACTING THERMOCOUPLE. IT IS AN INTEGRAL SAFETY COMPONENT. REPLACE ONLY WITH A FAST ACTING THERMOCOUPLE SUPPLIED BY WOLF STEEL LTD. - Page 50 FLEXIBLE VENT KITS REF NO. PART NO. DESCRIPTION GD420 (5 FT) GD430 (10 FT) TERMINAL KITS REF NO. PART NO. DESCRIPTION ROOF TERMINAL KITS REF NO. PART NO. DESCRIPTION...

- Page 51 ACCESSORIES REF NO. PART NO. DESCRIPTION...

- Page 52 12**...

-

Page 53: Troubleshooting

13.0 TROUBLESHOOTING WARNING ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT, WITH THE GLASS DOOR OPEN OR REMOVED. TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE. APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED. DO NOT USE ABRASIVE CLEANERS. - Page 54 SYMPTOM PROBLEM TEST SOLUTION Step 1: Step 2: Step 1: Step 2: Step 1: Step 2: NOTE: Starting from OFF, press the ON button on the transmitter. Approximately 4 seconds after the ON/OFF button is pressed the ignition board will start the spark. The fi...

- Page 55 SYMPTOM PROBLEM TEST SOLUTION 42.1_3...

-

Page 56: Warranty

14.0 WARRANTY NAPOLEON® GAS APPLIANCE PRESIDENT’ S LIFETIME LIMITED WARRANTY CONDITIONS AND LIMITATIONS 2.1B... -

Page 57: Service History

15.0 SERVICE HISTORY 43.1... - Page 58 15.0 NOTES 44.1...

- Page 59 44.1...

Need help?

Do you have a question about the GD80NT-1ME and is the answer not in the manual?

Questions and answers