Summary of Contents for Technosoft IBL2403-RS232

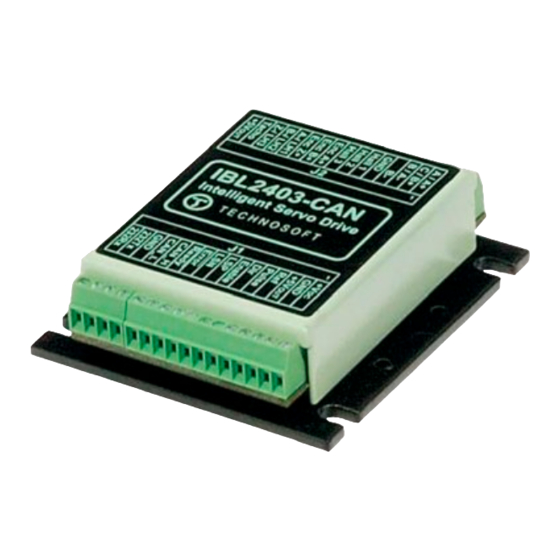

- Page 1 IBL2403-RS232 IBL2403-CAN Intelligent Servo Drive for Step, DC, Brushless DC and AC Motors Intelligent Servo Drive Technical Reference © Technosoft 2007...

- Page 3 T E C H N O S O F T IBL2403-RS232 IBL2403-CAN Technical Reference P091.037.IBL2403.UM.1007 Technosoft S.A. Buchaux 38 CH-2022 Bevaix, NE Switzerland Tel.: +41 (0) 32 732 5500 Fax: +41 (0) 32 732 5504 e-mail: contact@technosoftmotion.com http://www.technosoftmotion.com/...

- Page 5 Whilst Technosoft believes that the information and guidance given in this manual is correct, all parties must rely upon their own skill and judgment when making use of it. Technosoft does not assume any liability to anyone for any loss or damage caused by any error or omission in the work, whether such error or omission is the result of negligence or any other cause.

- Page 6 Help of the EasySetUp software – describes how to use EasySetUp to quickly setup any Technosoft drive for your application using only 2 dialogues. The output of EasySetUp is a set of setup data that can be downloaded into the drive EEPROM or saved on a PC file.

- Page 7 With EasyMotion Studio you can fully benefit from a key advantage of Technosoft drives – their capability to execute complex motions without requiring an external motion controller, thanks to their built-in motion controller. A demo version of EasyMotion Studio (with EasySetUp part fully functional) can be downloaded free of charge from Technosoft web page TML_LIB v2.0 (part no.

- Page 8 © Technosoft 2007 IBL2403 Technical Reference...

-

Page 9: Table Of Contents

Supply connection ..................34 3.2.11. Serial RS-232 connection ................. 36 3.2.12. CAN connection (IBL2403-CAN drives)............ 37 3.2.13. Special connection (Non-Autorun)............39 3.2.14. Master - Slave encoder connection ............40 3.2.15. Connectors Type and Mating Connectors ..........41 © Technosoft 2007 IBL2403 Technical Reference... - Page 10 DSP-402 and Manufacturer Specific Device Profile Overview ....50 5.1.4. Checking Setup Data Consistency .............. 50 5.2. Using the built-in Motion Controller and TML ........50 5.2.1. Technosoft Motion Language Overview ............51 5.2.2. Installing EasyMotion Studio................ 51 5.2.3. Getting Started with EasyMotion Studio ............52 5.2.4.

- Page 11 Master position units ................73 6.11. Master speed units ................73 6.12. Motor position units ................74 6.12.1. Brushless / DC brushed motor with quadrature encoder on motor... 74 6.12.2. Brushless motor with linear Hall signals ........... 74 © Technosoft 2007 IBL2403 Technical Reference...

- Page 12 DC brushed motor with tacho on motor ............ 76 6.13.5. Stepper motor open-loop control. No feedback device or incremental encoder on load ......................76 6.13.6. Stepper motor closed-loop control. Incremental encoder on motor..77 Memory Map ..................... 78 © Technosoft 2007 IBL2403 Technical Reference...

