Vertiv Alber Cellcorder CRT-400 User Manual

Hide thumbs

Also See for Alber Cellcorder CRT-400:

- Operating instructions manual (7 pages) ,

- Previewer user's manual (62 pages) ,

- User manual (210 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Summary of Contents for Vertiv Alber Cellcorder CRT-400

- Page 1 Alber Cellcorder ™ CRT–400 User’s Guide Vertiv Corporation 1050 Dearborn Drive Columbus, OH 43085 Tel: (954) 377-7101 Fax: (954) 377-7042 www.vertivco.com 590-2099-501A/SL-29414/4200-070...

- Page 2 Vertiv is strictly prohibited. Notice to Users Vertiv Corporation reserves the right to make changes to this document without notice to any user or reseller of this product. Vertiv Corporation also reserves the right to substitute or terminate distribution of this document, with no obligation to notify any person or party of such substitutions or terminations.

-

Page 3: Table Of Contents

Table of Contents Safety Information ..........................1-1 1.1. General............................1-1 1.2. Document Symbols ........................1-1 1.3. Safety Symbols ...........................1-2 1.4. Product Safety Practices ......................1-2 Preventive Maintenance ........................2-1 2.1. Visual Inspection ........................2-1 2.2. Cleaning System Components ....................2-1 2.3. Internal Component Replacement.....................2-1 2.4. Shipping, Storage, Normal Use Protection ................2-1 Product Overview ..........................3-1 3.1. - Page 4 6.1. F4/Done Voltage Testing......................6-2 6.2. Stored In Memory Explained .....................6-2 6.3. Resume Testing Explained ......................6-3 Setting Up To Take Resistance Readings ...................7-1 7.1. Check/Set Amp Hours ........................7-3 7.2. Set Intercell Connections ......................7-3 Taking Resistance Readings .......................8-1 8.1. Resistance Readings ........................8-1 Connecting Resistance Test Leads .....................9-1 9.1.

- Page 5 13.13. Setting Up Bluetooth Wireless Communication ..............13-10 Setting Up and Editing a Site Template ..................14-1 Working with Files........................15-1 15.1. Saving Readings and Files to the USB Flash Hard Drive ............15-1 15.2. File Types Located on the USB Flash Hard Drive..............15-2 15.3.

- Page 6 List of Figures Figure 1 - Serial Number Location and Label ................3-2 Figure 2 - Cellcorder Right Panel Connector/Infrared ..............3-2 Figure 3 - Cellcorder Left Panel Connector/Test Lead and USB ..........3-3 Figure 4 - CRT Front Panel Diagram Left................... 3-8 Figure 5 - CRT Front Panel Diagram Right.................

- Page 7 Figure 45 - CRT–Main Menu with F Buttons for CRT Setup/F4 ..........13-1 Figure 46 - CRT– Setup/Bat. Select–F4/ ................... 13-2 Figure 47 - CRT– Setup/Thresholds or F4/F2 ................13-3 Figure 48 - CRT Setup/Clear Memory or F4/F3 ............... 13-7 Figure 49 - CRT Setup/Display Functions.................

- Page 8 Figure 91 - Typical Discharge Curve with Metallic Resistance Problem ......... 19-5 Figure 92 - Typical Discharge Curve with a Cell with an Electrochemical Resistance Problem 19- Figure 93 - Normalized Internal Resistance Vs. Temperature ..........19-7 Figure 94 - Measuring Internal Resistance ................19-8 Figure 95 - Single Interconnections ...................

- Page 9 List of Tables Table 1 - Back Panel/Telco/Reset Switch/Power ..............3-16 Table 2 - Function Buttons ......................5-1 Table 3 - CRT-400 Keypad Buttons .................... 5-7 Table 4 - Editing a Site Template ....................14-3 Table 5 - Battery Maintenance Schedule ................... 18-4 590-2099-501A/SL-29414/4200-070 Revision 4...

-

Page 10: Safety Information

1.2. Document Symbols The symbols below appear in this manual or are affixed to the Vertiv device. It is important to review these symbols and to understand the type of instructional information they convey. Highlights areas related to user safety. -

Page 11: Safety Symbols

The following describe safety practices particular to the installation or operation of the product. Equipment Service If you have questions, contact Vertiv and request assistance. Except as explained in this manual, do not attempt to service Vertiv equipment. Any adjustment, maintenance or repair of this product must be performed by qualified personnel. - Page 12 CAUTION: Do not substitute parts or modify equipment. Due to the possibility of introducing additional hazards, do not substitute parts or perform any unauthorized modification to the product. If necessary, contact Vertiv to ensure the safety features are maintained. Ventilation Never block equipment ventilation ports or openings.

-

Page 13: Preventive Maintenance

Preventive Maintenance 2. Preventive Maintenance 2.1. Visual Inspection Visually inspect device components for damaged or frayed power cables, or damaged component panels, controls, and connectors. When damage is detected, remove the equipment from service until the damage is repaired. 2.2. Cleaning System Components Clean device components using a soft cloth, slightly moistened with water. -

Page 14: Product Overview

The size of the test current directly relates to the accuracy of the measurement. With Vertiv’s patented technology, the Cellcorder’s DC resistance test is not influenced by these factors. The Cellcorder reads single cells and multicell modules, and displays and records cell float voltage, internal cell resistance, and intercell connection resistance. -

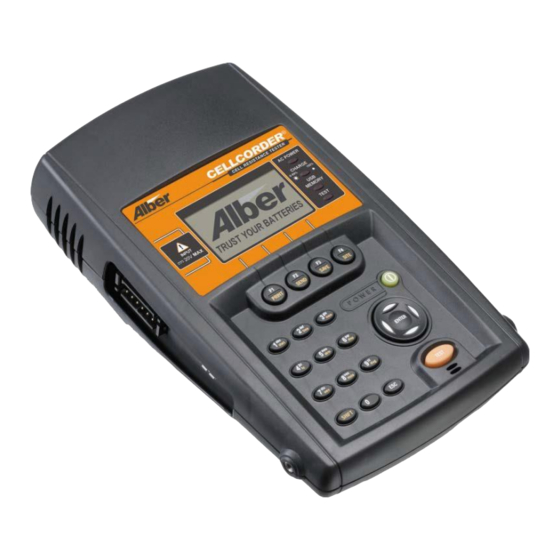

Page 15: Figure 1 - Serial Number Location And Label

The self–contained CRT–400 Cellcorder is comprised of a microprocessor, internal resistance test module, display, and rechargeable battery. Voltmeter probes part number 1100–222 and a three clip resistance set, part number 1100–221 are provided; optional test leads and accessories are available from Vertiv. Contact Vertiv at 954–377- 7101. Serial Number Location The label contains the model number, input information, serial number and the upcoming calibration date. -

Page 16: Figure 3 - Cellcorder Left Panel Connector/Test Lead And Usb

Product Overview Other Features Include Ventilation A temperature controlled cooling fan is installed. Figure 3 - Cellcorder Left Panel Connector/Test Lead and USB Test Lead Easy port for molded test cables and optimized battery clamps. USB connection Universal Serial Bus USB port for portable USB flash drive/data storage devices. May insert/remove with power on or off, the USB Memory amber LED lights up when the drive is accessed. - Page 17 Product Overview Internal Cell Resistance Using a patented process, the CRT–400 applies a momentary load and calculates internal cell resistance by determining instantaneous voltage drop and load current. Cells floating on–line or off–line can be measured. This method helps find weak, potentially failing cells when comparing internal cell resistance of all like cells in the string.

