Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric Lossnay LGH-15RX3

- Page 1 TECHNICAL MANUAL...

-

Page 2: Table Of Contents

CONTENTS CHAPTER 1 Ventilation for Healthy Living Necessity of Ventilation ............................Ventilation Standards ............................Ventilation Method .............................. Ventilation Performance ............................Outdoor Air (ventilation) Load ..........................10 CHAPTER 2 Lossnay Construction and Principle Construction and Features of Lossnay ......................16 Construction and Principle of Core ........................16 Calculation of the Total Heat Recovery Efficiency .................... - Page 3 CHAPTER 6 Examples of Lossnay Applications Large Office Building ............................70 Medium Size Office Building ..........................73 Multipurpose Tenant Building ..........................76 Urban Small-Scale Building ..........................79 Hospitals ................................80 Schools ................................82 Hotels (convention halls, wedding halls) ......................84 Public Halls (combination facilities such as day-care centres) ................

-

Page 4: Chapter 1 Ventilation For Healthy Living

CHAPTER 1 Ventilation for Healthy Living... -

Page 5: Necessity Of Ventilation

CHAPTER 1 G Ventilation for Healthy Living Fresh outdoor air must be introduced constantly at a set ratio in an air conditioning system. This fresh air is introduced to be mixed with the return air from the room, to adjust the temperature and humidity, supply oxygen, reduce body and other odors, remove tobacco smoke and to increase the cleanness of the air. - Page 6 CHAPTER 1 G Ventilation for Healthy Living In the case of Japan, an Instruction Guideline based on these regulations has been issued, and unified guidance is carried out. Part of the Instruction Guideline regarding ventilation is shown below. The fresh outdoor air intake must be 10 m or higher from ground level, and be distanced appropriately from the exhaust air outlet.

-

Page 7: Ventilation Standards

CHAPTER 1 G Ventilation for Healthy Living Effect of carbon dioxide (CO Concentration (%) Effect of concentration changes 0.03 (0.04) Standard atmosphere. 0.04 - 0.06 City air. 0.07 Tolerable concentration when many people stay for long time. There is no toxic level in alone. -

Page 8: Ventilation Method

CHAPTER 1 G Ventilation for Healthy Living 3. Ventilation Method 3.1 Ventilation class and selection points An appropriate ventilation method must be selected according to the purpose. Ventilation is composed of “Supply air” and “Exhaust air” functions. These functions are classified according to natural flow or mechanical ventilation using a fan (forced ventilation). - Page 9 CHAPTER 1 G Ventilation for Healthy Living 3.2 Comparison of ventilation methods There are two main types of ventilation methods. Centralized ventilation method This is mainly used in large buildings, with the fresh outdoor air intake being installed in one machine room. For this method, primary treatment of the fresh outdoor air, such as heat recovery to the intake air and dust removal is performed being distribution to the building by ducts.

- Page 10 CHAPTER 1 G Ventilation for Healthy Living Comparison of centralised ventilation method and independent zoned ventilation method Centralized ventilation method Independent zoned ventilation method The air transfer distance is long thus requiring As the air transfer distance is short, the fan power Fan power much fan power.

-

Page 11: Ventilation Performance

CHAPTER 1 G Ventilation for Healthy Living 4. Ventilation Performance The ventilation performance is largely affected by the installation conditions. Ample performance may not be achieved unless the model and usage methods are selected according to the conditions. Generally, the ventilation performance is expressed by “Air volume” and “wind pressure (static pressure)”, and these are necessary when considering ventilation. - Page 12 CHAPTER 1 G Ventilation for Healthy Living 4.3 Measurement of the air volume and wind pressure Mitsubishi measures the machine’s air volume and wind pressure with a device as shown below according to the Japan Industrial Standards (JIS B 8628). Measuring device using orifice (JIS B 8628 standards) Chamber Damper...

-

Page 13: Outdoor Air (Ventilation) Load

CHAPTER 1 G Ventilation for Healthy Living 5. Outdoor Air (ventilation) Load 5.1 How to calculate each approximate load The outdoor air load can be calculated with the following formula if the required outside air intake volume Q m /h to be introduced is known: γ... - Page 14 CHAPTER 1 G Ventilation for Healthy Living Example calculations of determining ventilation load during both cooling and heating are given as follows: 5.2 Ventilation load during cooling (in general office building) G Classification of cooling load Class Heat from walls (q from direct sunlight (q Indoor infiltration heat Heat from glass...

- Page 15 CHAPTER 1 G Ventilation for Healthy Living G Determining internal heat gain When classifying loads, the internal heat gain (indoor generated heat + indoor infiltration heat) will be the value of the outdoor air load subtracted from the approximate cooling load when it is assumed that there is no reheating load. (Internal heat gain) = 157.0 W/m (135 kcal/h·m...

- Page 16 CHAPTER 1 G Ventilation for Healthy Living 5.3 Ventilation load during heating Classification of heating load Class Heat lost from walls (q Heat lost from glass (q Indoor heat loss Heat loss from conduction & convection (q Accumulated heat load in walls (q Sensible heat (q Outdoor air load...

-

Page 18: Chapter 2 Lossnay Construction And Principle

CHAPTER 2 Lossnay Construction and Principle... -

Page 19: Construction And Features Of Lossnay

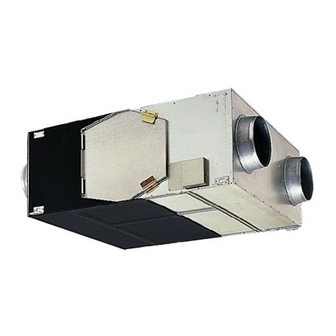

CHAPTER 2 G Lossnay Construction and Principle 1. Construction and Features of Lossnay G Lossnay construction The Lossnay is constructed so that the exhaust air passage from the indoor side to the outdoor side (RA → EA) and the fresh air Lossnay Core passage from the outdoor side to the indoor side (OA →... - Page 20 CHAPTER 2 G Lossnay Construction and Principle A comparison of the ordinary paper and the Lossnay Core plates is as shown in the table. Ordinary paper Water vapor is transferred, but gas elements that are easily dissolved in water such as CO , NO are also transferred.

