Subscribe to Our Youtube Channel

Summary of Contents for Festo MPA-S

- Page 1 Valve terminal MPA-S Pneumatic components description Valve terminal with MPA-S pneumatics Type: MPA-FB MPA-CPI MPA-MPM-… and MPA-ASI-… 534241 1309f [8028624]...

- Page 2 Essential or useful accessories. Information on environmentally sound usage. Text designations: • Activities that may be carried out in any order. 1. Activities that should be carried out in the order stated. – General lists. Festo – P.BE-MPA-EN – 1309f –...

- Page 3 General instructions on mounting and dismantling ....... Festo – P.BE-MPA-EN – 1309f – English...

- Page 4 ..........3.8.1 Load voltage supply via electrical supply plate (only for MPA-S valve terminal with CPX terminal or CPI interface) .

- Page 5 ..........5.4.4 Adding an electric supply plate (only for MPA-S valve terminal with CPX terminal or CPI interface) .

- Page 6 ........Separating the MPA-S valve terminal from the CPX terminal .

- Page 7 Instructions on this documentation This documentation serves the purpose of ensuring safe work with the MPS-S valve terminal and con- tains specific information on mounting, installing, commissioning, servicing and converting the MPA-S valve terminal. It covers only the description of the pneumatic components.

- Page 8 (You will find an overview of the descriptions in the system description of your CPX terminal.) MPA-S with respective package insert – multi-pin plug connection – CPI interface – AS-interface Tab. 1 Documentation for the MPA-S valve terminal Festo – P.BE-MPA-EN – 1309f – English...

-

Page 9: Table Of Contents

........Festo – P.BE-MPA-EN – 1309f – English... -

Page 10: Safety

• Observe the handling specifications for electrostatically sensitive devices. 1.1.2 Intended use The valve terminal MPA-S is intended for installation in machines or automated systems and may be used only as follows: – in excellent technical condition, – in original status without unauthorised modifications, –... -

Page 11: Requirements For Product Use

Appendix A). The product-relevant EU directives can be found in the declaration of conformity. Certificates and the declaration of conformity for this product can be found at www.festo.com. The product fulfils the requirements of EU directives and is marked with the CE certification. Festo – P.BE-MPA-EN – 1309f – English... -

Page 12: Instructions On This Description

Instructions on this description This description contains specific information on mounting, installing, commissioning, servicing and converting the MPA-S valve terminal. It includes only the description of the pneumatic components. Information on the electrical/electronic components can be found for: – MPA-S with CPX terminal: in the description on the respective CPX module. - Page 13 ........2.6.3 Proportional-pressure regulator with LCD display ......Festo – P.BE-MPA-EN – 1309f – English...

-

Page 14: The Mpa-S Valve Terminal

– The MPA-S valve terminal has a lower energy consumption – The power unit for the voltage supply to the MPA-S valve terminal can be designed more economic- ally depending on the individual case – The solenoid coils have lower power loss and produce less waste heat. -

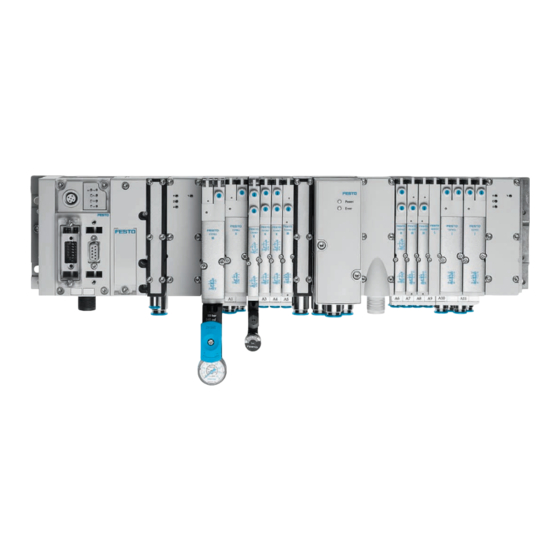

Page 15: Overview Of Variants

2) A max. of 64 solenoid coils can be supplied. 3) A max. of 128 solenoid coils can be supplied. Tab. 2.1 Number of valve locations of the MPA-S valve terminal with CPX terminal Fig. 2.1 MPA-S valve terminal with CPX terminal... - Page 16 2) A max. of 24 solenoid coils can be supplied. 3) A max. of 32 solenoid coils can be supplied. Tab. 2.2 Number of valve positions of the MPA-S valve terminal with CPI interface Fig. 2.2 MPA-S valve terminal with CPI interface...

- Page 17 1) A maximum of 24 solenoid coils can be actuated. The electrical connection of the solenoid coils is made centrally via the multi-pin plug. Tab. 2.3 Number of valve positions of the valve terminal MPA-S with multi-pin plug connection Fig. 2.3 Valve terminal MPA-S with multi-pin connection Festo –...

- Page 18 1) A max. of 4 solenoid coils can be supplied. 2) A max. of 8 solenoid coils can be supplied. Tab. 2.4 Number of valve positions of the MPA-S valve terminal with AS interface The maximum number of valve positions which can be controlled is dependent on the electronic module: –...

-

Page 19: Valve Terminal Design

Overview Valve terminal design The MPA-S valve terminal consists of the following pneumatic and electrical components. The most important components are shown in the following figure ( Fig. 2.5). Flat plate silencer or exhaust plate Right end plate Blanking plate... -

Page 20: Description Of Components

Overview Description of components The MPA-S valve terminal with CPX terminal or CPI module consists of the following pneumatic compon- ents: Only for MPA-S with CPX terminal: Inscription label with support Only for MPA-S with CPX terminal: LED/LCD Sub-base with working ports and serial... - Page 21 Exhaust plate (3/5) or flat plate silencer Vertical pressure shut-off plate Electronic module with LEDs Pressure regulator plate Valve or blanking plate Fig. 2.7 Components of the MPA-S valve terminal with CPX terminal or CPI module, 2nd level Festo – P.BE-MPA-EN – 1309f – English...

- Page 22 Overview The MPA-S valve terminal with electric multi-pin or AS interface consists of the following pneumatic components: Right end plate Manifold block with working lines and Pneumatic air supply plate electrical interlinking module Inscription label with support Seal (optionally separating seal for forming pressure zones) Fig.