-

Page 18: Cellcorder Crt-400

Product Overview 3.4. Cellcorder CRT-400 Part Number Part Description Cellcorder battery tester. KIT–1000–056/ KIT–1000–056BT* *Bluetooth model 5V@4A Desktop Power supply charges Cellcorder power supply/ charger module for Cellcorder KIT- 4000–034 Resistance test lead assembly Resistance Test Lead Assembly Clamps clips Test cell and intercell resistance values. - Page 19 Printer with IrDA interface 2025–132L Note: When using the IrDA interface Thermal Printer port with a CRT printer, the printer must Paper be set up in “IRDA Physical layer” mode 2025–126 to communicate with an Vertiv CRT-400. 590-2099-501A/SL-29414/4200-070 3- 6 Revision 4...

- Page 20 Product Overview Part Number Part Description Bluetooth® Hands–free communication while Headset testing. 2025–036 The hydrometer measures the amount of sulfuric acid in the electrolyte to determine if the battery needs charging. DMA 35n A data logger module is included in the Portable Hydrometer Kit Density/Specific...

-

Page 21: Panel Controls And Indicators

Product Overview 3.5. Panel Controls and Indicators This section illustrates the CRTs controls,indicators,and connectors. Note: Prior to powering up your CRT-400, be sure to charge the lithium ion rechargeable battery. When the Battery Charge LED is off, it indicates a fully charged battery. AJI§r SHIFT =Start... -

Page 22: Figure 5 - Crt Front Panel Diagram Right

Product Overview Figure 5 - CRT Front Panel Diagram Right Top Panel Indicators AC Power LED - indicator is illuminated red when connected to AC power. Battery Charge LED - indicator is illuminated green when charger/power supply is connected and charging is in process. -

Page 23: Figure 6 - Top Panel Led Indicators

Product Overview USB LED - indicator is illuminated yellow when the USB flash drive is engaged. Important Note!: The Portable USB flash drive should not be connected to the CRT-400 when the power cord is plugged into the CRT-400. Test LED - indicator is illuminated red when testing is in progress. The LED Flashes to indicate a problem with the resistance test. - Page 24 Product Overview The keypad offers alphanumeric data entry and the following options. Button Display Description Displays the main menu. To start, press Main start LCD window Shift then 1 Sets the date format and time. To set date and time, press Shift Data and Time LCD window then 2 Clears stored data and saves readings to USB.

-

Page 25: Figure 8 - Trans-Reflective Lcd Display

Product Overview Button Display Description To mute beeper, Mute LCD window Sets the internal beeper to either on or off. press Shift then 8 To access Diag/diagnostics LCD window Accesses diagnostics, menu. diagnostics, press Shift then 9. Trans–reflective LCD The high contrast, 128 x 64 pixel backlit graphical display shows menus, warnings, and test results. The display makes it easy to navigate through the menus. - Page 26 Product Overview The F1, F2, F3 and F4 buttons select the functions that display on the LCD Display directly above. These buttons also have the following options. Note: Press Shift on the keypad, then release SHIFT, then press F1, F2, F3 and F4 to select the orange text on any key.

-

Page 27: Figure 10 - Back Panel/Telco/Reset Switch/Power

Product Overview Press Test and Enter key simultaneously to reset the CRT. If the keys on the CRT lock-up, pressing these buttons simultaneously will reset the unit. Bottom Panel Connectors/Accessory Compartment TELCO - A modular RJ-11 jack for communicating with a remote computer via telephone not supported at this time. -

Page 28: Specifications

Product Overview 3.6. Specifications Physical • Dimensions - 12"Height x 7"Width x 3"Diameter or metric 305mm Height x 178mm Width x 76mm Diameter • Weight - 3.4 pounds or metric 1.5Kg • Keypad - Rubber keys with polyurethane coating Display •... -

Page 29: Table 1 - Back Panel/Telco/Reset Switch/Power

Product Overview Input Test Current Resistance Voltage Intercell Range/ Resolution Resolution Resolution ±0.1% of reading ±0.1% of reading ±1% of reading ±5µΩ ±1mV 2mΩ±2µΩ 4V to 6V 25A to35A ±25µΩ ±3mV 3.3mΩ±5µΩ 8V to 30A to ±75µΩ ±6mV 5mΩ±10µΩ ±400µΩ ±10mV 20mΩ±20µΩ... -

Page 30: Before Using The Crt-400

Before Using The CRT-400 4. Before Using The CRT-400 4.1. Highly Recommended Reading Please read the following sections of this manual as well as the other manuals mentioned in this list: • The Safety, Legal Warranty and user sections of this manual •... - Page 31 Before Using The CRT-400 Before Charging, Disconnect Any Test Leads Before charging the battery, disconnect any test leads. Open the accessory compartment cover by loosening the two slotted screws. Connect the charger to the power connector inside the accessory compartment located on the back of the CRT, then plug in the charger. When charging is complete, the green LED will turn off.

-

Page 32: Test Lead Connection Practices

Before Using The CRT-400 • One Hour Remaining 4.3. Test Lead Connection Practices This section summarizes good test lead connection practices to help ensure the accuracy of readings. For actual test lead connection, refer to “Connecting Resistance Test Leads” section. Always be consistent in how test leads are connected once testing has started on a battery. -

Page 33: Figure 12 - Usb Device

Before Using The CRT-400 Computer System Requirements for USB Windows XP, 2000 Available USB port (USB 2.0 recommended) Important Note!: The Portable USB flash drive should not be connected to the CRT-400 when the power cord is plugged into the CRT-400. Accessing Stored Data on the USB Device From PC Insert the USB flash hard drive into the computer’s USB port on the PC. -

Page 34: Figure 14 - Safely Remove Hardware Window

Before Using The CRT-400 2. The Safely Remove Hardware window displays. Highlight the USB Mass Storage Device and click Stop. Figure 14 - Safely Remove Hardware Window 3. A confirmation window displays. Scroll down with the mouse and select the device to be removed and click OK. -

Page 35: Understanding Bluetooth

Before Using The CRT-400 CAUTION: Make sure the light on the USB is off before removing the USB device from the PC. Failure to follow the Safe Hardware Removal steps could result in lost data. Using the USB Device with the CRT Insert the USB flash hard drive into the CRT’s USB port to read or write data. -

