Advertisement

Quick Links

Application Guide

Overview ............................................................... 1

Important Notices ................................................. 1

CSC-1001 Function ............................................... 1

Sample Applications .............................................. 2

Replacement by CSC-2001/2003 ........................... 3

Replacement by CSC-3011 .................................... 3

Overview

CSC-1001 Constant Volume Controllers have been

discontinued. However, they can be replaced with a

CSC-2001/2003/3011 controller and (for VAV applica-

tions) an RCC-1008/1108 relay.

For more information about a particular device, see

the respective device data sheet, installation guide,

and/or application guide.

Important Notices

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice. KMC

Controls, Inc. makes no representations or warran-

ties with respect to this document. In no event shall

KMC Controls, Inc. be liable for any damages, direct

or incidental, arising out of or related to the use of

this document.

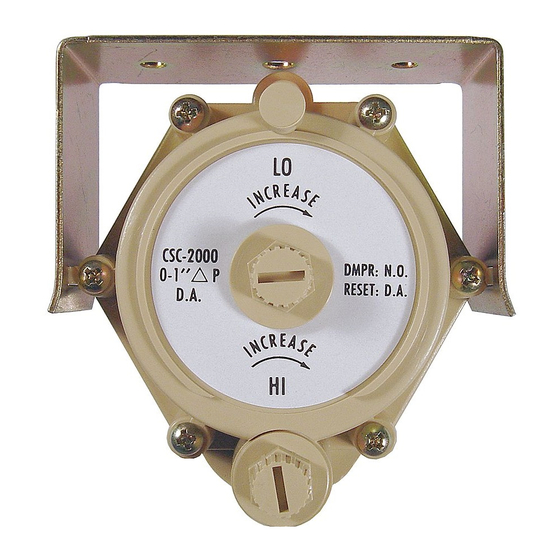

Replacing CSC-1001 with CSC-2000/3000 Series Controllers

Replacing CSC-1001 Controllers

with CSC-2000/3000 Series Controllers

CSC-1001

CSC-1001 Function

The CSC-1001 is designed for use with normally

open dampers in either of the following applications:

• Constant air volume (CAV) terminals

• Variable air volume (VAV) terminals with maxi-

mum flow limiting

CAV operation is configured by connecting a nor-

mally open actuator to the C port on the controller

(or the H port if the T port is open) and adjusting the

setpoint screw to the desired flow setpoint. Airflow

is measured by an SSS-1000 series sensor connected

between the HI and LO ports. Adjusting the setpoint

screw clockwise will increase the flow setpoint;

adjusting the screw counter-clockwise will decrease

the flow setpoint. The T port may be exhausted to

atmosphere during constant volume operation.

When used in VAV applications where a high flow

limit is necessary, the controller should have a

normally open damper connected to the H port, a

reverse acting thermostat connected to the T port,

and an SSS-1000 series flow pickup between HI and

LO. The C port should be capped (as installed from

the factory). With the T port exhausted, or at a low

pressure, the setpoint screw can be adjusted for the

maximum flow limit. The controller will supply the

H port with the higher of either the thermostat signal

or the configured maximum flow limit pressure, thus

limiting the maximum airflow once the thermostat

signal falls below the maximum flow setpoint.

1

CSC-3011

Application Guide, AN0811A Rev. A

Advertisement

Summary of Contents for KMC Controls CSC-2000 Series

- Page 1 In no event shall limit is necessary, the controller should have a KMC Controls, Inc. be liable for any damages, direct normally open damper connected to the H port, a or incidental, arising out of or related to the use of reverse acting thermostat connected to the T port, this document.

- Page 2 Sample Applications Constant Volume Application Actuator CSC-2001/2003 CSC-3011 Reset Volume Reset Volume SSS-1000 Series Controller Controller Airflow Sensor Actuator Constant Volume Airflow adjusted using DAMPER the LO Adjustment Knob (center knob) VAV Application with a High Flow Limit Thermostat SSS-1000 Series RA Cool Airflow Sensor Actuator...

- Page 3 Replacement by CSC-2001/2003 Replacement by CSC-3011 CSC-2000 Series Reset Volume Controllers may be A CSC-3011 “universal” Reset Volume Controller used to obtain the same functionality of CSC-1001 may also be used to obtain the same functionality of Constant Volume Controllers. For constant volume CSC-1001 Constant Volume Controllers.

Need help?

Do you have a question about the CSC-2000 Series and is the answer not in the manual?

Questions and answers