Summary of Contents for Dietz SANGO ADVANCED Series

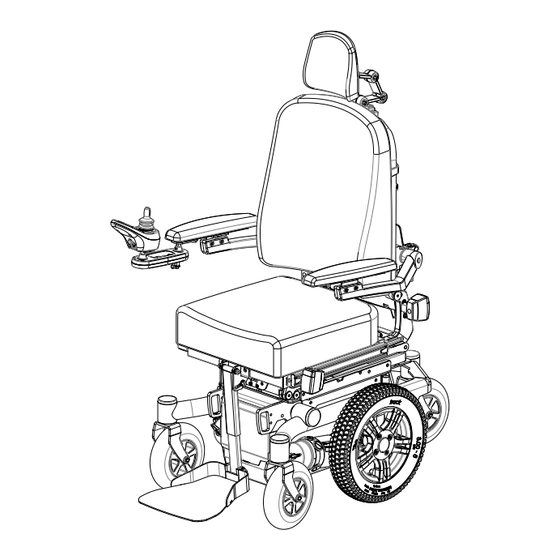

- Page 1 SERVICE MANUAL Sango Advanced R Sango Advanced F Sango Advanced M Sango Slimline M...

- Page 2 DIETZ-Power BV. The information provided is based on general data pertaining to constructions known at the time of issue. DIETZ-Power BV pursues a policy of continuous product development and therefore reserves the right to make changes. The information provided applies to the standard version of the product.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 Preface ......................5 1.1. About this manual 1.2. Symbols used in this manual 1.3. Service, support and ordering 2 Safety ........................ 7 2.1. Safety guidelines 2.2. Temperature 2.3. Moving parts 2.4. Electromagnetic radiation 2.5. - Page 4 Table of contents 7 Technical specifications ................33 7.1. Standards and requirements 7.2. Specifications operating force 7.3. Specifications Sango Advanced Sego Comfort 7.4. Specifications Sango Slimline Sego Comfort 7.5. Specifications batteries 7.6. Electrical diagrams 8 Warranty conditions ..................37 8.1. Warranty period 8.2.

-

Page 5: Preface

Qualified service technicians that perform the maintenance and solves technical problems of the wheelchair. • DIETZ-Power dealers who support customers when they call the dealer’s office with questions about the wheelchair. This service manual will serve as reference material to help the customer service employee. -

Page 6: Service, Support And Ordering

1 Preface 1.3. Service, support and ordering For information concerning specific settings, maintenance or repairs please contact your supplier. He is always prepared to help you. Ensure you have the following information at hand (see 2.4 Identification plate): • Type of the wheelchair •... -

Page 7: Safety

Programming should only be conducted by professionals with in-depth knowledge of wheelchair control systems. Incorrect programming could result in an unsafe set-up of the wheelchair for a user. DIETZ-Power accepts no responsibility for losses of any kind if the programming of the control system is altered without authorization of DIETZ-Power. -

Page 8: Moving Parts

2 Safety 2.3. Moving parts Warning Wheelchairs contain moving and rotating parts (figure 1). Contact with moving parts may result in serious physical injury or damage to the wheelchair. You should avoid any contact with the moving parts of the wheelchair. A. -

Page 9: Markings On The Wheelchair

2 Safety 2.5. Markings on the wheelchair Warning • The markings, symbols and instructions on the wheelchair are part of the safety features. They must not be covered up or removed. They must remain on the wheelchair and be clearly legible for the whole lifespan of the wheelchair. •... -

Page 10: Maintenance And Tools

(at least once a year) and before reuse. Check all parts of the maintenance checklist and make sure the checklist in the end-users manual will be entirely filled after each maintenance. Use only original DIETZ-Power parts for maintenance and repairs. Operation Chassis... -

Page 11: Tools

3 Maintenance and tools Batteries • The wheelchair is fitted with ‘dry’ gel batteries. The batteries are fully sealed and require no maintenance. • The use of ‘wet’ batteries is not permitted. If the batteries have to be replaced, use only dry batteries. •... -

Page 12: Driving Programs

3 Maintenance and tools Tools for electronic settings The following tools are needed to do the electronic settings as described in this manual: Part Description R-Net VR2 number PGDT R-Net programmer OEM (D50611) PGDT VR2 PC-Programmer B set (D50145) Universal meter (voltage and resistance Use the torques as indicated in the table below, unless specified otherwise Thread Size Pitch (mm) -

Page 13: Replacements And Adjustments

4 Replacements and adjustments 4 Replacements and adjustments 4.1. Preparation WHEELCHAIR for the most common wheelchair settings (chapter 5). Warning! • Take all the safety guidelines (2.1) into account when carry out any maintenance or repairs to the wheelchair. • Only do maintenance on an empty wheelchair. - Page 14 4 Replacements and adjustments 4.2.2. Replace a drive wheel 1. Follow the preparation (see 4.1). 2. Turn off the controller and set both freewheel switches in ‘Drive’ mode. 3. Lift the wheelchair using a lifting platform until the wheels are free from the floor.