Page 36: Getting Ready To Test Batteries With The Crt-400

Getting Ready to Test Batteries with the CRT-400 5. Getting Ready to Test Batteries with the CRT-400 5.1. Power To turn on the CRT-400, press the green Power button. To turn off, press and hold the green Power button until the message, Release power button appears on the LCD. The main menu window appears. 5.2. -

Page 37: Figure 17 - Crt-400 F1, F2, F3 And F4 Buttons

Getting Ready to Test Batteries with the CRT-400 Figure 17 - CRT-400 F1, F2, F3 and F4 buttons Test Mode/F1 Displays menus to measure voltage, determine resistance or add Specific Gravity SG and temperature readings. Note: Specific Gravity/Temperature are imported from a separate instrument. View Results/F2 Summarizes the Overall Voltage OV, cell voltage, cell resistance, and intercell resistance readings as averages, min/max lists, or threshold violations. -

Page 38: Navigation

Getting Ready to Test Batteries with the CRT-400 5.3. Navigation To scroll through LCD windows or lists, use the arrow keys. Figure 18 - CRT-400 Power and Arrow buttons To go back a LCD window, exit a function, or return to the main menu, press Back/F3, Cancel/F4 or ESC 5.4. -

Page 39: How To Edit Items Within The Site Template

Getting Ready to Test Batteries with the CRT-400 Figure 19 - CRT-400 with USB Flash Hard Drive 5.6. How to Edit Items within the Site Template This section is placed here to make it easy for beginners and first time users. Most alphanumeric keypad key types four characters: a number and three letters. -

Page 40: Figure 20 - Crt-400 Keypad Buttons

Getting Ready to Test Batteries with the CRT-400 To delete characters, highlight the character and press F1/Delete Char. Note: You cannot use the space key with file names. Using the keypad, type the location name at the blinking cursor. Figure 20 - CRT-400 Keypad Buttons Press F3/Load Data Functions Figure 21 - CRT-400 Load Data Functions 590-2099-501A/SL-29414/4200-070... - Page 41 Getting Ready to Test Batteries with the CRT-400 At the main menu, select Load Data/F3 to obtain this LCD window: Note: Using arrows allow access to the specifics of the site, such as LOCation, BATtery, etc. Press F1/SITE SETUP To load the site template When the USB flash hard drive has no sites stored, then the New Site LCD window appears.

-

Page 42: Table 3 - Crt-400 Keypad Buttons

Getting Ready to Test Batteries with the CRT-400 Press the down arrow to highlight the next information item, STG. • Press F1/Change • Press Save/F2 The following table lists all editable items and the keys to use arrows and the alphanumeric keypad. Note: Location, battery and string name are what is the minimum entry needed to begin testing. -

Page 43: Deselecting A Site

Getting Ready to Test Batteries with the CRT-400 5.7. Deselecting a Site Press Shift/F4 Site then Shift F3 Save. Figure 22 - Deselecting a Site When a site is selected and you want to take readings with no site selected, press Clear/F3 to clear. Confirm the change. -

Page 44: Figure 23 - Crt Set Up

Getting Ready to Test Batteries with the CRT-400 Figure 23 - CRT Set up CRT Setup/F4 Press F1/Battery Select Press F1 to access the Baseline Resistance Data File containing battery models that automatically set certain threshold parameters. Figure 24 - CRT Test Mode Reading USB Note: The USB flash hard drive must be inserted to accomplish this Battery Select function. - Page 45 Getting Ready to Test Batteries with the CRT-400 Selecting a Manufacturer To select a manufacturer, press F2/Accept. Selecting a Model Select a battery model and press F2/Accept. WARNING: Do not test any cells when the Cellcorder AC Power indicator is lit. Injury to personnel or damage to equipment could result.

-

Page 46: Taking Float Voltage Readings First

The maximum voltage the CRT can read is 20V. Do not attempt to read Overall Volts OV. The CRT calculates OV based on cell voltage readings. Note: Vertiv highly recommends that you take cell voltage measurements first to eliminate possible voltage skewing effects, then move on to cell/connection resistance. -

Page 47: F4/Done Voltage Testing

Taking Float Voltage Readings First • Press F1/Test Mode • Press F1 - Voltage The LCD displays the CELL ### and Volts and either Resume Testing or Stored in Memory. Note: The CRT ignores polarity in Voltage mode only, so that you may connect the leads either way. When the probes/test leads contact a cell, the CRT displays the voltage and beeps to indicate the reading is stored in temporary storage. -

Page 48: Resume Testing Explained

Taking Float Voltage Readings First Note: To display another cell number and/or retest a cell, type the number then press Enter, or use the arrows. To test again, press Retest/F3, place the probes onto the cell, and wait for the beep. Lift the leads; the next cell number appears. -

Page 49: Setting Up To Take Resistance Readings

Select the 3 clip resistance test leads pn 1100-221 and insert into the CRT, left side. Note: The standard jaws or test lead set may not provide the best connection to some cell posts. If you encounter poor post connection, contact Vertiv for a current list at 954–377-7101 or visit the website at www.vertivco.com. -

Page 50: Figure 30 - Crt-Test Mode/F1

Setting Up To Take Resistance Readings Figure 30 - CRT-Test Mode/F1 You have already set up a new site template to begin your first resistance test. • Press F1/Test Mode WARNING: Do not attempt to read internal resistance of an open cell/module while the battery is on-line. -

Page 51: Check/Set Amp Hours

Setting Up To Take Resistance Readings Based on cell voltage, the CRT determines the correct range, connects a fixed resistance across the cell and intercell under test, and briefly applies 60 Amps on 2V cells. Test current changes from 5 to 60 Amps depending upon cell/module voltage;... -

Page 52: Figure 31 - Quad Testing

Setting Up To Take Resistance Readings Triple Testing If you are testing batteries with six (6) terminals and they are connected in series or if three (3) positive terminals are connected together and the three (3) negatives are connected together. Please refer to Connections for Trip Post Cell –... -

Page 53: Taking Resistance Readings

Taking Resistance Readings 8. Taking Resistance Readings 8.1. Resistance Readings When taking a resistance reading, it is possible that the CRT is still on after you have completed the previous set up section. Figure 32 - CRT-Test Mode/F1 Turn on the CRT and select Test Mode/F1. The Test Mode menu displays. Press F2/Resistance Note: You have already set up Amp Hours, Intercell Type and Battery Voltage. -

Page 54: Connecting Resistance Test Leads

Connecting Resistance Test Leads 9. Connecting Resistance Test Leads When Ready to Test is flashing, depending on what type of intercell measurement is selected, connect the three clip resistance test leads to the cell and intercell under test. If using spike probes, refer to the manual that accompanied the spike probes. -