-

Page 21: Calculation Of The Total Heat Recovery Efficiency

CHAPTER 2 G Lossnay Construction and Principle 3. Calculation of the Total Heat Recovery Efficiency The Lossnay Core’s heat recovery efficiency can be considered Indoors Outdoors using the following three transfer rates: Exhaust air Supply air (Stale air) (Fresh cold or warm air) (1) Temperature (sensible heat) recovery efficiency (2) Humidity (latent heat) recovery efficiency (3) Enthalpy (total heat) recovery efficiency... -

Page 22: What Is A Psychrometric Chart

CHAPTER 2 G Lossnay Construction and Principle 4. What is a Psychrometric Chart? The chart which shows the properties of humid air is called a psychrometric chart. The psychrometric chart can be used to find the (1) Dry bulb temperature, (2) Wet bulb temperature, (3) Absolute humidity, (4) Relative humidity, (5) Dew point and (6) Enthalpy (total heat) of a certain air condition. -

Page 23: Calculation Of Lossnay Heat Recovery

CHAPTER 2 G Lossnay Construction and Principle 5. Calculation of Lossnay Heat Recovery The following figure shows the conditions of various air states when fresh air is introduced through the Lossnay Core. If a conventional sensible heat recovery unit is used alone and is assumed to have the same heat recovery efficiency as Lossnay, the condition of the air supplied to the room is expressed by point A in the figure. -

Page 24: Chapter 3 General Technical Considerations

CHAPTER 3 General Technical Considerations... -

Page 25: Lossnay Heat Recovery Effect

CHAPTER 3 G General Technical Considerations 1. Lossnay Heat Recovery Effect 1.1 Comparison of outdoor air load of various ventilators Examples of formulas to compare the heat recovered and outdoor air load when ventilating with the Lossnay (total heat recovery unit), sensible heat recovery ventilation (sensible HRV) and conventional ventilators are shown below. (1) Cooling during summer Conditions Model LGH-50R type... - Page 26 CHAPTER 3 G General Technical Considerations (2) Heating during winter Conditions: Model LGH-50R type Heat recovery efficiency table (%) (at 50Hz, high speed) (For winter) Ventilation rate: 500 m Conventional (Specific gravity of air ρ = 1.2 kg/m Lossnay Sensible HRV ventilator Temperature –...

-

Page 27: Example Heat Recovery Calculation

CHAPTER 3 G General Technical Considerations 2. Example Heat Recovery Calculation (1) Setting of conditions (Note: Tokyo Power, industrial power 6 kV supply) Units When Heating When Cooling 10h/day × 26 days/mo. × 5 mo./yr. = 1,300 h/yr 10h/day × 26 days/mo. × 4 mo./yr. = 1,040 h/yr Operation time (h/yr) Electricity fee... - Page 28 CHAPTER 3 G General Technical Considerations Psychrometric chart for calculating Lossnay economical effect 0.037 0.036 0.035 0.034 0.033 0.032 0.031 0.030 0.029 Humid air psychrometric chart 0.028 0.027 (-10 to +50°C, atmospheric pressure 101.325 kPa) 0.026 0.025 0.024 0.023 ± ∞...

-

Page 29: Calculation Of Lossnay Economical Effects

CHAPTER 3 G General Technical Considerations 3. Calculation of Lossnay Economical Effects The following is a sample questionnaire from which it is possible to assess the economical benefits of using the Lossnay in particular applications. (1) Setting of conditions Return air volume (RA) Outdoor air volume (OA) = Air volume ratio (RA/OA) = Air conditions... - Page 30 CHAPTER 3 G General Technical Considerations (4) Outdoor air load and heat recovery Heating Cooling = Air specific gravity × outdoor air volume = Air specific gravity × outdoor air volume Fresh air load without × (indoor enthalpy – outdoor air enthalpy) ×...

-

Page 31: Psychrometric Chart

CHAPTER 3 G General Technical Considerations 4. Psychrometric Chart... -

Page 32: The Result Of No Bacerial Cross Contamination For The Lossnay Core And Determining Resistance Of The Lossnay Core To Molds

The object of this test is to verify that there is no bacterial cross contamination from the outlet air to the inlet air of the Lossnay Core in the heat recovery process. (2) Client MITSUBISHI ELECTRIC CO. NAKATSUGAWA WORKS. (3) Test period April 26, 1999 - May 28, 1999 (4) Test method The configuration of the test equipment is shown below. - Page 33 CHAPTER 3 G General Technical Considerations Table 1 Test result with bacillus subtilis (CFU/30L air) 5.4 × 10 5.6 × 10 < 10 < 10 8.5 × 10 7.5 × 10 < 10 < 10 7.5 × 10 < 10 <...

-

Page 34: Flame-Proofing Properties Of Lossnay Core

CHAPTER 3 G General Technical Considerations 6. Flame-proofing Properties of Lossnay Core The Lossnay Core satisfied all requirements of Paragraph 4-3 of the Fire Prevention Law Enforcement Rules. Details of the tests carried out are as seen below. Notation format 2 - (3) Notification of flame-proofing property test (For flame-proof materials and related items) Flame-proofing committee test No., B-80028... - Page 35 Messrs. Mitsubishi Electric Corp., Japan Construction General Laboratories Nakatsugawa Works 5-8-1 Fujishirodai, Suita City 565 Tel: 06-872-0391 Hiorshi Wakabayashi Dr. of Engineering, Director Company name Mitsubishi Electric Corp., Nakatsugawa Works Applicant Address 1-3 Komanba-cho, Nakatsugawa, Gifu Single-face laminated Product Lossnay Core...

