Sea Recovery SRC Aqua Matic 700-1 Owner's Manual

Hide thumbs

Also See for SRC Aqua Matic 700-1:

- Owner's manual (223 pages) ,

- Owner's manual (362 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sea Recovery SRC Aqua Matic 700-1

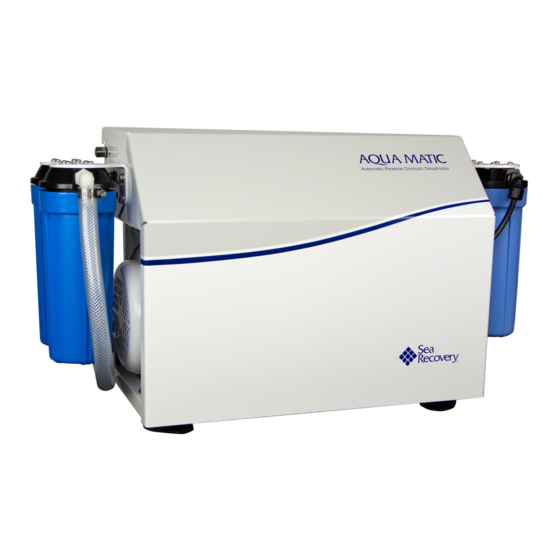

- Page 1 Aqua Matic Compact 450-1800 Owner’s Manual SYSTEM MODELS Aqua Matic 450-1 Aqua Matic 900-2 Aqua Matic 700-1 Aqua Matic 1400-2 Aqua Matic 900-1 Aqua Matic 1800-2 Owner’s Manual Manual PN B651140001 | Revision: 12-1-2017...

- Page 3 Aqua Matic Compact 450-1800 Owner's Manual Manual PN B651140001...

-

Page 5: Table Of Contents

Disposal...................................14 Compliance................................14 Chemical Warnings..............................15 Sea Recovery SRC SC Storage Chemical......................15 Sea Recovery SRC MCC-1 Membrane Cleaning Chemical..................15 Sea Recovery SRC MCC-2 Membrane Cleaning Chemical..................15 Sea Recovery SRC MCC-3 Membrane Cleaning Chemical..................16 Patent Information ..............................16 Chapter 2: System Description ................17 Pre-Installation Safety Checks .......................... - Page 6 Component Descriptions ............................22 Pre-filtration Components ............................. 22 Pressurization Components ..........................24 Brine Discharge Components ..........................24 Product Water Components ..........................25 Fresh Water System Components ........................25 Fresh Water Flush Components ........................... 26 Electronic Components ............................26 Miscellaneous Components ..........................27 Chapter 3: Electrical Specifications..............29 Electrical Requirements and Specs ........................

- Page 7 System Storage ..............................68 Powering the System ON ............................. 68 Automatic Mode ..............................69 Manual Mode ................................ 69 Startup Sequence ..............................70 Powering the System OFF ........................... 71 Automatic Mode ..............................71 Manual Mode ................................ 71 System Short- and Long-Term Storage ........................ 72 Once-through Configuration ..........................

- Page 8 Salinity Probe ..............................106 3-way Product Water Diversion Solenoid Valve ....................107 Charcoal Filter ..............................108 pH Neutralizing Filter ............................108 Ultraviolet Sterilizer ............................109 Fresh Water Flush Carbon Filter Element ......................109 UV Sterilizer Maintenance ..........................110 Exterior Surfaces ..............................111 Quartz Sleeve ..............................

-

Page 9: Preface: About This Manual

• SERIAL NUMBER: Helps Sea Recovery Corporation to determine the latest physical version and configuration of your System, ensuring that you are provided with correct part information. • TYPE: Tells Sea Recovery Corporation the production capacity of your System, which provides a bench mark in diagnosing product water flow and pressure concerns. -

Page 10: References

Sea Recovery s trademarked name or Sea Recovery s trademarked logo mark are not to be used in any form or manner except with Sea Recovery Corporation s written permission. Sea Recovery Corporation holds all rights to its copyrights and trademarks, and to the material contained in this manual. Any use of such requires the written permission from Sea Recovery Corporation. -

Page 11: Revision History

About this Manual in the design and manufacture of the is the property of Sea Recovery Corporation and protected by U.S. and international copyright laws. The content of this manual and the software, programming, and graphics used in the design and manufacture of the is for the purpose of operation, maintaining and repair of the . Any other use, including the reproduction, modification, distribution, transmission, republication, display or performance, of the ©... -

Page 13: Chapter 1: Introduction

Introduction Welcome Congratulations on your purchase of a new Sea Recovery Aqua Matic Compact Reverse Osmosis (RO) Desalination System! The Aqua Matic RO Desalination System is engineered to be easier to use and more reliable than conventional water-makers. Featuring the latest technology, the System is able to regulate and monitor functions without the need of an operator. -

Page 14: Parts Warning

Limited Warranty Sea Recovery warrants that the performs according to specifications for a period of 12 months from the date of shipment. Sea Recovery s liability under this warranty is limited to repair or replacement of the at Sea Recovery Corporation s discretion. -

Page 15: Cleaning

• Repairs made by Sea Recovery Corporation after the original warranty period has expired: Three (3) months • Normal, reoccurring user maintenance on the following is not covered by this or any Sea Recovery Corporation limited warranty: Sea Strainer Element, fuses, instrument calibration, cartridge filter elements and/or the centrifugal... -

Page 16: Safety

If System disposal is necessary, you must comply with all federal and state environmental regulations. Compliance • Sea Recovery s Reverse Osmosis Desalination Systems are Type Accepted by the American Bureau of Shipping, ABS. • Sea Recovery s Reverse Osmosis Desalination Systems comply with FCC § 15.105 •... -

Page 17: Chemical Warnings

CONTACT IMMEDIATELY FLUSH EYES WITH WATER FOR 15 MINUTES & GET IMMEDIATE MEDICAL ATTENTION. THOROUGHLY WASH AFFECTED SKIN AFTER HANDLING PRODUCT. MEDICAL PERSONNEL FAMILIAR WITH Sea Recovery “SRC SC”, SYSTEM & MEMBRANE STORAGE CHEMICAL, ARE AVAILABLE 24 HOURS A DAY, 7 DAYS A WEEK, U.S.A. TOLL FREE MEDICAL EMERGENCY NUMBER: 1-800-228-5635. -

Page 18: Sea Recovery Src Mcc-3 Membrane Cleaning Chemical

MEDICAL PERSONNEL FAMILIAR WITH Sea Recovery “SRC MCC2”, R.O. MEMBRANE ELEMENT ACID CLEANING CHEMICAL, ARE AVAILABLE 24 HOURS A DAY, 7 DAYS A WEEK, U.S.A. TOLL FREE MEDICAL EMERGENCY NUMBER: 1-800-228-5635. FOR INDUSTRIAL USE ONLY. DO NOT MIX WITH CHLORINATED SOLUTIONS OR COMPOUNDS. Use with adequate ventilation. Prevent breathing dust &... -

Page 19: Chapter 2: System Description

• Hypochlorite iodine • Bromide petroleum products Important: The use of non-authorized and/or the misuse of authorized chemicals will void your Sea Recovery Corporation warranty! For example, DO NOT connect the Aqua Matic RO Desalination System's inlet to your ship s potable water system if it contains chlorinated or brominated water. These chemicals destroy the copolymer components and the oxidants will damage the RO Membrane Element. -

Page 20: Installer Minimum Qualifications

• The System's Feed Water Sea Cock Valve is closed. • The System's main electrical disconnect switch is OFF, LOCKED and TAGGED. Installer Minimum Qualifications The System's Installer must have technical expertise in the following areas: • Electrical, Electronic, Electric Motors and Circuits •... -