Page 55: Connection For Dual Post Cells - Example One

Connecting Resistance Test Leads Connection for Dual Post Cells – Example One 9.2. There are many types of dual intercell connection schemes. Here are two examples that are commonly used. No matter what type, being consistent in how the leads are attached is the most important aspect of testing and taking readings. -

Page 56: Connection For Dual Post Cells - Example Two

Connecting Resistance Test Leads Connection for Dual Post Cells – Example Two 9.3. Figure 35 - Connections for Dual Post Cells – Example Two Take Two Readings Two readings are required, and the CRT will prompt the user to move the leads after each reading. •... -

Page 57: Connections For Triple Post Cells

Connecting Resistance Test Leads 9.4. Connections for Triple Post Cells Take Three Readings Reading with the intercell leads connected from terminal posts A to D. Figure 36 - Connections For Trip Post Cells – One Readings with the intercell leads connected from terminal posts B to E. Figure 37 - Connections for Trip Post Cells –... -

Page 58: Performing A Resistance Test

Connecting Resistance Test Leads Figure 38 - Connections for Trip Post Cells – Three 9.5. Performing a Resistance Test Since float voltage readings exist, the Resistance LCD window flashes Ready to Test. Press the Orange Test button. The Resistance LCD window displays Vc(act) or Vc(mem). Vc(act) shows the actual cell voltage being read. -

Page 59: Moving Probes From Cell To Cell

Connecting Resistance Test Leads 9.6. Moving Probes from Cell to Cell After the cell or Ric1 intercell resistance appears, move the probes to the next cell or intercell and press the Orange Test button. The cell or intercell number advances when the leads are moved. If the cell requires two or more intercell Ric resistance readings, move the black/red and black leads to the next Ric connection, then press the Orange Test button for each Ric measurement. -

Page 60: When No Float Voltages Exist

Connecting Resistance Test Leads 9.7. When No Float Voltages Exist When no float voltage readings exist, a message appears; select Yes/F1 to switch to Voltage mode, insert the voltage leads, and select the cell number to read voltage. Resume resistance testing when finished. -

Page 61: Understanding Voltage Skewing Effect

Understanding Voltage Skewing Effect 10. Understanding Voltage Skewing Effect The Cellcorder has the ability to read and record voltages at the same time resistance readings are taken. However, when doing so, a small error in the actual float voltage, results. This derivation manifests into a skewing effect of the voltage readings. -

Page 62: Using The Crt-400 As A Digital Voltmeter

Using the CRT-400 as a Digital Voltmeter 11. Using the CRT-400 as a Digital Voltmeter Note: These readings cannot be saved and the unit does not beep once the voltage of a cell is checked. Figure 39 - CRT–Test Mode/F1 Make sure the CRT is powered on and the voltage test leads are connected. -

Page 63: The Hydrometer And The Data Logger

The Hydrometer and the Data Logger 12. The Hydrometer and the Data Logger The optional hydrometer reads Specific Gravity SG and Temperature. The data storage logger that holds data for up to eight strings A to H, 256 readings for each string, is a separate module that mounts on the hydrometer. -

Page 64: Setting Up The Crt For Hydrometer Usage

The Hydrometer and the Data Logger 12.1. Setting Up the CRT for Hydrometer Usage To Setup the CRT for Hydrometer Usage Press F4/CRT Setup or select CRT Setup by pressing F4. Before transferring specific gravity and temperature data to the CRT – the CRT must know the specific temperature units that the hydrometer is set to, either Fahrenheit °F or Celsius °C. - Page 65 The Hydrometer and the Data Logger Note: Both the CRT and Hydrometer must be set to Fahrenheit °F or both the CRT and Hydrometer must be set to Celsius °C. Press F2/TEMP Change to Fahrenheit °F or Celsius °C by depressing F3–C/F. The temperature will need to be entered for the High Threshold by using the arrow keys.

-

Page 66: Taking Readings With The Hydrometer

The Hydrometer and the Data Logger Or press F4/Back may be selected again to go back to the main menu. 12.2. Taking Readings with the Hydrometer Once both the CRT and Hydrometer settings are ‘synchronized’ use the hydrometer as instructed in its manual. - Page 67 The Hydrometer and the Data Logger Cell Data/F2 Highlight a .CDF file name by using the arrow keys and press Select/F1. A warning displays if data exists in the CRT’s memory. Press F3 to Continue or F1 to Cancel. If F3 is pressed to Continue, the CRT reads the USB and loads the cell information. The main menu appears once the file has been selected or if Cancel/F1 is pressed.

-

Page 68: Transferring Hydrometer Data To Computer

The Hydrometer and the Data Logger • Slow - If the LED is flashing slowly, the channel is selected but has no data. Figure 44 - Data Logger The CRT-400 calls the data logger a “Hydrometer Memory Module” in the LCD window. Align the data logger’s IR port with the IR port on the right side of the Cellcorder. -

Page 69: Setting Up The Crt

Setting Up the CRT 13. Setting Up the CRT Once you select CRT Setup by depressing F4, the setup options display in the figure below. Figure 45 - CRT–Main Menu with F Buttons for CRT Setup/F4 CRT Setup/F4: • F1–Bat. Select/ •... -

Page 70: Selecting A Battery

Setting Up the CRT 13.1. Selecting a Battery This section accesses the USB flash hard drive to open a file called Battlist.blf, a baseline resistance data file that contains a list of common battery information. If the file is not loaded on the USB device, then it will need to be placed on the USB device to help select battery data information. -

Page 71: Setting Thresholds

Setting Up the CRT 13.5. Setting Thresholds To set thresholds press F2. Note: Shift/5 also accesses Thresholds. Figure 47 - CRT– Setup/Thresholds or F4/F2 Voltage and resistance thresholds can be set or changed outside of site setup. The Cellcorder indicates an out of tolerance reading by beeping twice and displaying the reading in reverse video. -

Page 72: Setting Thresholds Without A Site File

Setting Up the CRT 13.6. Setting Thresholds without a Site File Select CRT Setup F4 then ThresholdsF2, then choose Voltage, Cell Resistance, Intercell Resistance, Specific Gravity or Temperature. F1–Voltage F2– Cell Res. F3– Intercell Res. F1–Spec. Gravity F2–Temperature A series of LCD windows appears for parameters that may be set. Press the Arrows to change values. Press F2/Accept to accept the value displayed. - Page 73 Setting Up the CRT F2–Cell Resistance High F2–Cell Resistance Low F3–Intercell Resistance Threshold High F1–Specific Gravity Threshold High F1– Specific Gravity Threshold Low F2– Temperature Threshold High F2–Temperature Threshold Low 590-2099-501A/SL-29414/4200-070 13- 5 Revision 4...

