jurop LC 300 Original Instruction

Hide thumbs

Also See for LC 300:

- Instructions for installation, use and maintenance manual (32 pages) ,

- Original instructions manual (44 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for jurop LC 300

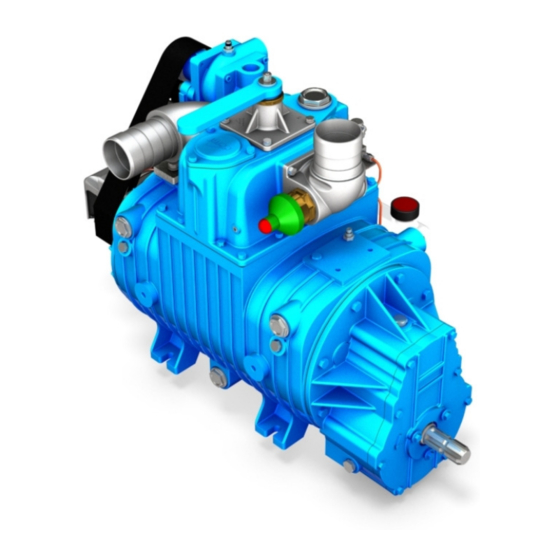

- Page 1 LC 300 – LC 420 Rev. 04 27-04-2012...

-

Page 2: Table Of Contents

Replacing the gear box components 10. TROUBLESHOOTING ......................p. 20 11. SCRAPPING ..........................p. 21 12. SPARE PARTS .......................... p. 21 12.1 Spare parts LC 300-420 D 12.2 Spare parts LC 300-420 M540-M1000-HDR 12.3 Accessories LC 300-420 ……………………………………………………………….………………………… 2 / 32... -

Page 3: Construction Features

……………………………………………………………….………………………… 1. CONSTRUCTION FEATURES Four-vane rotary pump with liquid cooled housing, suitable even for major duty operating • conditions with high volumetric efficiency and low noise. It has two inlet liquid points on the lower part of its body and four outlet points on the upper part. They do not interfere with the side mounted oil tank. -

Page 4: Technical Data

……………………………………………………………….………………………… 2. TECHNICAL DATA DIMENSIONS [mm] LC420 M – SX LC300 M – SX NOTE The position of the tank depends on the rotation direction pump. illustration shows the standard position. On request, the pumps are delivered with the tank mounted on the opposite side. ……………………………………………………………….…………………………... - Page 5 ……………………………………………………………….………………………… LC420 HDR – SX LC300 HDR – SX LC420 DIR – SX ……………………………………………………………….………………………… 5 / 32...

-

Page 6: Dimensions

……………………………………………………………….………………………… LC300 DIR – SX LC420 D USA – SX [all dimensions in inches] LC300 D USA – SX [all dimensions in inches] ……………………………………………………………….………………………… 6 / 32... -

Page 7: Legend Of Lubrication And Vanes Wear Check-Points

……………………………………………………………….………………………… LEGEND OF LUBRICATION AND VANES WEAR CHECK-POINTS PUMP LUBRICATION HOUSING GEARBOX CL : Vanes wear Tank filling Tank level Oilers checking Oil level Outlet plug Inlet plug point WEIGHT Model LC300 D LC300 M LC300 HDR LC420 D LC420 M LC420 HDR Weight (kg) NORMAL USE OF THE PUMP... -

Page 8: Performances

LC 420 l/min 12000 11170 10330 9000 6670 4833 10830 10170 9830 16,5 LC 300 l/min 8500 8000 7400 6420 4760 3450 7660 7250 7000 Room condition: P = 1013 mbar, T = 20° C Vacuum pump at max. speed. -

Page 9: Sound Pressure Level

……………………………………………………………….………………………… SOUND PRESSURE LEVEL LC300 LC420 Max. speed, 60% vacuum rate 70 db(A) 73 db(A) Max. speed, 90% vacuum rate 73 db(A) 75 db(A) (*): Noise of pump + exhaust silencer 15470D2CB0. Distance: 7m in open field. 3. SAFETY AND ACCIDENTS PREVENTION CAREFULLY OBSERVE THE FOLLOWING RULES When transporting the pump, use proper slinging. -