- Page 15 4 Replacements and adjustments 4.2.5. Replace a castor fork 1. Follow the preparation (see 4.1). 2. Remove the cap (A figure 7). 3. Unscrew the bolt (B). 4. Remove the castor fork and wheel from the side frame. 5. Unscrew the bolt and nut (C) to remove the castor wheel.

- Page 16 4 Replacements and adjustments 4.2.8. Replace the batteries 1. Follow the preparation (see 4.1). 2. Disconnect the battery connector (see 4.1.1). 3. Open the battery cover. 4. Loosen the screws (A figure 10). 5. Loosen the battery Velcro strap (B). 6.

-

Page 17: Dahl Preparation

4.3. Dahl preparation Warning! Dahl car docking is not possible in combination with 78Ah batteries. 4.3.1. Replace the slider To mount the Dahl docking plate the sliders needs to be replaced (side by side). 1. Remove the cables if needed 2. - Page 18 and the dedicated holes in the chassis (figure 14). Warning! • The Dahl high grade steel Torx bolts (D) only come in one length which is often too long. They need to be cut into the right length by the authorized engineer to fit the locking plate properly without damaging the batteries.

-

Page 19: Interface (All Types)

4 Replacements and adjustments 4.4. Interface (all types) 4.4.1. Adjust the centre of gravity (not recommended) The position of the interface can be adjusted in order to give the wheelchair better driving characteristics. This position depends on the seat depth and the drive type. -

Page 20: Legrests

4 Replacements and adjustments 4.4.4. Replace the tilt actuator of the tilt/lift interface 4.4.5. Replace the lift actuator of the tilt/lift interface 4.5. Legrests 4.5.1. Replace the actuator of a powered legrest 1. Follow the preparation (see 4.1). 2. Lift the legrest out of the wheelchair. 3. - Page 21 4 Replacements and adjustments 4.5.2. Replace the gasspring of a comfort legrest 1. Follow the preparation (see 4.1). 2. Lift the legrest out of the wheelchair. 3. Remove the screws and nuts (A figure 17). 4. Remove the old actuator (B) from the legrest.

-

Page 22: Seating System

4 Replacements and adjustments 4.6. Seating system 4.6.1. Replace the actuator of the backrest 1. Follow the preparation (see 4.1). 2. Remove the ISM cover. 3. Disconnect the ISM connecter. 4. Remove the bolts (A figure 23) and bushes (B). 5. -

Page 23: Wiring And Diagrams

5 Wiring and diagrams 5 Wiring and diagrams 5.1. Connecting wires When connecting the wires, check the following: • Fix the wires with tie wraps to the seat to prevent entrapment of loose wires between parts. • Ensure that the wires are not trapped under the seat. •... -

Page 24: Electrical Diagrams Vr2

5 Wiring and diagrams 5.2. Electrical diagrams VR2 Lighting module Lighting Attendant module Power module (max 2 actuators) Inhibit Switch Tilt Inhibit Switch Lift Motor 2 1 actuator Tilt 45° Lift/tilt 2 actuators Batteries Recline 1 actuator Legrest right 1 actuator Fuse Legrest left 1 actuator... -

Page 25: Electrical Diagrams R-Net

5 Wiring and diagrams 5.3. Electrical diagrams R-net BATT Bluetooth Omni Inhibit 2 Inhibit switch tilt Motor 1 Push buttons Inhibit switch lift Gyro DAC box Motor 2 Attendant module Lighting Lighting Batteries Fuse Legrest left 1 actuator Centre mount legrest length Tilt 45°... -

Page 26: Connect The Batteries

5 Wiring and diagrams 5.4. Connect the batteries See figure 26 how to connect the battery charger. The controller includes a ‘3-pin connection’. Ensure that the battery charger is properly connected so that the ‘negative pole’ and the ‘inhibit’ are connected, enabling the system to prevent the wheelchair from moving when the battery is being charged (figure... -

Page 27: Troubleshooting

TECHNICAL in case of controller issues for more detailed information. The R-net and VR2 technical manuals can be downloaded at the www.pgdt.com or www. DIETZ-Power.com website. Warning! Before changing bus cables, fuses and/or modules, remove both fuses from the battery compartment, so the system will be ‘dead’. - Page 28 6 Troubleshooting B. Wheelchair continuously drives slower than normal Cause Possible solution Speed limit due to Check if all seating options are in neutral microswitch signal from position. seating function. Measure resistance from the speed limit cable in different seating positions. Bad cable connections or a broken resistor influences the drive inhibit signal.