-

Page 74: Clearing Memory

Setting Up the CRT Temperature/Fahrenheit or Celsius On the Temperature LCD windows, before setting the high/low temperatures, select °Celsius or °Fahrenheit by selecting C/F–F3. Disabling A Threshold Setting any threshold value to zero (or 32°F / 0°C for temperature) disables the threshold. Use the arrows to enter threshold values. -

Page 75: Figure 48 - Crt Setup/Clear Memory Or F4/F3

Setting Up the CRT Figure 48 - CRT Setup/Clear Memory or F4/F3 Note: Also access Clear Memory. If you want to take readings on another battery, save the previous readings to the USB flash drive before clearing them from temporary storage. This function is used to save to the USB flash drive and/or clear temporary storage. -

Page 76: Displaying Additional Functions

Setting Up the CRT Note: Data will not clear until after you save it. Important: Powering off does not remove readings from temporary storage. To prolong battery life, the CRT–400 shuts down if inactive for ten minutes. At power up or power down, a message may appear: Readings are in temporary storage. -

Page 77: Sound Adjustment

Setting Up the CRT 13.9. Sound Adjustment Figure 50 - CRT Sound Adjustment Use Sound to turn the Cellcorder beeper off or on. 1. To adjust the sound, press F2 then Accept. 2. Use the up and down arrows to select off or on, and then press Accept. Note: Shift then 8 will also access sound. -

Page 78: Adjusting Date And Time

Setting Up the CRT 13.11. Adjusting Date and Time Figure 52 - CRT Time and Date Use Date to set the date, time, and date format. Use the up, down, left and right arrows to set the date and time, then press F2/Accept. To select date format (MM:DD:YY or other), press the corresponding F key. - Page 79 Setting Up the CRT The message “Checking for Bluetooth Option” is displayed. Please Wait appears. Initially, the message “No devices paired.” indicates no Bluetooth device is stored in memory. Select New/F1. Then F1-Headset. Note: Use the corresponding F key to select the desired device type. The message Configuring Bluetooth appears.

- Page 80 Setting Up the CRT The device Address and Name will display. Use the arrow keys to scroll to the desired device and press Select/F1 to connect to it. The LCD display flashes Connecting… Turn the wireless device on. Select Connect/F2. The connection is confirmed by the devices connection message.

- Page 81 Setting Up the CRT To connect, choose CRT Setup F4, use the down arrow to scroll to F3–Bluetooth and press F3. The message Checking for Bluetooth option appears. The last connected Bluetooth device will display. Decide if a new connection to a different device is needed or the established connection is desired.

- Page 82 Setting Up the CRT The last connected Bluetooth device will display. Turn the wireless device on. Select Connect/F2. The connection is confirmed by the devices connection message. The LCD displays the wireless connected symbol on the main menu. Deleting a Bluetooth Device That Is Not Connected Choose CRT Setup F4, use the down arrow to scroll to F3–...

- Page 83 Setting Up the CRT The last connected Bluetooth device(s) will display. Select DELETE/F3 and a warning message appears: “WARNING! Are you sure you want to delete Bluetooth device?” To delete, select Delete/ F1. The message No device paired appears. Select New if you would like to setup a new Bluetooth device, or press Cancel to go out of the Bluetooth setup function.

- Page 84 Setting Up the CRT The main menu will display and the square will be an x underneath the symbol. The device can now be deleted by following the instructions in “Deleting a Bluetooth device that is not connected”. Selecting a Different Bluetooth Device If a device name appears and you want a different device, press New and follow the instructions in “Discover and/or Choose A New Bluetooth Device”...

-

Page 85: Setting Up And Editing A Site Template

Setting Up and Editing a Site Template 14. Setting Up and Editing a Site Template Sites let you record details for locations remotely and use the same information for future testing. This section describes site LCD windows and setting up, linking, editing, and deleting sites. Note: To display the main menu from any LCD window, press and release Shift, then press 1. - Page 86 Setting Up and Editing a Site Template If the USB flash hard drive has no sites stored, then the New Site LCD window appears. If sites exist, press New to display New Site. To begin site setup for a new site location, make sure LOC is highlighted by using the arrow keys. Press Change/F1.

-

Page 87: Table 4 - Editing A Site Template

Setting Up and Editing a Site Template Item Description Edit Text Using Location name. 39 characters max. Left and right arrows and keypad Battery name. 18 characters max. Left and right arrows and keypad String name. 15 characters max. Left and right arrows and keypad Model number of battery. -

Page 88: Figure 54 - Crt Load Data Main Menu

Setting Up and Editing a Site Template Figure 54 - CRT Load Data Main Menu Site templates are useful because a field representative can set up a new location in the field when a pc and BAS software are not available. A site template can be set up before any testing is done with all the right thresholds etc. -

Page 89: Figure 55 - Crt Clear/F3/Deselect A Site

Setting Up and Editing a Site Template When sites have been stored previously, then Site 001 of ### appears, where ### is the number of sites on the USB flash hard drive. Available options are Select/F1, New/F2, More/F3, and Cancel/F4. Pressing More/F3 displays a new LCD window with options Change/F1, Delete/F2, and Back/F4. -

Page 90: Figure 56 - Crt Main Menu On Lcd/Load Data

Setting Up and Editing a Site Template To Edit an Existing Site Figure 56 - CRT Main Menu on LCD/Load Data To edit a site, at the main menu, select Load Data/F3 to obtain this LCD window. Press F1/Site Setup. Note: The USB flash hard drive must be inserted to accomplish this Load Data function. -

Page 91: Figure 57 - Crt Main Menu On Lcd/Load Data

Setting Up and Editing a Site Template Using the keypad or arrows, choose the item within the site that needs to be edited, Battery, String etc. Press F1/Change. Type the new data and press Save/Accept/F2. To edit another item, repeat the process. When editing is done, you may select the site by pressing Back/F4 then Select/F1. -

Page 92: Figure 58 - Crt Main Menu On Lcd/Load Data

Setting Up and Editing a Site Template To Link a File to a Site after Test Note: The USB flash hard drive must be inserted to accomplish this Load Data function. If the readings are only in the CRT’s temporary storage, first save them to the USB flash hard drive. Linking a .CDF file or an existing set of readings that are in the CRT’s memory to a site embeds Site Setup information. - Page 93 Setting Up and Editing a Site Template After the data loads into memory, the main menu appears. To confirm that the file is not already linked to a site, press Shift/F4 Site. The Active Site LCD window should be empty of data and nothing should display in location, battery or string names.

- Page 94 Setting Up and Editing a Site Template Using the keypad, type the file name at the blinking cursor and press Save/F2. To correct a mistyped entry, use the arrow keys to move to where the typo is located and type in the correct letter. Press F2/Save.

- Page 95 Setting Up and Editing a Site Template To select a different site, press Load/F2 from the Active Site LCD window to begin again. Note: To determine at any time what site is selected, press Shift/F4 Site. To Unlink a File and To Clear Thresholds If you want to have no site associated with a file that has been linked, press Shift/F4 Site to display the Active Site LCD window with location, battery, and string names of the site currently selected.

