Summary of Contents for Amphenol Telaire Chipcap 2

- Page 1 ® ® ChipCap Application Guide Amphenol AAS-916-127 Rev. J Advanced Sensors February 2018...

-

Page 2: Table Of Contents

ChipCap® 2 Humidity and Temperature Sensor Contents Sensor Performance ..............1 Relative Humidity (RH%) . - Page 3 Contents ChipCap® 2 Humidity and Temperature Sensor 3.1.3 Alarm Pads (1. Alarm Low, 8. Alarm High) ..........11 Analog Output (PDM) .

- Page 4 ChipCap® 2 Humidity and Temperature Sensor Contents 6.3.2 Polynomial Equation Temperature ............31 Alarm Function (Optional) .

- Page 5 Contents ChipCap® 2 Humidity and Temperature Sensor Application Guide...

-

Page 6: Sensor Performance

ChipCap® 2 Humidity and Temperature Sensor Sensor Performance 1.1 Relative Humidity (RH%) Resolution 14 bit (0.01%RH) ±2.0%RH (20~80%RH) Accuracy (Accuracies measured at 25°C, 5.0V) (Custom accuracy tolerance available.) Repeatability ±0.2%RH Hysteresis +/- 1.0% RH Linearity <2.0%RH 4.0 sec (τ 63%) Response Time (Measured at 25°C, 1 m/sec airflow for achieving 63% of step from 33%RH to 90%RH) -

Page 7: Temperature (°C)

ChipCap® 2 Humidity and Temperature Sensor 1.3 Temperature (°C) Resolution 14 bit (0.01°C) ±0.3°C Accuracy (Accuracies measured at 25°C, 5.0V) Repeatability ±0.1°C 5.0 sec (63%) Response Time (min. 5.0 sec, max. 20 sec) Operating Range - 40 to 125°C Long Term Drift <0.05°C/yr (Normal condition) 1.4 Typical Temperature Accuracy 1.5 Electrical Specifications... -

Page 8: Environmental

ChipCap® 2 Humidity and Temperature Sensor 1.6 Environmental 1.6.1 Operating Temperature Range - 40 to 125°C 1.6.2 Operating RH Range 0 to 100% RH (non-condensing) 1.7 Absolute Maximum Rating Parameter Supply Voltage (VDD) -0.3V 6.0V Storage Temp (T -55°C 150°C strg Junction Temp (T -55°C... -

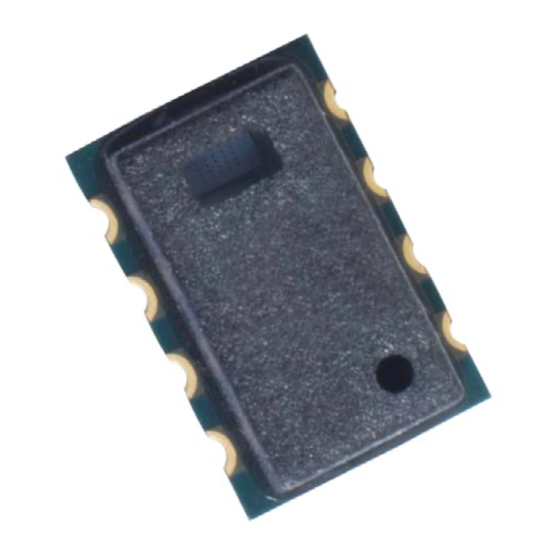

Page 9: Dimensions

ChipCap® 2 Humidity and Temperature Sensor 1.10 Dimensions (all measurements in mm (inches)) Application Guide... -

Page 10: General Information

Nor does Amphenol Advanced Sensors assume any liability arising out of the application or use in any product or circuit. Amphenol Advanced Sensors specifically disclaims all liability without limitation consequential or incidental damages. No statuary or fitness for particular purpose shall be implied. -

Page 11: Heating

ChipCap® 2 Humidity and Temperature Sensor Figure 1: Operating Conditions Heating Relative humidity is a function of temperature. Therefore, sensor placement and self-heating need to be carefully understood and managed. It is crucial to keep the temperature of the humidity sensing element the same as actual environment where the RH measurement is desired to be made. -

Page 12: Storage And Handling Information

Note: We are testing if both hydration process 32±2 °C 85±5 %RH, Duration: 45±5 hours (Non-Baking, Max time (50 hours) and stabilization in ambient room environment) can be used. Contact Amphenol Advanced Sensors customer support for customized recovery measures specific to your reflow soldering process. -