Page 21: System Specifications

(U.S. Gallons / Liters) (lbs / kg) SRC Aqua Matic 450-1 19 / 71 450 / 1703 153 / 69 SRC Aqua Matic 700-1 29 / 110 700 / 2650 156 / 71 SRC Aqua Matic 900-1 38 / 142... -

Page 22: Water Connections

Water Connections • Feed Inlet at the Sea Cock Valve: ¾ in. (19 mm) MNPT • Brine Discharge at the Thru Hull Discharge fitting: ¾ in. (19 mm) MNPT • Product at the Product Water Connector: ½ in. (12.7 mm) FNPT •... -

Page 23: Electrical Power Source

RO Membrane Element(s) are not installed. If the RO Membrane Element(s) are not installed, and you wish to install them at this time, then please contact Sea Recovery Corporation and supply us with your original Purchase Order Number, your Sea Recovery Corporation Invoice Number, and your System s Serial Number. -

Page 24: Component Descriptions

Feed Water. Caution: The resulting failure of the System to remain in operation is attributed to improper installation. Thus, it is the Installer's liability, and will not be not covered by the Sea Recovery Corporation warranty. 2. Sea Cock Valve Used (for safety reasons) to close the Feed Water line during repair, maintenance and disuse of the system. - Page 25 For additional information on obtaining this optional accessory, please contact Sea Recovery Corporation. Caution: Do not use third-party pre-filtration components! Use only Sea Recovery Corporation pre-filtration components. Third-party pre-filtration components do not fit properly, thus causing the seams to fall apart.

-

Page 26: Pressurization Components

4. RO Membrane Element and Vessel #2 Connected in series with the first RO Membrane Element and Vessel. The Sea Recovery R.O. System will have either one or two RO Membrane Element and Vessel depending on the model. The 2nd RO Membrane Element and Vessel may be added at any time to a system with only one. -

Page 27: Product Water Components

System Description Product Water Components The Product Water section provides a visual indicator for the clarity, quantity and quality of the Product Water. Post-filtration is the final step in Product Water quality control. The Post-filtration Subsystem is designed to limit unpleasant odor and taste, adjust the pH to neutral and sterilize biological matter (which may have passed through the RO Membrane Element). -

Page 28: Fresh Water Flush Components

High Pressure Pump Motor. Thus, a smaller KW generator can be used to start the system. Note that start-up amperage is reduced by 40% with the Soft Start installed. For additional information on obtaining this optional accessory, please contact Sea Recovery Corporation. Aqua Matic Compact 450-1800... -

Page 29: Miscellaneous Components

System Description Miscellaneous Components Note that the controller supports one tank-level switch. Please select either the low-level or high-level as described below. 1. Fresh Water Tank Low Level Switch To be supplied by the System's Owner. Provides an optional feature to the System Control Logic that works in conjunction with the Automatic Fresh Water Flush option. -

Page 31: Chapter 3: Electrical Specifications

Chapter Electrical Specifications Electrical Requirements and Specs The topics within this chapter address electrical requirements, safety information and specifications for the Aqua Matic RO Desalination System. For electrical schematics, please refer to the following diagrams in the Appendix: • Single-Phase Electrical Motor Wiring on page 95 •... -

Page 32: Power Source Requirements

Pump Electric Motor's normal-operating amperage plus the High Pressure Pump Electric Motor's normal-operating amperage. Voltage Min. Voltage Max. Voltage Min. Power Max. Power (VAC) (VAC) (VAC) (HZ) (HZ) Power Source Requirements Check line voltage and frequency to ensure that it agrees with system nameplate. Grounding and circuit protection should be done in accordance with National Electrical Code. - Page 33 Electrical Specifications Alternating Current Systems Single Phase Alternating Current (Oil Free Pumps) High Pressure Pump Motor Booster Pump Motor 2850 2850 2850 11.5 2850 3450 25.4 3450 3450 12.7 3450 Three Phase Alternating Current (Oil Free Pumps) High Pressure Pump Motor Booster Pump Motor 2850 24.9...

-

Page 34: Recommended Circuit Breaker Based On Operating Voltage

Recommended Circuit Breaker Based on Operating Voltage Operating Voltage Phase Recommended Circuit Breaker (Ampere) 110-115 VAC Single 220-230 VAC Single 220 VAC Three 380 VAC Three 460 VAC Three Recommended Power Wire Size to System Operating Voltage Phase Max Load Recommended Minimum Wire Size for Run Length (Amperes) 10 ft / 3 m... -

Page 35: Chapter 4: Installation

System (or its components) to an uneven surface will be attributed to improper installation; is the liability of the Installer; and is not covered by the Sea Recovery Corporation warranty. Grind mounting surfaces flat, or use appropriate shims on uneven surfaces, to ensure that System component mounting does not cause bending or warping. -

Page 36: Interconnecting Components With Supplied Hose

inches to ensure proper connection, relieve stress to the fitting and tube/hose, and allow easy detachment and re-attachment during maintenance or repair. 1. Cut tube-end squarely and cleanly. 2. Loosen nut by three turns on the fitting. 3. Insert tube into the fitting until it bottoms. 4. -

Page 37: Remote Touch Screen

Installation Important: If the RO Membrane Element and Pressure Vessel Assembly are mounted remotely, ensure that all high-pressure hoses have sufficient slack and are not pulled tightly into a sharp or immediate bend. 1. Using the supplied ¾ in. (19 mm) ID, clear, braided hose, connect the Suction Line components, Low Pressure line components and Brine Discharge Line components. -

Page 38: Uv Sterilizer

Optional Component (Owner/Installer-supplied) Description Fresh Water Tank Low Level Switch Provides an optional feature to the System Control Logic that works in conjunction with the Automatic Fresh Water Flush option. When installed and connected to the Main Printed Circuit Board, the Fresh Water Tank Low-Level Switch must be connected as a Normally Open (NO), One Pole Single Throw (1PST) switch. -

Page 39: Install Quartz Sleeve

Installation 2. Wrap ¼ in. (6.35 mm)-wide, PTFE tape counter-clockwise (2 to 3 turns) around the male threads of the ¼ in. (6.35 mm) fitting. DO NOT wrap tape around the first thread. 3. Finger-tighten the fitting into the cylinder ports to achieve desired alignment. Important: Do not back-off fitting. -

Page 40: Connect Plumbing

6. Lubricate the tips of the quartz sleeve with clean water and insert new O-Ring. Ensure that the O-Ring makes all-around contact with the cylinder pass-thru. 7. Tighten the compression nut while ensuring that the nut does not contact the quartz sleeve. Adjust O-Ring position as necessary. -

Page 41: Install Ultraviolet Lamp

Installation Install Ultraviolet Lamp Important: Perform this procedure only after the quartz sleeve installation and leak-tests are completed successfully. 1. Connect the UV lamp to the 4-point receptacle. If the lamp is not installed properly, lamp breakage will occur. 2. Insert lamp into quartz sleeve through compression-nut pass-thru. 3. - Page 42 • Disconnect all power to the UV unit before servicing. • Do not allow the inlet water temperature to drop below 35°F (2°C). • Do not allow the flow rate to exceed 2 GPM (7.5 LPM). • Do not cycle the UV unit more than three “ON/OFF” cycles in one 24-hour period. •...