-

Page 96: Figure 59 - Crt Main Menu On Lcd/Load Data

Setting Up and Editing a Site Template To accept the changes on the Active Site LCD window, press Cancel/F4. Press Shift/F3 Save to save the file. To Delete a Site Figure 59 - CRT Main Menu on LCD/LOAD DATA To delete a site, at the main menu, select Load Data/F3 to obtain this LCD window and select F1. Note: The USB flash hard drive must be inserted to accomplish this Load Data function. - Page 97 Setting Up and Editing a Site Template The Delete Site At confirm LCD window appears At the confirm LCD window, press Yes/F1. The site is now deleted. If the deleted site was the currently selected site, press Shift/F4 to display the Active Site LCD window to load or clear.

-

Page 98: Working With Files

Working with Files 15. Working with Files 15.1. Saving Readings and Files to the USB Flash Hard Drive Insert the USB flash hard drive into the CRT and turn on. To save readings, press Shift then F3. Enter File Name, type a name, up to eight characters, no spaces. Or press Select Names/F3 to select an existing file name. -

Page 99: File Types Located On The Usb Flash Hard Drive

Working with Files Saving readings to the USB flash hard drive does not delete them from the CRT’s temporary storage. After saving cell readings to the USB flash hard drive, you may clear the CRT’s temporary storage and take readings on another battery. You may also use Microsoft Explorer to transfer files from the USB device to a computer. - Page 100 Working with Files .ADF File Accumulated Data File The .CDF Data File can be imported by the BAS program into an .ADF accumulated data file, or viewed separately using the CRT–400 Previewer program. The ADF file contains sets of readings that were imported from CDF files.

-

Page 101: Figure 60 - Www.vertivco.com/Baseline Resistance Data

Working with Files Figure 60 - www.vertivco.com/Baseline Resistance Data 1. Review the page to look at the information provided. Figure 61 - Snapshot Baseline Resistance Data 590-2099-501A/SL-29414/4200-070 15- 4 Revision 4... -

Page 102: Figure 62 - File Download Window

Working with Files 2. Or the file may be downloaded by selecting the letters BLF from the downloading a BLF file paragraph on the same page. 3. Once you have clicked on BLF, the File Download window displays, select Save to save the file. Figure 62 - File Download Window 4. -

Page 103: Figure 64 - My Computer Icon

Working with Files 5. Remove the USB device from the computer as follows, double–click the My Computer icon on the Windows desktop. Figure 64 - My Computer ICON 6. Right click the Removable Disk drive, in this case (E) and select Eject from the menu. Or double- click the safely remove device icon, that is located in the toolbar. -

Page 104: Figure 66 - Safely Remove Hardware Window

Working with Files Figure 66 - Safely Remove Hardware Window 8. A confirmation window displays. Scroll down with the mouse and select the device to be removed and click OK. Figure 67 - Confirmation to Stop Hardware Device 9. Once the message. Safe To Remove Hardware appears, then remove the USB flash hard drive. Figure 68 - Safe to Remove Hardware Device 590-2099-501A/SL-29414/4200-070 15- 7... -

Page 105: Figure 69 - Crt Main Menu On Lcd/Load Data

Working with Files CAUTION: Make sure the light on the USB is off before removing the USB device from the PC. Failure to follow the Safe Hardware Removal steps could result in lost data. 14.2 To Load an Existing File Figure 69 - CRT Main Menu on LCD/Load Data Select Cell Data/F2. -

Page 106: Appending To An Existing File

Working with Files 15.3. Appending to an Existing File New readings can be appended to an already existing data file. Once the file is loaded, press F1/Test Mode and select either test: • F1–Voltage/Volt • F2–Resistance/Res • F3–S.G./Temp./SG/Temp Press F1-Voltage/Volt If available, data for Cell 001 appears. - Page 107 Working with Files Press F2–Resistance/RES or Confirm battery voltage, amp hours and intercell connections. Note: To display a cell number, type a number and press Enter or use the arrows. Resume testing on cells with no data (not yet tested) or press Retest to test cells previously tested. To go back to Test Mode after selecting F2–...

-

Page 108: Storing Data For Multiple Strings

Working with Files 15.4. Storing Data for Multiple Strings To read and store data for a new battery, first save the previous battery data to the USB flash drive by pressing Shift/ F3. Now enter the file name and then clear the data from CRT’s temporary storage by pressing F1. The CRT asks for confirmation, press F1 for Yes. -

Page 109: Sending Readings Via Ir

Working with Files At the confirm LCD window, press Yes/F1. When Data File Deleted appears, press Continue/F3. The main menu will appear once the file has been deleted. 15.6. Sending Readings Via IR Data can also be sent via IR or Bluetooth using the BAS or Previewer programs. Refer to the Battery Analysis System (BAS) User's Guide or CRT–400 Previewer User's Guide for more about creating and importing into an .ADF file. -

Page 110: Figure 71 - Bas Software Program Select Cellcorder

Working with Files Figure 71 - BAS Software Program Select Cellcorder 3. Power on the CRT. Press and release Shift then press F2. At the next LCD window, press F1 for IR or F2 for Bluetooth. Or press F4 to Cancel. Wait for the message, “Ready for data transfer”... -

Page 111: Figure 72 - Bas/Crt Interface Window

Working with Files Figure 72 - BAS/CRT Interface Window Figure 73 - BAS/Battery Data Capture Open or Create New File Note: If an .ADF file is not open, select or create one. On the Cellcorder Battery Data Capture window, select: 1. -

Page 112: Sending Readings Via Bluetooth Wireless

Working with Files When done, the CRT Interface window displays Data transfer completed. Figure 75 - BAS/CRT Interface Data Transfer Completed 4. Click Close. Once, finished, select F3/Cancel twice to go back to the main menu on the CRT. In the BAS software’s main menu, select File then Save, type the file name in the box provided, and click Save to store the .ADF file under Programs/Alber/Alber Battery Analysis/Cellcorder ADF Files. -

Page 113: Figure 76 - Bas Software Program Select Cellcorder

Working with Files Figure 76 - BAS Software Program Select Cellcorder 2. Power on the CRT–400. Press Shift then press F2. Press F2/Bluetooth. Wait for the message, Ready for data transfer to display. 3. On the BAS Instructions for CRT window, click Continue. On the CRT Interface window, click Include Configuration within the Battery Data area, to include site configuration data. -

Page 114: Figure 78 - Bas/Battery Data Capture Open Or Create New File

Working with Files Figure 78 - BAS/Battery Data Capture Open or Create New File 4. On the Cellcorder Battery Data Capture window, select the following: • number of cells to download • starting cell number • read date 5. Then click OK. Figure 79 - BAS/Cellcorder Battery Data Capture The Cellcorder displays Sending data…... -

Page 115: Figure 80 - Bas/Crt Interface Data Transfer Completed

Working with Files Figure 80 - BAS/CRT Interface Data Transfer Completed 7. In the BAS software’s main menu, select File then Save, type the file name in the box provided. 8. Click Save to store the .ADF file under Programs/Alber/Alber Battery Analysis/Cellcorder ADF Files. - Page 116 Working with Files Cell Data Listed For Each Cell • VOLT shows the cell voltage • RES shows the cell resistance • Int R1 shows the Intercell resistance R1 • Int R2 shows the intercell resistance R2 • Int R3 shows the intercell resistance R3 •...