-

Page 13: Safety Information

ELECTRICAL SHOCKS. DO NOT TOUCH LIVE PARTS WHILE THE POWER SUPPLIES ARE ON TO AVOID ELECTRIC ARCING AND HAZARDS, NEVER WARNING! CONNECT / DISCONNECT WIRES FROM THE DRIVE WHILE THE POWER SUPPLIES ARE ON © Technosoft 2007 IBL2403 Technical Reference... -

Page 14: Cautions

MUST COMPLY WITH THE PARAMETERS SPECIFIED IN THIS DOCUMENT TROUBLESHOOTING AND SERVICING ARE PERMITTED CAUTION! ONLY FOR PERSONNEL AUTHORISED BY TECHNOSOFT THE DRIVE CONTAINS ELECTROSTATICALLY SENSITIVE COMPONENTS WHICH MAY BE DAMAGED BY INCORRECT HANDLING. THEREFORE THE DRIVE SHALL BE REMOVED... - Page 15 Using the high- level Technosoft Motion Language (TML) the following operations can be executed directly at drive level: Setting various motion modes (profiles, PVT, PT, electronic gearing or camming , etc.)

-

Page 16: Key Features

CANopen – compatible with CiA standards: DS301 and DSP402 • TMLCAN – compatible with all Technosoft drives with CANbus interface • 1.5K × 16 internal SRAM memory • 8K × 16 E ROM to store TML programs and data • Nominal PWM switching frequency: 20 kHz •... -

Page 17: Supported Motor-Sensor Configurations

Figure 2.2. Brushless DC rotary motor. Position/speed/torque control. Hall sensors and quadrature encoder on motor Motion commands can be referred to the motor by setting in EasySetUp a rotary to rotary transmission with ratio 1:1 © Technosoft 2007 IBL2403 Technical Reference... - Page 18 (rotary or linear). Therefore, the motion commands (for position, Motion commands can be referred to the motor by setting in EasySetUp a rotary to rotary transmission with ratio 1:1 Available only for the IBL2403 CAN executions © Technosoft 2007 IBL2403 Technical Reference...

- Page 19 8. Open-loop control of a 2 or 3-phase step motor in position or speed. Scaling factors take into account the transmission ratio between motor and load (rotary or linear). Therefore, the motion commands (for position, speed and acceleration) expressed in SI units (or © Technosoft 2007 IBL2403 Technical Reference...

- Page 20 IU units refer to the motor. Figure 2.10. Encoder on motor shaft. Closed-loop control: motor position, speed or torque Motion commands can be referred to the motor by setting in EasySetUp a rotary to rotary transmission with ratio 1:1 © Technosoft 2007 IBL2403 Technical Reference...

-

Page 21: Ibl2403 Dimensions

2.4. IBL2403 Dimensions 50.0 mm 1.968 “ 18.0 mm 4 mm 2.5 mm 0.098 “ 0.709 “ 0.157 “ 19.0 mm 0.748 “ 65.0 mm 2.559 “ Figure 2.11. IBL2403 drive dimensions © Technosoft 2007 IBL2403 Technical Reference... -

Page 22: Electrical Specifications

Units Logic “LOW” -0.5 Logic “HIGH” 5÷24 Input voltage † Absolute maximum, surge (duration ≤ 1S) Logic “HIGH”; Internal 470 Ω pull-up to +5V Input current Logic “LOW” Input frequency Minimum pulse width µS © Technosoft 2007 IBL2403 Technical Reference... - Page 23 Gain error % FS Bandwidth (-3 dB) Linear Hall Inputs (LH1, LH2, LH3) Referenced to GND Min. Typ. Max. Units Maximum range Voltage range Operating range Programmable Input current -0.5 +0.5 Bandwidth (-3 dB) © Technosoft 2007 IBL2403 Technical Reference...

- Page 24 Bit rate = 125kbps …250kbps Number of network nodes Bit rate = 500kbps Bit rate = 1Mbps ±15 ESD Protection Human Body Model Supply Output Min. Typ. Max. Units Voltage 4.75 5.25 available current © Technosoft 2007 IBL2403 Technical Reference...

