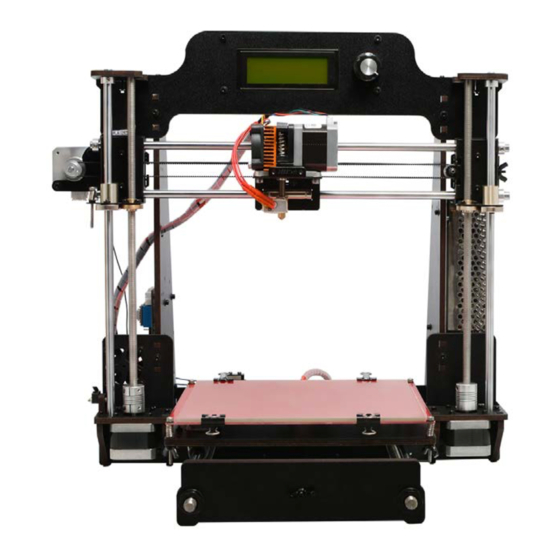

Geeetech Prusa I3 pro W Building Instruction

Hide thumbs

Also See for Prusa I3 pro W:

- Assemble instruction (100 pages) ,

- User manual (35 pages) ,

- Assembly manual (24 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Geeetech Prusa I3 pro W

- Page 1 Building Instruction of Geeetech Prusa I3 pro W 3D Printer Version 05-31-2017...

-

Page 2: Table Of Contents

25 Attach the heated bed ....................83 26 Mount the PSU ......................85 27 Mount the control board ..................94 28 Wiring ........................97 29 Tidy out the wires ....................110 30 Mount the filament spool..................111 31 Warm tips ......................112 www.geeetech.com... -

Page 3: Safety Instructions

We wouldn’t recommend leaving your printer running unattended, or at least until you are confident to do so. We cannot be held responsible for any loss, damage, threat, hurt or other negligent result from either building or using the printer. www.geeetech.com... -

Page 4: Preparations

8. Watch the building instruction videos here on YouTube: https://www.youtube.com/playlist?list=PLODCkot3GrigDNAiILi4PDbKfZE41VtgG Read through each chapter of these instructions to gain an over-all idea of what is involved and how long it might take, before starting on the work described. www.geeetech.com... -

Page 5: Unfold The Box And Check The Package

Shenzhen GETECH CO.,LTD 1.Unfold the box and check the package Unfold the package and take all the parts out to check the condition of the items. As you can see, all the parts are packed very carefully. www.geeetech.com... - Page 6 2. The part ID is corresponding to the number labeled on the bag of every part. Some parts may not have label, you can refer to the pictures on the package list. www.geeetech.com...

-

Page 7: Assemble The Rods Of A Y Axis

2) Thread the M10 washer > M10 spring washer >M10 nut > M10 nut > M10 washer on the left 3)(right)Thread the M10 washer < M10 spring washer < M10 nut < M10 nut< M10 spring washer < M10 washer on the right www.geeetech.com... - Page 8 Shenzhen GETECH CO.,LTD Step2. Assemble the 2 smooth rods www.geeetech.com...

- Page 9 Slide 3 Linear bearings on the smooth rods,one smooth rod with two pieces and another with one. Before you slide the bearings please make sure they are clean. ② Slide the screw locking ring on the end of the smooth rod. www.geeetech.com...

-

Page 10: Assemble Y Axis Support Plates

Shenzhen GETECH CO.,LTD 3 Assemble Y axis support plates Required parts Required quantity Part ID Picture NO. W9、 Support plate of Y axis(front) W 10 NO. W 11、 Support plate of Y axis(rear) W 12 M10 washer NO.8 M10 nut NO.12 www.geeetech.com... - Page 11 Step 4.Separately insert the another end of the smooth rods and the threaded rods into the upper and the lower of the mounting holes of the front support. Step5. Slightly fix the threaded rods and the wood plate with M10 nut and M10 washer. www.geeetech.com...

-

Page 12: Mount The Y Motor

Digital Caliper to measure. 4 Mount the Y Motor Required parts Required quantity Part ID Picture Y motor fix plate NO. W13 Stepper motor NO.58 Pulleys NO.39 M3 x 10mm screw NO.22 M3 x 16 mm screw NO.24 www.geeetech.com... - Page 13 Screw it as tight as possible. (Note the direction of the pulley as below picture) Step2. Then screw the motor on the Y motor holder with 3 M3 x 10mm screws and M3 washers. www.geeetech.com...

