ESAB Tig 4000i Aristo Instruction Manual

Hide thumbs

Also See for Tig 4000i Aristo:

- Instruction manual (24 pages) ,

- Instruction manual (26 pages)

Summary of Contents for ESAB Tig 4000i Aristo

- Page 1 Tig 4000i Aristot Instruction manual 0458 640 101 GB 060523 Valid for serial no. 620- -xxx- -xxxx...

-

Page 2: Table Of Contents

1 DIRECTIVE ............2 SAFETY . -

Page 3: Directive

DIRECTIVE DECLARATION OF CONFORMITY ESAB AB, Welding Equipment, SE--695 81 Laxå, Sweden, gives its unreserved guarantee that weld- ing power source Tig 4000i from serial number 620 complies with standard IEC/EN 60974--1, in ac- cordance with the requirements of directive (73/23/EEC) and addendum (93/68/EEC) and with stan- dard IEC/EN 60974--10 in accordance with the requirements of directive (89/336/EEC) and adden- dum (93/68/EEC). - Page 4 MALFUNCTION - - Call for expert assistance in the event of malfunction. READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING. PROTECT YOURSELF AND OTHERS! ESAB can provide you with all necessary welding protection and accessories. WARNING! Read and understand the instruction manual before installing or operating.

-

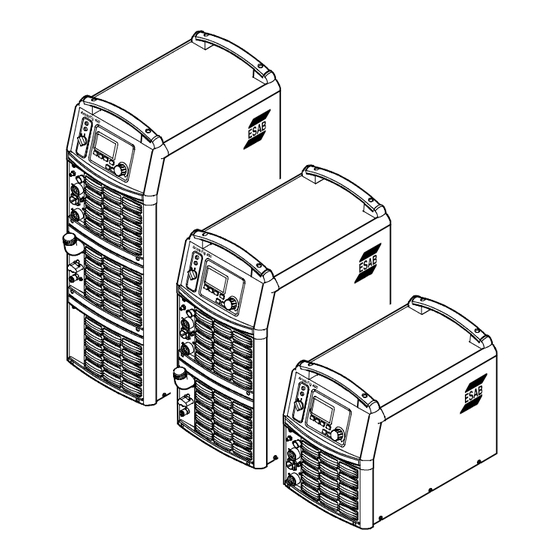

Page 5: Introduction

Tig 4000i with cooling unit, autotransformer and TA6 control panel NB: These instructions describe an Tig 4000i with cooling unit and autotransformer. ESAB’s accessories for the product can be found on page 19. Equipment The Tig 4000i is delivered with 5m return cable, instructions for power source and one instruction for the control panel. -

Page 6: Technical Data

TECHNICAL DATA Tig 4000i Tig 4000i not reconnectable reconnectable Mains voltage 400V, ±10%, 3∼ 50 Hz 208/230/400/460/475/500/575 V, ±10%, 3∼ 50/60 Hz Primary current 29 A 50/44/29/23/23/20/15 A 38 A 65/57/38/30/30/20/20 A No- -load powerin the energy-- 60 W 235 W saving mode, 6,5 min. -

Page 7: Installation

Enclosure class The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid objects or water. Equipment marked IP23 is designed for indoor and outdoor use. Application class The symbol indicates that the power source is designed for use in areas with increased electrical hazard. -

Page 8: Electrical Installation (With Autotransformer)

Electrical installation (with autotransformer) - - 8 - - bt23d1ea... -

Page 9: Mains Power Supply

Mains power supply Check that the unit is connected to the correct mains power supply voltage, and that it is protected by the correct fuse sizes. A protective earth connection must be made, in accordance with regulations. Rating plate with supply connection data. Recommended fuse sizes and minimum cable areas Tig 4000i 60 Hz... -

Page 10: Operation

OPERATION General safety regulations for the handling of the equipment can be found on page 3. Read through before you start using the equipment! Connections and control devices Connection for cooling water from the TIG Main power supply switch, 0 / 1 / START torch -- RED Connection with water lock for cooling wa- White indicating lamp -- Power supply ON... -

Page 11: Fan Control

Fan control The power source fans continue to run for 6,5 minutes after welding has stopped, and the unit switches to energy--saving mode. They start again when welding restarts. The fans run at reduced speed for welding currents up to 144 A, and at full speed for higher currents. -

Page 12: Maintenance

When carrying out TIG welding, the value for the pulse current can be changed with the remote control. For more information about the operation of the remote control unit, see the relevant operating instructions for the control panel. MAINTENANCE Regular maintenance is important for safe, reliable operation. Only those persons who have appropriate electrical knowledge (authorized personnel) may remove the safety plates to connect or carry out service, maintenance or repair work on welding equipment. -

Page 13: Fault Tracing

It is the obligation of the service unit which has carried out the service or repair work to make sure that the product still conforms to the said standard. Spare parts may be ordered through your nearest ESAB dealer, see the last page of this publication. -

Page 14: Diagram

Diagram - - 14 - - bt23e11a... - Page 15 - - 15 - - bt23e11a...

- Page 16 Cooling unit - - 16 - - bt23e11a...

-

Page 17: Ordering Number

0458 855 xxx Instruction manual Aristot TA6 The instruction manuals and the spare parts list are available on the Internet at www.esab.com Under ”Products” and ”Welding & cutting equipment”, you will find a link to the page where you can both search for and download instructions and spare parts lists. -

Page 18: Spare Parts List

Tig 4000i Spare parts list Item Ordering no. Denomination 0458 398 001 Filter 0458 383 001 Front grill - - 18 - - Edition 060523 ba37s... -

Page 19: Accessories

Tig 4000i Accessories Trolley ....... . . 0458 530 881 Remote control adapter RA12 12 pole . - Page 20 Tig 4000i Return cable 5 m 70 mm ....0700 006 895 Water flow guard 0.7 l/min ....0456 855 880 Edition 060523 - - 20 - - bt23a11a...

- Page 21 - - 21 - -...

- Page 22 - - 22 - -...

- Page 23 - - 23 - -...

- Page 24 ESAB subsidiaries and representative offices Europe Asia/Pacific Representative offices NORWAY AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna- -Liesing Sofia Shanghai Fax: +47 33 11 52 03...

Need help?

Do you have a question about the Tig 4000i Aristo and is the answer not in the manual?

Questions and answers