Siemens Sitrans LR250 Instruction Manual

Hart

Hide thumbs

Also See for Sitrans LR250:

- Operating instructions manual (306 pages) ,

- Quick start manual (272 pages) ,

- Instruction manual (175 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Instruction Manual

Advertisement

Table of Contents

Summary of Contents for Siemens Sitrans LR250

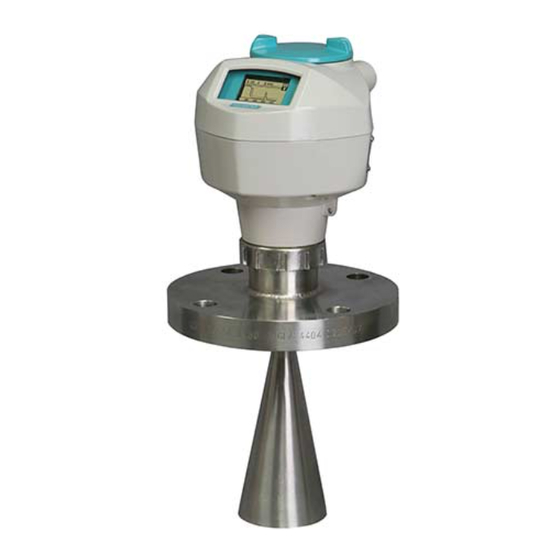

- Page 1 Instruction Manual July 2007 sitrans LR250 (HART)

- Page 2 DELLSONICS 北京迪妙声科技有限公司 BEJING DELLSONICS SCIENCE & TECHNOLOGY LTD. 公 司 简 介 北京迪妙声科技有限公司(原名北京妙声力科技有限公司) ,位于北京市海淀区中关村 南大街,是与西门子公司德国总部正式签约的西门子过程仪表及分析仪器核心合作伙伴, 也是西门子北方区域规模最大、实力最强的优秀代理商。 公司主营: 一、 西门子-妙声力(Milltronics)系列物位产品:超声波物位计、超声波液位差计、超声波泥水界 面计、超声波明渠流量计、雷达物位计、射频导纳物位计、射频导纳油水界面计、 ;射频导纳物位开关、 音叉式物位开关、阻旋式物位开关;皮带称、固体质量流量计、冲板流量计等。 二、 西门子过程仪表产品:电磁流量计、质量流量计、超声波流量计、 温度变送器、压力变送器、 阀门定位器、气体分析仪等。 三、 德国 UWT 公司的阻旋式料位开关、音叉式料位开关、重锤式料位计等产品。 四、 自行研发生产超声波液位计、温度变送器、压力变送器、数显表及油田专用仪器等产品。 成立于 1954 年的西门子-妙声力公司 是世界公认的超声波物位测量领域 (Milltronics) 的领导者, 全球最大的超声波物位仪表生产厂家, 在超声波、 雷达、 电容技术领域拥有超过 60 项专利,超声波产品的综合性能指标经美国《控制》杂志评比,其综合性能名列全球第一!...

-

Page 3: Table Of Contents

Table of Contents Table of Contents .......................i Safety Notes ............................1 Safety marking symbols ......................1 FCC Conformity ............................1 The Manual ............................2 Technical Support ..........................2 SITRANS LR250 Overview ....................4 Specifications ........................5 Power............................. 5 Performance..........................5 Interface ............................6 Mechanical........................... 6 Environmental ..........................7 Process............................ - Page 4 Operating via SIMATIC PDM ..................37 Functions in SIMATIC PDM ......................37 Device Description (DD) ......................37 Configuring a new device .......................38 Quick Start Wizard via SIMATIC PDM ..................38 Using Linearization via the Quick Start wizard ..............42 Configuring a stillpipe application ..................45 Calibrating LR250 via PDM ......................45 Changing parameter settings using SIMATIC PDM ............46 Parameters accessed via pull-down menus ..............46 Parameter Reference .....................53...

- Page 5 Process Pressure/Temperature derating curves ..............110 Horn Antenna or Wave Guide ....................111 Loop power ............................114 Typical Connection Drawing ....................114 Allowable operating area of SITRANS LR250 ..............114 Startup Behavior ........................115 Appendix E: Application Examples ................116 Liquid resin in storage vessel, level measurement ............116 Horizontal vessel with volume measurement ..............118...