-

Page 117: Viewing Results

Viewing Results 16. Viewing Results 16.1. Viewing Status When data is in Cellcorder temporary storage, the Status LCD windows display the total number of cells with data, overall voltage (OV), averages, min– max values, and threshold violations (faults). View Results/F2– Status View Results/F2–Average Status/F1 View Results/F2–Min Max Status/F2 Note: To go back a LCD window, exit a function, or return to the main menu, press Back/F4, Cancel/F3... -

Page 118: Figure 81 - View Results/F2-Faults/F3

Viewing Results Press Avg/F1 to display the average cell voltage Vc, cell resistance Rc, and intercell resistance Ric. Press More/F1 to display more average Ric, specific gravity SG, and temperature values. Min–Max View Results/F2–Min Max Status/F2 for reference. Press Min– Max/F2 to display minimum and maximum values for Vc, Rc and Ric, and the associated cell numbers. - Page 119 Viewing Results • F1/S/G • F2/Temperature • F3/RIC/intercell resistance Select Fault Parameters–S/G–TEMP–RIC Voltage/resistance fault LCD windows indicate cell number and fault type: Voltage, Internal or Intercell. The reading at fault is highlighted. To retest a voltage or resistance reading that violates thresholds, press Retest/F3.

-

Page 120: Using Diagnostics

Note: When using the IrDA interface port with a CRT printer, the printer must be set up in “IRDA Physical layer” mode to communicate with an Vertiv CRT-400. IR Port by pressing 3, then select PC Interface or Printer Interface. - Page 121 Using Diagnostics USB Flash Hard Drive Press Shift release, then press 9. Press 1 to check if the USB port is working properly. USB Port Good To check the version, press F1/VER. If the message, USB port failed appears then try another USB flash hard drive.

-

Page 122: A/D Linearity

17.2. A/D Linearity Important: Use Only When Instructed By Vertiv Technical Support To display readings from analog to a digital converter, select A/D Linearity by pressing 3. Select Channel Voltage Channel Voltage Channel/press 1 and the LCD window displays the actual value of the test current. - Page 123 Using Diagnostics Protection Circuit • 1 Over Voltage • 2 Reverse Polarity. Both choices necessitate lead connection and further directions on the LCD window. Modem (If Installed Use the down arrow to view the next diagnostics options. Reset modem by pressing 1. ) Buzzer Tests the buzzer by selecting 2.

-

Page 124: Utilizing Crt-400 Service Menu

Note: To go back a LCD window, exit a function, or return to the main menu, press Back/F3, Cancel/F3 or ESC. 18.1. Entering the Password The factory set default password is 1234. If the password is unknown, contact Vertiv for a password based on the randomly generated four numbers following Service code. Password and Service Code Service Menu to Calibrate the CRT–400... - Page 125 Utilizing CRT-400 Service Menu Flash Version Factory Defaults Resetting to factory defaults resets the calibration constants, sets the password to 1234, resets threshold settings, resets the values of any site in temporary memory, and restores display settings. WARNING: The Cellcorder loses calibration when reset to factory default and must be recalibrated.

-

Page 126: Changing The Password

Utilizing CRT-400 Service Menu Factory Defaults 18.2. Changing the Password You may change the password to any four digit number. To display the password protected Service Menu and Calibration Menus, press Shift release, then press 7. Type in the password and press Enter. Use the default password 1234. -

Page 127: Error Codes

Utilizing CRT-400 Service Menu 18.3. Error Codes USB flash hard drive error messages display text such as USB drive is not installed Press ESC to continue or out of memory, or numeric error codes. Determine if the problem is the USB flash hard drive. Remove the troublesome flash drive and, if available, insert another device. -

Page 128: Upgrading Firmware

30% to 40% higher than the average or baseline value, then capacity test those cells using a single cell tester, such as the Vertiv SCT. If most cells are above the normal expected readings, then capacity test the entire string. - Page 129 File transfer in progress appears and the frame number counts down. When the upgrade is successful. System is running Version nn.nnnnn appears, press Continue/F3. To Upgrade Firmware Using the IR Port W/BAS and PC Download the .UPG file from the Vertiv Web site, www.vertivco.com or an Vertiv CD to Program Files/Alber/Alber Battery Analysis, then use Windows Explorer to copy the file to the USB flash hard drive.

-

Page 130: Figure 82 - Communications Settings Com Port Bas Software

Utilizing CRT-400 Service Menu Note: The Frame: #### does not count down at this time. Start the BAS program. Check or choose the COM port that enables the IR interface. Select from the BAS software toolbar. To change the port click on the down arrow to select a highlight and select a port, then click OK. Figure 82 - Communications Settings Com Port BAS Software Then click the Start the Cellcorder Interface button. -

Page 131: Figure 84 - Bas/Crt Interface

Utilizing CRT-400 Service Menu Figure 84 - BAS/CRT Interface On the BAS CRT Interface window, click Load Update under Firmware Update. Select the .UPG file, then click Open. File transfer in progress begins to count down on the CRT. Note: The Frame: #### counts down at this time. When the upgrade is successful and the system is running Version nn.nnnnn appears, press Continue/F3. -

Page 132: Figure 85 - Bas/Crt Interface Window

Utilizing CRT-400 Service Menu Figure 85 - BAS/CRT Interface Window 590-2099-501A/SL-29414/4200-070 18- 9 Revision 4... -

Page 133: Application Note Cc-001

Application Note CC–001 19. Application Note CC–001 The Internal Resistance and Cellcorder document is available on Vertiv’s Web site at: http://www.vertivco.com/ Figure 86 - Valve Regulated and Vented Cells Introduction With the changeover from “vented” cells to “sealed,” VRLA cells, and the proliferation of UPS systems, an even greater impetus has been placed in finding economical and reliable ways to establish the state of a battery’s capacity and its conduction path. -

Page 134: Figure 87 - Classical Cell Model

The Nature Of Internal Resistance At Vertiv, we have centered our efforts on cell internal resistance. A refined cell model has been developed which subdivides the internal resistances of a cell, into its metallic and electrochemical components. -