- Page 25 Figure 2.12. De-rating with ambient temperature At altitudes over 1,000m, current and power rating are reduced due to thermal dissipation efficiency at higher altitudes. See Figure 2.13 – De-rating with altitude – the nominal current Stand-alone operation, vertical mounting © Technosoft 2007 IBL2403 Technical Reference...

- Page 26 PWM frequency with the motor parameters in order to avoid possible motor damage. Figure 2.16. Power De-rating with PWM Figure 2.17. Over-current diagram frequency – the output voltage, V – the motor supply voltage – the nominal power © Technosoft 2007 IBL2403 Technical Reference...

-

Page 27: Step 1. Hardware Installation

Before connecting the motor, be sure you have the right application programmed to E2ROM, else you can damage the CAUTION ! motor and drive. At power-on, the TML application is automatically executed. See paragraph 3.2.13 to disable this feature. © Technosoft 2007 IBL2403 Technical Reference... -

Page 28: Connectors And Connection Diagrams

T E C H N O S O F T Drive Name IBL2403-RS232 Article Number Serial Number P037.001.E001 AB1234 Figure 3.3. IBL2403-RS232 Identification Label Manufacturer T E C H N O S O F T Drive Name IBL2403-CAN Article Number Serial Number P037.001.E002... -

Page 29: J1 Connector Pinout

IBL2403 drive (P037.001.E001) • CAN-Bus negative line (negative during dominant bit) • Not connected on the no-CAN execution of the CAN_L IBL2403 drive (P037.001.E001) • Ground • RS-232 Data Transmission 232Tx • RS-232 Data Reception 232Rx © Technosoft 2007 IBL2403 Technical Reference... -

Page 30: J2 Connector Pinout

Z- / LH3 • Linear Hall 3 signal • Unipolar 0 V…+5 V analog input. May be used as analog position or speed feedback (from a Tacho tachometer) • 5V logic supply (internally generated) +5 V © Technosoft 2007 IBL2403 Technical Reference... -

Page 31: Digital I/O Connection

Figure 3.7. 24V Digital I/O connection Remarks: 1. In order to use 24V outputs, an external resistor needs to be connected to a supply of 2. The minimum value of external resistors must be 560 Ω. © Technosoft 2007 IBL2403 Technical Reference... -

Page 32: Digital I/O Connection

3.2.6. 5V Digital I/O connection 5V I/O Connection IBL2403 v1.1 Pulse +3.3V +3.3V 470R 470R Enable 470R 470R LOAD Error max. 6mA 470R 470R LOAD Ready max. 6mA +3.3V Figure 3.8. 5V Digital I/O connection © Technosoft 2007 IBL2403 Technical Reference... -

Page 33: Analog Inputs Connection

(+); 2 wire connects the signal minus to the drive negative input (-) and 3 wire connects the source ground to the drive GND © Technosoft 2007 IBL2403 Technical Reference... -

Page 34: Motor Connections

Before connecting the motor, be sure you have the right application programmed to E2ROM, else you can damage the CAUTION ! motor and drive. At power-on, the TML application is automatically executed. See paragraph 3.2.13 to disable this feature. © Technosoft 2007 IBL2403 Technical Reference... - Page 35 Before connecting the motor, be sure you have the right application programmed to E2ROM, else you can damage the CAUTION ! motor and drive. At power-on, the TML application is automatically executed. See paragraph 3.2.13 to disable this feature. © Technosoft 2007 IBL2403 Technical Reference...

- Page 36 Before connecting the motor, be sure you have the right application programmed to E2ROM, else you can damage the CAUTION ! motor and drive. At power-on, the TML application is automatically executed. See paragraph 3.2.13 to disable this feature. © Technosoft 2007 IBL2403 Technical Reference...

- Page 37 Before connecting the motor, be sure you have the right application programmed to E2ROM, else you can damage the CAUTION ! motor and drive. At power-on, the TML application is automatically executed. See paragraph 3.2.13 to disable this feature. © Technosoft 2007 IBL2403 Technical Reference...