-

Page 6: Safety Notes

FCC Conformity US Installations only: Federal Communications Commission (FCC) rules WARNING: Changes or modifications not expressly approved by Siemens Milltronics could void the user’s authority to operate the equipment. Notes: • This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. - Page 7 µF microFarad µs microsecond Pressure Equipment Directive safety approval pico Farads parts per million Primary Variable measured value Secondary Variable equivalent value sensitivity Time Varying Threshold threshold Input voltage Output voltage 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 3...

-

Page 8: Sitrans Lr250 Overview

500,000 applications worldwide (ultrasonic and radar). Programming SITRANS LR250 is very easy to install and configure via a graphical local user interface (LUI). You can modify the built in parameters either locally via the Siemens infrared hand- held programmer, or from a remote location via SIMATIC PDM. -

Page 9: Specifications

Specifications Siemens Milltronics makes every attempt to ensure the accuracy of these Note: specifications but reserves the right to change them at any time. Power Nominal 24 V DC with Loop For other configurations, see the chart under max. 550 Ohm loop resis-... -

Page 10: Interface

316 L stainless steel, optional Alloy N06022/2.4602 (C-22) HART® is a registered trademark of HART Communication Foundation. Display quality will be degraded in temperatures below –25 °C (–13 °F) and above +65 °C (+149 °F). Page 6 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 11: Environmental

• pollution degree Notes: Approvals • Check on page 8, for the specific configuration you are about to use or install. • Use appropriate conduit seals to maintain IP or NEMA rating. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 7... -

Page 12: Process

110. FM/CSA Intrinsically Safe connection drawing (North America only) on page 25 for drawing number 23650653. FM/CSA Non-incendive connection drawing (North America only) on page 26 for drawing number 23650673. Page 8 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 13: Flat Face Flange

Flat Face Flange Identification Assembly Identification Flange Series Heat Heat Flange Serial No. Logo Material Code Nominal Code Series Series Size 316L/ 1.4404 MMDDYYXXX 25556 A1B2C3 A1B2C3 25546 DN 80 PN 16 316L/ 1.4435 Page 12 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 14 Serial number: a unique number allotted to each flange, including the date of manufacture (MMDDYY) followed by a number from 001 to 999. Flange series: the Siemens Milltronics drawing identification. Nominal size: the flange size followed by the hole pattern for a particular flange class.

- Page 15 Logo Serial Number Thread Size Thread Series MMDDYYXXX G/PF Serial number:a unique number allotted to each flange, including the date of manufacture (MMDDYY) followed by a number from 001 to 999. Page 14 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

-

Page 16: Installation

• Installation shall only be performed by qualified personnel and in accordance with local governing regulations. • SITRANS LR250 is to be used only in the manner outlined in this manual, otherwise protection provided by the device may be impaired. -

Page 17: Mounting Location

3" horn = 10° 19° 4" horn = 8° streams. • Make allowance for beam width to avoid interference with emission cone • Avoid central locations on tall, narrow vessels. preferred undesirable Page 16 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 18: Orientation In A Vessel With Obstructions

Mounting toward the obstructions (see polarization reference on a Stillpipe or Bypass Pipe on page 18 point for an illustration.) display 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 17... -

Page 19: Mounting On A Stillpipe Or Bypass Pipe

Stillpipe or Bypass Pipe requirements An installation drawing number 23650689 is available on the product page of our website. Go to: www.siemens.com/LR250 and click on Downloads. • The pipe diameter must be matched with the horn size. Use the largest horn size... -

Page 20: Installation Instructions

Simply screw the device into the process connection, and hand tighten, or use a wrench. A torque of 40 N m (30 ft.lbs) is recommended Flanged Version Flanged Horn Flat Face Flange on page 11 and on page 12 for dimensions. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 19... -

Page 21: Wiring

Unscrew the cover for access to the terminals. Use a screwdriver for added leverage, if necessary. plug cable gland (or NPT cable entry) Depending on the approval rating, glands and plugs may be supplied with your instrument. Page 20 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 22 Depending on the system design, the power supply may be separate from the PLC, or integral to it. Loop resistance (total of cable resistance plus 250 Ohm [resistor]) must be less than 550 Ohm for the device to function properly. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 21...

