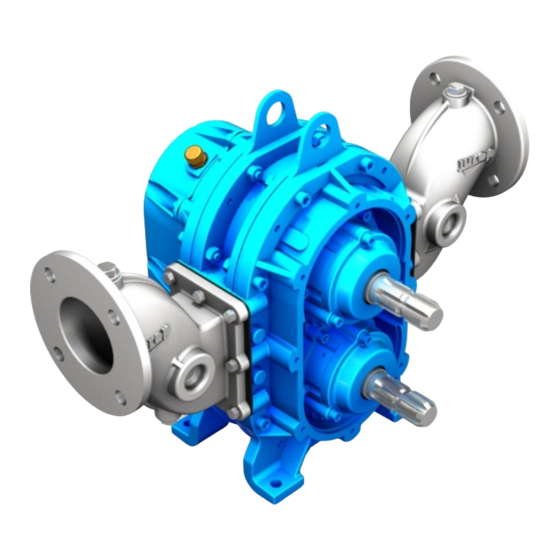

Summary of Contents for jurop VL 40

- Page 1 VL 7-40 Rev. 05 04-03-2015...

-

Page 3: Table Of Contents

Installation Spare parts VL 20 pag. 20 Spare parts VL 27 pag. 22 Checking at arrival pag. 4 Spare parts VL 40 pag. 24 Pump installation / Drive connection pag. 4 Starting-up instructions Oil level checking pag. 5 Pump test-run... -

Page 4: Introduction

1. General advises 1.1 Introduction It is recomended to: This booklet contains the necessary instructions for a correct installation, running test, normal use and maintenance of the pump as well as pratical suggestions for safe operating. - read and apply closely the instructions before running the pump The knowledge of the following, will grant trouble free operation for a long time. - Page 5 ASA E 1 " DIN 9611A VL27 DN 150 274 ASA E 1 " DIN 9611A VL40 DN 175 274 4500 4000 VL 40 VL 40 3500 3000 VL 27 VL 27 2500 VL 20 VL 20 2000 VL 14 1500...

-

Page 6: General Suggestions

3. Safety and accident prevention 3.1 General suggestions - Ordinary and extraordinary maintenance has to be done while Pay attention to the the unit is stopped and the drive disconnected. prescribed work-r.p.m. for the pump - Never start the pump if adequate foreseen safety devices are not installed. -

Page 7: Oil Level Checking

5. Starting-up instructions 5.1 Oil level checking - Before starting-up the pump check that the oil level in the gearbox reaches the filling port. (The quantity of oil is 1,0L.) 5.2 Pump test run - Rotation direction of the pump can be indifferently right or left. - Subsequently open all the gate-valves and make sure that there After starting-up it has to be determinate which one is the suction are no narrowings on the suction line. - Page 8 If the lobes show wear or tear marks or if the following dimensions are: A min: 98 mm. B min: 180 mm. C min: 65 mm. Fig. 4 bis Fig. 4 Replace them! 6.2.1.2 Check for wear marks of the housings and wear plates 6.2.1.3 Lobes disassembly of models VL 7-14-20 If the housings pos.

- Page 9 6.2.1.4 Lobes disassembly of model VL 27 material. Lift up the whole lobe/axle set taking it by the edge of the wearplate The lobes will slip out. (see fig. 6 bis), and strike it on a protection plate of suitable We suggest that two men should carry-out this operation, due to the weight of the whole set.

- Page 10 Fig. 8 6.2.2 Reassemble All parts that are weared off or damaged must be replaced with original spare parts. All seals and o-rings must always be replaced. The suitable seal kit can be used. Check that lobes and seals are of the same material (NBR-NBR, VITON-VITON).

- Page 11 6.2.2.2 Axle - Lobe group VL 7-14-20-27 Note: Do not insert the wear bushing pos. 30 ! (Axle - Lobe group Fig. 9 bis ø82 x 72 VL 27) 6.2.2.3 Seals housing group VL 7-14-20-27 (Refer to VL 14) Fig. 10 All edges must be ø78 x 6 rounded of - 1x45°...

- Page 12 6.2.2.4 Assemble of the pump housing - lobes - end plate VL7-VL14-VL-20 e- Insert the protection screen of pos. 23. (Refer to VL 14) f- Insert on the axle the bearing of pos. 22 by means of the introduction pipe of point “c” and take it to the correct position, Check that the two O-rings of the seals housing and the O-rings of striking with a hammer.

- Page 13 Fig. 12 Fig. 12/h 26 11 7 27 43 30 6.2.2.6 Timing and blocking of gears for VL 7-14-20-27 Fig.13 The timing of the gears is very important and the following instructions must be correctly followed. a- Insert the key in the axle groove. b- Insert the two gears taking care that the reference marks are matching.