- Page 38 The parasitic capacitance between the motor wires must not bypass 100nF. If very long cables (hundreds of meters) are used, this condition may not be met. In this case, add series inductors between the IBL2403 outputs and the cable. The inductors must be © Technosoft 2007 IBL2403 Technical Reference...

-

Page 39: Feedback Connections

A good shielding can be obtained if the motor wires are running inside a metallic cable guide. 3.2.9. Feedback connections 3.2.9.1 Single-ended encoder connection Single-ended encoder IBL2403 connection v1.1 Shield 470R Enc A+ Enc B+ 470R Enc Z + 470R +3.3V Figure 3.15. Single-ended encoder connection © Technosoft 2007 IBL2403 Technical Reference... - Page 40 120R terminator 470R Enc B+ B-/LH2 120R terminator Enc Z + 470R Z-/LH3 120R terminator +3.3V Figure 3.16. Differential encoder connection Remark: 120-Ω (0.25-W) terminators are required for long encoder cables, or noisy environments. © Technosoft 2007 IBL2403 Technical Reference...

- Page 41 3.2.9.3 Hall connection IBL2403 Hall connection v1.1 Internally generated +3.3V 3 x 1K Hall1 Hall2 Hall3 3 x 1K +3.3V Figure 3.17. Hall connection © Technosoft 2007 IBL2403 Technical Reference...

- Page 42 Linear Hall connection IBL2403 Linear Hall connection v1.1 3 x 10K A- / LH1 B- / LH2 C- / LH3 Internally generated 3 x 22nF 3 x 20K +3.3V Figure 3.18. Linear Hall connection © Technosoft 2007 IBL2403 Technical Reference...

- Page 43 If the IBL2403 5V supply output is used by another device (like for example an encoder) and the connection cable is longer than 5 meters, add a decoupling capacitor near the supplied device, between the +5V and GND lines. The capacitor value can be 1...10 μF, rated at 6.3V. © Technosoft 2007 IBL2403 Technical Reference...

-

Page 44: Supply Connection

This may cause an increase of the motor supply voltage (depending on the power supply characteristics). If the voltage bypasses the U value, the drive over-voltage protection is triggered and the drive power stage is disabled. © Technosoft 2007 IBL2403 Technical Reference... - Page 45 [kg], the angular speed ϖ will become linear speed measured in [m/s] and the friction torque T will become friction force measured in [N]. © Technosoft 2007 IBL2403 Technical Reference...

-

Page 46: Serial Rs-232 Connection

Do not rely on an earthed PC to provide the IBL2403 GND connection! The drive must be earthed through a separate circuit. Most communication problems are caused by the lack of such connection c) Always power-off all the IBL2403 supplies before inserting/removing the RS-232 serial connector. © Technosoft 2007 IBL2403 Technical Reference... -

Page 47: Can Connection (Ibl2403-Can Drives)

2. CAN signals are not insulated from other IBL2403 circuits. 3. CAN signals (CAN_H and CAN_L pins of J1 connector) are not connected pins on the IBL2403-RS232 drive 3.2.12.2 Recommendation for wiring a) Build CAN network using cables with 2-pairs of twisted wires (2 wires/pair) as follows: one pair for CAN_H with CAN_L and the other pair for CAN_V+ with CAN_GND. - Page 48 CAN_GND Host Address = 255 RS-232 120R 5%, 0.25W CAN_H IBL4203 Node CAN_L AXISID = 255 CAN_GND Figure 3.23. Multiple-Axis CAN network Remark: The AxisID must be set by software, using instruction AXISID number. © Technosoft 2007 IBL2403 Technical Reference...

-

Page 49: Special Connection (Non-Autorun)

To disable this feature in case that the application in the E2ROM is corrupted and the RS232 communication is lost, make the following connections: Connection for Non-Autorun IBL2403 v1.1 +3.3V 3 x 1K Hall1 Hall2 Hall3 3 x 1K +3.3V Figure 3.24. Connection for Non-Autorun © Technosoft 2007 IBL2403 Technical Reference... -

Page 50: Master - Slave Encoder Connection

M as t er Motor phases Master Shield Enc A+ Enc B+ IBL2403 v1.1 Slave +3.3V +3.3V 470R 470R Pulse +3.3V Slave Encoder Motor phases Figure 3.25. Master – Slave encoder connection using second encoder input © Technosoft 2007 IBL2403 Technical Reference... -