- Page 23 Loop Voltage versus Loop Resistance shaded area of the graph on page 114. Active barriers (repeating barriers) Manufacturer Part Number 7206 Stahl 9001/51-280-110-14 Pepperl+Fuchs KSD2-CI-S-Ex Pepperl+Fuchs KFD2-STC3-Ex1 E02009 - verify E02010 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 23...

-

Page 24: Intrinsically Safe Wiring

FM/CSA Intrinsically Safe connection drawing (North America only) NON-HAZARDOUS AREA HAZARDOUS AREA SAFE AREA APPARATUS NOTES: INTRINSICALLY SAFE Load 1. ANY CSA / FM INTRINSICALLY SAFE BARRIER / POWER SUPPLY, WITH ITS OUTPUT (SEE NOTE 1) 4 – 20 mA VOLTAGE (Uo) NOT EXCEEDING 30 V AND ITS OUTPUT CURRENT (Io) LIMITED BY LOAD RESISTANCE (Ro);... - Page 25 NON-HAZARDOUS LOCATION HAZARDOUS LOCATION (SAFE) CLASS I, DIV.2, GROUPS A, B, C, D METAL CONDUIT 1/2 “ NPT SITRANS LR 250 24 V POWER SUPPLY NOTES: Previously numbered 23650637 02/2005 Product Group RADAR 02 / NOV / 2005 R. CLYSDALE SITRANS LR 250 T.

-

Page 26: Instructions Specific To Hazardous Area Installations

- Aggressive substances: for example, acidic liquids or gases that may attack metals, or solvents that may affect polymeric materials. - Suitable precautions: for example, establishing from the material’s data sheet that it is resistant to specific chemicals. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 27... -

Page 27: Quick Start Via Local Operation

Quick Start via local operation SITRANS LR250 carries out its level measurement tasks according to settings made via parameters. The settings can be modified locally via the Local User Interface (LUI) which consists of an LCD display and a handheld programmer. - Page 28 FAR RANGE band • A deeper band indicates fewer items. • A band halfway down the menu bar indicates the current item is halfway down the list. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 29...

-

Page 29: Handheld Programmer (Part No. 7Ml1930-1Bk)

Right ARROW opens PROGRAM Opens the top level menu. mode. Up or Down ARROW toggles between LCD displays measured value in either linear units or linear units and percent. percent. Page 30 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML1998JE01... -

Page 30: Programming Sitrans Lr250

• Initial Quick Start parameter values are not default values and do not necessarily reflect the current device configuration. • SITRANS LR250 automatically returns to Measurement mode after a period of inactivity in PROGRAM mode (between 15 seconds and 10 minutes, depending on the menu level). - Page 31 The current value is highlighted. LOW CALIB... 2.2.1.6 Key in a new value. 20.000 +20.000 Press Right ARROW to accept it. The LCD returns to parameter view and displays the new selection. Page 32 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML1998JE01...

- Page 32 Right ARROW to update the profile. exit icon, selected Press Down ARROW to select the Exit icon, then Right ARROW to return to previous menu. transmit icon, exit icon, selected deselected 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 33...

-

Page 33: Quick Start Wizard Via The Handheld Programmer

Slower settings provide higher accuracy; faster settings allow for more level fluctuation 1.3. Sensor Units Select the units for the Quick Start variables (high and low calibration point, and level, distance, or space) M, CM, MM, FT, IN Options Page 34 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML1998JE01... - Page 34 YES, NO Options Display shows DONE when Quick Start is successfully completed. Press Mode to return to Measurement mode. SITRANS LR250 is now ready to operate. Dimensions The point from which High and Low Calibration points are referenced: see Flanged Horn on page 10 and on page 11.

-

Page 35: Level Application Example

Save new settings. Auto False Echo Suppression If SITRANS LR250 displays a false high level, or the reading is fluctuating between the correct level and a false high level, you can use the Auto False Echo Suppression 2.2.5. TVT (Auto False Echo Suppression) parameters to prevent false echo detection. - Page 36 Note: The layout of the dialog boxes shown may vary according to the resolution setting for your computer monitor. Click on NEXT to accept the default values. (Description, Message, and Installation Date fields can be left blank.) 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 39...