-

Page 36: Lossnay Core's Soundproofing Properties Test

Hz. This means that a sound source of 96.9 dB can be shielded to 63 dB. No. 122-1 Soundproofing effect test results Test number IVA-78-122 For Mitsubishi Electric Corporation Acceptance data : February 22, 1979 Report May 24, 1979 Nakatsugawa Works General Building Reseach Corporation The results of the tests are as noted below. -

Page 37: Change In Lossnay Core Over Time

CHAPTER 3 G General Technical Considerations 8. Change in Lossnay Core Over Time The following details show an example of a building that has installed the Lossnay units, from which it is possible to assess the change in the units over time. 8.1 Outline of building where Lossnay is installed Building name : Meiji Seimei, Nagoya Office/shop building... - Page 38 CHAPTER 3 G General Technical Considerations 8.3 Outline of Lossnay operation Start of operation : September 1972 Start of daily operation : 7:00 Average daily operation 11 hours End of daily operation : 18:00 Inspection after usage : November 1983 Bypass operation month : Three months of April, May, June : (134 –...

-

Page 39: Comparison Of Heat Recovery Techniques

CHAPTER 3 G General Technical Considerations 9. Comparison of Heat Recovery Techniques The methods by which heat recovery devices can be categorised may be considered as follows: Basic methods of total heat exchangersa Type Method Air flow Country of Static Conductive Cross-flow development... - Page 40 CHAPTER 3 G General Technical Considerations 9.2 Comparison of static-type and rotary-type heat recovery units Item Rotary-type Static-type <Conductive transmission-type: cross-flow> <Heat accumulation/humidity accumulation- Static-type transmission total heat recovery unit type: counterflow> The rotor core is composed of honeycomb-shaped with orthogonally layered honeycomb shaped treated paper formed into multiple layers.

-

Page 42: Chapter 4 Characteristics

CHAPTER 4 Characteristics... -

Page 43: How To Read The Lgh Series Lossnay Characteristic Curves

CHAPTER 4 G Characteristics 1. How to Read the LGH Series Lossnay Characteristic Curves 1.1 Obtaining characteristics from static pressure loss (1) Static pressure loss from straight pipe duct length (at required air volume) (2) Static pressure loss at curved section (at required air volume) (3) Static pressure loss of related parts (at required air volume) Total static pressure loss Estimated static pressure loss curve... - Page 44 CHAPTER 4 G Characteristics Reference The pressure loss caused by the outdoor air is as follows: Pressure loss caused by outdoor air (Pa) × V × (velocity) r : Air weight 1.2 kg/m v : Velocity (m/s) 2 4 6 8 10 12 14 16 18 Outdoor air (m/s) 2.2 Calculation of duct pressure loss When selecting a model that is to be used with a duct, calculate the volumes according to Tables 3, 4, 5 and 6, and then select...

- Page 45 CHAPTER 4 G Characteristics The figure obtained from Table 4 must then be corrected for duct type at various velocities. This can be done using Table 5 below. Table 5 Friction coefficient compensation table Average velocity (m/sec) Duct inner surface Example Very rough surface Concrete finish...

- Page 46 CHAPTER 4 G Characteristics (3) How to calculate curved sections Table 6 List of pressure losses in each duct section Length of Length of Duct Duct equivalent equivalent Outline diagram Conditions Outline diagram Conditions circular circular value value section section pipe pipe R/D = 0.5...

-

Page 47: How To Obtain Efficiency From Characteristic Curves

CHAPTER 4 G Characteristics 3. How to Obtain Efficiency from Characteristic Curves 3.1 Commercial-use Lossnay How to read Commercial-use Lossnay characteristic curve Recovery Static pressure efficiency outside unit Recovery efficiency Enthalpy recovery efficiency (heating) Enthalpy recovery efficiency (cooling) Total static pressure loss (or total straight pipe equivalent length) Static pressure loss related parts (straight pipe equivalent length total) Static pressure outside unit... -

Page 48: Sound

CHAPTER 4 G Characteristics 4. Sound Sound is emitted when any object is excited causing it to vibrate. The object that vibrates is called the sound source, and the energy that is generated at the source is transmitted through the air to the human ear. Humans can hear the sound only when the ear drum vibrates. - Page 49 CHAPTER 4 G Characteristics 4.3 Frequency analysis of sound It is said that the human ear senses differently according to the frequency. However, the sound generated from a vibration is not limited to one frequency, but instead, various frequencies are generated at differing levels. This is expressed by the NC curve, which is determined according to the difficulty of hearing a conversation.

- Page 50 CHAPTER 4 G Characteristics * Approximate values of noise levels using practical examples The following diagram shows noises found near us. Approximate degree of noise levels can be seen with these examples. * Noise levels and perception (dB) (Perception at site) Boiler making Painful to ear Forginb, rivetting,...

- Page 51 CHAPTER 4 G Characteristics 4.4 Indoor noise (1) Principle of indoor noise 1) Power levels Fig. 1 The Power level (PWL) of the sound source must be understood when considering noise effects. The following formula is used to obtain PWL from the Main unit measured sound pressure data (values noted in catalog) in an anechoic chamber.

- Page 52 CHAPTER 4 G Characteristics For the supply air diffuser (and return grille) in Fig. 2, PWL Transmission loss in ceiling material (dB) Example must be corrected for the noise alternation provided by the Material ( ) duct work (TL) such that: Plaster Plaster Lauan...