- Page 14 Shenzhen GETECH CO.,LTD Step3. Push the Y Motor holder tab into the square hole in Rear Plate. Then fix it with 2 M3x16mm screws, M3 Washers and M3 Square Nuts. www.geeetech.com...

-

Page 15: Build The Printing Platform

Shenzhen GETECH CO.,LTD 5 Build the printing platform Required parts Required quantity Part ID Picture Y platform support NO.W15 Y bearing block NO.W16 www.geeetech.com... - Page 16 M3 x 16 mm screw NO.24 M3 nut NO.10 M3 square nut NO.15 M3 washer NO.7 Step 1.Separately mount the 3 bearing blocks on the platform support plate with M3 x 16mmscrews and M3 washer, then fix the other ends with M3 nuts. www.geeetech.com...

- Page 17 Shenzhen GETECH CO.,LTD Step 2.Install the belt bracket on the belt-mount with 2 M3 x 12mm screws, M3 washer and M3 nut. www.geeetech.com...

- Page 18 Step3. Mount the belt mount on the platform support plate with M3 x 12mm screw, M3 washer and M3 square nut on the same side with the bearing block. (Note the direction: The direction of the belt brackt is same as the bearing block) www.geeetech.com...

- Page 19 Step 4.Put the build platform support on the Y- Axis holder, and then get it zip-tied to the 3 linear bearings of Y- Axis together. (Note the direction: The belt bracket is in the line with the pulley of Y motor.) www.geeetech.com...

- Page 20 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 21: Assemble The Y Idler

Step2. Put the driven wheel with ball bearing into the driven wheel holder; Thread the M4 x25mm screw through the driving wheel. Lock the other end with a M4 lock nut. You may need a pair of pliers to tighten locking nut. www.geeetech.com... - Page 22 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 23 *Do not screw it too tight, you should leave enough room for the wheel to turn freely. Step4. Mount the assembled bearing holder onto the front support plates from inside to outside. And screw it with a wing nut. www.geeetech.com...

-

Page 24: Mount The Y -Axis Belt

NO.35 Step1. Insert one end of the belt in the groove bracket. Pay attention to the tooth mesh of the belt and the groove. Step2. Thread the other end of the belt though the pulley of the Y motor. www.geeetech.com... - Page 25 Insert the end of the belt in the groove bracket Step 5.Tight the wing nut. Tips: The pulley, the belt bracket and the driven wheel must be flush to ensure the printing platform to move smoothly. www.geeetech.com...

-

Page 26: Mount The End Stop Of Y-Axis

End stop NO.52 M2.5 x 16 mm screw NO.20 M2.5 Hex nut NO.9 M2.5 washer NO.6 Mount the end stop on the rear support plate of Y axis with M2.5 x 16mm screw, M2.5 washer and M2.5 Hex nut. www.geeetech.com... -

Page 27: Assemble The Xz Frame And The Side Panel

Shenzhen GETECH CO.,LTD 9 Assemble the XZ frame and the side panel Required part Required quantity Part ID Picture X-Z frame (up) NO. W1-A www.geeetech.com... - Page 28 Right side frame NO.W3 M3 x 16 mm NO.24 screw M3 square nut NO.15 M3 washer NO.7 Step1. Screw up the X-Z frame (up) and the side panel with M3 x 16mm screws, M3 washer and M3 square nuts. www.geeetech.com...

- Page 29 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 30 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 31 Shenzhen GETECH CO.,LTD Step2. Screw up the X-Z frame (up) and the side panel with M3 x 16mm screws; M3 washer and M3 square nuts. www.geeetech.com...

-

Page 32: Assemble The 2 Z Motors Support

Note the direction of the holes of LCD knob. It is on the right. 10 Assemble the 2 Z motors support Required parts Required quantity Part ID Picture Z motor fix plate NO.W4 (left) Z motor fix plate NO.W5 (right) www.geeetech.com... - Page 33 M3 x 16 mm screw NO.24 M3 square nut NO.15 M3 washer NO.7 Step 1.Assamble Z motor support plate W6,W7 with Z motor fix plate (left) together with M3 x 16 mm screws, M3 washer and M3 square nuts. www.geeetech.com...

- Page 34 Shenzhen GETECH CO.,LTD Step 2.Assamble 2 Z motor support plates W6 with Z motor fix plate (right) together with M3 x 16 mm screws, M3 washer and M3 square nuts. www.geeetech.com...

- Page 35 Shenzhen GETECH CO.,LTD NOTE THE SMALL HOLE Step 3.Separately screw up the assembled Z motor supports to the left and rigt corners of the main frame with M3 x 16mm screws and M3 square nuts. www.geeetech.com...