- Page 14 Screw on the n. 8 screw of pos. 42. c- Insert the bushing of pos. 25 on the axle and take it to the correct 6.2.2.8 Assemble of the front end plate-housing of VL 7-14- position by means of the introduction pipe diam. 55x47 of a 20-27 suitable length (lubricate thoroughly the inside and outside of the bushing).

- Page 15 6.2.2.9 Checking of the running Lubricate the lobes with oil and grease. Turn the axles by hand making sure that the group turns smoothly. 6.2.2.10 Assemble of the oil tank and lubrication of the gears b- Mount the oil tank by means of the screws of pos. 39. (Refer to VL 14) c- Place the drain plug of pos.

-

Page 16: Trouble-Shooting

6.3 Trouble shooting TROUBLES A - The pump does not deliver CAUSE CORRECTION - Pumping level is to high - Reduce the pumping level - Weared-off lobes - Change the lobes - Clogged suction filter - Clean the filter B - Unstable delivery and vibrations of the pump CAUSE CORRECTION - Air infiltration in the suchtion line... - Page 17 7.1 Spare parts VL7...

-

Page 18: Spare Parts Vl 7

7.1 Spare parts VL7 Pos. Code Qt. Denomination Pos. Code Qt. Denomination (∑) 1 15036 - 018 - 00 2 End piston 4022 - 2002 - 38 4 OR 4350 15260 - 020 - 00 2 Connection 4022 - 2002 - 12 8 OR 2162 16100 - 093 - 00 2 Weaproof plate... - Page 19 7.2 Spare parts VL14...

-

Page 20: Spare Parts Vl 14

7.2 Spare parts VL14 Pos. Code Qt. Denomination Pos. Code Qt. Denomination (∑) 1 15036 - 014 - 00 4 End piston 4022 - 2002 - 36 4 OR 4275 16275 - 2NH - B0 2 Connection 4022 - 2002 - 38 4 OR 4350 16100 - 093 - 00 2 Weaproof plate... - Page 21 7.3 Spare parts VL20...

-

Page 22: Spare Parts Vl 20

7.3 Spare parts VL20 Pos. Code Qt. Denomination Pos. Code Qt. Denomination (∑) 1 15036 - 014 - 00 4 End piston 4022 - 2002 - 36 4 OR 4275 15260 - 016 - 00 2 Connection 4022 - 2002 - 38 4 OR 4350 16100 - 093 - 00 2 Weaproof plate... - Page 23 7.4 Spare parts VL27...

-

Page 24: Spare Parts Vl 27

7.4 Spare parts VL27 Pos. Code Qt. Denomination Pos. Code Qt. Denomination (∑) 1 15036 - 014 - 00 8 End piston 4023 - 1300 - 09 2 Bushing 35x40x17 15260 - 017 - 00 2 Connection 4022 - 2000 - 27 2 Seal ring 16100 - 092 - 00 1 Middle flange... - Page 25 7.5 Spare parts VL40...

-

Page 26: Spare Parts Vl 40

7.5 Spare parts VL40 Pos. Code Qt. Denomination Pos. Code Qt. Denomination (∑) 1 15036 - 014 - 00 8 End piston 4022 - 2000 - 27 2 Seal ring 15260 - 023 - 00 2 Connection 4026 - 3065 - 09 4 Selflocking ring M45 16100 - 092 - 00 1 Middle flange... - Page 27 SPARE PARTS REDUCTION GEAR (production from JANUARY 2001) REDUCTION GEAR FR 3,5 R.1:3,8 (cod. 4025800302) REDUCTION GEAR FR 3,5 R.1:3,2 (cod. 4025800400) POS CODE DENOMINATIONS Qt. 1 4023100155 BEARING 6210 4 2 4022200105 SEAL RING 50x65x8 BABSL 2 3 40222RPB00 GASKET 1 4 4026121405 SCREW TCEI 8,8 M 8 X 20 ZINC. 9 5 1684000000 DRAING PLUG 3/8” 1 6 4026910001 PLUG 3/8” 1 ...

- Page 28 04-03-2015 U.T. A.T. Jurop SpA Via Crosera, 50 33082 Azzano Decimo, PN (Italy) Tel. +39 0434 636811 Fax. +39 0434 636812 http://www.jurop.it e-mail: info@jurop.it Jurop SpA reserves the right to modify the products described in this manual without prior notice.

Need help?

Do you have a question about the VL 40 and is the answer not in the manual?

Questions and answers