-

Page 43: Chapter 5: Commissioning

Membrane Element has been installed, there will be an RO Membrane Element Serial Number tag attached to the High Pressure Vessel. If the RO Membrane Element Serial Number tag is missing or does not contain a serial number and date, then immediately contact the company that sold the System to you, the Installer, or Sea Recovery Corporation. -

Page 44: System Valve Positions

The controller is set by Sea Recovery Corporation prior to shipping, based on the ordered System features and optional equipment. The addition of the Fresh Water Flush to the System after it has shipped from Sea Recovery requires updates to the computer logic setup. The addition of, removal of, or changes to the length of the RO Membrane Element / Pressure Vessel Assembly requires updates to the control logic setup. - Page 45 Commissioning a) Manually start and stop the Booster Pump. b) Manually start and stop the High Pressure Pump. c) Manually energize the 3-Way Product-Water Diversion Valve at a specific product-water quality, in Parts per Million (PPM). The factory setting is 800 PPM Total Dissolved Solids (TDS), expressed as NaCl (i.e, Sodium Chloride, or salt).

- Page 46 4. Back Wash Time: Change the interval for automatic back washing by adjusting the number of days. 5. Language: Change the current controller language by selecting new language option. 6. Unit: Toggle the measurement standards between U.S. Standard and Metric Standard. Aqua Matic Compact 450-1800...

- Page 47 Commissioning a)Pressure: U.S. Standard = PSI (Pounds Per square Inch); Metric Standard = kPa (kilo Pasquel) b)Flow: U.S. Standard = GPM (Gallons Per Minute) or GPH (Gallons Per Hour); Metric Standard = LPM (LitersPer Minute) or LPH (Liters Per Hour)

-

Page 49: System Main Controller Update As Of 10/30/2017

SYSTEM MAIN CONTROLLER UPDATE AS OF 10/30/2017... -

Page 50: System Commissioning

Aqua Matic Compact 450-1800... - Page 52 Aqua Matic Compact 450-1800...

-

Page 54: Display Setting

Aqua Matic Compact 450-1800... -

Page 56: Setting System Clock

Aqua Matic Compact 450-1800... - Page 58 Aqua Matic Compact 450-1800...

- Page 60 Aqua Matic Compact 450-1800...

-

Page 62: Setting Fresh Water Flush

Aqua Matic Compact 450-1800... -

Page 65: Manual System Check

Dual Pre-filter or Commercial Pre-filter: Check for pleated cartridge filter elements. e) Oil/water Separator: Check for Oil/Water Separator filter element. f) RO Membrane Element(s): Check for Sea Recovery Serial Number and date on the label that is attached to each pressure vessel. -

Page 66: Multi Media Filter Backwash And Rinse

• Fresh Water Flush Valve Energize Solenoid • Back Pressure Regulator Electric Motor Actuator • UV Sterilizer Ballast and Lamp a) Perform a rotational check on the electric motor. Ask an assistant to view the fan section of the Booster Pump Motor and High Pressure Pump Motor, while you “Jog”... - Page 67 Commissioning...

-

Page 69: Chapter 6: General Operation

System by feeding Product Water into the System for a continuous 48-hour period. Caution: Never expose the RO Membrane Element to chemicals other than those supplied by Sea Recovery Corporation. Use caution when operating the system in harbors that may be polluted with chemicals, oil or... -

Page 70: Fresh Water Flush Warning

(2) weeks or more. Important: Third-party chemicals will destroy the RO Membrane Element! Only use Sea Recovery Corporation-supplied chemicals. Never use third-party chemicals, as they are incompatible with various System materials and will dissolve the co-polymer parts. -

Page 71: Automatic Mode

General Operation Automatic Mode Note: Auto Mode is highly recommended for Operators and Owners. 1. From the default screen, touch the START button. Note: All System readings, pressures, flows and salinity will be displayed on the Touch Screen. 2. Although the System is producing product water, it may not be potable (i.e. drinkable) for up to 30 minutes. The salinity of the Product Water diminishes gradually, until it reaches the preset setting. -

Page 72: Startup Sequence

Note: All System readings, pressures, flows and salinity will be displayed on the Main Touch Screen. Important: If an abnormality develops, touch the STOP button in the top right corner of the screen. A warning screen will display. Correct the problem and then repeat Steps 1-8. 9. -

Page 73: Powering The System Off

General Operation g) If the System includes the Automatic Fresh Water Flush the Automatic Fresh Water Flush Valve will energize to Fresh Water. After 7 to 15 minutes the Fresh Water Flush Valve will de-energize and the Stop sequence is complete. 14. -

Page 74: System Short- And Long-Term Storage

System Short- and Long-Term Storage The dark, moist interior of the RO Membrane Element is a breeding ground for micro-organisms. System operation, alone, does not protect the RO Membrane Element from production loss due to biological fouling. Prior to short-term shutdowns, the System must be rinsed (and winterized if the System is / will be exposed to freezing temperatures). -

Page 75: System Main Controller Update As Of 10/30/2017

SYSTEM MAIN CONTROLLER UPDATE AS OF 10/30/2017... -

Page 76: Manual Operation

Manual Operation The Aquamatic, Aquamatic XL and AquaWhisper DX desalination system controller provides two possible methods of operation; these are manual mode and automatic mode. In manual mode, the controller requires that the operator activate the relative pumps by pressing on the required pump operation icons. - Page 77 Manual Stop Booster Pump (Shown When Running) Control (Available but not active) Product Valve Control HP Pump (Not currently available) Control UV System (Not currently available) Control System Pressure (Shown if installed) (Not currently available) Control (Not currently available) 4. Press Booster Pump icon. NOTE: If starting system for the first time, allow time for the system to be primed before starting HP Pump.

- Page 78 NOTE: A warning message may pop up in the lower left hand corner of the screen giving details of the failure. The operator must correct this situation before being allowed to continue. Manual Stop (Shown When Running) Failure Warning Message NOTE: If the booster pump has been activated, and no conditions prohibiting operation of the high-pressure pump exist, the controller will make the 'Start HP Pump' button available, as shown below:...

- Page 79 6. Adjust pressure to 800 PSI (55 BAR) by pressing and holding the increase arrow icon. NOTE: If you have an Aqua Whisper DX use the regulator knob for this step. NOTE: Automatic Pressure Control: (only on Aquamatic & Aquamatic XL systems) System Pressure Control (Only 'increase' available)

- Page 80 System Pressure Control (Only 'Decrease' available) NOTE: If the UV Sterilizer is not installed skip next step. 7. Press UV Sterilizer icon. NOTE: It may take several minutes for UV Sterilizer to become active. The system must sense good potable water for the icon to activate. UV System Control (Shown if installed)

- Page 81 8. Press the Product Valve Icon to activate the Diversion valve. NOTE: Once the UV system has completed its warm up cycle or once the controller has detected potable water, the control system will make the 'Start|Stop Product Valve' button available.

-

Page 82: Automatic Operation

Automatic Operation Automatic startup operation allows for virtually hands free startup of the Aquamatic, Aquamatic XL or AquaWhisper DX system, and all associated equipment. This automatic startup operation can also be carried out remotely via the system remote control display (if installed). NOTE: Before attempting automatic start up, it is important to check that all system feed and reject valves are in the correct position. - Page 83 NOTE: If the control system is unable to successfully calibrate the pressure control regulator, an error message will be displayed, and automatic startup will be aborted. An example of this error message is shown below: NOTE: There will be a system priming delay of approximately 25 second once boost pump has turned on to when the HP Pump turns on.

- Page 84 NOTE: If the control system detects a dangerous condition, or a failure of a critical sensor during automatic operation. The system will bring the Aquamatic, Aquamatic XL and AquaWhipser DX system to a rapid stop, and display the detected failure in an alarm screen, as shown below: Detected system...

-

Page 85: Accessing Your Various Display Screens

Accessing Your Various Display Screens 1. Press Dashboard icon. Press Here All available system data is shown in the users chosen display unit. HP Pump Product water Inlet Salinity Pressure Product water HP Pump temperature outlet Pressure Product water Brine water flow rate flow rate 2. - Page 86 3. To get to any of the 3 screens (Pressure, Flow, or Water Quality) press the area in the boxes below. See Notice Other Live Data Other Live Data Other Live Data Aqua Matic Compact 450-1800...