- Page 36 Shenzhen GETECH CO.,LTD (Left) www.geeetech.com...

- Page 37 Shenzhen GETECH CO.,LTD (Right) www.geeetech.com...

-

Page 38: Mount The Fan

Required parts Required quantity Part ID Picture NO.49 M3 x20 mm NO.25 screw M3 nut NO.10 M3 washer NO.7 Fix the fan on the left back side of the frame with 4 M3 x 20 screws, M3 washer and www.geeetech.com... -

Page 39: Assemble Y - Z Axis

Shenzhen GETECH CO.,LTD M3 nuts. Mind the direction of the fan. (The side with the label is outward.) 12 Assemble Y - Z axis Required parts Required quantity Part ID Picture M3 x 16 mm screw NO.24 www.geeetech.com... - Page 40 Shenzhen GETECH CO.,LTD M3 nut NO.10 M3 square nut NO.15 M3 washer NO.7 Step1. Put the Y axis between the main frame. W14 is at the front of the frame. www.geeetech.com...

- Page 41 Shenzhen GETECH CO.,LTD Step2. Screw up the Y axis rear plate and the side panel with M3 x16mm screws,M3 washer and M3 square nuts. www.geeetech.com...

- Page 42 Shenzhen GETECH CO.,LTD Step3. Screw up the main frame to the Y axis connecting plate with 4 M3 x 16mm screws, M3 washer and M3 nuts. www.geeetech.com...

-

Page 43: Mount Z-Axis End Stop

Shenzhen GETECH CO.,LTD Step4. Screw up the M10 nuts on Y axis. 13 Mount Z-axis End stop Required parts Required quantity Part ID Picture End stop NO.52 M 2.5 x 16 mm NO.20 screw M 2.5 nut NO.9 M 2.5washer NO.6 www.geeetech.com... -

Page 44: Mount The 2 Z Motors

Shenzhen GETECH CO.,LTD Mount the endstop on the Z -axis motor base (left) with M2.5 x 16mm screw,M2.5 washer and M2.5 hex nut. 14 Mount the 2 Z motors Required parts Required quantity Part ID Picture www.geeetech.com... - Page 45 M3 washer NO.7 Step1. Thread the wires of the motors through the holes of the main fame. Then put the motor under the motor base. Step2. Screw up the motors with 4 M3 x 10mm screws and M3 washer. www.geeetech.com...

-

Page 46: Mount The Coupling

Shenzhen GETECH CO.,LTD Do the same with the other Z motor according the above steps. 15 Mount the coupling Required parts Required quantity Part ID Picture Coupling NO.38 Step1. Fix the two couplings on both of the motor shaft. Please note: www.geeetech.com... - Page 47 1. The opening of both end, one is 5mm, another is 8mm, connect the 5mm hole to the motor shaft. 2. Screw the jimmy screw of the 5mm part on the upper part of the flat side of the motor shaft tightly; you can see the boundary in the inner of the coupling. www.geeetech.com...

- Page 48 Shenzhen GETECH CO.,LTD Do the same with the coupling of the right motor shaft according the above steps. www.geeetech.com...

- Page 49 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 50: Assemble The X-Axis Motor End

Step1. Mount the linear bearing on X-axis motor end from bottom to up. Fix it up with M3 x 6mm screws. Step2. Mount the Z nut on the X-axis left end from bottom to up, fix with M3 x 6mm screws. www.geeetech.com... - Page 51 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 52: Mount X-Axis Motor

Shenzhen GETECH CO.,LTD 16.2 Mount X-axis motor Required parts Part ID Required quantity Picture Stepper motor No.58 Pulleys No.39 M3 x 6 mm screw No. 21 M3 washer NO.7 www.geeetech.com... - Page 53 Step 1.Mount the pulley on the motor shaft and fix it from the flat side. Note the direction of the pulley: the gear is at the bottom. Step 2.Mount the stepper motor to the motor end with 3 M3x6mm screws and M3 washers. www.geeetech.com...

-

Page 54: Mount The End Stop And The Endstop Trigger

Shenzhen GETECH CO.,LTD 16.3 Mount the end stop and the endstop trigger Required parts Part ID Required quantity Picture M2.5 x 8 mm No. 19 screw End stop No.52 M3 x 35 mm screw No. 26 M3 washer NO.7 www.geeetech.com... - Page 55 Step1. Mount the endstop on the top of the X-axis motor end with 2 M2.5 x 8mm screws. Mind the direction of the endstop paddle. Step2. Thread a M3 washer> spring> M3 washer in order to the M3x35mm screw. Step3. Thread the M3x35mm screw into the screw hole. www.geeetech.com...

