Subscribe to Our Youtube Channel

Summary of Contents for Nordson Liquidyn P-Jet CT

- Page 1 Liquidyn P-Jet CT Jet Valve Operating Manual ™ Electronic pdf files of Nordson EFD manuals are also available at nordsonefd.com...

- Page 2 Thank You! You have just purchased the world’s finest precision dispensing equipment. I want you to know that all of us at Nordson EFD value your business and will do everything in our power to make you a satisfied customer.

-

Page 3: Table Of Contents

Valve Cleaning ................................28 Shut Down the System ............................29 Disassemble the Valve ............................29 Clean the Valve Components ..........................30 Assemble the Valve (After Cleaning) ........................31 Continued on next page nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. - Page 4 Appendix A, About Non-Contact Dispensing........................41 Appendix B, P-Jet CT Valve Interface Overview ......................42 Electrical Control................................42 Optional Nozzle Heater Control ..........................43 Pneumatic Control ..............................44 Valve Configuration Options ............................44 nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

-

Page 5: Introduction

The exchangeable design also makes material-type with a syringe barrel material supply changeout and component replacement fast and easy. The Liquidyn P-Jet CT valve is configurable. Many choices for the material supply components and the nozzle are available, including an optional nozzle heater. -

Page 6: Nordson Efd Product Safety Statement

Hot surfaces! Avoid contact with the hot metal surfaces of heated components. If contact can not be avoided, wear heat-protective gloves and clothing when working around heated equipment. Failure to avoid contact with hot metal surfaces can result in personal injury. nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 7: Halogenated Hydrocarbon Solvent Hazards

Qualified personnel are those employees or contractors who are trained to safely perform their assigned tasks. They are familiar with all relevant safety rules and regulations and are physically capable of performing their assigned tasks. nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 8: Intended Use

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained for Nordson EFD equipment will be voided if instructions for installation, operation, and service are not followed. If the equipment is used in a manner not specified by Nordson EFD, the protection provided by the equipment may be impaired. -

Page 9: Fire Safety

• Test: Verify the operation of features and the performance of equipment using the appropriate sections of this manual. Return faulty or defective units to Nordson EFD for replacement. • Use only replacement parts that are designed for use with the original equipment. Contact your Nordson EFD representative for information and advice. -

Page 10: Important Disposable Component Safety Information

Disconnect and lock out system electrical power. If using hydraulic and pneumatic shutoff valves, close and relieve pressure. For Nordson EFD air-powered dispensers, remove the syringe barrel from the adapter assembly. For Nordson EFD electro-mechanical dispensers, slowly unscrew the barrel retainer and remove the barrel from the actuator. -

Page 11: Equipment-Specific Safety Information

• Operate heaters (optional) within the approved temperature range only. Refer to “Specifications” on page 12. • Use only heaters that are distributed by Nordson EFD specifically for this micro-dispensing valve. • Adhere to the maintenance intervals specified under “Service” on page 28. -

Page 12: Specifications

>97% (dispensing tolerance <3%) Service life >100,000,000 cycles Product classification IP65 Installation category II Compressed air quality class Pollution degree DIN ISO 8573-1, class 5 Approvals nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

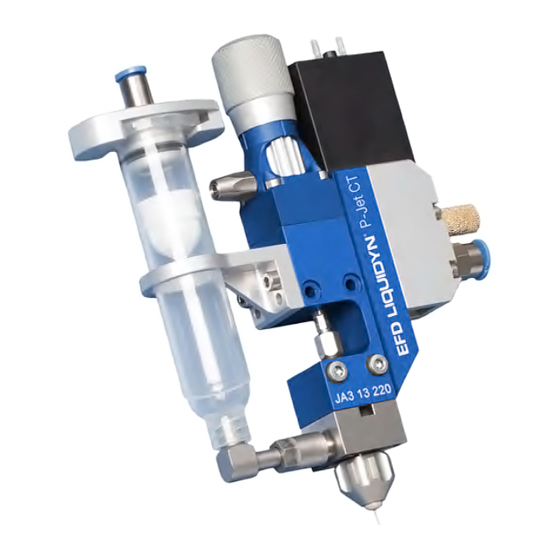

Page 13: Operating Features

Liquidyn P-Jet CT Jet Valve Operating Features The Liquidyn P-Jet CT micro-dispensing valve is shipped with the components shown under “Unpack the System Components” on page 14, along with any additional configuration selections and accessories. The valve can be uniquely configured to achieve the best dispensing result for your material and application. -

