MTS Sensors Temposonics R Series Datasheet

Magnetostrictive, absolute, non-contact linear-position sensors, synchronous serial interface ssi output

Hide thumbs

Also See for Temposonics R Series:

- Operation manual (42 pages) ,

- Datasheet (15 pages) ,

- Datasheet (7 pages)

Table of Contents

Advertisement

Quick Links

Temposonics

Magnetostrictive, Absolute, Non-contact

R-Series Models RP and RH

Synchronous Serial Interface (SSI) Output

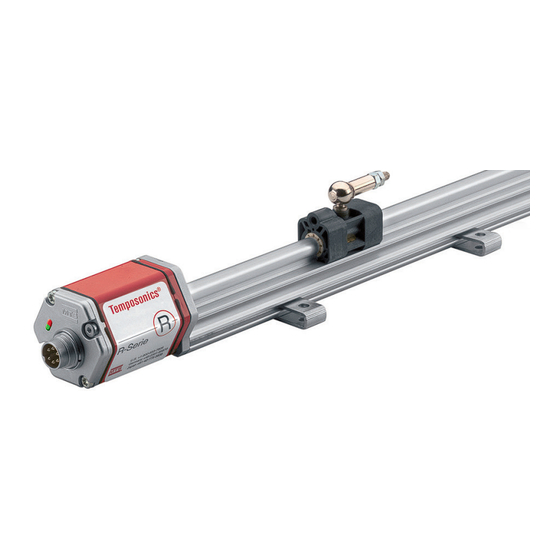

Model RP Profile-style position sensor

FEATURES

„ Linear, Absolute Measurement

„ LEDs For Sensor Diagnostics

„ Non-Contact Sensing Technology

„ Linearity Deviation Less Than 0.01%

„ Repeatability Within 0.001%

„ Direct 24/25/26 Bit SSI Output, Gray/Binary Formats

„ Synchronous Measurement for Accurate Velocity/Acceleration

Calculations

BENEFITS

„ Superior Accuracy; Resolution Down to 0.5 Micron

„ Rugged Industrial Sensor

„ High-Speed Update Options

„ Linearity Correction Options

„ Velocity Output Option

„ Optional Differential Measurement Between Two Magnets

APPLICATIONS

„ Continuous Operation In Harsh Industrial Conditions

„ High Pressure Conditions

„ For Fast, Precision Motion Control

TYPICAL INDUSTRIES

„ Factory Automation

„ Fluid Power

„ Plastic Injection and Blow Molding

„ Material Handling and Packaging

„ Woodworking, Metalworking and Machine Tools

Linear-Position Sensors

Data Sheet

®

Model RH Rod-style position sensor

Time-based Magnetostrictive position sensing principle

Movable position magnet

Magnetic field encompasses

entire waveguide - generated

by the interrogation pulse

Interrogation

Return wire

Waveguide

Strain-Pulse detector

Bias magnet

Benefits of Magnetostriction

Temposonics

linear-position

magnetostrictive position sensing principle developed by MTS.

Within the sensing element, a sonic-strain pulse is induced in a

specially designed magnetostrictive waveguide by the momentary

interaction of two magnetic fields. One field comes from a moveable

permanent magnet that passes along the outside of the sensor. The

other field comes from an "interrogation" current pulse applied along

the waveguide. The resulting strain pulse travels at sonic speed along

the waveguide and is detected at the head of the sensing element.

The position of the magnet is determined with high precision and

speed by accurately measuring the elapsed time between the applica-

tion of the interrogation pulse and the arrival of the resulting strain

pulse with a high-speed counter. The elapsed time measurement is

directly proportional to the position of the permanent magnet and is

an absolute value. Therefore, the sensor's output signal corresponds

to absolute position, instead of incremental, and never requires

recalibration or re-homing after a power loss. Absolute, non-contact

sensing eliminates wear, and guarantees the best durability and

output repeatability.

All specifications are subject to change. Contact MTS for specifications and

engineering drawings that are critical to your application. Drawings contained

in this document are for reference only. Go to http://www.mtssensors.com for

the latest support documentation and related media.