- Page 23 Exhaust plate (3/5) or flat plate silencer Vertical pressure shut-off plate Valve or blanking plates Pressure regulator plate Electronic module with LEDs Fig. 2.9 Components of the MPA-S valve terminal with electric multi-pin or AS interface, 2nd level Festo – P.BE-MPA-EN – 1309f – English...

-

Page 24: Sizes

– MPA1: width 10 mm – MPA2: width 20 mm 2.4.2 Valves The MPA-S valve terminal can be equipped with 2x 2/2-way valves, 2x 3/2-way valves, 5/2-way valves (monostable and impulse), 5/3-way valves and proportional-pressure regulators. Festo – P.BE-MPA-EN – 1309f – English... - Page 25 – Vacuum operation at –0.9 … 0 bar Identification of the valves The valves of the MPA-S valve terminal are marked by identification codes. By means of this identifica- tion on the top of the valve, you can ascertain the equipment of your MPA-S valve terminal.

-

Page 26: Proportional Pressure Regulator

Identification of the proportional pressure regulator The proportional pressure regulators on the MPA-S valve terminal are marked by identification codes. With this identification, you can ascertain the type of proportional pressure regulator. Festo – P.BE-MPA-EN – 1309f – English... -

Page 27: Pressure Sensor Plate

An additional LED indicates common errors. The MPA-S valve terminal can be equipped with up to 4 pressure sensor plates. The limits for pressure monitoring are set through parameterisation. The pressure sensor plate can be parameterised via the PLC or the Festo Handheld (CPX-MMI). -

Page 28: Pressure Zone Separation

Pressure zone separation of the pilot channels (12/14) and (82/84) is not intended, as on the MPA-S valve terminal the pilot air supply for pilot control of the valves is supplied centrally via the corresponding electrical interface (pneumatic interface, multiple con- nector plate, AS interface or CPI interface). - Page 29 – Supply duct (1) and exhaust ducts (3) and (5) – Exhaust ducts (3) and (5) only. You can recognize whether your MPA-S valve terminal is equipped with pressure zones, and if so how many, either from the marking notch on the sub-base ( Tab.

- Page 30 Overview Separating seals for MPA-S valve terminals Additional identification of the seals/separating seals for the MPA-S valve terminal with exhaust plates Position of the marking for separating seals MPA-S with flat plate silencer MPA-S with exhaust plate Without marking: seal with open channels...

-

Page 31: Vertical Stacking

Sub-base type MPA...-...-AP-... with electronic module type VMPA...-...EM... 1) Instructions on installing the vertical stacking components chapter 3 Tab. 2.10 Components of the pneumatics module of the MPA-S valve terminal Festo – P.BE-MPA-EN – 1309f – English... - Page 32 VMPA1-HS. Pressure regulator plates The pressure regulator plates of the vertical stacking are marked on the MPA-S valve terminal with the ident. code. This is marked on the side of the pressure regulator plate. You can identify the pressure regulator plate using the following table.

- Page 33 – If different air pressures are required at ports (2) and (4) instead of the operating pressure of the valve terminal. – If the reversible pressure regulator cannot be used. For example, when 2x 3/2-way valves with duc- ted solenoid exhaust (82/84) are used. Festo – P.BE-MPA-EN – 1309f – English...

- Page 34 In the valve, the exhaust flows from the corresponding work channel 3 in Tab. 2.15) to channel (1) and is guided in the pressure regulator plate to the corresponding exhaust channel of the sub-base. Tab. 2.14 Reversible A or B pressure regulator Festo – P.BE-MPA-EN – 1309f – English...

- Page 35 – If the air pressure in channel (2) or (4) is not supposed to be the same as the operating pressure of the valve terminal. – When fast exhausting is required. – When the pressure regulator must always be adjustable. Festo – P.BE-MPA-EN – 1309f – English...

- Page 36 The regulated pressure is switched to channel (2) inside the valve. The unregulated exhaust air is switched inside the valve from channel (4) to channel (1) and then in the pressure regulator plate to channel (3). Pressure regulator Intermediate plate Valve Sub-base Fig. 2.13 Reversible B pressure regulator Festo – P.BE-MPA-EN – 1309f – English...

-

Page 37: Operation And Connection Elements

Overview Operation and connection elements You will find the following pneumatic connecting and control elements on the MPA-S valve terminal: Manual override (per pilot solenoid coil, Exhaust air (3) of the proportional pressure non-detenting or turning with detent) regulator Manual override cover cap Pressure input (1) of the proportional Common exhaust port (3/5), “Valves”... -

Page 38: Manual Override (Mo)

Cover cap, concealed: This cover cap completely covers the MO, which is thus secured against undesired actuation. Tab. 2.17 Manual override cover caps Mounting of the MO cover caps is described in section 4.4. Festo – P.BE-MPA-EN – 1309f – English... -

Page 39: Operating And Connection Elements Of The Pressure Regulator Plates

Pressure gauge (optional) Connection M5 with blanking plug Connection for pressure gauge (can be Connection M5 with QS-fitting turned 90°) Fig. 2.15 Operating and connection elements of the pressure regulator plates Festo – P.BE-MPA-EN – 1309f – English... -

Page 40: Multi-Pin Connecting Components

Overview 2.5.3 Multi-pin connecting components You will find the following electric connecting elements on the multi-pin plug connection of the MPA-S valve terminal: Multi-pin plug cover with cable SUB-D connection Connection for functional earth Fig. 2.16 Electric connecting elements of MPA-S valve terminal with multi-pin plug connection Information on the electronics module of the MPA-S valve terminal can be found in the package insert and the MPA-.. -

Page 41: Display Components

Overview Display components You will find the following display elements on the pneumatic modules of the MPA-S valve terminal with multi-pin plug connection or AS interface: MPA1: MPA2: yellow LEDs: signal status display of the pilot yellow LEDs: signal status display of the pilot... - Page 42 Fig. 2.18 Electric connection and display components of the MPA-S valve terminal with CPX terminal or CPI interface Information on the electric connection and display elements of the CPX bus node can be found in the corresponding electronics description ( system description for your CPX terminal, table “Descriptions of the CPX terminal”).