- Page 87 4. Pressing the arrow button in the top left hand corner of the water quality screen two times will return you to the main menu screen as shown below:...

-

Page 88: Accessing System Fault & Warning Log

Accessing System Fault & Warning Log 1. Press Information Icon Press here Press Message tab. 3. Press the 'Fault Log' or 'Warning Log' area, as shown on the below. Aqua Matic Compact 450-1800... -

Page 89: Accessing High Pressure Pump Hour Meter

Pressing the arrow button in the top left hand corner on the screen to exit Accessing High Pressure Pump Hour Meter The Aquamatic, Aquamatic XL, and AquaWhisper DX desalination system controller constantly records your high pressure pumps operational hours. To access the high-pressure pump hours display press on the 'Current Run Time' area, available on most screens. - Page 90 2. The high-pressure pump hours display screen also contains additional information Total operation hours of unit Current operation timer Estimated hours remaining before pump service System live required Estimated hours remaining before pump oil change required The high-pressure pump hour display provides two maintenance life timers, these being pump life, and oil life.

-

Page 91: Short-Term Shutdown Procedure

General Operation Short-term Shutdown Procedure Short-term shutdown is defined as a period of up to four (4) weeks, in which the System is not being used. To effectively protect the System and RO Membrane Element(s) during the short-term shutdown, you must perform a Fresh Water Rinse (i.e., a rinse with fresh Product Water from the System). -

Page 92: Long-Term Shutdown Procedure

Long-term (or prolonged) shutdown occurs when the System remains unused for over four (4) weeks. Before a long-term shutdown, the System must first be rinsed with Fresh Product Water, and then with Sea Recovery Corporation's System and Membrane Element Storage Chemical (SRC SC). SRC SC inhibits bacterial growth, while maintaining the RO Membrane Element's high flux and salt rejection properties. -

Page 93: Draining Component Water (For Winterizing)

To properly assess the RO Membrane Element's performance changes, Sea Recovery Corporation strongly recommends that you maintain a daily log of readings for comparison. When making performance comparisons, you must consider, and compensate for, the following variables: •... -

Page 94: About New Systems

If your RO Membrane Element is excessively fouled and in-field cleaning is not successful, you may return it to Sea Recovery Corporation or to an authorized Service Dealer for professional chemical cleaning. If your RO Membrane Element requires professional cleaning, please contact Sea Recovery Corporation for a Return Authorization Number, price quote and return instructions. - Page 95 7. Once again, fill the container with 10 gallons (37.8 liters) of clean, potable water. 8. Add 1.5 lbs. (0.68 kg) of Sea Recovery Membrane Cleaning Compound MCC 1, MCC 2 or MCC 3 to the water container and thoroughly mix the solution until the cleaning compound has dissolved.

-

Page 97: Chapter 7: Maintenance And Repair

• SERIAL NUMBER: Helps Sea Recovery Corporation to determine the latest physical version and configuration of your System, ensuring that you are provided with correct part information. • TYPE: Tells Sea Recovery Corporation the production capacity of your System, which provides a bench mark in diagnosing product water flow and pressure concerns. -

Page 98: System Safety Check

• Hypochlorite iodine • Bromide petroleum products Important: The use of non-authorized and/or the misuse of authorized chemicals will void your Sea Recovery Corporation warranty! For example, DO NOT connect the Aqua Matic RO Desalination System's inlet to your ship s potable water system if it contains chlorinated or brominated water. These chemicals destroy the copolymer components and the oxidants will damage the RO Membrane Element. -

Page 99: Weekly Quick Check

• The use of third-party, non-Sea Recovery components, spares and assemblies will damage the Sea Recovery System and/or specific components within the System. • The use of third-party, non-Sea Recovery components, spares and assemblies will void any and all warranty of the System and/or void the affected component within the System. -

Page 100: Component Maintenance And Repair

Feed Water. Caution: If the Sea Recovery System is connected to a Sea Chest or Stand Up Pipe, do not plumb the Sea Recovery System feed line to the top of these feed water arrangements. If plumbed to the bottom, the System will intake air and experience continual shut down. - Page 101 Maintenance and Repair Attention: The Booster Pump must rotate in the counter-clockwise direction. Rotating the Booster Pump in the clockwise direction will cause extensive damage. Attention: When switching from 3-Phase Generator power to 3-Phase Shore power, always check phases prior to operating the System. Otherwise, reverse rotation (and extensive damage) may occur when the power is out-of-phase.

-

Page 102: T-Connector Pressure Pick-Up

Some Electric Motors supplied by Sea Recovery have permanently sealed and lubricated bearings. Others require lubrication from time to time. If your Electric Motor has grease jerks at each end of the motor (over the front and rear bearings), the bearings require lubrication every six months. Give three pumps of high temperature motor bearing lubricant into each grease jerk. -

Page 103: Commercial Or Dual Pre-Filter Element Replacement

USE ONLY SEA RECOVERY SUPPLIED PRE-FILTER ELEMENTS. The System's resulting failure, and/or damage to the System caused by third-party pre-filter elements, is attributed to improper maintenance and operation, is the liability of the operator and owner, and is not covered by the Sea Recovery Corporation warranty. -

Page 104: Transducer Manifold

5. Wipe the O-Ring with a damp cloth. 6. Sparingly lubricate the O-Ring with O-Ring lubricant. 7. Insert the new Sea Recovery Corporation Oil/Water Separator Filter Element into the bowl. 8. Place the lid on top of the housing. 9. Replace the lid-locking ring. Tighten into place with hands. Do not use a wrench or other tool to tighten. Do not over tighten, as over tightening causes stress to the bowl and lid-lock ring threads, leading to cracks, breakage, and difficult disassembly at the next filter change. -

Page 105: High Pressure Hose

• This pump is manufactured to very tight tolerance spacing between moving parts. Any debris entering the pump will cause extensive and expensive damage to the internal parts. The Sea Recovery Pre-filter will stop any debris and protect the High Pressure Pump. Use caution when changing filter elements and do not allow any debris from the pre-filter element to enter the outlet port of its housing. - Page 106 17. Run a rag through the High Pressure Vessel to remove biological film or debris from the inside of the vessel. 18. A new Sea Recovery Corporation RO Membrane Element includes a “U” cup Brine Seal (#8) at one end of the element.

-

Page 107: High Pressure Manifold

Maintenance and Repair High Pressure Manifold Replace the High Pressure Manifold if it is visibly cracked, broken and leaking. Replace the High Pressure fitting O-Rings if damaged, worn, or leaking. High Pressure Transducer Pressure Transducers are irreparable and cannot be calibrated. If inoperative, check connections at the transducer and at the Printed Circuit Board to ensure that there is no visible corrosion or loose connections. -

Page 108: Brine Discharge And Product Water Flow Meters

Caution: Do not over tighten the packing gland. Over tightening will cause premature wear and failure of the packing and stem. Important: Over tightening can cause excessive drag, increasing the torque requirement of the valve s electric motor. Excessive drag resulting in an increased torque requirement will cause the valve motor to draw high current. -

Page 109: 3-Way Product Water Diversion Solenoid Valve

Maintenance and Repair 3-way Product Water Diversion Solenoid Valve Note: Do not assume that the valve s solenoid is non-operational. Check it by performing a function test as described in the topic Manual System Check on page 45. Caution: Over tightening the tube fittings can cause the diversion valve's internal ports to move out of the proper position, thereby causing internal blockage or bypass. -

Page 110: Charcoal Filter

Otherwise, the Charcoal Filter element must be replaced every three to four months (it cannot be cleaned). Caution: Do not use third-party charcoal or carbon filter elements! Use only Sea Recovery Corporation Filter Elements. Many third-party Filter Elements fit improperly; the seams fall apart; and they allow bypass. They are also designed for low flow rates, causing extensive damage (due to pressure build-up on the product water line) if used in the System. -