- Page 37 Linearization via the Quick Start wizard on page 42. Select the vessel shape, and click on NEXT. Application with Stillpipe on page 120 for a Low Dielectric Liquid application. Page 40 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 38 Check parameter settings, and click on BACK to return and revise values, or TRANSFER to transfer values to the device. The message Quick Setup was successful will appear. Click on OK, then click on OK again to synchronize with the device. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 41...

-

Page 39: Using Linearization Via The Quick Start Wizard

In Step 2 – Application Type, select a volume application, for example Volume in a vessel, and press Next. In Step 3 – Vessel Shape, choose the vessel shape option Linearization Table and click on Linearization. linearization Page 42 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 40 Enter the desired level and volume values, and click on OK. Reset resets values to the values in the offline table. Note: c. In the Step 3 window, click on NEXT. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 43...

- Page 41 In Step 5 – Summary, check parameter values. Click on BACK to return and revise values, or TRANSFER to transfer values to the device. The message Quick Setup was successful will appear. Click on OK, then click on OK again to synchronize with the device. Page 44 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

-

Page 42: Configuring A Stillpipe Application

Continue through steps 3 to 5 then click on Transfer to download settings to the device. Calibrating LR250 via PDM Quick Start Wizard via SIMATIC PDM • on page 38 for configuration instructions for a simple application. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 45... -

Page 43: Changing Parameter Settings Using Simatic Pdm

• Clicking on Cancel during an upload from device to SIMATIC PDM will result in some parameters being updated. Launch SIMATIC PDM, connect to SITRANS LR250, and upload data from the device. Adjust parameter values in the parameter value field then press Enter. The status fields read Changed. - Page 44 • You can save a profile or delete a saved profile. • After saving a profile open menu View – Show echo profile. save delete 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 47...

- Page 45 SITRANS LR 250 first learns the echo profile. Then the learned profile, or part of it, is used to Auto False Echo Suppression screen out false echoes. (See on page 105 for a more detailed explanation.) Page 48 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 46 When buttons are visible, click on Close. Auto TVT is now on, and the learned TVT curve will be used. To turn Auto False Echo Suppression off or on, reopen menu Device – Auto False Echo Suppression and click on Off or On. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 49...

- Page 47 Change the position of the cursor on the TVT curve using the Point+ and Point– buttons: raise and lower the curve using Offset+ and Offset–. • Alternatively, enter values for Point and Offset directly into the dialog boxes. • Press Transfer to Device. Page 50 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 48 Set Address The default address for the device is 0. To reset the address via the handheld programmer see 5. 1 .Device Address on page 86. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 51...

-

Page 49: Parameter Reference

Do not use the Quick Start wizard to modify individual parameters. • Because the settings are inter-related, the initial Quick Start parameter values are not default values. • The initial Quick Start values do not necessarily reflect the current device configuration. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 53... -

Page 50: Quick Start

Select the units for the Quick Start variables (high and low calibration point, and level, distance, or space). M, CM, MM, FT, IN Options 1.4. Operation SITRANS LR250 stops updating measurements and NO SERVICE associated loop current. Last valid measurement value is displayed. Distance to material surface referenced from Low LEVEL Calibration Point (process empty level). -

Page 51: Setup

2.1.1. Software Revision Corresponds to the software or firmware that is embedded in the SITRANS LR250. 2.1.2. Loader Revision Corresponds to the software used to update the SITRANS LR250. 2.1.3. Hardware Revision Corresponds to the electronics hardware of the SITRANS LR250. 7ML19985JE01 SITRANS LR250 (HART) –... -

Page 52: Input

* LIQUID Options LIQUID LOW DK (low dielectric liquid) 2.2.1.13. Propagation Factor Related 2.2.4.1.2. Position parameters 2.2.4.4.3. CLEF Range You can configure each of the related parameters, to suit your particular application. Page 56 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 53 The point from which level measurement is referenced. For the reference point see for Dimensions Flanged Horn each configuration, see on page 10 and on page 11. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 57...