Page 135: Figure 88 - Internal Resistance Model

Application Note CC–001 Figure 88 - Internal Resistance Model Another group focusing on internal resistance is prestigious Nippon Telephone and Telegraph. Their research and field personnel have shown that a major result of the lead acid battery deterioration mechanism is an increased internal resistance. A 500 microsecond duration pulse technique is used to measure cell internal resistance. -

Page 136: Figure 89 - Capacity And Internal Resistance Ratio

Application Note CC–001 Figure 89 - Capacity and Internal Resistance Ratio Part of this belief that a straight line cannot describe a capacity relationship is rooted in the differences exhibited during battery discharges from cells with metallic vs. electrochemical resistance problems. The typical discharge curve of a cell at 100% capacity. -

Page 137: Figure 91 - Typical Discharge Curve With Metallic Resistance Problem

Application Note CC–001 A battery's capacity is adversely affected by an increased internal resistance. Obviously, the power is dissipated internally, I2 x RINTERNAL, and is not available where it is really needed… at the load. Thus, actual capacity is diminished. However, during discharge this reduction in capacity appears differently depending upon whether the resistance change is primarily metallic or electrochemical in nature. -

Page 138: Figure 92 - Typical Discharge Curve With A Cell With An Electrochemical Resistance Problem

Application Note CC–001 Figure 92 - Typical Discharge Curve with a Cell with an Electrochemical Resistance Problem Battery Aging and Internal Resistance Internal resistance provides a clue to aging. The aging process of a battery’s cells is based upon the rates at which their materials and construction deteriorate under design conditions. -

Page 139: Figure 93 - Normalized Internal Resistance Vs. Temperature

Application Note CC–001 Figure 93 - Normalized Internal Resistance Vs. Temperature In temperate climates, VRLA cells in unconditioned temperature environments may show considerable internal resistance variation between quarterly measurements. Recording of the ambient temperatures at the time of measurement will save you further testing and false alarms. Similarly, cells chilled by air conditioning exhibit higher readings than their sheltered neighbors. -

Page 140: Figure 94 - Measuring Internal Resistance

Vertiv Research Carefully conducted Vertiv experiments have revealed other important properties of cell internal resistance. One is the relationship between metallic resistance and electrochemical resistance. Many would expect that as the energy stored in a fully charged cell diminishes, the internal resistance of the cell would increase both proportionately and significantly. - Page 141 Application Note CC–001 Measured amounts of energy were methodically removed and each time the internal resistance was read. It was found that the internal resistance rose no more than 3% after removal of 32% of the cell’s energy. Upon continued discharge, the internal resistance increased rapidly in a non–linear fashion. Since it is extremely unlikely that the cells’...

- Page 142 Application Note CC–001 Surprisingly, the IEEE/ANSI VRLA P–1188 proposed standard is more liberal in this matter. It recommends that from 25% to about 43%, the cell’s manufacturer be contacted. Above 43%, a load test be done ASAP. Actually, the standard is expressed in the reciprocal of internal resistance, conductance (mhos.) Data Anomalies Another part of the battery literates’...

- Page 143 Application Note CC–001 Whether you use numbers or characters, the important thing is to make the filename as recognizable as possible while avoiding duplicate filenames. This helps immensely in finding files and to avoid overwriting, deleting or copying wrong files, especially when using operating systems before version MSDOS 6.

- Page 144 Battery Conference and Exhibition, Solihull, UK 8. Johnson Controls, “Impedance and Conductance Testing,” Application Note Form 41–7271, Aug. 1994, Milwaukee, WI and Vertiv in–house data. 9. G. Alber, "Are Internal Cell Parameter Measurements a Substitute or Supplement to Capacity Testing?" Sep. 1994, NE Utilities Battery Conference, Albany, N.Y.

-

Page 145: Application Note Cc-002-A

Single Interconnections The following figure shows how the Vertiv Cellcorder should ideally be connected to obtain the proper measurement. Note that, ideally, the reading includes both the intercell connector resistance and the post to intercell connection resistance. -

Page 146: Figure 95 - Single Interconnections

Application Note CC–002–A Figure 95 - Single Interconnections The next figure (Fig 2A) below shows the connection for VRLA cells, such as the ABSOLYTE II batteries, where the terminal post is accessible. Figure (Fig 2B) below shows the connection for VRLA cells where the terminal post is not accessible. -

Page 147: Figure 97 - (Figure 3A And 3B) Connections For Dual Posts

Application Note CC–002–A Note: Do not connect to the stainless steel bolt heads to make this measurement. Dual Interconnections Figures (3A) and (3B) below, show the typical intercell connections for dual post cells. This type of interconnection requires that two readings be taken. The first one shown should be with the intercell leads connected from Terminal Post A to Terminal Post C. -

Page 148: Figure 98 - (Figure 4) Connections For Triple Posts

Application Note CC–002–A Figure 98 - (Figure 4) Connections for Triple Posts. For VRLA cells or flooded cells configured as shown in the figure below, four readings are made, forming two “X’s.” Terminal Posts A to E then B to D, and B to F then C to E. Figure 99 - (Fig 5) Connections for Triple Posts. -

Page 149: Cellcorder Connection Options

Cellcorder Connection Options 21. Cellcorder Connection Options For further information on which Cellcorder leads are best suited to your individual requirements, contact your local VERTIV representative or VERTIV directly at: www.vertivco.com Phone (954) 377- 7101Fax (954) 377-7042. 1101•001 l'so..JIItdk 5"41'1'Mt><... -

Page 150: Cellcorder Jaw Options

Cellcorder Jaw Options 22. Cellcorder Jaw Options Figure 101 - CRT–400 Cellcorder Jaw Options 590-2099-501A/SL-29414/4200-070 Revision 4... -

Page 151: Index

Index 23. Index .ADF File 15-3 CRT-400 .BLF Baseline Resistance File 15-3 Communication 3-15 CRT-400 .CSV File Comma Separated Value File 15-3 A/D Linearity 17-3 Battery 3-15 AC Power 3-14 CRT-400 AC Power LED 3-9 Main Menu Functions 5-1 Auto Ranging 3-3 Damaged Equipment 1-2 Data Analysis, Storage and Transfer 3-4 BAS Software 3-1... - Page 152 Index Single Interconnections 20-1 Load Module 17-2 Measurement Capabilities 3-3 Single Testing 7-3 Metallic Resistance 19-5 Sound Adjustment 13-9 Modem (If Installed) 17-4 Specific Gravity Threshold 13-6 Specific Gravity Thresholds 12-3 Momentary Test Discharge 19-8 Stop a Resistance Test 9-6 Moving Probes 9-6 Nature Of Internal Resistance 19-2 Storage 2-1...

Need help?

Do you have a question about the Alber Cellcorder CRT-400 and is the answer not in the manual?

Questions and answers

Is there a certain size flash drive that is compatable with the CTR400

A 256MB USB flash drive is compatible with the Vertiv Cellcorder CRT-400.

This answer is automatically generated