Page 111: Ultraviolet Sterilizer

2. Remove the Carbon Filter Element from the bowl. 3. Remove the O-Ring from the top of the bowl. 4. Replace the Carbon Filter Element with a new Sea Recovery Corporation element. 5. Wipe the O-Ring with a damp cloth. -

Page 112: Uv Sterilizer Maintenance

9. Screw the bowl on clockwise. 10. Hand turn to seal the O-Ring. Do not use a wrench or other tool to tighten, and do not over tighten. Over tightening causes stress to the lid and bowl threads, which can result in damage, breakage, or cracks, as well as difficulty removing it in the future. -

Page 113: Exterior Surfaces

Maintenance and Repair Type 12 VDC Operating UV Sterilizer for 2 gallon (7.5 liters) per minute of water flow Ballast Type Solid State Bulb Type 16 Watts Single Ended Bulb Life 8000 Hours minimum Materials Body: SS304; Ballast Box: PVC Power Cord 13 ft (4 meters) 2 conductors Weight... -

Page 114: Repairing Leaks

2. Use a temporary tube to direct water from the UV unit to a container or drainage. 3. Pressurize the UV unit and flush unit with sample valve that is fully opened for 3.5 minutes. Sea Recovery Corporation recommends using a valve that has a discharge orifice smaller than ¼” (6mm). After flushing for 3.5 minutes, reduce valve opening to 50% and flush for 3 minutes. -

Page 115: Chapter 8: Troubleshooting

Chapter Troubleshooting This chapter provides information and procedures for troubleshooting abnormal System behavior. For each symptom, one or more causes are provided, and each includes one or more corresponding tests to help identify the correct cause of the problem and correct it. When diagnosing System issues, eliminate the listed causes one-by-one until the correct cause is found. -

Page 116: Thru-Hull Inlet Fitting

• Warning on the water maker. For detailed information please check warning on the water maker display. • Alarm on the water maker. For detailed information please check alarm on the water maker display • Low Pressure Sensor (#) failed to measure the pressure. Check wiring. •... -

Page 117: Inlet Vacuum/Pressure Gauges

Troubleshooting 1. Problem: One or more fittings/connections is causing air to enter the Feed Line. a. Description: System feed water pressure is low and insufficient to keep the System in operation. This section of the Feed Line is under a vacuum condition when the System is in operation. Look for air bubbles moving through the Sea Strainer or feed line. -

Page 118: T-Connector Pressure Pickup

T-Connector Pressure Pickup 1. Problem: Low Pressure Transducer does not register pressure. a. Description: The ¼ in. (5 mm) O.D. tube connecting the T-Connector to the Low Pressure Transducer Manifold may become kinked or debris may block the tube. b. Solution: Replace any hose or tube that is kinked. Disconnect each end of the tube and blow air through the tube to ensure that it is not blocked. -

Page 119: Dual Pre-Filter

Troubleshooting Dual Pre-Filter 1. Problem:The Feed Water Pressure into the Pre-filter is higher than normal, and the Feed Water Pressure into the High Pressure Pump is lower than normal. a. Description: The pressure differential readings across the Pre-filter indicate that the elements are filled with debris blocking the feed water. - Page 120 Pressure Pump. Damage to the High pressure Pump caused by debris is the responsibility of the person performing maintenance to the System, is the liability of the person performing maintenance to the System, and is not covered by the Sea Recovery warranty. b. Solutions: a.

-

Page 121: Hp Pump Assembly

When used regularly the seal will give approximately 8,000 hours of use.The seal continually wears during use and must be replaced approximately every 8,000 hours or at the sign of leakage. b. Solution: Return the High Pressure Pump to Sea Recovery for service and Seal replacement. 7. Problem: Knocking Noise a. - Page 122 b. If the end plug develops a crack (between the product water port and the pressurized feed water), a similar increase in Product Water flow and high Product Water salinity will occur. c. At ONE end of the RO Membrane Element, there is a “U” cup seal referred to as the “brine seal.” NEVER use two Brine Seals.

-

Page 123: Automated Motor-Actuated Back Pressure Regulator

Troubleshooting Vessel, remove the end plug and inspect the Brine O-Rings for wear or damage. Replace them if wear or damage is present. b. Solution: Replace the O-Ring if wear or damage is present. Automated Motor-Actuated Back Pressure Regulator Prior to assuming that the Back Pressure Regulator s Electric Motor Actuator has failed, perform a Function Test. 1. -

Page 124: Salinity Probe

c. Feed Water may be exiting the Product Water Line, resulting in lower than normal Brine Water Flow. Abnormalities that would allow Feed Water to bypass into the Product Water Line include the following: the RO Membrane Element is not installed; the RO Membrane Element is damaged allowing brine water to mix with product water;... -

Page 125: System Main Controller Update As Of 10/30/2017

SYSTEM MAIN CONTROLLER UPDATE AS OF 10/30/2017... -

Page 126: System Fault Error Messages

Aqua Matic Compact 450-1800... - Page 127 Salinity sensor fault detected. Possible sensor failure. Only manual mode permitted. Product flow sensor fault detected. Possible sensor failure. By-pass to continue.

- Page 128 Brine flow sensor fault detected. Possible sensor failure. By-pass to continue. High pressure pump inlet pressure low. Please check filtration for high fouling. High pressure pump inlet pressure high. Pump damage can occur if started. HP pump inlet sensor in by-pass & HP pump outlet pressure low.

- Page 129 HP pump outlet exceeded maximum permissible pressure. System stopped. HP pump outlet sensor in by-pass & brine flow low. Possible cavitation. Brine flow low during manual operation. Possible pump cavitation. Brine flow low during fresh water flush. Possible loss of feed supply.

- Page 130 Operation requested in feed water warmer than system temperature specifications. Operation requested in feed water colder than system temperature specifications. Aqua Matic Compact 450-1800...

- Page 132 Extended delay in production of potable water. Check settings & feed water quality. Aqua Matic Compact 450-1800...

-

Page 135: Chapter 9: Glossary

Chapter Glossary Terms Cascading Failure A failure in a system of interconnected parts in which the failure of a part can trigger the failure of successive parts. Boundary Layer (Also known as Concentration Polarization.) When water permeates through the membrane, nearly all the salt is left behind in the brine channel. - Page 136 the feed water channel between the membrane envelopes. A wrap is applied to the membrane element to maintain the cylindrical configuration. The center tube is also the permeate (product water) collecting channel. Several elements may be connected in series within a single or multiple pressure vessels). Water Temperature Effect The product water flow through the membrane is significantly affected by the water temperature.

-

Page 137: Chapter 10: Appendix

Chapter Appendix... -

Page 143: Single-Phase Electrical Motor Wiring

Appendix Single-Phase Electrical Motor Wiring... -

Page 144: Three-Phase Electrical Motor Wiring

Three-Phase Electrical Motor Wiring Aqua Matic Compact 450-1800... -

Page 145: Three Phase Transformer Wiring

Appendix Three Phase Transformer Wiring... -

Page 146: New System Initial Readings Form

New System Initial Readings Form Aqua Matic Compact 450-1800... -

Page 147: Daily System Readings

Appendix Daily System Readings... -

Page 149: Chapter 11: Exploded Parts Views

Chapter Exploded Parts Views... -

Page 150: Pre-Installation Matrix Drawing

Pre-Installation Matrix Drawings Aqua Matic Compact 450-1800... - Page 151 Figure 1: Standard Filter Exploded Parts View...

- Page 152 Figure 2: Standard Filter with UV Sterilizer Aqua Matic Compact 450-1800...