Page 10: Installation

……………………………………………………………….………………………… 4. INSTALLATION LEGEND OF MAIN COMPONENTS Water recycle pump Venting valve on pump housing Venting valve on water recycle pump Cooling water inlet Cooling water outlet Vanes check-port Oil filling port Lubricating oil tank Check valve Oil tank emptying port Oilers Self-lubricating pump Vacuum... -

Page 11: Cooling System

……………………………………………………………….………………………… VACUUM – PRESSURE LINE COOLING SYSTEM Pos. Description Pos. Description Primary flow shutoff valve Silencer - oil separator Secondary shutoff Recycle pump Vacuum relief valve* Water – air heat exchanger Suction filter* Expansion tank Over-pressure safety relief valve Exchanger inlet port Safety valves: •... -

Page 12: Drive

……………………………………………………………….………………………… Characteristic curve “Flow – Head” of the recycle pump. The cooling liquid temperature must not exceed 60° C. The air flow generated by the exchanger fans must be kept free of obstacles. 5. DRIVE CARDAN SHAFT DRIVE Use telescopic cardan shafts. In order to achieve a uniform motion of the driven shaft, the following requirements must be met: Equal working angle α... -

Page 13: Hydraulic Drive

……………………………………………………………….………………………… Install a suitable pulley on the smooth shaft as close as possible to the pump: max 35 mm. • Apply an adequate belt tension (see manufacturer’s data). Max 3000N. • Do not use driven or driving pulleys with a pitch diameter inferior to 180 mm. Small pulleys •... -

Page 14: Start-Up

……………………………………………………………….………………………… Description Hydraulic pump Distributor Hydraulic motor Oil filter Heat exchanger Safety valve *: optional components Distributor: open-centre distributor in central idle position (vacuum pump off). It must be equipped with • an adjustable overpressure safety valve. Motor pipeline: outlet pipe must not be of a smaller diameter than that of the inlet port. Inlet pipes •... -

Page 15: Operating Precautions

……………………………………………………………….………………………… Vacuum line Open all valves of the vacuum-pressure system. • Open all gate valves and remove any possible obstacle from the line. • PRECAUTIONS WHEN STARTING THE SYSTEM Check oil levels in gearbox and side mounted tank. Check that all protection devices are correctly installed. Check that there are no obstacles in the vacuum line. -

Page 16: Ordinary Maintenance

……………………………………………………………….………………………… WARNING Rotation speed. Once the needed vacuum rate has been reached, we recommend reducing the vacuum pump speed to its working speed (see paragraph “Usage limitations”): this allows keeping the achieved vacuum/pressure rate constant. The pump speed can also be reduced to values lower than the working speed during the tank discharging phase (with the 4-way valve in pressure mode) without increasing the draining time. -

Page 17: Checking The Side Mounted Tank Oil Level

……………………………………………………………….………………………… CHECKING THE SIDE MOUNTED OIL TANK LEVEL Do not run the pump with oil level under the minimum level: that may lead to dry functioning and cause serious damages. Tank capacity: 4 litres. Use pure mineral oil. Recommended lubricants Room Viscosity ESSO... -

Page 18: Extraordinary Maintenance

……………………………………………………………….………………………… Recommended lubricants Viscosity Type ESSO SHELL TOTAL MOBIL BLASIA SPARTAN EP OMALA OIL CARTER EP MOBILGEAR ENERGOL GR EP mineral oil VG 220 XP 220 Use SAE 80W-90 mineral oil as an alternative to the lubricants written above. Dispose of exhausted oil as provided by current specification. When changing the oil, also replace the outlet plug washer. -

Page 19: Replacing The Vanes

……………………………………………………………….………………………… REPLACING VANES When replacing the vanes proceed as follows: Remove the vacuum pump from its bearing frame • and wash it before disassembling. Drain the cooling liquid from the pump housing (1) • Remove the water pump cover (2) and the carter •... -

Page 20: Replacing The Gear Box Components

……………………………………………………………….………………………… REPLACING GEAR BOX COMPONENTS The pump with a 540 rpm gear box can be transformed into a pump with a 1000 rpm gear box (and vice versa). Remove the gearbox as above described. Remove also the pinion from the drive shaft. •... -

Page 21: Scrapping

……………………………………………………………….………………………… The non-return valve leaks Clean or replace if necessary Worn seal rings Replace Tank gate valves or gaskets leak Replace damaged or worn parts Tank connection pipes leak or are obstructed Replace damaged pipes Obstructed primary shutoff or suction filter Remove and clean Encrusted exhaust port Remove and clean... - Page 22 ……………………………………………………………….………………………… 12.1 LC 300-420 D ……………………………………………………………….………………………… 22 / 32...