- Page 53 CHAPTER 4 G Characteristics 2) When supply air diffuser (and return grille) is sound source ..part 1 (A) If the main unit is separated from the supply air diffuser Fig. 6 (and return grille) as shown in Fig. 6, the use of a silencer box a), silence duct b) or silence grille c) is recommended.

-

Page 54: Nc Curves (Lgh-Rx 3 Series)

CHAPTER 4 G Characteristics 5. NC Curves (LGH-RX Series) G Ceiling embedded-type LGH-15RX Background noise : 25 dB or less (A range) Background noise : 25 dB or less (A range) Measurement site : Anechoic chamber Measurement site : Anechoic chamber Operation conditions : Lossnay ventilation Operation conditions : Lossnay ventilation 1.5 m below... - Page 55 CHAPTER 4 G Characteristics LGH-50RX Background noise : 25 dB or less (A range) Background noise : 25 dB or less (A range) Measurement site : Anechoic chamber Measurement site : Anechoic chamber Operation conditions : Lossnay ventilation Operation conditions : Lossnay ventilation 1.5 m below 1.5 m below Measurement point...

- Page 56 CHAPTER 4 G Characteristics LGH-150RX Background noise : 25 dB or less (A range) Background noise : 25 dB or less (A range) Measurement site : Anechoic chamber Measurement site : Anechoic chamber Operation conditions : Lossnay ventilation Operation conditions : Lossnay ventilation 1.5 m below 1.5 m below Measurement point...

- Page 57 CHAPTER 4 G Characteristics G Lossnay Pack-type for Buildings LP-200B LP-350B Background noise : 51 dB (A range) Background noise : 51 dB (A range) Measurement site : Fan test operation site Measurement site : Fan test operation site Measurement position : 1.5 m from the front center of the Measurement position : 1.5 m from the front center of the unit, 1 m above the floor unit, 1 m above the floor...

-

Page 58: List Of Models

CHAPTER 4 G Characteristics 6. List of Models 6.1 Model specifications... - Page 59 CHAPTER 4 G Characteristics 6.2 List of material colours for Industrial Lossnay...

- Page 60 CHAPTER 4 G Characteristics 6.3 List of material colours for Building Lossnay...

- Page 61 CHAPTER 4 G Characteristics 6.4 List of industrial/business Lossnay accessories Model Accessories Duct packaging site LGH-15RX Duct connection flanges ..× 4 * Top view. There LGH-25RX Mounting screws ... . . × 34 is a space between the EA Washers .

-

Page 62: Chapter 5 System Design Recommendations

CHAPTER 5 System Design Recommendations... -

Page 63: Lossnay Usage Conditions

CHAPTER 5 G System Design Recommendations 1. Lossnay Usage Conditions Main unit installation conditions Outdoor air and exhaust air conditions Commercial-use Lossnay -10°C to +40°C, RH80% or less -10°C to + 40°C, RH80% or less. Same as left LP model Lossnays -10°C to +40°C, RH80% or less The room air temperature/humidity is controlled by separate devices. -

Page 64: Noise Value Of Lossnay With Built-In Fans

CHAPTER 5 G System Design Recommendations 2. Noise Value of Lossnay with Built-in Fans The noise level specified for Lossnay units is as that measured in an anechoic chamber. The sound level may increase by 8 to 11 dB according to the installation construction material, and room contents. When using the Lossnay in a quiet room, it is recommended that measures such as installing a muffling duct, optional silencer intake/exhaust grill (PZ-FG type)* or silencer box (PZ-SB type)* be carried out. -

Page 65: Transmission Rate Of Various Gases And Related Maximum Workplace Concentration

CHAPTER 5 G System Design Recommendations 6. Transmission Rate of Various Gases and Related Maximum Workplace Concentration Air volume Exhaust air Supply air Transmission Max. workplace Measurement ratio concentration concentration rate concentrations conditions (ppm) (ppm) (ppm) Measurement method Hydrogen fluoride <0.5 Hydrogen chloride <0.5... -

Page 66: Solubility Of Odors And Toxic Gases, Etc., In Water And Effect On Lossnay Core

CHAPTER 5 G System Design Recommendations 7. Solubility of Odors and Toxic Gases, etc., in Water and Effect on Lossnay Core Main Molecular Sulubility Max. Non-toxic/ Useability generation Gas name formula vapour in water workplace toxic/ of Lossnay site mist odor concentration m /m... -

Page 67: Positioning Of The Supply/Exhaust Fans And The Air Transmission Rate (Excluding Moisture Resistant Total Heat Recovery Units)

CHAPTER 5 G System Design Recommendations 8. Positioning of the Supply/Exhaust Fans and the Air Transmission Rate (excluding moisture resistant total heat recovery units) The following four methods can be used for when setting the Lossnay supply and exhaust fans around the Lossnay Core. When using the LU and LUT models, methods a or b should be used in respect of both the Lossnay Core air leakage and effective air ventilation. -

Page 68: Combined Operation With Other Air Conditioners

CHAPTER 5 G System Design Recommendations 9. Combined Operation with other Air Conditioners Connecting the Lossnay can configure the following system. Interlocked with City Multi M-NET transmission cable City Multi indoor unit Lossnay unit LGH-**RX Remote controller Interlocked with Mr. Slim Mr.Slim (A, K-control) indoor unit Lossnay unit... -

Page 69: Automatic Ventilation Switching

CHAPTER 5 G System Design Recommendations 10. Automatic Ventilation Switching Effect of Automatic Ventilation Mode The automatic damper mode automatically provides the correct ventilation for the conditions in the room. It eliminates the need for troublesome switch operations when setting the Lossnay ventilator to “By-pass” ventilation. The following shows the effect “By-pass”... -