Page 51: Connectors Type And Mating Connectors

Board connector Motor & Feedback Phoenix MPT 0,5/8 – 2,54 Contact Supply, I/O & Serial Phoenix MPT 0,5/8 – 2,54 Contact The mating connector accepts wires of 0.14 … 0.5 mm (AWG26 … AWG20) © Technosoft 2007 IBL2403 Technical Reference... -

Page 52: Step 2. Drive Setup

4. Step 2. Drive Setup 4.1. Installing EasySetUp EasySetUp is a PC software platform for the setup of the Technosoft drives. It can be downloaded free of charge from Technosoft web page. EasySetUp comes with an Update via Internet tool through which you can check if your software version is up-to-date, and when necessary download and install the latest updates. -

Page 53: Establish Communication

Implement on your master the TML commands you need to send to the drives/motors using one of the supported communication channels. The implementation must be done according with Technosoft communication protocols. Combine TML programming at drive level with one of the other options (see Section 5.3) 4.2.1. -

Page 54: Setup Drive/Motor

4.2.2. Setup drive/motor Press New button and select your drive type. The selection continues with the motor technology (for example: brushless or brushed) and type of feedback device (for example: Incremental encoder, Linear Halls). © Technosoft 2007 IBL2403 Technical Reference... -

Page 55: Download Setup Data To Drive/Motor

The selection opens 2 setup dialogues: for Motor Setup and for Drive setup through which you can configure and parameterize a Technosoft drive, plus several predefined control panels customized for the product selected. In the Motor setup dialogue you can introduce the data of your motor and the associated sensors. -

Page 56: Changing The Drive Axis Id

You can use the Data Logger or the Control Panel evaluation tools to quickly measure and analyze your application behavior. In case of errors like protections triggered, use the Drive Status control panel to find the cause. 4.3. Changing the drive Axis ID © Technosoft 2007 IBL2403 Technical Reference... -

Page 57: Setting Canbus Rate

The IBL2403 drives can work with the following rates on the CAN: 125kHz, 250kHz, 500KHz, 1MHz. In the Drive Setup dialogue you can choose the initial CAN rate after power on. This information is stored in the setup table. The CAN rate is initialized using the following algorithm: © Technosoft 2007 IBL2403 Technical Reference... -

Page 58: Creating An Image File With The Setup Data

EEPROM Programmer tool, which comes with EasySetUp but may also be installed separately. The EEPROM Programmer was specifically designed for repetitive fast and easy programming of .sw files into the Technosoft drives during production. © Technosoft 2007 IBL2403 Technical Reference... -

Page 59: Step 3. Motion Programming

The Network Management is node oriented and follows a master-slave structure. NMT objects are used for executing NMT services. Through NMT services the drive can be initialized, started, monitored, reset or stopped. The IBL2403 is a NMT slave in a CANopen network. © Technosoft 2007 IBL2403 Technical Reference... -

Page 60: Technocan Extension (For Ibl2403 Can Execution)

5.1.2. TechnoCAN Extension (for IBL2403 CAN execution) In order to take full advantage of the powerful Technosoft Motion Language (TML) built into the IBL2403, Technosoft has developed an extension to CANopen, called TechnoCAN through which TML commands can be exchanged with the drives. -

Page 61: Technosoft Motion Language Overview

EasyMotion Studio is an integrated development environment for the setup and motion programming of Technosoft intelligent drives. It comes with an Update via Internet tool through which you can check if your software version is up-to-date, and when necessary download and install the latest updates. -

Page 62: Getting Started With Easymotion Studio

The setup component contains all the information needed to configure and parameterize a Technosoft drive. This information is preserved in the drive/motor EEPROM in the setup table. The setup table is copied at power-on into the RAM memory of the drive/motor and is used during runtime. - Page 63 255 which is the default axis ID of the drives. Press New button and select your drive type. Depending on the product chosen, the selection may continue with the motor technology (for example: brushless or brushed) and the type of feedback device (for example: incremental encoder). © Technosoft 2007 IBL2403 Technical Reference...