-

Page 43: Pressure Sensor Plate

The pressure sensor plate has the following display elements: Pressure sensor plate Red LED: pressure not reached Red LED: pressure exceeded Red LED: common error display Green LED: pressure maintained Fig. 2.19 Display components of the pressure sensor plate Festo – P.BE-MPA-EN – 1309f – English... -

Page 44: Proportional Pressure Regulator

Overview 2.6.2 Proportional pressure regulator The LED proportional pressure regulator has the following display components: Green power LED Red error LED Proportional pressure regulator Fig. 2.20 Display elements of the proportional pressure regulator Festo – P.BE-MPA-EN – 1309f – English... -

Page 45: Proportional-Pressure Regulator With Lcd Display

– Current pressure valve (short pressing and holding down of the DOWN and/or UP key displays the setpoint value) – Dynamic bar graph display for fast signal changes (dependent on the displayed signal in the num- bers field) Festo – P.BE-MPA-EN – 1309f – English... - Page 46 DOWN), “Exxx” is displayed in the numbers field. In this case, xxx stands for the display switch-off time in seconds. The display exposure time can now be set with the UP and DOWN keys. The setting range lies between OFF and 999 seconds. Festo – P.BE-MPA-EN – 1309f – English...

- Page 47 ..........3.8.1 Load voltage supply via electrical supply plate (only for MPA-S valve terminal with CPX terminal or CPI interface) .

-

Page 48: General Instructions On Mounting And Dismantling

Special information on replacing or adding pneumatic components can be found in chapter 5. – Information on mounting the MPA-S valve terminal with CPX terminal can be found in the CPX system manual. – Information on dismounting and mounting of I/O modules is provided in the I/O mod- ule description ( system description for your CPX terminal, table “Descriptions for... -

Page 49: Mounting Variants

Tab. A.4). Tab. 3.1 Mounting methods of the MPA-S valve terminal Note • Mount the MPA-S valve terminal so that there is sufficient space for heat dissipation and ensure that the maximum limits for temperatures are observed ( Technical data). - Page 50 Tab. 3.2 Required mounting points for mounting on H-rails Mounting Proceed as follows: 1. Make sure the mounting surface can support the MPA-S valve terminal (weights Appendix A.1, Tab. A.1). 2. Mount the H-rail (DIN mounting rail EN 60715 - 35x7.5; width 35 mm, height 7.5 mm). Make sure there is sufficient space for connecting the power supply cables and tubing.

- Page 51 Clamping component of the H-rail clamping unit Fig. 3.1 Mounting of the MPA-S valve terminal on an H-rail 6. Turn the clamping components for mechanical interlock vertically behind the H-rail ( Fig. 3.2, arrow A). Then tighten the retaining screws of the H-rail clamping unit with 1.3 Nm to secure the MPA-S valve terminal against tilting or sliding.

- Page 52 Fig. 3.2 Rear view: Mounting on an H-rail using the CPX terminal as an example Further instructions on mounting the MPA-S valve terminal with CPX terminal on an H-rail can be found in the system description for your CPX terminal.

-

Page 53: Mounting/Dismounting On Walls

Mounting/dismounting on walls Note Installation on uneven, flexible surfaces can damage the valve terminal MPA-S. • Mount the MPA-S valve terminal only on a flat, torsionally rigid surface. Note Overloading of mounting holes or natural resonance when vibrating can cause damage. -

Page 54: Standard Fastening Points Of The Valve Terminal

Tab. 3.3 Mounting options for the MPA-S valve terminal Mounting Proceed as follows: 1. Make sure that the fastening surface is flat and that it can support the MPA-S valve terminal (weights Appendix A, Tab. A.1). Make sure there is sufficient space for connecting the power supply cables and tubing. -

Page 55: Additional Fastening Of The Valve Terminal

Mounting and installation Dismounting Proceed as follows: 1. Secure a hanging-mounted MPA-S valve terminal from falling down before you loosen it from the mounting surface. 2. Loosen the mounting screws ( Tab. 3.3). 3. Remove the MPA-S valve terminal from the mounting surface. -

Page 56: Mounting/Dismounting The Inscription Label Holder

Mounting/dismounting the inscription label holder An inscription label holder can be mounted onto each sub-base to enable the valves or work connec- tions to be distinguished. Information on accessories can be found in the Festo Catalogue www.festo.com/catalogue). Mounting Proceed as follows: •... - Page 57 ( Fig. 3.5). Hole for unlocking the inscription label Inscription label holder holder Fig. 3.5 Dismounting the inscription label holder 3. Pull the inscription label holder out of the fixture in the sub-base. Festo – P.BE-MPA-EN – 1309f – English...

-

Page 58: Compressed Air Preparation

Operate system equipment with unlubricated compressed air, if possible. In this way, you protect the environment. Festo pneumatic valves and actuators have been designed so that, if used as intended, they will not require additional lubrication and will still achieve a long service life. - Page 59 Incorrect supplemental oil and an oil rate in the compressed air that is too high will reduce the service life of the valve terminal. • Use Festo special oil OFSW-32 or the alternatives listed in the Festo catalogue (as per DIN 51524-HLP32, basic viscosity 32 CST at 40 °C).

-

Page 60: General Instructions On Installation

Note Handle all modules and components of the MPA-S valve terminal with great care. • Note especially the following: – Exact placement of screws in the plastic thread (to avoid damage to thread) –... - Page 61 • Separate the exhaust ducts, if necessary, by using pressure zones ( section 2.4.7). Festo – P.BE-MPA-EN – 1309f – English...

-

Page 62: Connecting The Mpa-S Valve Terminal

Dependent on the variant of the pneumatic interface, CPI interface, multiple connector plate or AS in- terface, the pilot control is supplied with internal or external pilot air. You can ascertain the pilot control variant for which your MPA-S valve terminal is equipped by the following features ( Tab. 3.5). -

Page 63: Mpa-S Valve Terminal With Pressure Zone Separation

A, Fig. A.1 … Fig. A.5). If the proportional pressure regulator is to regulate the operating pressure for the valves on the MPA-S valve terminal, the valves must be positioned to the right of the proportion- al pressure regulator. For every pressure zone, a pressure zone seal and a pneumatic air supply plate are re- quired ( Fig. -

Page 64: Operation Of The Mpa-S

Operation of the MPA-S... valve terminal with reversible pressure regulators Note Operation of the MPA-S... valve terminal with reversible pressure regulators (Ident. code PN, PM, PL, PK): • No 2x 2/2-directional control valves with ident. code D, I and 2x 3/2-directional control valves with ident. - Page 65 Fig. 3.7) to set the desired controlled variable ( “Flow diagrams of the pressure regulator plates” in Appendix A). Setting the pressure regulator plates (size MPA1) with the adjusting screw 1 Fig. 3.7 Festo – P.BE-MPA-EN – 1309f – English...