Page 70: Vertical Installation Of Lgh Series

CHAPTER 5 G System Design Recommendations 11. Vertical Installation of LGH Series Installation of ceiling embedded-type industrial Lossnay 11.1 Top/bottom reverse installation Bottom All LGH-RX models can be installed in reverse. Bottom 11.2 Vertical installation Vertical installation is possible, but the installation pattern is limited for some models. Refer to the following table for the installation patterns. -

Page 71: Installation Of Supplementary Fan Devices After Lossnay Unit

CHAPTER 5 G System Design Recommendations 12. Installation of Supplementary Fan Devices After Lossnay Unit On occasions it may be necessary to install additional fans in the ductwork following the LGH type Lossnay. This is because of the inclusion of extra components such as control dampers, high-efficiency filters, sound attenuators, etc. which create a significant extra static pressure to the airflow. -

Page 72: Chapter 6 Examples Of Lossnay Applications

CHAPTER 6 Examples of Lossnay Applications... -

Page 73: Large Office Building

CHAPTER 6 G Examples of Lossnay Applications Lossnay ventilation systems are proposed for eight types of applications in this chapter. These systems are planned for Japanese use, and actual systems will differ according to each country. These should be used only as reference. 1. - Page 74 CHAPTER 6 G Examples of Lossnay Applications (2) Ventilation For general offices, a ceiling embedded-type Lossnay will be installed in the ceiling. The inside of the ceiling will be used as a return chamber for exhaust, and the air from the Lossnay will be supplied to the air-conditioning return duct and mixed with the air in the air conditioning passage.

- Page 75 CHAPTER 6 G Examples of Lossnay Applications A gallery will be constructed on the outer wall for the outer wall exhaust air outlets to allow for blending in with the exterior. Reference floor air conditioner system layout A Air-cooling heat pump air conditioner = Lossnay B Air-cooling heat pump air conditioner Additional room...

-

Page 76: Medium Size Office Building

CHAPTER 6 G Examples of Lossnay Applications (3) Humidification If the load fluctuation of the required humidification amount is proportional to the ventilation volume, it is ideal to combine the humidifier installation with the ventilation system. For this application, the humidifier is installed on with the air supply side of the Lossnay. - Page 77 CHAPTER 6 G Examples of Lossnay Applications 2.2 Current topics For general office buildings of the past, centralised air conditioning methods allowing the total centralised control and systematization of the entire building (or divided into floor systems) were favoured due mainly to facility control, uniformity of operation hours, maintenance efficiency and building usage.

- Page 78 CHAPTER 6 G Examples of Lossnay Applications 2.3 Proposed details A) General floors An independent dispersed-type control system incorporating an air cooling heat pump chiller and cassette-type fan coil unit for cooling and heating is used. This can cater for load fluctuations resulting from increases in office automation systems or changes in partitions hence requiting independent control of each module zone (approx.

-

Page 79: Multipurpose Tenant Building

CHAPTER 6 G Examples of Lossnay Applications 2.5 System trends Creation of an environment including independence, management and control of each zone can be realised as work trends become more diversified. Simultaneous cooling/heating system due to necessity from increased fixed sash windows and increase in office automation systems. - Page 80 CHAPTER 6 G Examples of Lossnay Applications 3.3 Plan details (1) Lower floors for business • 4F to 8F: Tenant offices – Lossnay installation sites: A machine room installation-type package and building machine room on each floor Lossnay is applied as a centralized method for each unit. To reduce installation space, a package-type LP Lossnay (One system for ground and 1st floor banking institution, one with built-in air-supply fan and filter is incorporated and...

- Page 81 CHAPTER 6 G Examples of Lossnay Applications Air conditioning system diagram 3.4 Effect (1) Management in tenant units is clear and simple (2) Maintenance is simple as the maximum centralization can be planned while having independent tenants. (3) As ventilation units are considered per floor, there are few openings on the outer wall, making designing of the outer wall more simple.

-

Page 82: Urban Small-Scale Building

CHAPTER 6 G Examples of Lossnay Applications 4. Urban Small-Scale Building 4.1 System plan points This system is based on effectively using available space within a limited area by installing the air conditioner and ventilator in available excess space. For this application, the air flow must be considered for the entire floor with the ventilator installed in the ceiling space. Setting outline Application : Office... -

Page 83: Hospitals

CHAPTER 6 G Examples of Lossnay Applications 4.4 Effect (1) Accurate ventilation is possible with Class 1 ventilation (forced simultaneous air intake/exhaust) using the Lossnay. (2) Outdoor air supply to the toilet and kitchenette is possible with the Lossnay, and accurate ventilation is possible even in highly sealed buildings. - Page 84 CHAPTER 6 G Examples of Lossnay Applications 5.3 Plan proposals GF layout (1) Air conditioning Centralised heat source control using a fan coil for the Medicine supply general system allows efficient operating time control and storage energy conservation. Machine Gastro 24-hour system using a package air conditioner for special room X-ray...

-

Page 85: Schools

CHAPTER 6 G Examples of Lossnay Applications 5.4 Effect (1) The following is possible by independently ventilating the air-conditioned rooms with the Lossnay: Transmission of diseases can be prevented by shielding the air between rooms. Infiltration of outside noise can be prevented with the Lossnay Core’s soundproof properties. As outdoor air does not need to be taken in from the hallway, the door can be sealed, shutting out hallway noise. - Page 86 CHAPTER 6 G Examples of Lossnay Applications 6.4 Plan details (1) To pursue comfor t, save energy and space, an air Classroom layout conditioning and ventilation system using a ceiling embedded-type fan coil unit and ceiling embedded-type Lossnay was applied. (2) Automatic operation using a weekly program timer was (Hallway) applied, energising when the general classrooms and special...