- Page 54 The point from which level measurement is referenced. See on page 10 Flanged Horn on page 11. The value produced by the echo processing which represents the distance from sen- sor reference point to the target. Page 58 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 55 2.2.1.19. Sensor Offset A constant offset that can be added to Sensor value to compensate if the sensor has been changed. Units are defined in Sensor Units. Default: 0 m Values 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 59...

- Page 56 Upright, linear (flat volume bottom) CONE/ maximum Conical or pyramidal volume, bottom dimension A maximum PARABOLIC BOT/ volume, Parabolic bottom dimension A maximum HALF SPHERE/ volume, Half-sphere bottom dimension A Page 60 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 57 -sloped. If the vessel is horizontal with parabolic ends, the depth of the end. See 2.2.2.1. Vessel Shape for an illustration. Range: 0.0000 to 99999 mm Values Default: 0.0 Vessel Shape Related Parameters 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 61...

- Page 58 Level values are defined in sensor units. Volume units are defined by the user but are not explicitly stated in the SITRANS LR250. Range: 0.0000 to 99999 mm Level Values Default: 0.0...

- Page 59 2.2.4.1. Echo select 2.2.4.1.1. Algorithm Selects the algorithm to be applied to the echo profile to extract the true echo. true First echo Largest echo Options Best of Largest or First echo 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 63...

- Page 60 When Echo Confidence exceeds the Echo Threshold, the echo is evaluated. Range: 0 to 99 Values Default: 5 Related 2.4.1. Fail-safe Timer Parameters Use this feature when an incorrect material level is reported. Page 64 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 61 2.2.4.2.1. Echo Lock Ensure the agitator is always running while SITRANS LR250 is Note: monitoring the vessel, to avoid stationary blade detection.

- Page 62 Default: 0.0 m Related 2.2.4.1.2.Position parameters 2.2.4.1.2. Position We recommend setting to Hybrid Algorithm and setting CLEF Range to 0.5 m (1.64 ft). Echo Lock on page 104 for more detail. Page 66 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 63 When SITRANS LR250 is located in the center of the vessel, the TVT hover level may be lowered to increase the confidence level of the largest echo.

- Page 64 Range: 0.00 to 20.00 m Values Default: 1.00 m Press RIGHT ARROW to open Edit mode. Enter the new value and press RIGHT ARROW to accept it. 2.2.5.6. Auto False Echo Suppression Page 68 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 65 Adjusts the TVT curve at a specified range. Options 2.2.6. TVT shaper A breakpoint on the TVT curve, normalized to 0. 2.2.6.1. Shaper 1-9 Range: –50 to 50 dB Values Default: 0 dB 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 69...

- Page 66 10 m/min. mat. agitator Use a setting just faster than the maximum filling or emptying rate (whichever is faster). Slower settings provide higher accuracy; faster settings allow for more level fluctuation. Page 70 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 67 2.2.7.2. Fill Rate Defines the maximum rate at which the reported sensor value is allowed to increase. Allows you to adjust the SITRANS LR250 response to increases in the actual material level. Fill Rate is automatically updated whenever Response Rate is altered.

-

Page 68: Output

Values Range: 3.6 mA to 22.6 mA 2.3.1.2. mA Output Function Alters the mA output/measurement function and allows the output to be set independently. Manual * Level Space Options Distance Volume Page 72 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 69 Output Function Parameters Enter the reading that is to correspond to a 4 mA output. Units are defined in Sensor units for Level, Space, or Distance. Units are unspecified for Volume. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 73...

- Page 70 4. Enter this value in 4 mA Output Trim. 5. Restore mA Output Function to previous setting. 6. Confirm that the mA output is as expected. Page 74 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

-

Page 71: Fail-Safe

Defines a user-defined level to report when the Fail-safe timer expires. Range: 3.6 mA to 22.6 mA Values Default: 22.6 mA Fail-safe Material Level must be set to VALUE to use this value. Note: 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 75... -

Page 72: Diagnostics

3.14.2. Maximum Internal Temperature Read Only. Displays (in degrees C) the maximum temperature recorded by the internal electronics. The high and low values are maintained over a power cycle. Page 76 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 73: Remaining Device Lifetime