- Page 66 Adjusting knob in the locking level Adjusting knob in the setting level Adjusting knob in the free-running level Adjusting knob Fig. 3.8 Setting the pressure regulator plates (size MPA2) with the aid of the adjusting knob Festo – P.BE-MPA-EN – 1309f – English...

- Page 67 Fig. 3.9) to set the desired controlled variable ( “Flow diagrams of the pressure regulator plates” in Appendix A). Adjusting screw, internal hexagon socket (spanner size 2.0) Setting the pressure regulator plates (size MPA2) with the adjusting screw 1 Fig. 3.9 Festo – P.BE-MPA-EN – 1309f – English...

-

Page 68: Controller With Rigid Threaded Connection (Mpa1)

Fig. A.1 The following requirements must be fulfilled in order to operate your MPA-S valve terminal at the supply port (1) with vacuum or low pressure between –0.9 ... 3 bar: –... - Page 69 – The operating pressure at port (1) can be used as an ejector pulse at port (2). The operating pressure is switched to port (2) with solenoid coil 12. If the MPA-S valve terminal is also equipped with other valves, operate this valve in a separate pressure zone with separated exhaust duct (5).

-

Page 70: Connecting The Pneumatic Lines

Mounting and installation 3.6.7 Connecting the pneumatic lines • Use blanking plugs to seal connections not required for the functional reliability of the MPA-S valve terminal. Position of the pneumatic ports If the MPA-S valve terminals are equipped with flat plate silencers, the exhaust air (3/5) and (82/84) will be vented through the flat plate silencers. - Page 71 Exhaust air of the G¼” VPPM-…TA 1) Dependent on your order, the MPA-S valve terminal may already be equipped with QS fittings. 2) Only for valve terminal MPA-S with exhaust plate or air supply plate Tab. 3.9 Assignment of the connections...

-

Page 72: Installation Of The Tubing Lines

If the pneumatic tubing is under pressure when dismounted, it may execute uncon- trolled movements, causing injury to persons. Carry out the subsequent steps first be- fore disconnecting the pneumatic tubing on the MPA-S valve terminal: • Switch off the compressed air supply. -

Page 73: Common Pneumatic Lines

1. Mark all pneumatic tubing. 2. Loosen the clamping screw 1 of the fitting or, if necessary, press down the locking ring of the fit- ting 2, e.g. with the QSO releasing tool from Festo. 3. Remove the tubing from the fitting. -

Page 74: Connecting The Electric Cables

CPX terminal, table “Descriptions of the CPX terminal”). 3.8.1 Load voltage supply via electrical supply plate (only for MPA-S valve terminal with CPX terminal or CPI interface) The electric air supply plate type VMPA-FB-SP-...-V-... supplies the valves additionally with load voltage when, for example, the valve terminal is to be operated with different voltage zones or when the re- quired load voltage cannot be provided by the CPX terminal alone. - Page 75 Damage to components and malfunctions! • Please observe, – that with MPA-S valve terminals with more than 8 sub-bases, an electric supply plate is required for supplemental supply of load voltage. – to the right of the electrical air supply plate, only electronics modules with separ- ated circuits of type VMPA..-FB-EMG-..

-

Page 76: Earthing The Mpa-S Valve Terminal

Fig. 3.15) at low impedance (short cable with large cross-sectional area) to the earth potential. • Please note the supplementary instructions on the MPA-S valve terminals with CPX terminal in the system description of your CPX terminal. This prevents malfunctions due to electromagnetic interference and ensures electro- magnetic compatibility in accordance with EMC directives. - Page 77 MPA-S valve terminal with CPX terminal MPA-S valve terminal with multi-pin plug connection MPA-S valve terminal with CPI interface MPA-S valve terminal with AS interface Earth terminal Fig. 3.15 Earthing the MPA-S valve terminal Festo – P.BE-MPA-EN – 1309f – English...

-

Page 78: Address Assignment Of The Valves

3.9.1 MPA-S valve terminal with CPX terminal Maximum 16 MPA pneumatic modules are permitted on the MPA-S valve terminal with CPX terminal. The following number of solenoid coils is therefore possible (if only valves of the same size are used): –... -

Page 79: Mpa-S Valve Terminal With Cpi Module Or As-Interface

Addresses of the solenoid coils 12 Pneumatics module (MPA2) Fig. 3.16 Example: address assignment of an MPA-S valve terminal with CPX terminal, 6 valve posi- tions (top view) Detailed instructions on addressing the pneumatics modules of the MPA-S valve terminal with CPX terminal can be found in the MPA-... -

Page 80: Mpa-S Valve Terminal With Multi-Pin Plug Connection

– Solenoid coil 12 occupies the higher-value address. Example of address assignment Caution Note that addresses may be shifted if the valve terminal is expanded subsequently. In the subsequent example, an MPA-S valve terminal type MPA-MPM-PI with the following components is addressed: Component MPA1... - Page 81 1) 0 V with positive-switching control signals; in the case of negative switching control signals, connect 24 V; mixed operation is impermissible! Tab. 3.15 Example: address assignment of the MPA-S valve terminal with multi-pin plug connection and 12 valve positions...

- Page 82 VMPA1-MPM-EMM-8 occupies two ad- dresses per valve position Fig. 3.17 Example: address assignment of the MPA-S valve terminal with multi-pin plug connection and 12 valve positions, type MPA-MPM-… (top view) Festo – P.BE-MPA-EN – 1309f – English...

- Page 83 ........... . 4.5.1 MPA-S valve terminal with CPX terminal or CPI connection ....

-

Page 84: Prior To Commissioning

The gradual pressure build-up of the overall supply does not affect the actuator in that case. The actuator would react sud- denly (e.g. a cylinder would extend or retract suddenly, depending on the valve function). Festo – P.BE-MPA-EN – 1309f – English... - Page 85 (1) start-up valve branched upstream slowly fast before pressure slowly of the soft-start rise at (1) valve Tab. 4.1 Effects of slow start-up pressurisation Festo – P.BE-MPA-EN – 1309f – English...