Page 14: Installation

Open-end wrench for 3.5 mm tappet rod Open-end wrench for 6 mm tappet nut Hex wrench for 1.5 mm adjustment knob (Not shown) Optional components (ordered and shipped separately) nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 15: Assemble The Valve (Initial Assembly)

Torque: 5 N•m (3.7 ft-lb) maximum • Optional: Install a tube connector (for non-syringe barrel installations). Continued on next page nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 16: Change The Fluid Body Or Tappet (Optional)

Loosen the tappet nut with a wrench (6 mm to loosen the tappet nut; 3.5 mm to hold the tappet rod steady). Continued on next page nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. - Page 17 O-ring. Mount the initial or replacement fluid body precisely over the tappet without tilting it. Tighten the screws crosswise. Torque: 0.8 N•m (5.9 ft-lb) maximum nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

-

Page 18: Install A Nozzle Heater (Optional)

Be sure to connect the heater Torque for a steel nozzle: 1.2 N•m (10.6 in.-lb) Torque for a plastic nozzle: 0.5 N•m (4.4 in.-lb) cable plug in the correct orientation. nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 19: Mount The Valve

Quick-release fastener M4 x 30 mounting screws (for mounting Lever (secures the hook) onto a socket; not included) Example of the quick-release mounting option nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 20: Connect Cables

T10 = Liquidyn T10 or T20 heater controller V10 = Liquidyn V10, V10M, V10D, or M10D controller V200 = Liquidyn V200 controller PLC = Higher-level controller nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 21: Connect The Air Supply

For the operating pressure, connect 6 mm OD tubing to the plug-in connector on the side of the valve. For the fluid pressure, connect 4 mm or 6 mm tubing to the syringe barrel adapter (syringe barrel installations only). NOTE: Nordson EFD recommends installing a precision pressure regulator with a maximum control tolerance of 0.2%. Air input (fluid pressure;... -

Page 22: Installation Example

Air pressure source Precision pressure regulator Pressure Operating pressure accumulator 6 mm air supply tubing (at least 0.4 liter) Liquidyn P-Jet CT valve connection diagram nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 23: Initial Startup

This section provides recommendations for system startup and operation. System startup for the valve depends on the control unit. If you are using a Nordson EFD Liquidyn valve controller, obtain the controller manual. If you are using higher-level controller, the control is set up by the customer. -

Page 24: Parameter Settings

• To achieve 50Hz with a 2 ms Pulse Time, set the pause time to 18 ms. • To achieve 50Hz with a 10 ms Pulse Time, set the pause time to 10 ms. Dispensing cycle Pulse time Pause time nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 25: Recommended Setup Adjustments

Down = lower operating pressure or temperature / tighten screw / smaller diameter Up = greater operating pressure or temperature / loosen screw / larger diameter nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 26: Tappet Adjustment

Turn the force screw counterclockwise until it stops. Turn the force screw clockwise for 25 clicks (15 clicks = one full turn). Completely tighten the raster element to secure the force screw. nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 27: Adjusting The Stroke

This can be felt when the torque elevates. Turn the knob 270° counterclockwise. Tighten the locking set screw to prevent accidental turning of the knob. Torque: 0.3 N•m (2.7 in.-lb) maximum nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 28: Service

Regularly perform maintenance on your micro-dispensing valve. Regular maintenance will save you cost-intensive repairs and is a requirement for long valve lifespan. Nordson EFD valves are designed to be maintained easily. All the material-carrying parts can be removed, cleaned, and maintained by the customer. -

Page 29: Shut Down The System

• Optional: If you are using a heater, use the heater key to remove the nozzle retaining nut. Remove the nozzle from the fluid body. Continued on next page nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 30: Clean The Valve Components

Use the pipe cleaners from the cleaning kit to clean the disassembled components (luer lock adapter, nozzle retaining nut, nozzle, fluid body, and the tappet if needed). Continued on next page nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 31: Assemble The Valve (After Cleaning)