- Page 64 Click on your selection. EasyMotion Studio opens the Project window where on the left side you can see the structure of a project. At beginning both the new project and its first application are named “Untitled”. The application has 2 components: S Setup and M Motion (program). © Technosoft 2007 IBL2403 Technical Reference...

- Page 65 DIP switches OFF and it is connected to your PC port COM1 via an RS-232 cable, the communication shall establish automatically. 5.2.3.3 Setup drive/motor In the project window left side, select “S Setup”, to access the setup data for your application. © Technosoft 2007 IBL2403 Technical Reference...

- Page 66 Setup and for Drive Setup (same like on EasySetUp) through which you can configure and parameterize a Technosoft drive. In the Motor setup dialogue you can introduce the data of your motor and the associated sensors. Data introduction is accompanied by a series of tests having as goal to check the connections to the drive and/or to determine or validate a part of the motor and sensors parameters.

- Page 67 . The TML program may also include cam tables used for electronic camming applications The customization of the interrupt service routines and homing routines is available only for IBL2403 CAN executions Optional for IBL2403 CANopen execution © Technosoft 2007 IBL2403 Technical Reference...

-

Page 68: Combining Canopen /Or Other Host With Tml

CANopen master control. A detailed description of these advanced programming features is included in the CANopen Programming (part no. P091.063.UM.xxxx) manual. All features presented below require usage of EasyMotion Studio as TML programming tool © Technosoft 2007 IBL2403 Technical Reference... -

Page 69: Using Tml Functions To Split Motion Between Master And Drives

EasySetUp. 5.3.1. Using TML Functions to Split Motion between Master and Drives With Technosoft intelligent drives you can really distribute the intelligence between a CANopen master and the drives in complex multi-axis applications. Instead of trying to command each step of an axis movement, you can program the drives using TML to execute complex tasks and inform the master when these are done. -

Page 70: Customizing The Drive Reaction To Fault Conditions (For Ibl2403 Can Executions)

A TML Library for PC is a collection of high-level functions allowing you to control from a PC a network of Technosoft intelligent drives. It is an ideal tool for quick implementation on PCs of motion control applications with Technosoft products. -

Page 71: Using Motion Libraries For Plc-Based Systems

A TML Motion Library for PLC is a collection of high-level functions and function blocks allowing you to control from a PLC the Technosoft intelligent drives. The motion control function blocks are developed in accordance with the PLC IEC61131-3 standard and represent an ideal tool for quick implementation on PLCs of motion control applications with Technosoft products. -

Page 72: Scaling Factors

6. Scaling factors Technosoft drives work with parameters and variables represented in the drive internal units (IU). These correspond to various signal types: position, speed, current, voltage, etc. Each type of signal has its own internal representation in IU and a specific scaling factor. This chapter presents the drive internal units and their relation with the international standard units (SI). -

Page 73: Dc Brushed Motor With Quadrature Encoder On Load And Tacho On Motor

No_encoder_lines – is the motor encoder number of lines per revolution Tr – transmission ratio between the motor displacement in SI units and load displacement in SI units SI units for position are [rad] for a rotary movement , [m] for a linear movement © Technosoft 2007 IBL2403 Technical Reference... -

Page 74: Stepper Motor Open-Loop Control. Incremental Encoder On Load

512 and 8192. By default it is set at 2048 counts per turn. The correspondence with the load speed in SI units is: × π × For rotary motors: Load Speed Motor Speed × × resolution Pole_Pitch For linear motors: Load_Speed[SI] = ×Motor_Speed[IU] resolution× Tr × T © Technosoft 2007 IBL2403 Technical Reference... -

Page 75: Dc Brushed Motor With Quadrature Encoder On Load And Tacho On Motor

SI units is: × π × Load Speed Motor Speed μ × × × steps steps SI units for speed are [rad/s] for a rotary movement, [m/s] for a linear movement © Technosoft 2007 IBL2403 Technical Reference... -

