Advertisement

Quick Links

O

O

R

I

G

I

N

A

L

I

R

I

G

I

N

A

L

I

I

,

I

,

N

S

T

A

L

L

A

T

I

O

N

U

S

N

S

T

A

L

L

A

T

I

O

N

U

S

M

A

I

N

T

E

N

A

N

C

E

M

A

N

M

A

I

N

T

E

N

A

N

C

E

M

A

Rev. 07

18-03-2016

PR 150-200-250

EN

N

S

T

R

U

C

T

I

O

N

S

N

S

T

R

U

C

T

I

O

N

S

E

A

N

D

E

A

N

D

U

A

L

N

U

A

L

Advertisement

Subscribe to Our Youtube Channel

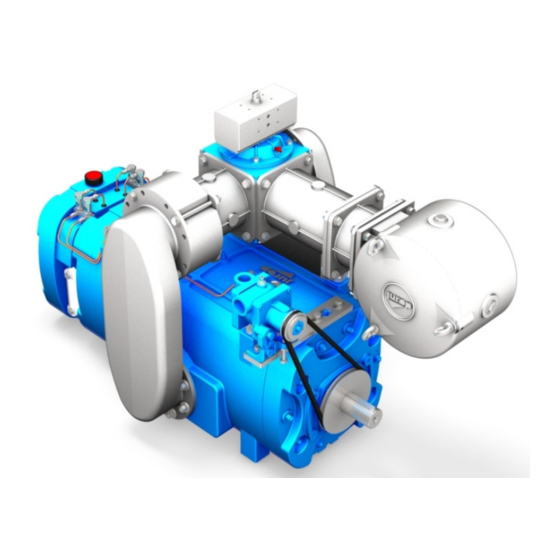

Summary of Contents for jurop PR 150

- Page 1 PR 150-200-250 Rev. 07 18-03-2016...

- Page 4 1 Dimensions and performances Vacuum pump/compressor. Series PR. Lubricated, sliding vanes pump. Application The pumps are delivered for right or left rotation NOTE • Sludge and slurry suction vehicles . Dusty materials upon request. with suitable suction filter. • Vacuum plants. Cooling and lubrication •...

- Page 5 Flow rate/pressure Power/pressure PR 150 PR 150 1100 1000 A: 1300 RPM A: 1300 RPM B: 1200 RPM B: 1200 RPM C: 1100 RPM C: 1100 RPM Absolute pressure bar Absolute pressure bar PR 200 PR 200 1800 1600 1400...

- Page 6 Sound pressure level PR 150 PR 200 PR 250 fig. 1 fig. 2 fig. 3 N 95 N 95 N 95 N 90 N 90 N 90 N 85 N 85 N 85 N 80 N 80 N 80 N 75...

- Page 7 (see pos.4 fig. 3.1). The rubber pipelines of the vacuum line must be of oil and corrosion-resistant material. Before connecting the pipeline be sure that the inside is clean. Draining taps must be placed on the lowest part of the suction connection in order to drain the condensation.

- Page 8 PR150-200-250 VACUUM LINE AND COOLING SYSTEM Installation layout Fig. 3.1 Pos. Model Code Description Pos. Model Code Description PR150-250 18450.029.10 Primary shutoff (Mild steel) 18521.021.00 Filter suction unit (Left - Pneumatic) 18450.027.10 Primary shutoff (Stainless steel) 18521.026.00 Filter suction unit (Right - Manual) PR150 14450.020.00 Secondary shutoff (Mild steel)

-

Page 9: Cardan Shaft Drive

PR150-200-250 HYDRAULIC DRIVE Installation layout Fig. 3.3 Pos. Model Code Description Pos. Model Code Description PR150-250 HDR pump PR150 4022.3040.11 Oil filter PR150-200 4024.3020.00 Distributor PR200-250 4022.3040.12 Oil filter PR250 4024.3040.00 Distributor PR150 4021.5010.31 Heat exchanger PR150 4024.1070.04 HDR motor PR200 4021.5010.41 Heat exchanger... - Page 10 The rate of vacuum and pressure. The whole cooling system as shown has an approximate capacity of 30÷50 l. for the PR 150÷250. 3.6 The oil pump is adjusted during the assembling of the During the wintertime antifreeze glicole must be added with vacuum pump.

- Page 11 Internal wash-up is necessary in case of accidental suction of liquids due to malfunctioning of the primary or secondary shutoff. This operation must last not more than 30”; if necessary repeat it after 10’. Such operation must be carried out only on cooled pumps. 1.

- Page 12 Clean with detergent and with a jet of air. Tighten the nuts pos. 78 by means of a dynamometric wrench adjusted at 62 Nm (PR150) and 88 Nm (PR200-250) and pull out the nr 2 steady pins.

-

Page 13: Troubleshooting

4.9 Trouble-shooting TROUBLES A. The pump overheats Cause Correction • Faulty lubrication. • Check the lubrication system and the oil pump. • Oil missing. • Re-fill the tank. • Revolutions to high. • Reduce revolutions. • Operation-time too long at too •... - Page 14 5.2 Part list layout Mod. PR 150...

- Page 15 4026141509...

- Page 16 5.3 Part list layout Mod. PR 200...

- Page 17 Part list mod. PR 200 Pos. Code Description Pos. Code Description 1401200700 Drip oiler Oil pump 4 outlets CCW 4024250500 1407200800 Water recycling pump cw 4025350024 Belt SPZ 1060 texrope 1407200900 Water recycling pump ccw 4025422300 Cone bushing 2820 Ø 16 Vane PR 200 Pulley SPZ 71x1 1601604900...

- Page 18 5.4 Part list layout Mod. PR 250...

- Page 19 Part list mod. PR 250 Pos. Code Description Pos. Code Description Drip oiler Oil pump 4 outlets CCW 1401200700 4024250500 1407200800 Water recycling pump cw 4025350024 Belt SPZ 1060 texrope 1407200900 Water recycling pump ccw 4025422300 Cone bushing 2820 Ø 16 Vane PR250 Pulley SPZ 71x1 1601605100...

- Page 20 01-01-2002 U.T. A.T. Jurop SpA Via Crosera, 50 33082 Azzano Decimo, PN (ITALY) Tel. +39 0434 636811 Fax. +39 0434 636812 http://www.jurop.it e-mail: info@jurop.it Jurop SpA reserves the right to modify the products described in this manual without prior notice.

Need help?

Do you have a question about the PR 150 and is the answer not in the manual?

Questions and answers