Page 13: Reconditioning Procedure

ChipCap® 2 Humidity and Temperature Sensor Although the sensor endures the extreme conditions of -50°C~150°C, 0%~100%RH (non condensing), long term exposure in such an environment may also offset the sensor reading. Hence, once the package is opened, it is recommended to store it in a clean environment with temperature at 5°C~55°C and humidity at 10%~70%RH. ChipCap 2 is ESD protected up to 4000V and has Latchup of ±100mA or (up to +8V / down to -4V) relative to VSS/VSSA, and is also packed in ESD protected shipping material. -

Page 14: Traceability Information

ChipCap® 2 Humidity and Temperature Sensor 2.9 Traceability Information ChipCap 2 is laser marked with product type and lot identification. Further information about an individual sensor is electronically stored on the chip. The first line denotes the sensor type: CC2-A for PDM output, CC2-D for I²C output. Lot identification is printed on the second line with a 5 digit alphanumeric code. - Page 15 ChipCap® 2 Humidity and Temperature Sensor 2.10 Shipping Package (cont.) Inbox: 500 ea Inbox: 2,500 each Dimension: 360 x 355 x 50 mm Dimension: 215 x 210 x 30 mm Outbox: 5,000 each (5 x Inbox 500) Dimension: 320 x 225 x 235 mm Outbox: 20,000 each (8 x Inbox 2500) Dimensions: 645 x 360 x 310 mm Figure 5: Packing (Box)

-

Page 16: Interface Specification

ChipCap® 2 Humidity and Temperature Sensor Interface Specification 3.1 Digital Output (I ² C Interface) Figure 6: Pin Assignments Table 1: Pin Assignments Pin-No Name Description Alarm_Low Low alarm output Ready Ready signal (conversion complete output) C data C clock Core voltage CORE Ground supply... -

Page 17: Serial Clock & Data Pads (3. Sda, 4. Scl)

ChipCap® 2 Humidity and Temperature Sensor 3.1.2 Serial Clock & Data Pads (3. SDA, 4. SCL) The sensor’s data is transferred in and out through the SDA pad, while the communication between ChipCap 2 and the microcontroller (MCU) is synchronized through the SCL pad. ChipCap 2 has an internal temperature compensated oscillator that provides time base for all operation, and uses an I²C -compatible communication protocol with support for 20 KHz to 400 KHz bit rates. -

Page 18: Analog Output (Pdm)

ChipCap® 2 Humidity and Temperature Sensor 3.2 Analog Output (PDM) Figure 8: Pin Assignments Table 2: Pin Assignments for Analog Output Pin-No Name Description PDM_T Temperature PDM PDM_H Humidity PDM C data (Not Used) C clock (Not Used) Core voltage CORE Ground supply Supply voltage (2.3-5.5V) -

Page 19: Pdm Output Pads (1.Pdm_T, 2.Pdm_H)

ChipCap® 2 Humidity and Temperature Sensor 3.2.2 PDM Output Pads (1.PDM_T, 2.PDM_H) Temperature PDM (Pulse Density Modulation) appears on the PDM_T/Alarm_Low pad (1) and corrected Humidity PDM appears on the PDM_H pad (2). When pad (1) is selected for Temperature PDM, the Alarm_Low function is disabled and only one Alarm function (Alarm_High: pad 8) is usable. -

Page 20: Electrical Specification

ChipCap® 2 Humidity and Temperature Sensor Electrical Specification 4.1 Absolute Maximum Rating Table 3 below shows the Absolute Maximum Ratings for ChipCap 2. Exposure to these extreme condition for extended period may deteriorate the sensor performance and accelerate aging. Functional operation is not implied at these conditions. - Page 21 ChipCap® 2 Humidity and Temperature Sensor Table 5: Electrical Characteristics Specifications Parameter Symbol Conditions Min Typ Max Units Supply Supply Current (varies with update At maximum update rate 750 1100 μA rate and output mode) Extra Current with PDM enabled At maximum update rate μA Sleep Mode Current...

-

Page 22: Output Pad Drive Strength

ChipCap® 2 Humidity and Temperature Sensor 4.3 Output Pad Drive Strength The output pad drive strength at different supply voltages and operating temperatures is shown in Table 6 and Table 7 below. Table 6: Output High Drive Strength Output High Drive Strength (mA) -40°C 25°C 125°C... -

Page 23: Communicating With Chipcap 2

ChipCap® 2 Humidity and Temperature Sensor Communicating with ChipCap 2 5.1 Power–On Sequence ² On system power-on reset (POR), the ChipCap 2 wakes as an I C device regardless of the output protocol programmed in EEPROM. After power-on reset, it enters the command window. It then waits for a Start_CM command for 10 ms if Fast Startup bit is not set in EEPROM (Factory Setting) or for 3 ms if fast startup bit is set in EEPROM (see Figure 11). -

Page 24: I2C Features And Timing

ChipCap® 2 Humidity and Temperature Sensor 5.2 I C Features and Timing The ChipCap 2 uses I C-compatible communication protocol with support for 20kHz and 400kHz bit rates. The I slave address (0x00 to 0x7F) is selected by the Device_ID bits in the Cust_Config EEPROM word (see Table 16 on page 38 for bit assignments). - Page 25 ChipCap® 2 Humidity and Temperature Sensor Table 8: I C Parameters s Data setup time on SDA relative to SCL edge SUDAT s Stop condition setup time on SCL SUSTO s Bus free time between stop condition and start condition 1.