-

Page 87: Hotels (Convention Halls, Wedding Halls)

CHAPTER 6 G Examples of Lossnay Applications 7. Hotels (convention halls, wedding halls) 7.1 System plan points Hotels in Japan often have functions such as a resort hotel at tourist spots, convention hotel with conference and banquet halls, and business hotels for short-term stays. These are all labeled as hotels, and often, more importance is laid on the wedding, convention and banquet halls, etc. -

Page 88: Public Halls (Combination Facilities Such As Day-Care Centres)

CHAPTER 6 G Examples of Lossnay Applications 7.4 System trends The load characteristics at hotels is complex compared to general buildings, and are greatly affected by the bearing, time, and operation state as mentioned above. Further to this, the high ceilings in meeting rooms and banquet halls, requires preheating and precooling to be considered. - Page 89 CHAPTER 6 G Examples of Lossnay Applications 8.4 Effect (1) Operation is possible without special knowledge, so management is easy. (2) Operation is possible according to each room’s needs, and is thus energy-saving. (3) Soundproof ventilation is possible with the separately installed ventilators. (4) Energy saving ventilation is possible with the heat recovery ventilation.

-

Page 90: Chapter 7 Installation Considerations

CHAPTER 7 Installation Considerations... -

Page 91: Lgh-Series Lossnay Ceiling Embedded-Type (Lgh-Rx 3 Series)

CHAPTER 7 G Installation Considerations 1. LGH-Series Lossnay Ceiling Embedded-Type (LGH-RX Series) LGH-15 · 25 · 35 · 50 · 80 · 100RX models I Installation diagram Always leave inspection holes ( 450 or 600) on the air filter and Lossnay Core removal side. Always insulate the two ducts outside the room (intake Exhaust air grill Suspension bolt position... - Page 92 CHAPTER 7 G Installation Considerations (1) The ceiling embedded-type: 150 · 250 · 350 · 500 · 800 · 1000 · 1500 and 2000 m /h types are available. Select an adequate model according to the room size, air volume for the application and noise levels. (2) The LGH-15 ·...

- Page 93 CHAPTER 7 G Installation Considerations 1.1 Selecting Duct Attachment Direction You can choose between two directions for the outside duct (OA, EA) piping direction, to improve construction. Standard Construction Construction with the Direction Changed I It is possible I You can avoid *A space is to set the unit obstructions of the...

-

Page 94: Business Lossnay Suspended Exposed-Type

CHAPTER 7 G Installation Considerations 2. Business Lossnay Suspended Exposed-Type (1) Leave at least a 400 mm maintenance space at the right side of the main unit for connection of the control switch and power to the main unit. When attaching square duct When attaching round duct PZ-20CVU Suspension bolt position... -

Page 95: Building Lossnay Pack-Type (Lp-200B, 350B · 500B · 750B · 1000B)

CHAPTER 7 G Installation Considerations 3. Building Lossnay Pack-type (LP-200B · 350B · 500B · 750B · 1000B) System concept diagram Installation examples <Combination with air handling unit> <Combination with package air Package air conditioner conditioner> LP-200B Air handling unit LP-1000B Lossnay Chamber... - Page 96 CHAPTER 7 G Installation Considerations 3.3 Flange dimensions LP-200B LP-350B 18-ø 10 holes 14-ø 10 holes Pitch Pitch 100 × 2 = 200 100 × 3 = 300 Unit (mm) Unit (mm) LP-500B 22-ø 10 holes Pitch 100 × 4 = 400 Unit (mm) LP-750B ·...

- Page 97 CHAPTER 7 G Installation Considerations 3.4 Transportation and installation (1) LP-200B · 350B · 500B The product is shipped in the fully assembled state. Transport the unit gently and do not apply shock or tilt the unit. Filler plate Use eyebolts (or eyenuts) when lifting the unit. Always use Hook for the four eyebolts, and fix with rope.

-

Page 98: Building Lossnay Unit Vertical-Type (Lut-2302 · 2303 · 3002 · 3003)

CHAPTER 7 G Installation Considerations 4. Building Lossnay Unit Vertical-type (LUT-2302 · 2303 · 3002 · 3003) 4.1 Main unit dimensions and flange dimensions This unit is for indoor installation. The flange is an inner-flange. The special filter is not sold separately and must be prepared by the user. (Two on Core’s intake side.) Unit (mm) LUT-2302... - Page 99 CHAPTER 7 G Installation Considerations 4.3 Combination dimensions The combined-type uses a combination of single-type units. The combined-type is shipped in the disassembled state. (A combination of single-type units.) LUT-2302 LUT-2303 LUT-2304 LUT-2305 LUT-2306 LUT-2307 LUT-2308 1000 1500 2000 2500 3000 3500 4000...

-

Page 100: Building Lossnay Unit Horizontal-Type (Lu-80 · 160 · 500)

CHAPTER 7 G Installation Considerations Fig. 1 Fig. 2 Top connection fitting M10 screw Crane Rope Washer Shackle Rope Eyebolt for lifting Lossnay unit 45° or 45° or more more M8 screw Bottom connection fitting 5. Building Lossnay Unit Horizontal-type (LU-80 · 160 · 500) 5.1 Main unit installation surface diagram (anchor bolt installation position) For LU-80 For LU-160... - Page 101 CHAPTER 7 G Installation Considerations 5.3 Combination dimensions and flange dimensions LU-1602 · 1603 · 1604 · 1605 · 1606 Unit (mm) Pitch 100 × 6 = 600 LU-1602 1010 Pitch 100 × 10 = 1000 LU-1603 1520 1180 1260 1220 Pitch 100 ×...