- Page 23 ……………………………………………………………….………………………… Spare parts LC 300 D Pos Code Description Q.ty Pos Code Description Q.ty 1401200700 OIL DRIPPER 4022300001 OIL FILTER 1407200900 WATER PUMP SX (LC D SX) 4023100047 BEARING 6309 C3 1407200800 WATER PUMP DX (LC D DX) 4023110098 BEARING NU 309 ECJ/C3...

- Page 24 ……………………………………………………………….………………………… Spare parts LC 420 D Pos Code Description Q.ty Pos Code Description Q.ty 1401200700 OIL DRIPPER 4023100047 BEARING 6309 C3 1407200900 WATER PUMP SX (LC D SX) 4023110098 BEARING NU 309 ECJ/C3 1407200800 WATER PUMP DX (LC D DX) 4023250502 RUBBER BALL D90 1521505900...

- Page 25 ……………………………………………………………….………………………… 12.2 LC 300-420 M540 - M1000 - HDR ……………………………………………………………….………………………… 25 / 32...

-

Page 26: Spare Parts Lc 300-420 M540-M1000-Hdr

……………………………………………………………….………………………… Spare parts LC 300-420 M540 - M1000 - HDR Pos Code Description Q.ty Pos Code Description Q.ty GEARBOX 540 – 1000 RPM 4026351506 TOOTHED WASHER M10 4025350019 BELT SPZ 925 4026351505 TOOTHED WASHER M8 1407200900 WATER PUMP SX 4026356002... - Page 27 ……………………………………………………………….………………………… Lubrication lines LC 300-420 HDR – M ……………………………………………………………….………………………… 27 / 32...

- Page 28 ……………………………………………………………….………………………… Lubrication lines LC 300 HDR - M Pos Code Description Q.ty Pos Code Description Q.ty 166301D5SB0 LUBRICATION LINE 16630D5LB0 LUBRICATION LINE 166301D5TB0 LUBRICATION LINE 16630D5JB0 LUBRICATION LINE 16630D5UB0 LUBRICATION LINE 166301T7B0 LUBRICATION LINE 16630D5YB0 LUBRICATION LINE 166301T4B0 LUBRICATION LINE...

-

Page 29: Accessories Lc 300-420

……………………………………………………………….………………………… 12.3 Accessories LC 300-420 ……………………………………………………………….………………………… 29 / 32... - Page 30 ……………………………………………………………….………………………… Accessories LC300 Pos Code Description Q.ty Pos Code Description Q.ty 143028B7B0 PNEUMATIC OPERATED 4-WAY KIT THREADED MANIFOLD 160858KNB0 CONVEYOR 1627505600 THREADED MANIFOLD 161258B4B0 ACTUATOR SUPPORT 4026350706 WASHER GROWER M8 1640580QB0 ACTUATOR COVER 4026102807 SCREW M8X25 167007ZAB0 CONVEYOR NUT 4026135504 SCREW M10X10 1680700200 FALNGE GASKET...

- Page 31 ……………………………………………………………….………………………… Accessories LC420 Pos Code Description Q.ty Pos Code Description Q.ty 143028GZB0 PNEUMATIC OPERATED 4-WAY KIT THREADED MANIFOLD 160858KBB0 CONVEYOR 1627504900 THREADED MANIFOLD 161258H0B0 ACTUATOR SUPPORT 4026351505 TOOTHED WASHER M8 1640580QB0 ACTUATOR COVER 4026102807 SCREW M8X25 167007ZAB0 CONVEYOR NUT 4026135504 SCREW M10X10 1680707800 FALNGE GASKET...

- Page 32 27-04-2012 U.T. A.T. Jurop SpA Via Crosera, 50 33082 Azzano Decimo, PN (Italy) Tel. +39 0434 636811 Fax. +39 0434 636812 http://www.jurop.it e-mail: info@jurop.it Jurop SpA reserves the right to modify the products described in this manual without prior notice.

Need help?

Do you have a question about the LC 300 and is the answer not in the manual?

Questions and answers

Where do I buy a replacement pump