-

Page 26: Measurement Modes

ChipCap® 2 Humidity and Temperature Sensor 5.3 Measurement Modes The ChipCap 2 can be programmed to operate in either Sleep Mode or Update Mode. The measurement mode is selected with the Measurement_Mode bit in the ChipCap 2 Config Register word. In Sleep Mode, the part waits for commands from the master before taking measurements (see section 5.3.2 below). - Page 27 ChipCap® 2 Humidity and Temperature Sensor 5.3.2 Data Fetch in Sleep Mode (cont.) Figure 14 below shows the measurement and communication sequence for Sleep Mode. The master sends an MR command to wake the ChipCap 2 from power down. After ChipCap 2 wakes up, a measurement cycle is performed consisting of both a temperature and a capacitance conversion followed by the ChipCap 2 Core correction calculations.

-

Page 28: Status Bits

ChipCap® 2 Humidity and Temperature Sensor 5.3.2 Data Fetch in Sleep Mode (cont.) In Sleep Mode, I C are used to request a measurement with a MR command and to fetch data from the digital output register using a Data Fetch (DF) command (see section 5.7 on page 26 for details on the MR command). Detecting when data is ready to be fetched can be handled either by polling or by monitoring the Ready pin (see section 5.8 on page 26 for details on the Ready pin). -

Page 29: Data Fetch (Df)

ChipCap® 2 Humidity and Temperature Sensor 5.6 Data Fetch (DF) The Data Fetch (DF) command is used to fetch data in any digital output mode. An I C Data Fetch command starts with the 7-bit slave address and the 8th bit = 1 (READ). The ChipCap 2 as the slave sends an acknowledgement (ACK) indicating success. - Page 30 ChipCap® 2 Humidity and Temperature Sensor C DF – 2 Bytes: Slave returns only humidity (RH) data to the master in 2 bytes. A 15 14 13 Device Slave Address [6:0] RH Data [13:8] RH Data [7:0] Wait for Slave ACK Master ACK Master ACK Master NACK...

-

Page 31: Measurement Request (Mr)

ChipCap® 2 Humidity and Temperature Sensor 5.6 Data Fetch (DF) (cont.) Humidity & Temperature Conversion Formula Humidity Output (%RH) (RH_High [5:0] x 256 + RH_Low [7:0])/ 2 x 100 Temperature Output (°C) (Temp_High [7:0] x 64 + Temp_Low [7:2]/ 4)/ 2 x 165 - 40 Measurement Request (MR) A measurement request (MR) is a Sleep-Mode-only command sent by the master to wake up the ChipCap 2 and start a... -

Page 32: Command Mode

ChipCap® 2 Humidity and Temperature Sensor 5.9 Command Mode Command Mode commands are only supported for the I C protocol. As shown in Figure 18 below, commands are 4-byte packets with the first byte being a 7-bit slave address followed by 0 for write. The second byte is the command byte and the last two bytes form a 16-bit data field. -

Page 33: Command Encodings

ChipCap® 2 Humidity and Temperature Sensor 5.10 Command Encodings Table 11 describes all the commands that are offered in Command Mode. Note: Only the commands listed in Table 11 are valid. Other encodings might cause unpredictable results. If data is not needed for the command, zeros must be supplied as data to complete the 4-byte packet. - Page 34 ChipCap® 2 Humidity and Temperature Sensor 5.11 Command Response and Data Fetch (cont.) For all commands except EEPROM Read and Get Revision, the data fetch should be terminated after the response byte is read. If the command was a Get Revision, then the user will fetch a one byte Revision as shown in Figure 19 on page 30, example 2.

-

Page 35: Eeprom

ChipCap® 2 Humidity and Temperature Sensor 5.11 Command Response and Data Fetch (cont.) C DF - Command Status Response - 1 Byte (1) I Device Slave Address [6:0] Status Diagnostics Response [7:6] [5:2] [1:0] Wait for Master ACK Master NACK Slave ACK Device Slave Address [6:0] Status Diagnostics Response... - Page 36 ChipCap® 2 Humidity and Temperature Sensor Table 14: EEPROM Word Assignments EEPROM Word Bit Range IC Default Name Description and Notes 13:0 0x3FFF PDM_Clip_High PDM high clipping limit 13:0 0x0000 PDM_Clip_Low PDM low clipping limit 13:0 0x3FFF Alarm_High_On High alarm on trip point 13:0 0x3FFF Alarm_High_Off High alarm off trip point...