In SIMATIC PDM, open the menu Device – Maintenance, click on Remaining Device Lifetime. 3. 1 5.5. Maintenance Alert Activation a) Enable b) Modify limit values as required. Click Write to accept the changes. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 77... - Page 74 Read only. Displays the status of the Maintenance Alerts. Maintenance Required Alert active Options Maintenance Demanded Alert Active (view only) Open the menu View – Display Status, click on the Maintenance tab and check the Device Lifetime Status window. Page 78 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

-

Page 75: Remaining Sensor Lifetime

To modify the value via PDM, open the menu Device – Maintenance and click on Remaining Device Lifetime. 3. 1 6.5. Maintenance Alert Activation a) Enable b) Modify limit values as required. Click Write to accept the changes. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 79... - Page 76 Read only. Displays the status of the Maintenance Alerts Maintenance Required Alert active Options Maintenance Demanded Alert Active (view only) Open the menu View – Display Status, click on the Maintenance tab and check the Sensor Lifetime Status window. Page 80 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

-

Page 77: Service

To perform a reset to factory defaults via SIMATIC PDM, open the menu Device – Device Reset and click on Factory Defaults. 4.2. Manufacture Date The date of manufacture of the SITRANS LR250 (yy mm dd). 4.3. LCD Fast Mode Affects Measurement mode only: has no effect on Navigation mode. -

Page 78: Lcd Contrast

4.9. Power-on Resets The number of power cycles that have occurred since manufacture. Open the menu View – Wear. 4.11. Memory Test Allows verification of the RAM, EEPROM, and Flash memory of the SITRANS LR250. IDLE No test in progress. BUSY Test in progress. - Page 79 Read only. Displays the status of the Maintenance Alerts. Maintenance Required Alert active Options Maintenance Demanded Alert Active (view only) Open the menu View – Display Status, click on the Maintenance tab and check the Service Schedule Status window. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 83...

-

Page 80: Calibration Interval

4.17.4. Maintenance Demanded Limit If the time remaining till next calibration is equal to or less than this limit, a Maintenance Demanded status is generated. Range: 0 to 20 years Values Default: 0.019 years Page 84 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 81 Open the menu View – Display Status, click on the Maintenance tab and check the Calibration Schedule Status window. 4.17.9. Acknowledge Allows you to acknowledge either a Maintenance Required or a Maintenance Demanded alert. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 85...

-

Page 82: Communication

Edit mode. Key in a new value and press Right ARROW to accept it. 5.2. Communication Control SITRANS LR250 can only reset this parameter via the handheld Note: programmer. Enables /disables the read/write access to parameters via remote communications. -

Page 83: Security

• After a new value is stored in Unlock Value (6.2), that value will be recalled after a reset to Factory Defaults. • Consult your Siemens Milltronics representative if you have forgotten the unlock value. Stores the value to be entered in 6.1. Lock to unlock programming. If Lock is on,... -

Page 84: Appendix A: Alphabetical Parameter List

Dimension L (2.2.3.3.) Distance Measurement (2.2.8.4.) Echo Lock (2.2.4.2.1.) Echo Profile (3.1.) Echo Threshold (2.2.4.1.3.) Empty rate (2.2.7.3.) Fail-safe Level (2.4.4.) Fail-safe Material Level (2.4.2.) Fail-safe Timer (2.4.1.) Far Range (2.2.1.12.) 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 89... - Page 85 Power-on Resets (4.9.) Propagation Factor (2.2.1.13.) Transducer Block (TB) Values (for diagnostic purposes) (2.2.8.) Response Rate (2.2.7.1.) Sensor Offset (2.2.1.19.) Sensor Units (2.2. 1 .4.) Software Revision (2.1.1.) Space Measurement (2.2.8.3.) Page 90 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 86 Parameter Name (Parameter Number) Page Number Strength (2.2.4.5.2.) TVT Hover Level (2.2.5.1.) Unlock value (6.2.) Vessel Shape (2.2.2.1.) Vol 1 (2.2.3.4.2.) Volume Breakpoints (2.2.3.) Volume Measurement (2.2.8.5.) Window (2.2.4.2.6.) 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 91...