- Page 29 6 Troubleshooting F. Wheelchair has too little power to drive properly Cause Possible solution Tyre pressure of drive wheels Check pressure and inflate if needed. See User or castors is too low manual for correct value. Programming of speed and Check programming and make corrections if Torque Settings is not correct needed.

- Page 30 6 Troubleshooting J. Wheelchair wobbles overall or moves up and down when driving Cause Possible solution Drive wheels have radial Check for misalignment of tyres. If misaligned, misaligned tyres. Can be reduce tyre pressure to 1 bar, drive for several caused by long (weeks) minutes at moderate speed and increase inactive periods...

- Page 31 This can cause problems when turning on carpet and can have a negative effect on the range. If the problem is not solved with the help of the solutions in the tables, contact DIETZ-Power. SANGO ADVANCED / SLIMLINE - 31...

-

Page 32: Seat Adjustments

6 Troubleshooting 6.2. Seat adjustments 32 - SANGO ADVANCED / SLIMLINE... -

Page 33: Technical Specifications

7 Technical specifications 7 Technical specifications 7.1. Standards and requirements This product complies with the provisions of the Medical Devices Directive and therefore carries the CE mark. The wheelchair conforms to the following standards and requirements. This has been verified by independent test institutes. Standard Description Weight... -

Page 34: Specifications Sango Advanced Sego Comfort

7 Technical specifications 7.3. Specifications Sango Advanced Sego Comfort Manufacturer DIETZ-Power B.V. - Vlamovenweg 12 - 5708 JV Helmond User weight max. 160 kg Class B SANGO ADVANCED Type Specifications min. max. min. max. min. max. Unit Overall length incl. leg rest... -

Page 35: Specifications Sango Slimline Sego Comfort

7 Technical specifications 7.4. Specifications Sango Slimline Sego Comfort Manufacturer DIETZ-Power B.V. - Vlamovenweg 12 - 5708 JV Helmond User weight max. 136 kg Class B SANGO SLIMLINE Type Specifications min. max. Unit Overall length incl. leg rest 1070 1265 mm... -

Page 36: Specifications Batteries

7 Technical specifications Specifications were measured with 9» and 14» wheels, powered legrests and in most extreme positions (for min. most stripped version and max. most extended version) Measured with powered legrest, lift/tilt module and powered backrest. Measured with the powered adjustments in the neutral position. With the powered adjustments in the most extreme positions the specifications will be 9°... -

Page 37: Warranty Conditions

Dealers and/or users have statutory (legal) rights in relation to the purchase of consumer products. The warranty conditions applying to products/parts sold by DIETZ-Power B.V. are set out below. The warranty applies to any product/part that becomes defective or needs to be repaired or replaced as the result of a manufacturing fault or material defect within the stated warranty period. -

Page 38: Warranty Provisions

8 Warranty conditions 8.2. Warranty provisions The manufacturer shall not provide any warranty if: • the product has been passed on to a different owner. The warranty applies only to the first owner to whom the manufacturer supplied the product/parts. The warranty is not transferable and applies only to those models bought from the manufacturer;... - Page 39 8 Warranty conditions • whether the dealer should order a new product/part from the manufacturer. The dealer then receives an invoice detailing the shipping costs involved. The dealer arranges and pays for the defective product/ part to be sent to the manufacturer. Once the manufacturer has received the defective product/part, it is assessed.

- Page 40 Sango is a product manufactured by: DIETZ-Power B.V. Vlamovenweg 12 5708 JV Helmond The Netherlands +31 492 792 196 info@DIETZ-Power.com www.DIETZ-Power.com...

![Wheelchair Dietz AS[01] Manual](https://static-data2.manualslib.com/product-images/a82/1599654/60x60/dietz-as-01-wheelchair.jpg)

![Wheelchair Dietz AS[01] Operating Instructions Manual](https://static-data2.manualslib.com/product-images/a82/1308262/60x60/dietz-as-01-wheelchair.jpg)

Need help?

Do you have a question about the SANGO ADVANCED Series and is the answer not in the manual?

Questions and answers