- Page 153 Figure 3: Standard Filter with Plankton Filter Exploded Parts View...

- Page 154 Figure 4: Commercial Pre-filter (CFP) with Oil/Water Separator (OWS) Aqua Matic Compact 450-1800...

- Page 155 Exploded Parts View Figure 5: Commercial Pre-filter (CFP) with UV Sterilizer...

- Page 156 Figure 6: Commercial Pre-filter (CFP) with Plankton Filter Aqua Matic Compact 450-1800...

- Page 157 B001990001 INSTALLATION KIT AQUA SERIES UNITS ITEM NO. QTY. PART NUMBER DESCRIPTION 0112652500 ADAP 1/2 MNPT X 1/2 BARB NYLON 01126526DG ADAP 1/2 MPT X 3/4 BARB NYLON 0112653700 ADAP 3/4 MPT X 3/4 BARB NYLON 0204020869 ELB90 1/4 TUBE X 1/4 MPT PLAST 0204021969 ELB90 3/8 TUBE X 1/2 MPT PLAST 20 ft.

- Page 158 B006080002 SEA STRAINER ASSY 3/4-B ITEM NO. QTY. PART NO. DESCRIPTION B006080002 SEA STRAINER ASSY 3/4-B (INCLUDES P/N 2-7) 0101073783 ELB90 .75 MNPT X .75 BARB PVC 05181434AA HOSE CLAMP 3/4" SS 0421051239 SEA STRAINER-3/4 BRONZE 0421051239-1 SIGHT GLASS 0421051239-7 BASKET MONEL 0421051239-2 O-RING, LID SEA STRAINER...

- Page 159 B008800001 PLANKTON FILTER ASSY-AW SINGLE ITEM NO. QTY. PART NO. DESCRIPTION B008800001 PLANKTON FILTER ASSY-AW SINGLE (INCLUDES P/N 2-7) 05181434AA HOSE CLAMP 3/4" SS 0805823578 ELEMENT PLANKTON 0101073783 ELB90 .75 MNPT X .75 BARB PVC 20200402102 SINGLE FILTER BRACKET 0713020473 FILTER HOUSING-LID .75 X 10 ASM 2614010473 O-RING 237 BLUE HOUSING...

- Page 160 B008800002 PLANKTON FILTER ASSY-AW DOUBLE ITEM NO. QTY. PART NO. DESCRIPTION 0713020473 FILTER HOUSING/LID 3/4 X 10 01013737CL NIPPLE 3/4 NPT X CLOSE PVC "S 0101423783 TEE 3/4 FT X 3/4 FT X 3/4 FT P 0101653783 ADAP 3/4 MPT X 3/4 BARB PVC 0101013783 ELB90 3/4 FPT X 3/4 FPT PVC 0101073783...

- Page 161 B016080026 BOSTR PMP ASY 110-230-50-60-1P BILL OF MATERIAL (B.O.M.) ITEM NO. FILE/DWG. NAME DESCRIPTION QTY. 1221515772-1 BOOSTER PUMP VOLUTE N200 1221515772-2 MOTOR MOUNTING BRACKET 1221515772-3 SEAL BOOSTER PUMP HEAD 29121181PP IMPELLER 1519081110 MOTOR .50 HP 110-230-50-60-1PH 1920023632 STRAIN RELIEF 90 CG90-6250 01120737DG ELB90 0.75 MPT x BARB NYLON 0112653700...

- Page 162 RECOMMENDED SPARES: QTY. PART NUMBER DESCRIPTION B655800009 SEAL KIT BOOSTER PMP N200 B655800012 SEAL KIT BOOSTER PMP N200/HP75 291211181PP IMPELLER 4.8 N200 B016080026 BOSTR PMP ASY 110-230-50-60-1P...

- Page 163 B016080027 BOSTR PMP ASY 208-460-50-60-3P BILL OF MATERIAL (B.O.M.) ITEM NO. FILE/DWG. NAME DESCRIPTION QTY. 1221514722-3 BRACKET,MTG,PUMP,BOOSTER 1221515772-1 BOOSTER PUMP VOLUTE N200 1221515772-2 MOTOR MOUNTING BRACKET 1221515772-3 SEAL BOOSTER PUMP HEAD 29121181PP IMPELLER 1520181110 MOTOR .50 HP 208-230-460-50-60 1920023632 STRAIN RELIEF 90 CG90-6250 01120737DG ELB90 0.75 MPT x BARB NYLON 0112653700...

- Page 164 RECOMMENDED SPARES: QTY. PART NUMBER DESCRIPTION B655800009 SEAL KIT BOOSTER PMP N200 B655800012 SEAL KIT BOOSTER PMP N200/HP75 291211181PP IMPELLER 4.8 N200 B016080027 BOSTR PMP ASY 208-460-50-60-3P...

- Page 165 B075000001 MULTI MEDIA FILTER PLUMBING ASSY ITEM NO. PART NO. DESCRIPTION 05180851CC GAUGE BRACKET CBM SS 0101693783 UNION .75 SL x .75 SL PVC 0101673783 UNION .75 FNPT x .75 FNPT PVC 14011317AR VALVE 3-WAY BALL .75 SL 0101652683 ADAP 1/2 MPT X 3/4 BARB PVC 0204020869 ELB90 1/4 TUBE X 1/4 MPT PLAST 05181434AA...

- Page 166 B071080002 MEDIA FILTER ASSY -4 HS/AW/UW ITEM NO. PART NO. DESCRIPTION 0708040468-1 MEDIA FILTER HOUSING 818 ALMOND 20200404010 BRACKET L"" MOUNTING FEET 20200325000 SKID MEDIA FILTER AS>7/97 061100043000 WASHER FLAT OS 1/4"SS 061060045000 NUT HEX 1/4-20 W/INSERT SS 05180851CC GAUGE BRACKET CBM SS 0204010869 ELB90 1/4 TUBE X 1/4 FPT PLAST 061142145012...

- Page 167 MEDIA SAND #A1000 25 POUNDS MEDIA GARNET 8-12 17 POUNDS...

- Page 168 Oil/Water Separator Elements). Use only Sea Recovery supplied Prefiltration Elements. Third party prefiltration elements on the market do not properly fit into the Sea Recovery Filter Housings, the seams fall apart, and they will allow by-pass resulting in EXTENSIVE AND EXPENSIVE DAMAGE TO THE HIGH PRESSURE PUMP AS WELL AS PREMATURE FOULING OF THE R.O.

- Page 169 B108140001 PREFILTER DUAL AQM II Caution: Do not use third-party pre-filtration components! Use only Sea Recovery Corporation pre-filtration components. Third-party pre-filtration components do not fit properly, thus causing the seams to fall apart. They also allow bypass, which results in extensive damage to the High Pressure Pump, as well as to premature fouling of the RO Membrane Element.

- Page 170 Aqua Matic Compact 450-1800...

- Page 171 B109120001 COMMERCIAL PREFILTER ASSY 32.5 SQ FT SRC AQM ITEM NO. PART NO. DESCRIPTION B109120001 COMMERCIAL PREFILTER ASSY 32.5 SQ FT (INCLUDES P/N 2-11) 2614018969 O-RING 034 FOR COMMERCIAL FILTER 3901040100 ADAPTER SPACER RING 0204020100 ELB90 .25 TUBE JQ x .25MNPT 0204990300 PLUG 1/4 JQ 05181434AA...

- Page 172 B111120001 OIL/WATER SEPARATOR ASSY SRC 32.5 SQ FT ITEM NO. PART NO. DESCRIPTION B111120001 OIL / WATER SEPARATOR ASSY SRC 32.5 SQ FT (INCLUDES P/N 2-9) 08020723KD ELEMENT OWSE 32.5 SQFT 0101653783 ADAP 3/4 MPT X 3/4 BARB PVC 05181434AA HOSE CLAMP 3/4"...

