Table of Contents

Advertisement

Quick Links

WIDOS

W. Dommer Söhne GmbH

Working Instructions

Heating Element Butt Welding Machine

Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Dieter Dommer, Jürgen Dommer

Einsteinstr. 5

D-71254 Ditzingen-Heimerdingen

info @ widos.de

Translation

WIDOS 5100

Keep for further use!

Phone +49 7152 9939 - 0

Fax

+49 7152 9939 - 40

http://www.widos.de

Kunststoffschweißtechnik

Advertisement

Table of Contents

Summary of Contents for widos 5100

- Page 1 WIDOS Einsteinstr. 5 Phone +49 7152 9939 - 0 W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen +49 7152 9939 - 40 info @ widos.de http://www.widos.de Kunststoffschweißtechnik Working Instructions Translation Heating Element Butt Welding Machine WIDOS 5100 Keep for further use! Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Dieter Dommer, Jürgen Dommer...

- Page 2 Phone: ++49 371 / 8 15 73 - 0 Phone: ++41 71 / 3 88 89 79 Fax: ++49 371 / 8 15 73 - 20 Fax: ++41 71 / 3 88 89 73 30.06.11 Working instructions WIDOS 5100 Page 2 of 45...

- Page 3 Therefore the searched information can be easily found. WIDOS 30.06.2011 W.Dommer Söhne GmbH Einsteinstraße 5 D- 71254 Ditzingen- Heimerdingen All rights reserved Reprinting only allowed with permission of the corporation. Any changes prior to technical innovations. 30.06.11 Working instructions WIDOS 5100 Page 3 of 45...

-

Page 4: Table Of Contents

Safety measures........................6 1.3. Conformity ..........................6 1.4. Machine overview .........................7 1.5. Designation of the product ....................7 1.5.1 Technical data ........................8 1.5.1.1 WIDOS 5100 General data ..................8 1.5.1.2 Heating element ......................8 1.5.1.3 Planer.........................9 1.5.1.4 Hydraulic aggregate ....................9 1.5.1.5 Basic frame ........................9 1.5.1.6 Protective box ......................10... - Page 5 HYDRAULIC AND ELECTRIC DIAGRAMS ..............32 10. SPARE PARTS LIST ....................34 10.1. Basic machine ........................34 10.2. Hydraulic aggregat......................36 10.3. Planer ...........................39 10.4. Heating element ........................41 10.5. Reception box ........................43 11. DECLARATION OF CONFORMITY................45 30.06.11 Working Instructions WIDOS 5100 Page 5 of 45...

-

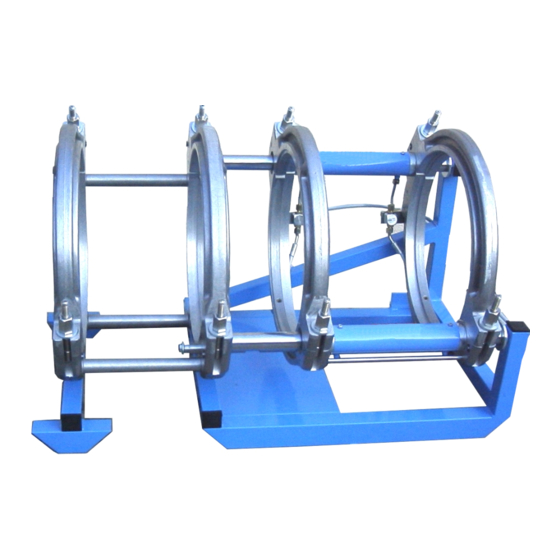

Page 6: Description Of Product

All technical details of the machine are put together as a general arrangement. 1.1. Usage and purpose-oriented use The WIDOS 5100 has been designed for heating element butt welding of pipes and fittings with a diameter range of Ø = 200 - 450 mm. -

Page 7: Machine Overview

The product is designated by two type labels which are attached at the aggregate and at the basic machine. They contain the type, the serial number and the year of construction of the machine. 30.06.11 Working Instructions WIDOS 5100 Page 7 of 45... -

Page 8: Technical Data

Description of product Chapter 1 Kunststoffschweißtechnik 1.5.1 Technical data 1.5.1.1 WIDOS 5100 General data Material wich can be welded: PE80, PE 100, PVDF, PP Pipe diameter range: = 200 - 450 mm ∅ outside Dimension transport box (l x w x h):... -