- Page 102 CHAPTER 7 G Installation Considerations 5.4 Transportation and installation The product is shipped in the fully assembled state. Transport the unit gently and do not apply shock or tilt the unit. (1) Use eyebolts (or eyenuts) and rope when lifting the unit. Make sure that the rope can withstand the weight of the unit. Always use all four eyebolts, and fix the rope.

-

Page 103: Industrial Moisture Resistant Lossnay (Lup-80 · 160 · 500)

CHAPTER 7 G Installation Considerations 6. Industrial Moisture Resistant Lossnay (LUP-80 · 160 · 500) The moisture resistant Lossnay requires drains. Install the unit by lifting it from the floor with a base, etc., so that draining from under the unit is also possible. (A base is provided for the combined types.) 6.1 Combination-type installation surface diagram (anchor bolt installation position, drain pipe position) For LUP-160 combination... - Page 104 CHAPTER 7 G Installation Considerations LUP-502 · 503 · 504 · 505 · 506 Unit (mm) Pitch 100 × 10 = 1000 LUP-502 1730 1170 1250 1210 Pitch 100 × 20 = 2000 LUP-503 2600 2040 2120 2080 LUP-500- Pitch 100 × 27 = 2700 type set LUP-504 3470...

- Page 105 CHAPTER 7 G Installation Considerations 6.5 Precautions for installation (1) Installation and usage conditions The unit can be used in a temperature range of -10°C to + 80°C. Lossnay Core The Lossnay cannot be used where toxic gases and corrosive elements such as acids, alkalis, organic solvents, oil mist or paints exist.

-

Page 106: Chapter 8 Filtering For Freshness

CHAPTER 8 Filtering for Freshness... -

Page 107: Necessity Of Filters

CHAPTER 8 G Filtering for Freshness 1. Necessity of Filters Clean air is necessary for humans to live a comfortable and healthy life. Besides atmospheric pollution that has been generated with the development of modern industries and the growth in the use of automobiles, air pollution in air-tight room has progressed to the point where it adversely affects the human body, and is now a major problem. -

Page 108: Calculation Table For Dust Collection Efficiency Of Each Lossnay Filter

CHAPTER 8 G Filtering for Freshness 3. Calculation Table for Dust Collection Efficiency of Each Lossnay Filter Measurement method ASHRAE Countingh method Gravitational Colorimetric Applicable (DOP method) method method Application model Tested dust Compound Atomspheric JIS 14 types DOP 0.3 µm Filter type dust dust... - Page 109 CHAPTER 8 G Filtering for Freshness The ability of the filters used within the Lossnay units are shown below, expressed in terms of collection ratio (%). Colourimetric method High efficiency 90% filter filter NP/400 0.8 1.0 8.0 10.0 Particle diameter (µm)

-

Page 110: Comparison Of Dust Collection Efficiency Measurement Methods

CHAPTER 8 G Filtering for Freshness 4. Comparison of Dust Collection Efficiency Measurement Methods The gravitational, colorimetric and counting methods used for measuring dust collection efficiency each have differing features and must be used according to the application of the filter. Inward flow dust Outward flow dust Efficiency... - Page 111 CHAPTER 8 G Filtering for Freshness Gravitational method This method is used for air filters which remove coarse dust (10 µm or more). The measurement method is determined by the gravitational ratio of the dust amount on the in-flow side and out-flow sides. In-flow side dust amount –...

-

Page 112: Calculation Of Dust Concentration

CHAPTER 8 G Filtering for Freshness 5. Calculation of Dust Concentration An air conditioning system using the Lossnay is shown below. Using this diagram the level of dust concentration can be easily determined. Dust concentration study diagram High-efficiency filter ηo Indoor unit Lossnay unit Indoor unit filter ηi... - Page 113 CHAPTER 8 G Filtering for Freshness [Calculation example] The indoor dust concentration for the following types of design conditions with the above system shall be used in the following example. Outline of air conditioning Air conditioning area No. of persons in room Outdoor air intake volume Cooling capacity Heating capacity...

-

Page 114: Chapter 9 Service Life And Maintenance

CHAPTER 9 Service Life and Maintenance... -

Page 115: Service Life

CHAPTER 9 G Service Life and Maintenance 1. Service Life The Lossnay Core has no moving parts. This stationary design eliminates vibration troubles and also permits greater installation flexibility. In addition, chemicals are not used in the heat recovery system. Performance characteristics remain constant throughout the period of service. -

Page 116: Chapter 10 Ventilation Standards In Each Country

CHAPTER 10 Ventilation Standards in Each Country... -

Page 117: Ventilation Standards In Each Country

CHAPTER 10 G Ventilation Standards in Each Country 1. Ventilation Standards in Each Country 1.1 Japan Table Summary of Laws Related to Ventilation Item Acceptable Range Room Environment Standard Values Reference pages Related Laws If a central air quality management system or Applicable buildings are mechanical ventilation equipment is installed, comply buildings designed to... - Page 118 CHAPTER 10 G Ventilation Standards in Each Country 1.2 The Building Standard Law of Japan (Building Standards Legal Enforcement Ordinance) Legal article 28, clause 2 Regulation 20, clause 2,3,4 Regulation 129, clause 2,3 Notice from Ministry of Contruction No. 1826, 1970 1.2.1 Types of ventilation equipment that should be installed for special buildings.

- Page 119 CHAPTER 10 G Ventilation Standards in Each Country 1.2.2 About ventilation capabilities, etc. For regular buildings, omitting central air quality management devices, there are no regulations regarding ventilation capabilities and such. (For regular buildings with central air management devices, the characteristics that the device should have are the same as for buildings designed for a special purpose).