Page 76: Stepper Motor Closed-Loop Control. Incremental Encoder On Motor

T – is the slow loop sampling period expressed in [s]. You can read this value in the “Advanced” dialogue, which can be opened from the “Drive Setup”. SI units for speed are [rad/s] for a rotary movement , [m/s] for a linear movement © Technosoft 2007 IBL2403 Technical Reference... -

Page 77: Acceleration Units

Tr – transmission ratio between the motor displacement in SI units and load displacement in SI units SI units for acceleration are [rad/s ] for a rotary movement, [m/s ] for a linear movement © Technosoft 2007 IBL2403 Technical Reference... -

Page 78: Dc Brushed Motor With Quadrature Encoder On Load And Tacho On Motor

The internal acceleration units are load encoder counts / (slow loop sampling period) . The correspondence with the load acceleration in SI units is: For rotary-to-rotary transmission: × π × Load Accelerati Load Accelerati × × encoder lines For rotary-to-linear transmission: © Technosoft 2007 IBL2403 Technical Reference... -

Page 79: Stepper Motor Closed-Loop Control. Incremental Encoder On Motor

× × × encoder lines where: No_encoder_lines – is the rotary encoder number of lines per revolution SI units for jerk are [rad/s ] for a rotary movement, [m/s ] for a linear movement © Technosoft 2007 IBL2403 Technical Reference... -

Page 80: Brushless Motor With Linear Hall Signals

No_encoder_lines – is the encoder number of lines per revolution T – is the slow loop sampling period expressed in [s]. You can read this value in the “Advanced” dialogue, which can be opened from the “Drive Setup” © Technosoft 2007 IBL2403 Technical Reference... -

Page 81: Stepper Motor Open-Loop Control. No Feedback Device

Tr – transmission ratio between the motor displacement in SI units and load displacement in SI units SI units for jerk are [rad/s ] for a rotary movement, [m/s ] for a linear movement © Technosoft 2007 IBL2403 Technical Reference... -

Page 82: Current Units

“Drive Info” dialogue, which can be opened from the “Drive Setup”. Remark: the voltage measurement units occur in the scaling of the over voltage and under voltage protections and the supply voltage measurement © Technosoft 2007 IBL2403 Technical Reference... -

Page 83: Time Units

When the master position is an encoder, the correspondence with the international standard (SI) units is: × π × Master speed Master speed × × encoder lines where: No_encoder_lines – is the master number of encoder lines per revolution © Technosoft 2007 IBL2403 Technical Reference... -

Page 84: Motor Position Units

The internal motor position units are motor µsteps. The correspondence with the motor position I s: in SI units × π × Motor Position Motor Position μ × steps steps SI units for motor position are: [rad] for a rotary motor, [m] for a linear motor © Technosoft 2007 IBL2403 Technical Reference... - Page 85 512 and 8192. By default it is set at 2048 counts per turn. The correspondence with the motor speed in SI units is: × π × For rotary motors: Motor Speed Motor Speed × resolution Pole_Pitch For linear motors: Motor_Speed[SI] = ×Motor_Speed[IU] resolution× T © Technosoft 2007 IBL2403 Technical Reference...

-

Page 86: Stepper Motor Open-Loop Control. No Feedback Device Or Incremental Encoder On Load

Motor Speed μ × × steps steps where: No_steps – is the number of motor steps per revolution SI units for motor speed are [rad/s] for a rotary motor, [m/s] for a linear motor © Technosoft 2007 IBL2403 Technical Reference... -

Page 87: Stepper Motor Closed-Loop Control. Incremental Encoder On Motor

No_encoder_lines – is the motor encoder number of lines per revolution T – is the slow loop sampling period expressed in [s]. You can read this value in the “Advanced” dialogue, which can be opened from the “Drive Setup”. © Technosoft 2007 IBL2403 Technical Reference... -

Page 88: Memory Map

Data Memory (PM) (DM) 8270h 0A70h Program Memory Not used as for TML programs Data Memory Not used as Data Memory Program Memory for data acquisition 0FFFh 87FFh Figure 8.1. IBL2403 / IBL2403-CAN Memory Map © Technosoft 2007 IBL2403 Technical Reference...

Need help?

Do you have a question about the IBL2403-RS232 and is the answer not in the manual?

Questions and answers