- Page 173 B114140001 PH NEUTRALIZER / CHARCOAL DUAL AQMC II / MOD ITEM NO. QTY. PART NO. DESCRIPTION B114140001 PH NEUTRALIZER / CHARCOAL DUAL AQMC II / MOD (INCLUDES P/N 2-9) 0713020573 FILTER HOUSING/LID 3/8 X 10 20200402101 DUAL BRACKET, PRE-FILTER, CHRCL/PLNKTN 08251950AS ELEMENT PH 9 3/4"...

- Page 174 B156140001 HP PUMP / MOTOR ASSY AQMCII APP ITEM NO. QTY. PART NO. DESCRIPTION B156140001 HP PUMP MOTOR ASSY 1 PHASE (INCLUDES P/N 2-24) 15AE261912 MOTOR 3/2.5 HP 115/230 1PH 12572405DS HPRA PUMP 4.37 GPM (CP) 1317021869 ELB90 -6 FLARE X 3/4 UNF SS 12207602RW COUPLER TX1 AQM2 061120091000...

- Page 176 B156140002 HP PUMP / MOTOR ASSY AQMCII APP 3PH ITEM NO. QTY. PART NO. DESCRIPTION B156140002 HP PUMP / MOTOR ASSY AQMC II 3PH (INCLUDES P/N 2-24) 15AF271910 MOTOR 3/2.5 HP 3 PH AQM 50/6 12572405DS HPRA PUMP 4.37 GPM (CP) 1317021869 ELB90 -6 FLARE X 3/4 UNF SS 12207602RW...

- Page 178 B156140003 HP PUMP/MOTOR ASSY AQMCII PLGR 110/220/5/6/1PH (Standard) ITEM NO. PART NO. DESCRIPTION B156140003 HP PUMP MOTOR ASSY AQMC II PLGR 110/220/5/6/1PH (INCLUDES P/N 2-21) 15AC062412 MOTOR 2.5 HP 50/60 110/220 061142157016 BOLT HEX 3/8-16 X 1 SS 061080056000 WASHER FLAT 3/8" SS 061142150016 BOLT HEX 5/16-18 X 1.0LG SS 061060050000...

- Page 180 B156140004 HP PUMP/MOTOR ASSY AQMCII PLGR 220/440/60/3PH ITEM NO. PART NO. DESCRIPTION B156140004 HP PUMP MOTOR ASSY AQMC II PLGR 220/440/60/3PH (INCLUDES P/N 2-21) 061142157016 BOLT HEX 3/8-16 X 1 SS 061080056000 WASHER FLAT 3/8" SS 061142150016 BOLT HEX 5/16-18 X 1.0LG SS 061060050000 HEX NUT 5/16-18 W/INSERT SS 061100049000...

- Page 182 B156140006 HP PUMP/MOTOR PLGR AQMCII 110/220/6/1 SMALL 60 ITEM NO. PART NO. DESCRIPTION B156140003 HP PUMP MOTOR PLGR AQMC II 110/220/6/1SMALL 60 HZ (INCLUDES P/N 2-21) 15AD062412 MOTOR 2.1 HP 50/60 110/220 061142157016 BOLT HEX 3/8-16 X 1 SS 061080056000 WASHER FLAT 3/8"...

- Page 184 B198000032 MEMBRANE RACK 450-1 ITEM NO. PART NO. DESCRIPTION 2408132500 VESSEL HIGH PRESSURE 450GPD 2724011233 MEMBRANE 450GPD W-SEAL 0520210600 RETAINER PORT MVA AW 2614014900 O-RING 230 BRINE 3" END PLUG 2614010100 O-RING 116 PRODUCT 0101370820 NIPPLE .25 NPT X 2.0 PVC 2453512402 END PLUG DUAL 3"...

- Page 186 B198000033 MEMBRANE RACK 700-1 ITEM NO. QTY. PART NO. DESCRIPTION 2408132500-01 VESSEL HIGH PRESSURE 700GPD 2724011333 MEMBRANE 700GPD W-SEAL 0520210600 RETAINER PORT MVA AW 2614014900 O-RING 230 BRINE 3" END PLUG 2614010100 O-RING 116 PRODUCT 0101370820 NIPPLE .25 NPT X 2.0 PVC 2453512402 END PLUG DUAL 3"...

- Page 188 B198000034 MEMBRANE RACK 900-1 ITEM NO. QTY. PART NO. DESCRIPTION 2408132500-02 VESSEL HIGH PRESSURE 900GPD 2724011433 MEMBRANE 900GPD W/SEAL 0520210600 RETAINER PORT MVA AW 2614014900 O-RING 230 BRINE 3" END PLUG 2614010100 O-RING 116 PRODUCT 0101370820 NIPPLE .25 NPT X 2.0 PVC 2453512402 END PLUG DUAL 3"...

- Page 190 B198000035 MEMBRANE RACK 900-2 ITEM NO. QTY. PART NUMBER DESCRIPTION 2408132500 VESSEL HIGH PRESSURE 450GPD 2724011233 MEMBRANE 450GPD W-SEAL 0520210600 RETAINER PORT MVA AW 2614014900 O-RING 230 BRINE 3" END PLUG 2614010100 O-RING 116 PRODUCT 0101370820 NIPPLE .25 NPT X 2.0 PVC 2453512402 END PLUG DUAL 3"...

- Page 192 B198000036 MEMBRANE RACK 1400-2 ITEM NO. QTY. PART NO. DESCRIPTION 2408132500-01 VESSEL HIGH PRESSURE 700GPD 2724011333 MEMBRANE 700GPD W-SEAL 0520210600 RETAINER PORT MVA AW 2614014900 O-RING 230 BRINE 3" END PLUG 2614010100 O-RING 116 PRODUCT 0101370815 NIPPLE 1/4 NPT X 1 1/2 PVC 2453512402 END PLUG DUAL 3"...

- Page 194 B198000037 MEMBRANE RACK 1800-2 ITEM NO. QTY. PART NO. DESCRIPTION 2408132500-02 VESSEL HIGH PRESSURE 900GPD 2724011433 MEMBRANE 900GPD W/SEAL 0520210600 RETAINER PORT MVA AW 2614014900 O-RING 230 BRINE 3" END PLUG 2614010100 O-RING 116 PRODUCT 0101370815 NIPPLE 1/4 NPT X 1 1/2 PVC 2453512402 END PLUG DUAL 3"...

- Page 196 B476160002 BACK PRESSURE REGULATOR ASSY ITEM NO. QTY. PART NO. DESCRIPTION B476160002 BACK PRESSURE REGULATOR ASSY AQMC II (INCLUDES P/N 2-8) 1417017896 VALVE PRESS REGULATOR-AS B079400004 BPR GEAR ASSY AQM II 0117230819 ELB90 ST 1/4 MPT X 1/4 FPT SS 0204022369 ELB90 1/2 TUBE X 1/4 MPT PLASTIC 1317011769...

- Page 197 B480160002 WET PLATE ASSY AQMC III ITEM PART NUMBER DESCRIPTION B476160004 BPR CONNECTION, AQMXL,ASSY 14012007 MAMANIFOLD, AQM 1-4 DV, NYL, PRESS, LOW, 6X1.5X3 14012044 MANIFOLD, PROB, NYL, PRESS, LOW, 6X1.5X2 11026520AO Turbo-Flowmeter 11026920AO FLOWMETER IN-LINE .53-7.9GPM 1401096100 VALVE SOLENOID 12VDC 20-4096 PROBE, CONDUCTIVITY, 5-WIRE, 5 LONG CABLE 2020083900...