-

Page 86: Manual Override (Mo)

The assignment of the manual overrides to the solenoid coils is as follows: Manual override for solenoid coils 12 Valve size MPA2 Manual override for solenoid coils 14 Valve size MPA1 Fig. 4.2 Position of the manual overrides (top view) Festo – P.BE-MPA-EN – 1309f – English... -

Page 87: Testing The Valves And The Valve/Actuator Combination

Commissioning Testing the valves and the valve/actuator combination Note Before commissioning the MPA-S valve terminal, observe the specifications concerning the medium ( section 3.6.1 “Pilot control (pilot air supply)”). The MPA-S valve terminal should be commissioned as follows: Commissioning variants... - Page 88 If the manual override is in the actuated state, it is not possible to reset the valve to its neutral position with an electric signal. The manual override is dominant in this case. 4. Switch off the compressed air supply after testing the valves. Festo – P.BE-MPA-EN – 1309f – English...

- Page 89 The pilot valve returns to its neutral position and thus also the monostable power valve (not for impulse valve, ident. code J). Tab. 4.4 Non-detenting operation of the manual override Festo – P.BE-MPA-EN – 1309f – English...

- Page 90 • Remove the screwdriver. The pilot valve returns to its neutral position and thus also the power valve (not for impulse valve, ident. code J). Tab. 4.5 Turning with detent actuation of the manual override Festo – P.BE-MPA-EN – 1309f – English...

-

Page 91: Mounting/Removing The Manual Override Cover Cap (Optional)

2. Place the cap on the manual override so that the snap hooks of the cover can grip into the recess on the manual override. 3. Clip the manual override cap into the recesses of the manual override ( Fig. 4.3): Manual override cover caps Fig. 4.3 Mounting the manual override cover caps Festo – P.BE-MPA-EN – 1309f – English... -

Page 92: Dismounting

During dismantling, the snap hooks of the cover will be damaged. 4.4.2 Dismounting Proceed as follows: • Use a suitable screwdriver to lift the manual override coverer caps from the manual override Fig. 4.4): Fig. 4.4 Dismounting the manual override cover caps Festo – P.BE-MPA-EN – 1309f – English... -

Page 93: Led Display Of The Valves

MPA2: red LED for solenoid coil 14 MPA2: yellow LED for solenoid coil 12 Valve size MPA2 MPA2: MO for solenoid coil 12 Valve size MPA1 Fig. 4.5 Assignment of the LEDs and manual overrides to the solenoid coils Festo – P.BE-MPA-EN – 1309f – English... -

Page 94: Mpa-S Valve Terminal With Cpx Terminal Or Cpi Connection

MPA pneumatics module Tab. 4.6 Significance of the LED display (MPA-S valve terminal with CPX terminal or CPI module) Further instructions on commissioning and diagnosing the MPA pneumatics modules can be found in the MPA-... electronics description. -

Page 95: Mpa-S Valve Terminal With Multi-Pin Plug Connection Or As-Interface

OK or – The pilot exhaust is blocked or – Servicing required Tab. 4.7 Significance of the LED display (MPA-S valve terminal with multi-pin plug connection or AS-interface) Commissioning instructions for the proportional pressure regulator Note • Make sure there is sufficient space for the tube couplings. In this way you will pre- vent the tubes from being bent. - Page 96 Tab. 4.8 Output signal of the proportional pressure regulator Additional important specifications on commissioning the proportional pressure regulat- or, such as parameterisation, significance of the LED display, can be found in the MPA-... electronics description. Festo – P.BE-MPA-EN – 1309f – English...

-

Page 97: Error Handling

No supply pressure • Switch on supply pressure. Setpoint value reached • Modify setpoint value. Proportional pressure regulator • Send the valve to the Festo defective repair service. Flow rate too low Restriction of the flow cross • Use alternative connections. -

Page 98: Operating Statuses Of The Pneumatic System

– Tubing connected with care — – Regulated pilot air supply Fast reaction Sufficient pressure supply by means Exhaust the MPA-S valve terminal via of compressed air supply all exhaust plates. Trouble-free Non-return valves in common exhaust This applies when several systems... - Page 99 ..........5.4.4 Adding an electric supply plate (only for MPA-S valve terminal with CPX terminal or CPI interface) .

-

Page 100: General Instructions

– Operating and load voltage supply. Note • Handle all modules and components of the MPA-S valve terminal with care. • Note especially the following when mounting components: – Position screws exactly before tightening (otherwise their threads may be dam- aged). -

Page 101: Dismantling The Mpa-S Valve Terminal

Conversion and maintenance Dismantling the MPA-S valve terminal Providing the MPA-S valve terminal is easily accessible, it need not be dismantled when the following components are replaced or removed: – Valves or blanking plates – Electronics module – Exhaust plates or flat plate silencer. -

Page 102: Cleaning The Flat Plate Silencer

4. Fasten the flat plate silencer or exhaust plate only with the original screws. Tighten the sub-bases in diagonally opposite sequence with 0.65 Nm (±10 %) or the flat plate silencer with 1.0 Nm (±10 %). Festo – P.BE-MPA-EN – 1309f – English... -

Page 103: Replacing Valves Or Cover Plates

Conversion and maintenance 5.3.4 Replacing valves or cover plates The sub-bases of the MPA-S valve terminal with multi-pin plug connection support actu- ation of one or two solenoid coils per valve position, dependent on the built-in MPA elec- tronics module ( Tab. - Page 104 Mounting valve or blanking plate (MPA1) Mounting screws of the component Sub-base Valve or blanking plate Electronics module Cord seal Fig. 5.3 Mounting valve or blanking plate (MPA2) 4. Place the component on the sub-base. Festo – P.BE-MPA-EN – 1309f – English...

-

Page 105: Replacing The Proportional Pressure Regulator

Fastening screws of the electronics module sure regulator (tightening torque 1.0 Nm (tightening torque 0.4 Nm (±20 %)) (±10 %)) Electronics module Fig. 5.4 Mounting the proportional pressure regulator and the electronics module Festo – P.BE-MPA-EN – 1309f – English... -

Page 106: Replacing Electronics Modules

Mounting of the electronics module to the proportional pressure regulator is described in the assembly instructions VMPA-…TA-..The MPA-S valve terminal is equipped with one electronics module per sub-base. It provides the follow- ing number of contacts between the electrical interlinking module and the solenoid coils, dependent on the size of the sub-bases: –... - Page 107 – VMPA1-FB-EMS-… type CPX-GE-EV-S – VMPA2-FB-EMS-… – System supply (7/8”, 4-pin): type CPX-GE-EV-S-7/8-4POL MPA-S valve terminal with CPI interface: – via the CPI interface, type VMPA-CPI. …with separated circuits: – Valve supply modules (M18 or 7/8”): – VMPA1-FB-EMG-… type CPX-GE-EV-V...