-

Page 87: Device Status Icons

• Simulation or substitute value • Communication is good; device is in simulation mode or works with substitute values. • Out of operation • Communication is good; device is out of action. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 93... -

Page 88: General Fault Codes

As a result, a valid measurement has not been taken for the failsafe timer period, and the device will be put into failsafe mode. Page 94 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 89 Inspect for heat-related damage and contact your local Sie- mens representative if repair is required. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 95...

- Page 90 Factory calibration for the device Repair required: contact your local has been lost. Siemens representative. S: 35 Factory calibration for the device Repair required: contact your local has been lost. Siemens representative. Page 96 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 91 Point and Low Calibration Point is breakpoints, and/or Auto False-Echo not less than zero; check the break- 2.2.3. Volume Suppression, are set to invalid val- points (only required if Breakpoints ues. is not set to 0). 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 97...

- Page 92 S: 53 Configuration lost: one or more Restore user parameters using parameter settings have been lost. SIMATIC PDM. This may occur after a firmware upgrade causes user parameters to be reset. Page 98 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

-

Page 93: Operation Troubleshooting

• check nameplate rating against Screen blank voltage supply • check power wiring or source too much load resistance • change barrier type, or • remove something from the loop, or • increase supply voltage 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 99... -

Page 94: Clef Range (2.2.4.4.3.)

2.2. 1 .2. Material • vessel near empty and • ensure selection is low dK material LIQUID LOW DK 2.2.4.1.2. Position • set to Hybrid 2.2.4.4.3. CLEF Range • set to 0.5 m Page 100 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 95: Appendix C: Maintenance

Appendix C: Maintenance SITRANS LR250 requires no maintenance or cleaning under normal operating conditions. Under severe operating conditions, the horn antenna may require periodic cleaning. If cleaning becomes necessary: • Note the antenna material and the process medium, and select a cleaning solution that will not react adversely with either. -

Page 96: Appendix D: Technical Reference

Appendix D: Technical Reference Principles of Operation SITRANS LR250 is a 2-wire 25 GHz pulse radar level transmitter for continuous monitoring of liquids and slurries . Radar level measurement uses the time of flight principle to determine distance to a material surface. The device transmits a signal and waits for the return echo. -

Page 97: Time Varying Threshold (Tvt) Curves

A new measurement outside the Echo Lock Window must meet the sampling criteria before the window will move to include it. The other available options, Maximum Verification and Total Lock are not recommended for radar. Page 104 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 98: Echo Position Detection

Use Auto False Echo Suppression when the material level is substantially lower than pro- cess full level (ideally when the tank is empty or almost empty). 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 105... -

Page 99: Measurement Range

Measurement Range Near Range 2.2.1.11. Near Range programs SITRANS LR250 to ignore the zone in front of the antenna. The default blanking distance is 50 mm (1.97") from end of horn antenna. 2.2.5.6. Near Range allows you to increase the blanking value from its factory default. But... -

Page 100: Ma Output

4 mA 20 mA When SITRANS LR250 is put into PROGRAM mode it stops responding to the process. It stores the most recent measurement, and holds the associated readings and mA signal output. The instrument reverts to the parameter last addressed during the previous program session. -

Page 101: Loss Of Echo (Loe)

2.4.2. Fail-safe Material Level Fail-safe Material Level Use Maximum mA Limit as material level Use Minimum mA Limit as material level HOLD Level remains at last reading VALUE User-selected value Page 108 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 102: Maximum Process Temperature Chart

Where the chart does not apply, please use your own judgement regarding the use of SITRANS LR250. Parameter 3. 1 4.1 is required to monitor the Internal Temperature. It gives you an excellent indication of how reliably the product will perform thermally when installed on your process vessel. -

Page 103: Process Pressure/Temperature Derating Curves

The process pressure boundary assembly comprises the components that act as a barrier against pressure loss from the process vessel: that is, the combination of process connec- tion body and emitter, but normally excluding the electrical enclosure. Page 110 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... -

Page 104: Horn Antenna Or Wave Guide

WARNING: Never attempt to loosen, remove or disassemble process connection or instrument housing while vessel contents are under pressure. Customer to provide adequate bolting and flat-faced gasket to retain vessel pressure and provide sufficient sealing. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 111... - Page 105 25546, 25547, 25580 or 25581 stamped on flange. process temperature (°C) PN40 PN40 WARNING: Never attempt to loosen, remove or disassemble process connection or instrument housing while vessel contents are under pressure. Page 112 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01...