-

Page 37: Converting Pdm To Analog Signal

ChipCap® 2 Humidity and Temperature Sensor Converting PDM to Analog Signal 6.1 PDM (Pulse Density Modulation) Both corrected humidity and temperature are available in PDM output. Humidity PDM appears on PDM_H (2) pad and Temperature PDM appears on the PDM_T (1) pad. The PDM frequency is 231.25 kHz ±15% (i.e., the oscillator frequency 1.85 MHz ±15% divided by 8). -

Page 38: Analog Output Characteristics

ChipCap® 2 Humidity and Temperature Sensor 6.2 Low Pass Filtering (cont.) For a different (higher) resistor, the normalized ripple VPP (mV/V) can be calculated as: VPP (mV/V) = 4324 / [R(k ) * C(nF)] Or the setting time t for a 0% to 90% setting can be calculated as: SETT (ms) = 0.0023 * R(k ... -

Page 39: Alarm Function (Optional)

ChipCap® 2 Humidity and Temperature Sensor Alarm Function (Optional) 7.1 Alarm Output The alarm output can be used to monitor whether the Humidity reading has exceeded or fallen below pre-programmed values. The alarm can be used to drive an open-drain load connected to VDD as shown in Figure 23 on page 36 or it can function as a full push-pull driver. -

Page 40: Alarm Polarity

ChipCap® 2 Humidity and Temperature Sensor Alarm Polarity For both alarm pins, the polarity of the alarm output is selected using the Alarm Polarity bit in the Alarm_High_Cfg and Alarm_Low_Cfg registers in EEPROM word Cust_Config (see Table 16 on page 38 for bit assignments). Another feature of the polarity bits is the ability to create two high alarms or two low alarms. - Page 41 ChipCap® 2 Humidity and Temperature Sensor 7.5 Alarm Polarity (cont.) HUMIDIFIER DEHUMIDIFIER CC2 D 100nF CORE 220nF PDM_H ALARM_HIGH ALARM_LOW Figure 22: Bang-Bang Humidity Control (High Voltage Application): ChipCap 2 I C:2 Alarms / Humidity Output (Optional) ChipCap 2 also can be directly installed to a device without MCU interface when only a switch on/off function is required at the desired humidity level (e.g., bathroom vent fan, humidifiers, dehumidifiers).

- Page 42 ChipCap® 2 Humidity and Temperature Sensor 7.5 Alarm Polarity (cont.) Hi Alarm Pin On Alarm_Hi_On Hi Alarm Pin Off Hysteresis Alarm_Hi_Off Lo Alarm Pin Off Alarm_Low_Off Hysteresis Alarm_Low_On Lo Alarm Pin On Time Figure 24: Example of Alarm Function HIGH ALARM PIN Measurement <...

- Page 43 ChipCap® 2 Humidity and Temperature Sensor 7.5 Alarm Polarity (cont.) Table 16: Cust_Config Bit Assignments Bit Range IC Default Name Description and Notes 0101000 Device_ID C slave address Alarm_Low_Cfg Configure the Alarm_Low output pin: Bits Description Alarm Polarity 0 = Active High 1 = Active Low Output Configuration 0 = Full push-pull...

-

Page 44: Part Number List

ChipCap® 2 Humidity and Temperature Sensor Part Number List Table 17: Part Number List Telaire part no. Description CC2A25 ChipCap 2, analog, 2%, 5v CC2A23 ChipCap 2, analog, 2%, 3.3v CC2D23S ChipCap 2, digital, sleep mode, 2%, 3.3v CC2D25S ChipCap 2, digital, sleep mode, 2%, 5v CC2D23 ChipCap 2, digital, 2%, 3.3v CC2D25... - Page 45 ChipCap® 2 Humidity and Temperature Sensor Application Guide...

- Page 47 Taunton, TA2 8QY, UK St Marys, Pennsylvania 15857, U.S.A. T: +44-1823-335-200 T: 814-834-9140 F: 814-781-7969 Amphenol Advanced Sensors www.amphenol-sensors.com www.telaire.com ©2017 Amphenol Thermometrics, Inc. All rights reserved. Technical content subject to change without notice. AAS-916-127 Rev. J - February 2018...

Need help?

Do you have a question about the Telaire Chipcap 2 and is the answer not in the manual?

Questions and answers