Page 9: Planer

Length of stroke of cylinder: 195 mm Max. force: (F=P*A) 14140 N (at 100 bar) Velocity of piston rod: 2.2 cm/s For article numbers and component parts see spare parts list 30.06.11 Working Instructions WIDOS 5100 Page 9 of 45... -

Page 10: Protective Box

Hexagonal socket screw size 4; 5; 7 with T-grip (for reduction inserts and adapters) Torx srew driver T10 optional Reduction inserts, roller brackets for the pipes, current transformer for model 42 V 30.06.11 Working Instructions WIDOS 5100 Page 10 of 45... -

Page 11: Safety Rules

T h e r e g u l a t i o n s f o r t h e p r e v e n t i o n o f a c c i d e n t s a r e v a l i d ( U V V ) . 30.06.11 Working Instructions WIDOS 5100 Page 11 of 45... -

Page 12: Obligations Of The Owner

A person who is being trained may only work at the machine under supervision of an • experienced person. 30.06.11 Working Instructions WIDOS 5100 Page 12 of 45... -

Page 13: Dangers While Handling The Machine

Chapter 2 Kunststoffschweißtechnik 2.7. Dangers while handling the machine The machine WIDOS 5100 is constructed according to the latest technical standard and the acknowledged technical safety rules. However, dangers for the operator or other persons standing nearby may occur, also materials damages are possible. -

Page 14: Specific Dangers

• Do not stand or put hands or foot between clamped pipe ends. • Do not stand or put hands between the inner clamping devices with not yet clamped pipes. • Do not block opening and closing of the machine slides. 30.06.11 Working Instructions WIDOS 5100 Page 14 of 45... -

Page 15: Risk Of Injury By Noises

• Machine parts wich are not in a perfect condition are to be replaced immediately. • Only use original WIDOS spare and wear parts. • In case of purchase orders please always state the machine number! 2.13. -

Page 16: Functional Description

(cooling time). The weld joint can be unclamped, the welding process is finished. Heating element heats the pipes up to welding temperature Finished weld joint with internal and external bead 30.06.11 Working Instructions WIDOS 5100 Page 16 of 45... -

Page 17: Operating And Indicating Elements

Hydraulic connection for - Non-dropping quick-action hose coupling closing Hydraulic connection for - Non-dropping quick-action hose coupling opening Screw with oil level stick - Checking the oil-level - Filling in oil 30.06.11 Working Instructions WIDOS 5100 Page 17 of 45... -

Page 18: Elements At Heating Element And Planer

When inserting the heating element take care that it lies in the zone of the throat of the tear- off bar (see arrow). 30.06.11 Working Instructions WIDOS 5100 Page 18 of 45... -

Page 19: Starting And Operating

(e.g. PE cleaner or pipe cleaning tissues which are available at the WIDOS company). The anti-adhesive coating of the heating element must remain undamaged in the working area. -

Page 20: Connection Hydraulic Aggregate With The Basic Machine

• pipe fittings often have an only short straight surface area on which they can be clamped. ⇒ Fittings often need to be clamped in the inner clamping tools with narrow reduction inserts. 30.06.11 Working Instructions WIDOS 5100 Page 20 of 45... -

Page 21: Welding Process

Therefore they are to be cleaned with non-fraying paper and detergent (e.g. PE - cleaner) before every welding or if they are dirty. The anti-adhesive coating of the heating element has to remain undamaged in the working area. 30.06.11 Working Instructions WIDOS 5100 Page 21 of 45... - Page 22 • Put the workpieces into the clamping tools, tighten the clamping nuts tightly and align the workpieces with respect to one another. In case of long pipe ends, use WIDOS rollerstands for alignment. • Close the slide, thereby reading the movement pressure on the manometer.

- Page 23 During the cooling down period re-adjust pressure, if necessary (the pressure for cooling down is the same as the set adjustment pressure). • After expiration of the cooling down period, release pressure, remove the welded part and open the slide. 30.06.11 Working Instructions WIDOS 5100 Page 23 of 45...