- Page 108 – with common circuit – with diagnostic functions D2 Tab. 5.3 Electronics modules for the MPA-S valve terminal with CPX terminal Additional information on MPA electronics modules can be found in the package insert and in the corresponding MPA-..electronics description.

- Page 109 VMPA2… 1) Two solenoid coils can be controlled per valve position. 2) One solenoid coil can be controlled per valve position. Tab. 5.4 Electronics modules for the MPA-S valve terminal with multi-pin plug connection (MPA...-MPM-...) Dismantling the electronics module Before dismantling the electronics module, all valves or blanking plates on the corres- ponding electronics module must first be removed ( section 5.3.4).

- Page 110 Mounting the electronics module Caution When replacing an electronics module, mount only an electronics module of the same type. – You then avoid problems in actuating the solenoid coils and damage to the electrical contacts. Festo – P.BE-MPA-EN – 1309f – English...

-

Page 111: Replacing The Sub-Base, Supply Plate Or Mpa-S End Plate

Replacing the sub-base, supply plate or MPA-S end plate Dismantling Proceed as follows: 1. Disconnect the electrical and pneumatic connections and then remove the MPA-S valve terminal from its mounting surface ( section 3.2). 2. Place the MPA-S valve terminal on a flat working surface. - Page 112 1. Check the exposed seals for damage. Replace damaged seals. 2. Place the seal onto the guide pins of the sub-base or air supply plate. Guide pins Seal (optional separating seal for pressure zone separation) Fig. 5.7 Sub-base mounting Festo – P.BE-MPA-EN – 1309f – English...

- Page 113 .Fig. 5.8). Then tighten the screws with a tightening torque of 1.8 Nm (±10 %). Fig. 5.8 Sub-base fittings 4. Mount the MPA-S valve terminal onto the mounting surface ( section 3.2, “Wall mounting” or “H-rail mounting”). 5. Then install the pneumatic and electrical connections ( chapter 3).

-

Page 114: Replacing Interlinking Boards - Mpa-S With Multi-Pin Plug Connection Or As Interface

Replacing interlinking boards – MPA-S with multi-pin plug connection or AS interface With the multi-pin plug connection, the electrical interlinking has a modular construction. That means, every sub-base has its own board. The following interlinking boards are available for the MPA-S valve terminal with multi-pin plug connection: Interlinking board for ... - Page 115 Fig. 5.10 Unlocking the interlinking board Mounting Proceed as follows: 1. Push the interlinking board to be mounted into the sub-base from the right until it clips into posi- tion. Fig. 5.11 Mounting the interlinking board Festo – P.BE-MPA-EN – 1309f – English...

-

Page 116: Conversion Of The Mpa-S Valve Terminal

Independent of the available pressure zones, all pilot controls of the MPA-S valve terminal are supplied with the same pilot air supply. You can ascertain the pilot control variant for which your MPA-S is equipped by the following features listed in chapter 3, Tab. 3.5. - Page 117 MPA-S valve terminal with CPX terminal Disconnecting the CPX pneumatic interface: – from the sub-base of the MPA-S valve terminal is described in Appendix B. – from the CPX terminal is described in the system description of your CPX terminal.

- Page 118 5. Pull the multi-pin plug connection plate away from the pneumatic sub-bases. For mounting, proceed as follows: 1. Check the exposed seals for damage. Replace damaged seals. 2. Place the seal onto the guide pins of the multi-pin plug connection plate. Festo – P.BE-MPA-EN – 1309f – English...

- Page 119 Pneumatic sub-base Fig. 5.14 Mounting the multi-pin plug connection plate 3. Push the multi-pin plug connection plate together with the pneumatic sub-bases. Make sure that the seal and the components are correctly positioned. Festo – P.BE-MPA-EN – 1309f – English...

-

Page 120: Conversion Of The Mpa-S Valve Terminal To Different Pressure Zones

Conversion of the MPA-S valve terminal to different pressure zones Basic information on pressure zone separation can be found in chapter 2 section 2.4.7). The MPA-S valve terminal can be equipped with the following number of pressure zones, depending on the alternative electrical connection: Alternative electrical connection... - Page 121 MPA1-FB-EV-V. Dismantling Proceed as follows: 1. Loosen the electrical and pneumatic connections and then remove the MPA-S valve terminal from the mounting surface ( chapter 3). 2. Place the MPA-S valve terminal on a flat working surface.

-

Page 122: Adding Valve Positions

5.4.3 Adding valve positions You can easily adapt the MPA-S valve terminal to the requirements of your machine or system by adding valve positions. The smallest extension unit is a sub-base with 4 valve positions (MPA1) or 2 valve posi- tions (MPA2). - Page 123 × n MPA-S valve terminal with CPX terminal Note A maximum of 16 MPA sub-bases are permitted for the MPA-S valve terminal with CPX terminal and electric supply plate. Without the electric supply plate, 8 MPA sub-bases are permitted. Festo – P.BE-MPA-EN – 1309f – English...

- Page 124 Tab. 5.10 Valve position extension Dismantling Proceed as follows: 1. Loosen the MPA-S valve terminal from the mounting surface ( chapter 3). 2. Dismantle the sub-base or air supply plate at the point where you wish to extend the terminal section 5.3.7).

-

Page 125: Adding An Electric Supply Plate (Only For Mpa-S Valve Terminal With Cpx Terminal Or Cpi Interface)

5.4.4 Adding an electric supply plate (only for MPA-S valve terminal with CPX terminal or CPI interface) The electric supply plate is intended as an intermediate supplier of load voltage for the valves. - Page 126 Tab. 5.11 Electric supply plates Mounting Proceed as follows: 1. Loosen the electric and pneumatic connections and then remove the MPA-S valve terminal from its mounting surface ( chapter 3). 2. Mount the electric supply plate as described in the VMPA-FB-SP-...-V-... assembly instructions.