- Page 120 CHAPTER 10 G Ventilation Standards in Each Country Theoretical waste gas volume Fuel type Theoretical waste gas Theoretical waste gas Heat produced volume per unit (m /kJ) volume (m Name of fuel (kJ / m 46,000 0.000258 11.87 40,000 0.000258 10.32 19,000 0.000258...

- Page 121 CHAPTER 10 G Ventilation Standards in Each Country The N value showing floor space occupied by one person is calculated by a general rule, and can not be uniformly regulated. However, the numerical values provided by JIS A3302 (Sewage purification tank management disposal by number of people calculation table, separated by the intended use of the building) allow some references to be drawn.

- Page 122 CHAPTER 10 G Ventilation Standards in Each Country 1.2.3 When accommodated people are present Joint ventilation method *1 35 m /h·person Pressure ventilation method *2 However, when adjusting h·person and humidity (note: during air adjustment), you can figure 1/2 of this value. (Note: In other words, the value 35 m /h·person expresses value when performing maintenance on the room environment, depending to a certain degree on the outside air taken in.

- Page 123 CHAPTER 10 G Ventilation Standards in Each Country 1.2.5 Standards when the ventilation equipment goes through the fire prevention section Ministry of Construction Noice No. 1579 (28 December, 1974) Building Standards Legal Enforcement Ordinance No. 12, Section 16 In a notice from the Ministry of Construction regarding laws related to the ventilation in medium and high rise apartment buildings, generally if the air path of the ventilation, etc., goes through the fire prevention section of a fireproof structure, a fireproofing damper device must be installed.

- Page 124 CHAPTER 10 G Ventilation Standards in Each Country (3) When there is danger of fire spreading in the fire prevention area By law, a fire prevention structure must be constructed if there is a danger of fire spreading from the opening section in the outer wall (Article 2, clause 6).

- Page 125 CHAPTER 10 G Ventilation Standards in Each Country 1.3 Law for Maintenance of Sanitation in Buildings (Laws regarding the protection of a sanitary environment in buildings) If the total extended area designated in a building for specific use (See Caution 1) is more than 3,000 m (according to Article 1 of the regulations in the School and Education Laws, this area designated for specific use for schools is 8,000 m , see Caution...

- Page 126 CHAPTER 10 G Ventilation Standards in Each Country 1.4 Industrial Safety and Health Act These laws include many categories that in the past were covered independently in relation to labor safety and sanitation. The included items that should be complied with, in addition to those related to air adjustment such as waste air figured per one laborer, ventilation, dust removal, air flow, and heat and humidity control, are boiler construction, manufacture, use, operator certification, certification of workers carrying out the construction of the air adjustment device, or the safety of working on scaffolding or other high places.

- Page 127 CHAPTER 10 G Ventilation Standards in Each Country Standards when a central air quality management system (See Caution 1) In the Office Sanitation Standard Regulations, which differ from the Building Standards Law, whether or not a central air quality management system or other such system must be installed is not stated (in other words, it is dealt with in other laws), but if a central air quality management system or other such system is installed, adjust the device so that the air supplied to the room (See Caution 2) complies with the standards shown below.

- Page 128 CHAPTER 10 G Ventilation Standards in Each Country 2. U.S. ASHRAE standard 62 - 1999 Application Outdoor air recommendation Occupancy Dry Cleaner 30 cfm/person 30 people/100 m Dining room 20 cfm/person 70 people/100 m Bars 30 cfm/person 100 people/100 m Kitchens 15 cfm/person 20 people/100 m...

-

Page 130: Chapter 11 Lossnay Q And A

CHAPTER 11 Lossnay Q and A... - Page 131 CHAPTER 11 G Lossnay Q and A Question Answer Remarks There is no problem with the life of the paper unless it is intentionally Depending on how it damaged, directly placed in water or in direct sunlight (ultra-violet rays). is stored, paper can Paper is used for the The life is longer than metal as it does not rust.

- Page 132 CHAPTER 11 G Lossnay Q and A Question Answer Remarks Between 55 to 60% of the heat energy that escapes with ventilation is There are also recovered by the Lossnay, so the cooling/heating cost can be reduced by "savings in approximately 43,000 yen per year.

- Page 133 CHAPTER 11 G Lossnay Q and A Question Answer Remarks According to the results obtained from the test performed by the Tokyo University Hospital (Inspection Centre, Prof. Kihachiro Shimizu), as the supply air and exhaust air pass through different passages, transmission Can the Lossnay be used of bacteria from exhaust side to supply side is low.

- Page 134 CHAPTER 11 G Lossnay Q and A Question Answer Remarks Tobacco smoke tends to stick to dust in the air, and when it passes Ample filtering will not through the Lossnay Core, most of the nicotine and tar will be filtered by be possible with a the air filter.

- Page 135 CHAPTER 11 G Lossnay Q and A Question Answer Remarks The Lossnay uses the forced simultaneous supply/exhaust method so the insufficient ventilation found in standard ventilators with no air intake is not found. Caution (1) The fresh air supplied to the room should not short circulate being drawn back into the return grille.

- Page 136 CHAPTER 11 G Lossnay Q and A Question Answer Remarks Class 1 ventilation refers to mechanical ventilation (forced simultaneous air supply/exhaust) using both intake and exhaust fans for suction feed. All Lossnay models (with built-in air-feed fans) are Class 1 ventilators. The ventilation method is classified in relation to the degree of natural and/or mechanical ventilation employed.

- Page 137 MEMO...

- Page 138 2001.03 <MEE>...

Need help?

Do you have a question about the Lossnay LGH-15RX3 and is the answer not in the manual?

Questions and answers