Fromm FS360 Series Service Manual

Semi-automatic wrapping machine

Hide thumbs

Also See for FS360 Series:

- Assembly and using manual (31 pages) ,

- Assembly instruction manual (38 pages)

Table of Contents

Advertisement

FROMM

SERVICE MANUAL FS360_EN01 Version00.doc

FROMM

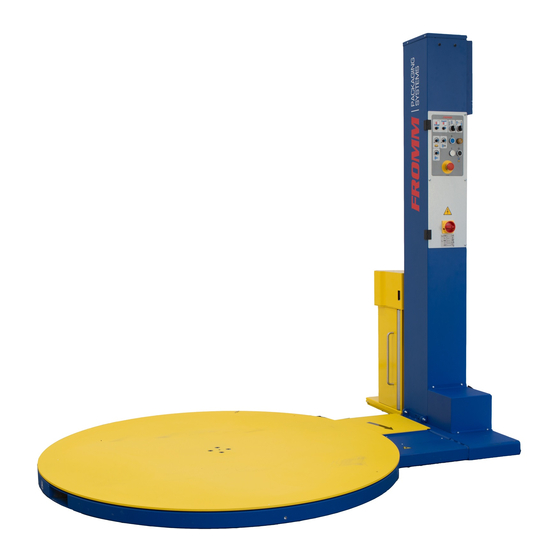

Semi-Automatic

WRAPPING MACHINE

FS360 Series

SERVICE MANUAL

V01

1

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author's authorisation © 2018

Advertisement

Table of Contents

Summary of Contents for Fromm FS360 Series

- Page 1 SERVICE MANUAL FS360_EN01 Version00.doc FROMM Semi-Automatic WRAPPING MACHINE FS360 Series SERVICE MANUAL For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 2: Table Of Contents

Alarms (Error Codes and their meanings) Maintenance Instructions Machine decommissioning Warranty conditions For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 3 Tutustukaa huolellisesti käyttöohjeeseen ennen laitteen asennusta jä käyttöönottoa. Näin vältytte mahdollisilta vahingoilta käyttäes-sänne konetta. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 4 Or download directly from our website: http://www.fromm-stretch.com Or contact your Fromm Distributor. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 5: Ec Declaration Of Conformity

UNI EN 415-6-2013 UNI EN415-10:2014 01/01/2018 Name: Mr. Reinhard Fromm Function: Legal Representative For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... -

Page 6: Identification Plate

If the identification plate should become damaged for any reason, immediately contact the MANUFACTURER. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... -

Page 7: Machine Data

Manufactured by Distributed by Date UNITS Operating Panel Turntable Mast Carriage For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... -

Page 8: General Information

For any problems, contact: SPARE PARTS The spare parts can be ordered from: For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 9 The power supply must comply with the applicable standards in terms of voltage variations allowed, voltage fluctuation, generation of waves, reduction of high harmonics, etc. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 10 DIMENSIONS / DIAGRAM Refer to the following diagram for the dimensions: For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 11: Safety Instructions

The following conditions must always be met unless otherwise indicated in other instructions in this manual. This wrapping machine has been supplied by FROMM WRAPPING SYSTEMS and can be used only to wrap pallets that meet the requirements indicated in the description of the machine in the TECHNICAL DATA chapter. - Page 12 The safety devices must not be bypassed or turned off. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 13 There is an acoustic signal device installed in the control cabinet that activates briefly, as a warning, before the machine is operated. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 14: Analysis Of Residual Risks

Slipping, tripping and falling: Pay attention to the product loading operations. Carefully follow the operating procedures in the user and maintenance manual. Maintenance operations: the maintenance operations must be performed only by FROMM ASSISTANCE SERVICE specialists. Keep device pressed (optional): the residual risk is associated with the risk of being crushed between the turntable and the product and between the carriage and the bottom part of the machine. - Page 15 Check that the machine stops within a few fractions of a second. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 16: Warnings