-

Page 127: Adding A Pressure Sensor Plate

Tab. 5.12 Pressure sensor plates Mounting Proceed as follows: 1. Loosen the electric and pneumatic connections and then remove the MPA-S valve terminal from its mounting surface ( chapter 3). 2. Mount the pressure sensor plate as described in the mounting instructions VMPA-FB-PS-...-.. -

Page 128: De-Commissioning And Disposal

1. Then proceed logically as described in the section 5.3.7, under Mounting point 1 … 3. 2. Mount the proportional pressure regulator as described in the mounting instructions VMPA-…TA-..3. Mount the MPA-S valve terminal onto the mounting surface ( chapter 3, “Wall mounting” or “H-rail mounting”). - Page 129 ............Festo – P.BE-MPA-EN – 1309f – English...

-

Page 130: Technical Appendix

Right end plate (MPA-S) 55 g Per valve (MPA1/MPA2) Approx. 56 g/approx. 100 g Per cover plate (MPA1/MPA2) 24 g/44 g Per pressure regulator plate (MPA1/MPA2) 100 g/180 g Tab. A.1 Technical data: mechanical Festo – P.BE-MPA-EN – 1309f – English... - Page 131 1.8 Nm (±10 %) Retaining screw for H-rail clamping unit 1.30 Nm Components on sub-bases (valve, blanking plate or MPA1: 0.25 Nm (±10 %) pressure regulator) MPA2: 0.65 Nm (±10 %) Tab. A.2 Technical data: mechanical Festo – P.BE-MPA-EN – 1309f – English...

-

Page 132: Operating And Environmental Conditions

Medium –5 … +50 °C Relative air humidity 90 % at 40 ºC Protection class to EN 60529 IP 65 (with cable from Festo accessories) Corrosion protection KBK1 (as per FN940070) Mounting position any, with H-rail mounting only horizontal Tab. A.3 Technical data: ambient conditions... - Page 133 2 For wall mounting: Valve terminal MPA-S with CPI, ASI or multi-pin plug connection: – up to a valve terminal length of 280 mm, without additional fastening: severity level 2 –...

- Page 134 5 g acceleration at 60 … 150 Hz Shock: ±30 g at 11 ms duration; 5 shocks per direction Continuous shock: — Tab. A.5 Technical data: explanation on vibration and shock resistance (severity level) Festo – P.BE-MPA-EN – 1309f – English...

-

Page 135: Pneumatics

Valve position Ident. code MU, NU, KU, –0.9 … 10 bar and HU at port (1) All valve sub-bases at port (12/14) Diagrams Fig. A.1 … Fig. A.5, pressure P2 (max. 8 bar) Tab. A.6 Technical data: solenoid valves Festo – P.BE-MPA-EN – 1309f – English... - Page 136 Operating pressure at port (1) [bar] Fig. A.2 Diagram: Required pilot pressure related to the operating pressure with use of valve sub-ba- ses with ident. code DS, HS, KS, MS and NS, width 10 mm Festo – P.BE-MPA-EN – 1309f – English...

- Page 137 Operating pressure at port (1) [bar] Fig. A.4 Diagram: Required pilot pressure related to the operating pressure with use of valve sub-ba- ses with ident. code DS, HS, KS, MS and NS, width 20 mm Festo – P.BE-MPA-EN – 1309f – English...

- Page 138 (12/14) [bar] Operating pressure at port (1) [bar] Fig. A.5 Diagram: Required pilot pressure related to the operating pressure with use of valve sub-ba- ses with ident. code MU, NU, KU and HU Festo – P.BE-MPA-EN – 1309f – English...

- Page 139 2) Flow direction 1 } 4 or 4 } 3/5 not with valves having ident. codes I, W and X 3) Values for the mid-position are specified in brackets Tab. A.7 Technical data: nominal flow rates MPA1 Festo – P.BE-MPA-EN – 1309f – English...

- Page 140 2x 3/2-way KU, HU 2x 3/2-way 2x 3/2-way W, X 1x 3/2-way D, I 2x 2/2-way 2x 2/2-way 1) Ident. code of the valve sub-base Tab. A.9 Technical data: valve switching times MPA1 Festo – P.BE-MPA-EN – 1309f – English...

- Page 141 Pressure regulator plates P pressure regulator MPA1 Output pressure Flow rate Fig. A.6 Diagram on size MPA1 of the P pressure regulator (ident. code: PF and PA): flow as a function of the output pressure Festo – P.BE-MPA-EN – 1309f – English...

- Page 142 A pressure regulator MPA1 Output pressure Flow rate Fig. A.8 Diagram on size MPA1 of the B pressure regulator (ident. code: PG and PB): flow as a functi- on of the output pressure Festo – P.BE-MPA-EN – 1309f – English...

- Page 143 B pressure regulator MPA2 Output pressure Flow rate Fig. A.10 Diagram on size MPA2 of the B pressure regulator (ident. code: PH and PC): flow as a functi- on of the output pressure Festo – P.BE-MPA-EN – 1309f – English...

- Page 144 Reversible B pressure regulator MPA2 Output pressure Flow rate Fig. A.12 Diagram for size MPA2 of the reversible B pressure regulator (ident. code: PN and PL): Flow as a function of the output pressure Festo – P.BE-MPA-EN – 1309f – English...

- Page 145 Reversible A pressure regulator MPA2 Output pressure Flow rate Fig. A.13 Diagram for size MPA2 of the reversible A pressure regulator (ident. code: PM and PK): Flow as a function of the output pressure Festo – P.BE-MPA-EN – 1309f – English...

- Page 146 Characteristic curves for flow rate for type VPPM-6TA-L-1-... 2 bar valve variant: type VPPM-6TA-L-1-F-OL2H-… 6 bar valve variant: type VPPM-6TA-L-1-F-OL6H-… 10 bar valve variant: type VPPM-6TA-L-1-F-OL10H-… Tab. A.11 Characteristic curves for flow rate of the proportional pressure regulator type VPPM-6TA-L-1-… Festo – P.BE-MPA-EN – 1309f – English...

- Page 147 Characteristic curves for flow rate for type VPPM-8TA-L-1-... 2 bar valve variant: type VPPM-8TA-L-1-F-OL2H-… 6 bar valve variant: type VPPM-8TA-L-1-F-OL6H-… 10 bar valve variant: type VPPM-8TA-L-1-F-OL10H-… Tab. A.12 Characteristic curves for flow rate of the proportional pressure regulator type VPPM-8TA-L-1-… Festo – P.BE-MPA-EN – 1309f – English...