• Optional: To use a different tappet, go to “Change the Fluid Body or Tappet (Optional)” on page 16. Return here to continue. Continued on next page nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. - Page 32 (Syringe barrel installations only) Mount the syringe barrel holder. • (Syringe barrel installations only) Install the syringe barrel and syringe barrel adapter. • Mount the valve and restore the system to normal operation. nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

-

Page 33: Replacement Parts

7825038* Plastic fluid body PEEK** 7825182 2.5 m (8.2 ft) M8 valve cable *Other selections are available. Contact your Nordson EFD application specialist for assistance. **Polyetheretherketone nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 34: Nozzles And Nozzle Retaining Nuts

*Many nozzle types and sizes are available. Contact your Nordson EFD application specialist for assistance. The retaining nut secures the nozzle to the valve. The choice of retaining nut depends on the type of nozzle and whether or not a nozzle heater is installed. Contact your Nordson EFD application specialist for assistance. Nozzle... -

Page 35: Syringe Barrels And Accessories

Liquidyn P-Jet CT Jet Valve Replacement Parts (continued) Syringe Barrels and Accessories Many syringe barrel sizes and accessories are available. Contact your Nordson EFD application specialist for assistance. 5, 6 2, 3 Item Description Configuration Options • Luer lock adapter for 3cc to 50cc syringe barrels •... -

Page 36: Material Supply Tubing Components

Liquidyn P-Jet CT Jet Valve Replacement Parts (continued) Material Supply Tubing Components The following material supply tubing and connectors are available from Nordson EFD. Additional selections may be available. Contact your Nordson EFD application specialist for assistance. Steel Tubing Connectors... -

Page 37: Accessories

7825020 Quick-release fastener — Two (2) M4 hex screws (minimum length: 10 mm) Customer supplied Precision Pressure Regulator Nordson EFD recommends a dry, oil-free, filtered air supply (40 µm filter grade). Part # Description 7825268 Precision pressure regulator nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 38: Nozzle Heaters

7825235 EPDM nozzle heater O-ring EPDM Heater Key The heater key is required to install the heater retaining nuts. Part # Description Item 7825209 Heater key nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 39: Tools And Supplies

Standard cleaning kit (order based on O-ring type) Perlast: 7825194 Viton: 7825196 EPDM: 7825198 Perlast: 7825195 Expanded cleaning kit (order based on O-ring type) Viton: 7825197 nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 40: Technical Data

(0.6") 15 mm 13 mm (0.6") (0.5") SW10 20 mm (0.8") M8 Valve Cable Pin Positions Color Function Brown None Black Valve (+) Blue Valve (-) nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 41: Appendix A, About Non-Contact Dispensing

At a certain point, it is physically impossible to transfer the required energy to the dispensed material any longer, particularly in the dispensing of highly viscous materials. nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 42: Appendix B, P-Jet Ct Valve Interface Overview

Appendix B, P-Jet CT Valve Interface Overview The Liquidyn P-Jet CT pneumatic micro-dispensing jet valve is designed for the non-contact dispensing of low- to medium-viscosity materials, including oils, greases, glues, flux, and filled products. The valve can be operated using a Nordson EFD Liquidyn valve controller or directly by the customer via a 24V input using a customer-supplied controller or a programmable logic controller (PLC). -

Page 43: Optional Nozzle Heater Control

Nozzle Heater Cable Pin Positions 6-pin plug M5 plug Color Function Brown Heating coil White Heating coil White Not assigned Black PT100 RTD Blue PT100 RTD White Not assigned nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide. -

Page 44: Pneumatic Control

100 bar (1450 psi) CAUTION Ensure that the pressure limit values for the syringe barrel and air pressure tubing are not exceeded. NOTE: Nordson EFD recommends installing a precision pressure regulator with a maximum control tolerance of 0.2%. Valve Configuration Options •... - Page 45 Liquidyn P-Jet CT Jet Valve Notes nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

- Page 46 NORDSON EFD ONE YEAR LIMITED WARRANTY Nordson EFD products are warranted for one year from date of purchase to be free from defects in material and workmanship (but not against damage caused by misuse, abrasion, corrosion, negligence, accident, faulty installation or by dispensing material incompatible with equipment) when the equipment is installed and operated in accordance with factory recommendations and instructions.

Need help?

Do you have a question about the Liquidyn P-Jet CT and is the answer not in the manual?

Questions and answers