Fig 7 It is important that the guidelines are carefully observed. Machine operators could otherwise be at risk, the consequence of which could make the warranty null and void with no chance of claiming from FROMM WRAPPING SYSTEMS. Figure 8: Operations that must not be performed. - Page 17 E = Parachute system C = Main switch R= Reactivation button For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 18 E = Parachute system For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 19 The machine’s function is to wrap pallets with stretch film, which is through rotation of the disk and movement of the carriage up and down the column For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 20 If you have to work with products of a different type than previously indicated, contact the MANUFACTURER’S technical assistance service to receive written authorisation. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 21: Caution

The machine must never be stacked and does not support external loads. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... -

Page 22: Safety Devices

The power supply must comply with the applicable standards in terms of voltage variations allowed, voltage fluctuation, generation of waves, reduction of high harmonics, etc. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... -

Page 23: Installation Instructions

Fig.2 (Example FS machine) Fig.3 Fig.4 Fig.6 Adjustment (on the floor) Fig.5 For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 24 (R). (pulling it towards movement; you). manual movement up. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 25 SERVICE MANUAL FS360_EN01 Version00.doc INSTALLATION INSTRUCTIONS Assembly CUTTING Device FS360 for FIRST INSTALLATION: For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 26: First Check

Start the machine and, during rotation, place a mechanical block in position 2. (Fig.2). The machine must stop in emergency. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 27 When the machine is switch off or alarms (safety) occurred the contactor it is in “O”. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 28: Functions Control

11. Check the functionality of Potentiometers (Fig. 1) and selectors (Fig. 2 / 3) Fig.2 Fig.3 Fig.1 For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 29 Stretch film carriage (available only with carriage pre-stretch). Potentiometer for adjusting tension film carriage. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 30 Carriage with one roll brake Fig.1 Fig.2 Carriage with one motor pre-stretch fixed Fig.1 Fig.2 For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 31 “fault” that triggered the Error has been solved. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 32 (This condition will only happen when the machine will be completely stopped). For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 33 Automatic wrapping only up with carriage auto return t the end of the cycle; Manual wrapping. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 34 Stretch film carriage (available only with carriage pre-stretch). Potentiometer for adjusting stretch film carriage. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 35 10 seconds For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 36: Errors During Operation

Fig.1 If the problem persists, contact the company’s after-sales customer service For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 37 Fig.3 If the problem persists, contact the company’s after-sales customer service For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 38 The door is open The bracket is pressed The doors are open For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 39 “O”. If the problem persists, contact the company’s after-sales customer service For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 40 Check the voltage to the micro switches that normally work closed. Replace the micro switches. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 41 Check that the cables/connections arrive at the board. Photocell malfunction Replace the photocell For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 42 "TimeOutTable" (time> = 60 s). To reset the error, press Reactivation button. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 43 (R). (pulling it towards movement; you). manual movement up. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 44: Maintenance Instructions

Check there are no film or packaging residues in the brake system, if there are remove them. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... - Page 45 If the disk has clearance on the central bearing then the bolts must be locked; Carefully secure the disk with lock tide no. 243. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 46 Check the conditions of wear of the carriage unit’s wheels; (Fig.5) Fig.2 Fig.1 Fig.3 Fig.4 Fig.5 For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 47 Remove the rollers, check them and then reassemble all using the specific tools (1) (Fig.1). Fig.2 Fig.3 Fig.1 For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 48 Check the conditions of wear of the spring (7). Replace if necessary (Fig. 3). Fig.1 Fig.2 Fig 3 For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

- Page 49 The “X” symbol in the maintenance diagram indicates the notes regarding maintenance or check of the parts or of the system. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018...

-

Page 50: Machine Decommissioning

MUST BE DISPOSED OF BY SPECIALISED COMPANIES THAT OPERATE IN COMPLIANCE WITH THE LAWS IN FORCE IN THE USER’S COUNTRY. For further updates, see our website www.fromm-stretch.com and Login! It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018... -

Page 51: Warranty Conditions

FROMM distributor to the end customer. The warranty is valid for a period of 24 months, with machine use of 8 hours per day, 40 hours per week. The warranty includes all materials or defects from FROMM. The warranty excludes: consumable pieces;...

Need help?

Do you have a question about the FS360 Series and is the answer not in the manual?

Questions and answers