- Page 198 B502160001 MANIFOLD ASSY AQMC / AQW DX RADIAL AXIAL PUMP ITEM NO. QTY. PART NO. DESCRIPTION B502160001 MANIFOLD ASSY AQMC / AQW DX DX (INCLUDES P/N 2-6) 5301400801 MANIFOLD LP PICKUP, AQM II 2317100200 TRANSDUCER 0-200 PSI 7/16" SAE 01126526DG ADAP 1/2 MPT X 3/4 BARB NYLON 0117349400 PLUG .43-20 SS BOSS...

- Page 199 B502160002 MANIFOLD LP ASSY AQMC/AQW DX GP PUMP ITEM NO. QTY. PART NO. DESCRIPTION B502160002 MANIFOLD LP ASSY AQMC / AQW DX (INCLUDES P/N 2-5) 2317100200 TRANSDUCER 0-200 PSI 7/16" SAE 01126526DG ADAP 1/2 MPT X 3/4 BARB NYLON 5301400801 MANIFOLD LP PICKUP, AQM II 0204090869 CONN 1/4 TUBE X 1/4 MPT PLASTIC...

- Page 200 B5262000CV UV STERILIZER 12VDC 2GPM BILL OF MATERIAL (B.O.M.) ITEM NO. FILE/DWG. NAME DESCRIPTION QTY. 40000306CV UV STERILIZER 2 GPM 12VDC 05011647AI SUPPORT,PIPE,2.00 0204091869 FITTING,PP,3/8 ODx3/8 MT 0254011000 ELB90 0.25 MPT X 0.50BARB NY 05181432AA CLAMP,HOSE,SS,1/2" 061100043000 WASHER FLAT OS .25 SS 061142145020 SCREW,HEX HEAD,.25-20x1-1/4",SS 061182143024...

- Page 201 B591120001 CLEAN AND RINSE KIT ITEM NO. QTY. PART NUMBER DESCRIPTION 14011334AR VALVE 3-WAY BALL 3/4 MPT 0101063783 ELB90 .75 FNPT X .75 BARB PVC 0501164200 PIPE SUPPORT 1 1/8" #36 0101613783 ADAP 3/4 FPT X 3/4 BARB PVC 05181434AA HOSE CLAMP 3/4"...

- Page 202 61012017 KIT, CON RL,HMI,7 IN, AQMC-AWDXC BILL OF MATERIAL (B.O.M.) ITEM PART NUMBER DESCRIPTION 90012013 BOARD,CONTROLLER,5X 7,PLC,PROGRAM&WIFI,PARKER BRAND 90012015 HMI,DISPLAY,7 IN PROGRAMMED 90012289 DONGLE,HMI,RS485,POWER,AQ 90012014 CONVERTER,12V TO 24V,HMI 11012072 BRACKET,FRONT COVER,HMI,AQM 1904010643 STRAIN RELIEF 3444 BLK 061160620006 SC PHIL PAN A #6 X .375 SS 061080018000 WASHER FLAT #6 SS 065080028000...

- Page 203 B598000008 FRESH WATER FLUSH (0.50 INCH) ITEM NO. QTY. PART NO. DESCRIPTION 0713020873 FILTER HOUSING 1/2 X 10" 0803004773 CHARCOAL FILTER 10 IN 14172105AT VALVE CHECK .25 MNPT SS 0204091769 CONN 3/8 TUBE X 1/4 MPT PLASTIC 1401095998 VALVE SOLENOID 12VDC AED/CSFE 0101340883 PLUG 1/4 MPT PVC 3131680298...

- Page 204 Aqua Matic Compact 450-1800...

- Page 205 B610140004 NMEA 2000 ENABLED ITEM NO. QTY. PART NO. DESCRIPTION 31316809MT MICRO CAP 31316801MT MICRO BULKHEAD FEED-THRU ASSY 31316812MT MICRO SINGLE ENDED CORDSET MALE Exploded Parts View...

- Page 206 61012029 REMOTE KIT, 100FT CABLE, PARKER BILL OF MATERIAL (B.O.M.) ITEM PART NUMBER DESCRIPTION 0901128 REMOTE CABLE ASSY 100' AQM 7IN 11012072 BRACKET,FRONT COVER,HMI,AQM 90012014 CONVERTER,12V TO 24V,HMI 90012015 HMI,DISPLAY,7 IN PROGRAMMED 90012289 DONGLE,HMI,RS485,POWER,AQ 061060020000 NUT,HEX 6-32 W-INSERT SS 061080018000 WASHER FLAT #6 SS 061080028000 WASHER FLAT #10 SS...

- Page 207 61012030 REMOTE KIT, 200FT CABLE, PARKER BILL OF MATERIAL (B.O.M.) ITEM PART NUMBER DESCRIPTION 0901130 REMOTE CABLE ASSY 200' AQM 7IN 11012072 BRACKET,FRONT COVER,HMI,AQM 90012014 CONVERTER,12V TO 24V,HMI 90012015 HMI,DISPLAY,7 IN PROGRAMMED 90012289 DONGLE,HMI,RS485,POWER,AQ 061060020000 NUT,HEX 6-32 W-INSERT SS 061080018000 WASHER FLAT #6 SS 061080028000 WASHER FLAT #10 SS...

- Page 208 61012032 REMOTE KIT, 200FT CABLE, PARKER 4 INCH HMI BILL OF MATERIAL (B.O.M.) ITEM PART NUMBER DESCRIPTION 0901130 REMOTE CABLE ASSY 200' AQM 7IN 11012164 BEZEL4INCH NEW REMOTE HMI 90012014 CONVERTER,12V TO 24V,HMI 90012016 HMI,DISPLAY,4.3" PROGRAMMED 90012289 DONGLE,HMI,RS485,POWER,AQ 061060020000 NUT,HEX 6-32 W-INSERT SS 061080018000 WASHER FLAT #6 SS 061080028000...

- Page 209 SOFT START ASSY B596800015 SOFT START 115V 50-60HZ B596800014 SOFT START 230V 50-60HZ...

- Page 210 B619160001 CONTROLLER CHASSIS AQMC II 1PH ITEM NO. QTY. PART NO. DESCRIPTION 31310603BF CONTACTOR 30A AW>12/99 12VDC 31314301CW POWER SUPPLY 12V DC 31310110BF CONTACTOR 9A AUX AW>12/99 12VD 3131310400 FUSE HOLDER 3131301500 FUSE QUICK BLOW 2A 31311523DM TERMINAL BLOCK 31318301DK EMI FILTER 31311524DM TERMINAL 8 AWG DIN GREEN...

- Page 211 B619160002 CONTROLLER CHASSIS AQMC II 3PH ITEM NO. QTY. PART NO. DESCRIPTION 31310603BF CONTACTOR 30A AW>12/99 12VDC 3131131500 ELEC TRANSFORMER 480/120 BUCK 31314301CW POWER SUPPLY 12V DC 31310110BF CONTACTOR 9A AUX AW>12/99 12VD 3131310400 FUSE HOLDER 31311523DM TERMINAL BLOCK 31311524DM TERMINAL 8 AWG DIN GREEN 3131301500 FUSE QUICK BLOW 2A...

-

Page 213: Chapter 12: Electrical Diagrams (Foldouts)

Chapter Electrical Diagrams - Foldouts... - Page 214 PT-Pressure Transducer PI-Pressure Indicator M-Meter FG-Flow Gauge TDS-TDS Meter P-Pump PLC-Program Logic Controller Commercial P&ID...

- Page 218 ELECTRICAL UPDATE AS OF 10/30/2017...

- Page 223 Part Number: B651140001 Sea Recovery Corporation P.O. Box 5288 • Carson, CA 90745-5288 • sales@searecovery.com www.searecovery.com...

Need help?

Do you have a question about the SRC Aqua Matic 700-1 and is the answer not in the manual?

Questions and answers