SENS

RS

O

Document Part Number

550989 Revision E

Magnetic field from

position magnet

Interaction of magnetic

fields causes waveguide to

generate a strain pulse

sensors

use

the

time-based

®

Advertisement

Table of Contents

Summary of Contents for MTS Sensors Temposonics R Series

- Page 1 Temposonics ® ® Magnetostrictive, Absolute, Non-contact SENS Linear-Position Sensors R-Series Models RP and RH Document Part Number Synchronous Serial Interface (SSI) Output 550989 Revision E Data Sheet Model RP Profile-style position sensor Model RH Rod-style position sensor Time-based Magnetostrictive position sensing principle FEATURES Movable position magnet „...

-

Page 2: Product Overview

1), or Class 2 rating according to the National Electrical Code (USA) / Canadian Electrical Code. ** The IP rating is not part of the UL Recognition. R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors... -

Page 3: Synchronous Serial Interface (Ssi)

Sensor measurement cycle Measurement starts Data available Data delivered Figure 4. Asynchronous measuring mode, controller loop timing R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® MTS Sensors Product Data Sheet, Part No.: 550989 E (EN) 05/2014... - Page 4 Many motion control applications require velocity and/or acceleration be calculated, and therefore, must rely on position data having minimal delay, and minimal timing variability. With the Synchronous Measuring Mode, MTS Sensors has developed a proprietary algorithm to not only guarantee true measurement synchronization but at the same time minimize any propagation delay relative to the controller loop rate.

-

Page 5: Enhanced Monitoring And Diagnostics

(see ‘Figure 8’). The setup software allows the following set of parameters to be field programmed. R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® MTS Sensors Product Data Sheet, Part No.: 550989 E (EN) 05/2014... -

Page 6: Model Rp Profile-Style Sensor Dimension References

For Model RP profile-style sensor Ball-jointed arm (M5 thread) 9 mm 40 mm (0.35 in.) (1.58 in.) R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors... - Page 7 (optional, ordered separately) 5 mm (0.20 in.) M5 Threaded stud and nut T-Slot nut, M5 thread Detail R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® MTS Sensors Product Data Sheet, Part No.: 550989 E (EN) 05/2014...

- Page 8 46 mm 53 mm Table 2. Model RH Rod-style sensor housing style and flange type references R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors...

- Page 9 (This float is used with the Model RH 3.4 mm (0.13 in.) rod-style sensors for hydraulic fluid or fresh water applications only) R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® MTS Sensors Product Data Sheet, Part No.: 550989 E (EN) 05/2014...

-

Page 10: Model Rh Rod-Style Sensor Mounting

(2) M4 thread 2.5 mm hex socket head screws Figure 14. Fluid cylinder installation R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors... -

Page 11: Connections And Wiring

7-Pin DIN (D70) 18 mm Mates with standard male (M16) (0.7 in.) dia. integral connector 54 mm (2.1 in.) R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® MTS Sensors Product Data Sheet, Part No.: 550989 E (EN) 05/2014... - Page 12 = Cable length (maximum cable length is dependent on baud rate). 6 - 7 CABLE TERMINATION = Pigtail cable without connector R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors...

- Page 13 OPTIONAL ADVANCED OUTPUTS (18- 22) + the 3 digit Output code defined (Continue to the next page) R-Series Models RP and RH Temposonics Linear-Position Sensors - SSI Output ® MTS Sensors Product Data Sheet, Part No.: 550989 E (EN) 05/2014...

-

Page 14: Ordering Information

= Additional alarm bit + even parity bit = Additional alarm bit + even parity bit + LCO R-Series Models RP and RH Temposonics ® Linear-Position Sensors - SSI Output Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors... - Page 15 Fax + 39 030 982 3359 Fax + 49 2351 56491 info.it@mtssensors.com info.de@mtssensors.com www.mtssensor.com www.mtssensor.de JAPAN CHINA MTS Sensors Technology Corp. MTS Sensors 737 Aihara-machi, Room 504, Huajing Commercial Center, Machida-shi, No. 188, North Qinzhou Road Tokyo 194-0211, Japan 200233 Shanghai, China Tel.

Need help?

Do you have a question about the Temposonics R Series and is the answer not in the manual?

Questions and answers