-

Page 24: Welding Logs And Tables

WIDOS Einsteinstr. 5 Phone +49 7152 9939 - 0 W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen +49 7152 9939 - 40 info @ widos.de http://www.widos.de Kunststoffschweißtechnik 6. Welding logs and tables 30.06.11 Working Instructions WIDOS 5100 Page 24 of 45... - Page 25 Welding logs and tables Chapter 6 Kunststoffschweißtechnik 30.06.11 Working Instructions WIDOS 5100 Page 25 of 45...

- Page 26 14,7 13,6 18,2 11,0 22,4 27,4 26,0 10,8 21,0 12,8 17,6 13,4 16,6 13,6 20,5 11,0 25,2 30,8 11,9 21,0 14,2 17,6 14,8 17,0 18,4 13,6 22,7 11,0 27,9 34,2 30.06.2011 Working instructions WIDOS 5100 Page 26/ 1 of 48...

- Page 27 11,0 31,3 38,3 12,1 15,0 21,0 17,9 17,6 18,7 17,0 23,2 13,6 28,6 11,0 35,2 43,1 10,9 13,6 26,0 16,9 21,0 20,1 17,6 21,1 26,1 13,6 32,2 11,0 39,7 48,5 30.06.2011 Working instructions WIDOS 5100 Page 26/ 2 of 48...

- Page 28 15,3 26,0 19,1 21,0 22,7 17,6 23,7 17,0 29,4 13,6 36,3 11,0 44,7 54,7 11,0 13,8 17,2 26,0 21,5 21,0 25,5 17,6 26,7 17,0 33,1 13,6 40,9 11,0 50,3 61,5 30.06.2011 Working instructions WIDOS 5100 Page 26/ 3 of 48...

- Page 29 • prefabrication under workshop conditions • low additional pressure at unclamping • no additional pressure during further cooling down • load onto the workpieces only after being completely cooled down 30.06.2011 Working instructions WIDOS 5100 Page 26/ 4 of 48...

- Page 30 [bar] time [mm] [mm] [mm] time pressure [min] 11,4 17,6 18,2 27,4 33,2 12,8 17,6 20,5 30,8 37,4 14,2 17,6 22,7 34,2 10,7 15,9 17,6 25,4 38,3 30.06.2011 Working instructions WIDOS 5100 Page 27 / 1 of 48...

- Page 31 • low additional pressure at unclamping • no additional pressure during further cooling down • load onto the workpieces only after being completely cooled down 30.06.2011 Working instructions WIDOS 5100 Page 27 / 2 of 48...

- Page 32 [bar] min. over welding [bar] time [mm] [mm] [mm] time pressure [min] 13,5 10,5 10,8 15,0 11,0 11,9 16,5 12,5 13,5 30.06.2011 Working instructions WIDOS 5100 Page 28 of 48...

-

Page 33: Maintenance And Repair

• Remove the red screw at the top of the aggregate. • Take out the oil dip rod, clean it with a dry tissue and insert it again. • The oil-level must be between the two markers. 30.06.11 Working Instructions WIDOS 5100 Page 29 of 45... -

Page 34: Venting The Hydraulic Cylinders

The lower vent screws always have to be vented at first because there is a direct connection between the upper and the lower cylinders. ⇒ If air remains in the lower cylinder, it will ascend in the upper cylinder when pressure is applied. 30.06.11 Working Instructions WIDOS 5100 Page 30 of 45... -

Page 35: Transport

During the transport of the machine there may be cold weldings between the piston rod and the eyes of the planer shell. These spots on the piston rod may damage the sealing. Therefore the eyes must be lubricated with PTFE-spray before transport! 30.06.11 Working Instructions WIDOS 5100 Page 31 of 45... -

Page 36: Hydraulic And Electric Diagrams

WIDOS Einsteinstr. 5 Phone +49 7152 9939 - 0 W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen +49 7152 9939 - 40 info @ widos.de http://www.widos.de Kunststoffschweißtechnik 9. Hydraulic and electric diagrams 30.06.11 Working Instructions WIDOS 5100 Page 32 of 45... - Page 37 Hydraulic and elektric diagrams Chapter 9 Kunststoffschweißtechnik 30.06.11 Working Instructions WIDOS 5100 Page 33 of 45...