-

Page 148: Electrical Data

– Emitted interference – Immunity to interference 1) The MPA-S valve terminal is intended for use in an industrial environment. Outside of industrial environments, e.g. in commercial and mixed-residential areas, actions to suppress interference may have to be taken. 2) The maximum signal cable length for the MPA-S valve terminal with multi-pin plug connection is 10 m Tab. - Page 149 Tab. A.16 Electric data: MPA-S valve terminal with CPX terminal or CPI-interface Technical data on the electronics module of the MPA-S valve terminal with CPX terminal or CPI-interface can be found in the electronics description for the module ( system de- scription for your CPX terminal, table “Descriptions of the CPX terminal”).

-

Page 150: Product Key

The product key is an 11-character alphanumeric code that uniquely identifies a product. With it, you can retrieve the following product data: – Type designation – Manufacturing date – Complete order code (degree of completion at the time of shipment from Festo) – Revision (hardware/software version) – Serial number – Customer-order-related information. - Page 151 ........Separating the MPA-S valve terminal from the CPX terminal .

-

Page 152: Supplementary Component Overview

MPA-S valve terminal with multi-pin plug connection and modular electrical interlinking module (type MPA-MPM-...): How many addresses a valve occupies depends on: –... - Page 153 Ident. code: E (piston spool valve) Function: – 5/3-directional control valve – Mid-position exhausted (12/14) (82/84) Ident. code: G (piston spool valve) Function: – 5/3-directional control valve – Mid position closed (12/14) (82/84) Tab. B.2 5/3-directional control valves Festo – P.BE-MPA-EN – 1309f – English...

- Page 154 – Two monostable 3/2-directional control valves – Normally closed 12/14 82/84 – Mechanical spring return Ident. code: KU (polymer poppet valve) Function: – Two monostable 3/2-directional control valves – Normally closed 12/14 82/84 – Mechanical spring return Festo – P.BE-MPA-EN – 1309f – English...

- Page 155 – Pneumatic spring return Ident. code: X (piston spool valve) (14) Function: – A 3/2-way valve, monostable, normally (12/14) (82/84) closed, external compressed air supply – Pneumatic spring return Tab. B.3 3/2-directional control valves Festo – P.BE-MPA-EN – 1309f – English...

- Page 156 – Two monostable 2/2-directional control valves, normally closed – Pneumatic spring return 12/14 82/84 Ident. code: DS (piston spool valve) Function: – Two monostable 2/2-directional control valves, normally closed – Mechanical spring return 12/14 82/84 Festo – P.BE-MPA-EN – 1309f – English...

- Page 157 1) Note: If this 2/2-directional control valve (ident. code I) is also operated with other valves on the MPA-S valve terminal, this 2/2-dir- ectional control valve must be operated in a separate pressure zone with a separated exhaust duct (5).

- Page 158 3 12 Pressure regulator plate for port (4) (A regulator) Ident. code: PG or PB Function: – Regulates the operating pressure in channel (4) downstream of the directional control valve. 14 5 3 12 Festo – P.BE-MPA-EN – 1309f – English...

- Page 159 Combination with 2x 2/2-directional control valves (ident. codes D and I) and 2x 3/2-directional control valves (ident. codes H, K and N) is not permitted. Tab. B.5 Pressure regulator plates for regulating outputs (1), (2) and (4) Festo – P.BE-MPA-EN – 1309f – English...

- Page 160 Tab. B.6 Proportional pressure regulator Vertical pressure shut-off plate VMPA1-HS Ident. code: PS 12/14 Function: – Permits a valve change under operating and pilot pressure 3 12/14 82/84 5 Tab. B.7 Vertical pressure shut-off plate Festo – P.BE-MPA-EN – 1309f – English...

-

Page 161: Separating The Mpa-S Valve Terminal From The Cpx Terminal

Supplementary component overview Separating the MPA-S valve terminal from the CPX terminal The valve terminal MPA-S is connected to the CPX terminal through a port pattern ( Fig. B.1). CPX terminal Valve terminal MPA-S Port pattern Fig. B.1 Port pattern... -

Page 162: Dismantling

B.2.1 Dismantling Proceed as follows: 1. Loosen the electrical and pneumatic connections and then remove the MPA-S valve terminal from its mounting surface ( section 5.2, “Dismantling the MPA-S valve terminal”). 2. Loosen the fastening screws between the port pattern and the MPA manifold block in the se- quence 3, 2, 1 ( Fig. -

Page 163: Mounting

Pneumatic manifold blocks Port pattern Fig. B.3 Mounting the MPA-S valve terminal to the port pattern 3. Push the port pattern together with the pneumatic manifold blocks. Make sure that the seal and the components are correctly positioned toward each other. - Page 164 5. Fasten the MPA-S valve terminal to the mounting surface ( CPX system description). 6. Complete the electrical and pneumatic connections of the MPA-S valve terminal to the CPX terminal. Further information can be found – on the electrical connections in the CPX system description –...

- Page 165 Glossary Glossary Festo – P.BE-MPA-EN – 1309f – English...

- Page 166 MPA1 or MPA2 Size of the valves: MPA1 = 10 mm, MPA2 = 20 mm MPA-S valve terminal with Variant of the MPA-S valve terminal with Sub-D plug multi-pin plug connection All solenoid coils are connected centrally via the Sub-D plug. The type MPA…-MPM-…...

- Page 167 – Size MPA2 (type MPAS...2) with 2 valve positions Separating seal Special seal for formation of pressure zones Tubing connections Connecting the pneumatic supply cables (tubing) to the MPA-S valve terminal Valve Monostable, impulse or mid-position valves Valve terminal MPA-S...

- Page 168 Glossary Festo – P.BE-MPA-EN – 1309f – English...

- Page 169 ..– Wall mounting ......Festo – P.BE-MPA-EN – 1309f – English...

- Page 170 ......CPX terminal ......Festo – P.BE-MPA-EN – 1309f – English...

- Page 171 ....Wall mounting, mounting/dismounting ..Weights, Components ....Festo – P.BE-MPA-EN – 1309f – English...

- Page 172 MPA-S Festo – P.BE-MPA-EN – 1309f – English...

- Page 174 Copyright: Festo AG & Co. KG Postfach 73726 Esslingen Germany Phone: +49 711 347-0 Fax: +49 711 347-2144 e-mail: service_international@festo.com Reproduction, distribution or sale of this document or communica- tion of its contents to others without express authorization is Internet: prohibited.

Need help?

Do you have a question about the MPA-S and is the answer not in the manual?

Questions and answers