Table of Contents

Advertisement

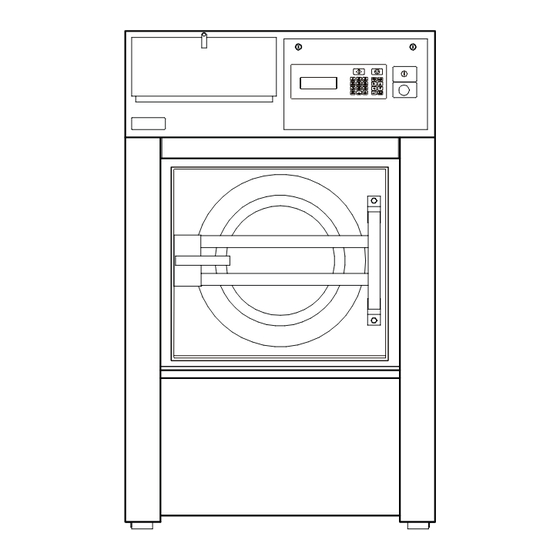

MFS80, MFS100, MFS125, MFS180, MFS230, MFS275

WASHER SAFETY .................................................................. 2

INSTALLATION REQUIREMENTS ......................................... 3

Tools, Parts, and Equipment ................................................. 3

Location Requirements ........................................................ 3

Electrical Requirements ......................................................... 6

Water Supply Requirements ................................................. 7

Drain Requirements .............................................................. 7

INSTALLATION INSTRUCTIONS ........................................... 8

Transport, Handling, Inspection, and Storage ...................... 8

Moving to Final Location ...................................................... 8

Water, Drain, and Venting Connections ................................ 9

Electrical Connection ......................................................... 10

Remove Shipping Brackets ................................................ 13

Complete Installation .......................................................... 15

Break-In Period .................................................................. 15

Controls Troubleshooting ................................................... 15

WASHER MAINTENANCE ................................................... 16

Maintenance Schedule ........................................................ 16

Vibration Switch Adjustment and Function Test ................. 17

Belt Inspection, Adjustment, and Replacement .................. 18

Tightening Moments ............................................................ 19

Lubrication .......................................................................... 20

Water and Steam Filters ..................................................... 20

Thrust of Door Seal ............................................................. 21

Spring Unit .......................................................................... 22

INSTALLATION INSTRUCTIONS

COMMERCIAL WASHER

TABLE OF CONTENTS

Fuse Capacities .....................................................................22

Earth Leakage Trips ...............................................................22

TROUBLESHOOTING .............................................................23

REMOVING THE WASHER FROM SERVICE.........................24

DIMENSIONS AND TECHNICAL SPECIFICATIONS .............25

Models MFS80, MFS100, and MFS125 ..............................25

Dimensions and Connections ...........................................26

Torque Specifications ........................................................26

Technical Specifications ....................................................27

Model MFS180 .....................................................................29

Dimensions and Connections ...........................................30

Torque Specifications ........................................................30

Models MFS230 and MFS275 .............................................31

Dimensions and Connections ...........................................32

Torque Specifications ........................................................32

(Models MFS180, MFS230, and MFS275) ........................33

with Tilting Feature ..............................................................35

Dimensions and Connections ...........................................35

Technical Specifications ...................................................35

www.maytagcommerciallaundry.com

1

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the MFS80 and is the answer not in the manual?

Questions and answers