-

Page 38: Spare Parts List

@ widos.de http://www.widos.de Kunststoffschweißtechnik 10. Spare parts list 10.1. Basic machine 8 - 10 15 - 17 27 / 28 29 - 30 19 - 22 39 - 40 33 - 35 30.06.2011 Working Instructions WIDOS 5100 Page 34 of 45... - Page 39 Spare parts list Chapter 10 Kunststoffschweißtechnik Basic machine WIDOS 5100 Pos. Name Piece Art.no. Upper clamp 071105 Outer clamp, fixed 071101 Inner clamp, fixed 071102 Inner clamp, movable 071103 Outer clamp, movable 071104 Hydraulic cylinder 071106 Gasket set for cylinder...

- Page 40 Spare parts list Chapter 10 Kunststoffschweißtechnik Basic machine WIDOS 5100 Pos. Name Piece Art.no. Support 071141 Protective cap 45x45 J0225 Pan-head screw M10x20 DIN 912 0912J020 Reduction insert OD 355-400 1 set 0708...* Adaptor half coupling (OD 315) 1 set...

-

Page 41: Hydraulic Aggregat

52 – 56 48 - 50 17 / 18 / 21 - 23 19–23 31 / 32 15 / 16 13 / 14 57 / 59 43 - 47 36 - 42 30.06.2011 Working Instructions WIDOS 5100 Page 36 of 45... - Page 42 Hydraulic and elektric diagrams Chapter 9 Kunststoffschweißtechnik 28 / 30 30.06.11 Working Instructions WIDOS 5100 Page 37 of 45...

- Page 43 Spare parts list Chapter 10 Kunststoffschweißtechnik Hydraulic Aggregate WIDOS 5100 Pos. Name Piece Order no. Cover 1010021 Pan-head screw M4x12 DIN 912 0912D012 Motor on request Pump 1,9 l 102103 Capacitor 12,5 F EK12220 Universal RC - link EE0104 Connection cable with plug...

- Page 44 Spare parts list Chapter 10 Kunststoffschweißtechnik Hydraulic Aggregate WIDOS 5100 Pos. Name Piece Order no. Bearing block on request Pan-head screw M5x45 DIN 912 0912E045 Control knob for pressure setting 101022 Bush 101047 Set screw 101050 Plate "Pressure values" SCHM4600...

-

Page 45: Planer

Spare parts list Chapter 10 Kunststoffschweißtechnik 10.3. Planer 9 - 11 12 - 17 6 - 8 30.06.2011 Working Instructions WIDOS 5100 Page 39 of 45... - Page 46 Switch for Motor ESMBF16 Collctor carbon 1 set EKMBF23 Connection cable EK3220 Cylinder head screw M 10x40 DIN 912 0912J040 Handlebar 071409 Ball button 0319C40 Cylinder head screw M 10x40 DIN 912 0912J040 30.06.2011 Working instructions WIDOS 5100 page 40 of 45...

-

Page 47: Heating Element

Spare parts list Chapter 10 Kunststoffschweißtechnik 10.4. Heating element 2 - 3 14 - 17 4 - 7 10 - 11 20 - 21 30.06.2011 Working Instructions WIDOS 5100 Page 41 of 45... - Page 48 Spare parts list Chapiter 10 Kunststoffschweißtechnik Heating Element WIDOS 5100 Pos. Name Piece Art.no. Frame for terminal box 071534 Connecting cable EK3220 Bolting HKL EVH1313 Pan-head screw M 5x25 DIN 912 0912E025 PTFE-distance washer 211508 Washer M5 DIN 125 0125E...

-

Page 49: Reception Box

Spare parts list Chapter 10 Kunststoffschweißtechnik 10.5. Reception box 30.06.2011 Working Instructions WIDOS 5100 Page 43 of 45... - Page 50 Spare parts list Chapter 10 Kunststoffschweißtechnik Reception box Widos 5100 Pos. Name Piece Order no. Mounting 071512 Heat absorbing steel sheet 0715121 Blind rivet 4x10 DIN 7337 7337D010 Fitting cap on request Handlebar 071409 Sherical button 0319C40 30.06.2011 Working instructions WIDOS 5100...

-

Page 51: Declaration Of Conformity

Safety technology requirements at fluid technical devices and components 4. EN 60555, EN 50082, EN 55014 Electro-magnetic resistence The technical documentation is completely available. Ditzingen - Heimerdingen, the 30.06.11 Dieter Dommer (Manager) 30.06.2011 Working Instructions WIDOS 5100 Page 45 of 45...

Need help?

Do you have a question about the 5100 and is the answer not in the manual?

Questions and answers