- Page 106 25581 stamped on flange. process temperature (°C) Process Temperature (°C) 300 lb 300lb WARNING: Never attempt to loosen, remove or disassemble process connection or instrument housing while vessel contents are under pressure. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 113...

-

Page 107: Loop Power

LR250 loop current IL Allowable operating area of SITRANS LR250 Loop Voltage versus Loop Resistance Power Supply Requirements Power Supply Requirements 1000 1000 (30.0v,845 ohms) (30.0v,845 ohms) RL=44.6*VL - 493.4... -

Page 108: Startup Behavior

Startup Behavior Notes: • SITRANS LR250 is designed to start reliably with a power supply capable of delivering at least 25 mA. • When connected to a power supply with a current limit of < 25 mA, the LR250 may not start reliably. -

Page 109: Appendix E: Application Examples

Low Calibration Pt. = vessel bottom High Calibration Pt.= 0.5 m from sensor reference point. Max.fill/empty rate = 0.2 m/min. In the event of a loss of echo: SITRANS LR250 is to go into Fail-safe 0% Level High after 2 minutes. Low Cal Point Parameter Parameter No. - Page 110 Function (cont’ d ) type Name Values 2.4.1. Fail-safe Timer 2 minutes Independent 2.4.2. Fail-safe Material Failsafe level set to parameters Level High Return to Measurement: press Mode to start normal operation. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 117...

-

Page 111: Horizontal Vessel With Volume Measurement

Select vessel shape, Parabolic Ends, and enter values for A and L, to obtain a volume reading instead of level. In the event of a loss of echo: SITRANS LR250 is to go into Fail-safe High after 2 minutes. sensor reference 0.5 m... - Page 112 2.2.3.2. Dimension A 0.8 m 2.2.3.3. Dimension L 2.4.1. Fail-safe Timer 2 minutes 2.4.2. Fail-safe Material Failsafe level set to Level High Return to Measurement: press Mode to start normal operation. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 119...

-

Page 113: Application With Stillpipe

Level is reported as Quick Start Volume when a vessel Wizard shape is selected. 1.5. Low Calibration Point 1.6. High Calibration Point 0.5 m 1.7. Apply? (Apply changes) Transfers Quick Start settings to device. Page 120 SITRANS LR250 (HART) – INSTRUCTION MANUAL 7ML19985JE01... - Page 114 Low Cal Pt. – Low Cal Pt. – Low Cal Pt. – 700 mm 700 mm 1000 mm 1000 mm settings Since pipe dimensions may vary slightly, the propagation factor may also vary. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 121...

-

Page 115: Appendix G: Software Revision History

/SIMATIC PDM: View > Display > 1.01.00 1.01.00 07/27/2007 Distance correctly reported. • eDD/SIMATIC PDM: Improved rendering of the echo profile and TVT. electronic Device Description Operation types on page 54 for an illustration of Distance. 7ML19985JE01 SITRANS LR250 (HART) – INSTRUCTION MANUAL Page 127... -

Page 116: Lcd Menu Structure

2.2.4.3FILTERING LCD menu structure 2. SETUP (cont’ d ) 2.2.4.3.2 DAMPING FILTER 2.2.4.4 TANK BOTTOM ALG 2.2.4.4.3 CLEF RANGE Notes: 2.2.4.5 NOISE • In Navigation mode ARROW keys navigate the menu in the 2.2.4.5.1 CONFIDENCE direction of the arrow.. 2.2.4.5.2 STRENGTH •... - Page 117 4.18.3 MAINT REQ LIMIT 4.18.4 MAINT DEM LIMIT 4.18.5 ALERT ACTIVATION 4.18.6 TOTAL CALIB.INTRV 4.18.7 MAINT STAT 4.18.8 ACK STATUS 4.18.9 ACK COMMUNICATION DEVICE ADDRESS 5.2 COMM. CONTROL SECURITY LOCK 6.2 UNLOCK VALUE LANGUAGE 7ML19985JE01 SITRANS LR250– INSTRUCTION MANUAL Page 139...

Need help?

Do you have a question about the Sitrans LR250 and is the answer not in the manual?

Questions and answers