-

Page 56: Assemble X Axis Idler End

Step1. Mount the linear bearing on X-axis idler end from bottom to up. Fix it up with M3 x 6mm screws. Step2.Mount the Z axis nut on the bottom of X-axis idler end with 4 M3 x 6mm screws. www.geeetech.com... -

Page 57: Assemble The Extruder Carriage

Shenzhen GETECH CO.,LTD 18 Assemble the extruder carriage Required parts Part ID Required quantity Picture Bearing mount No.M3 www.geeetech.com... - Page 58 No.M4 Extruder bracket No.M5 Linear Bearing No.33 LM8LUU Belt bracket No.47 M3x6mm screw No. 21 M4x6mm screw No. 28 M3 nut No.10 Step1. Fix the 4 Bearing Brackets on the back of the X Carriage loosely with M3x6mm screws. www.geeetech.com...

- Page 59 Shenzhen GETECH CO.,LTD Step2. Insert the linear bearing into the bearing mount slot and tight the screw. www.geeetech.com...

- Page 60 Shenzhen GETECH CO.,LTD Step3. Fix the belt bracket on the back of the carriage with 2 M3 x6mm screws and M3 hex nuts. www.geeetech.com...

- Page 61 Shenzhen GETECH CO.,LTD Step3. Fix the extruder holder on the front side of the X carriage with M4x6mm screws. www.geeetech.com...

-

Page 62: Assemble The X&Z Axis

Shenzhen GETECH CO.,LTD 19 Assemble the X&Z axis Required part Part ID Required number Picture L300mm Threaded No.4 L322mm Smooth No.1 L390mm Smooth No.2 www.geeetech.com... - Page 63 Step2. Thread the L300 threaded rod to the nut of both end of X axis. Keep both end of X axis at the same place of the rod, you are advised to measure the distance of the both side so that they are at the same level when you put them up. www.geeetech.com...

- Page 64 Shenzhen GETECH CO.,LTD Step3. Plug the threaded rod on the X motor end to the left coupling on the left motor of the Z axis. Then thread the 320mm smooth rod into the linear bearing. www.geeetech.com...

- Page 65 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 66 Shenzhen GETECH CO.,LTD Step4. Thread the L390mm smooth rod into the X motor end > thread the extruder carriage on the two rods. Step5. Thread the two X axis smooth rods into the hole of X idler end. www.geeetech.com...

- Page 67 Shenzhen GETECH CO.,LTD Step6. Plug the vertical threaded rod into the coupling on the right motor of the Z axis. Then thread the 320mm smooth rod into the linear bearing. www.geeetech.com...

-

Page 68: Assemble The Z Axis Top Mount

Shenzhen GETECH CO.,LTD 20 Assemble the Z axis top mount Required part Part ID Required number Picture www.geeetech.com... - Page 69 Step3. Screw up the top mount, the main frame and the side panel with M3 x 16mm screw and M3 Square nut. Step4. Screw up the locking ring on smooth rods. www.geeetech.com...

- Page 70 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 71 Shenzhen GETECH CO.,LTD Step 5.After fixing the top mount, the length of X-axis and Z-axis is confirmed. Next step is to screw up the both end of X-axis with the locking rings. www.geeetech.com...

- Page 72 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 73: Assemble X Idler

Note: It is very important to make sure the verticality of the smooth rod and the threaded rod of Z axis, the horizontality of X axis, otherwise it will impede the movement of Z axis. 21 Assemble X idler Required parts Part ID Required quantity Picture Drivenwheel holder No.37 www.geeetech.com... - Page 74 Step2. Insert the driver wheel with the ball bearing into the middle of the driving wheel holder. Put the M4 x25 screw through the driving wheel. Lock the other end with a M4 lock nut. You may need a pair of pliers to tighten locking nut. www.geeetech.com...

- Page 75 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 76: Add The X Axis Belt

Step3. Thread another end of the belt through the X motor end around the pulley. Step4. Insert another end of the belt into the groove, pull tightly and cut the spare part. Confirm the length of the belt.Then insert the belt into the groove. www.geeetech.com... - Page 77 Shenzhen GETECH CO.,LTD Step5. Taut the belt and tighten the wing nut on the idle end. www.geeetech.com...

- Page 78 Shenzhen GETECH CO.,LTD *Note the direction of the driven wheel, the side with lock nut should be outward, or it will scratch the wood plate. www.geeetech.com...

- Page 79 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 80: Mount The Extruder

Shenzhen GETECH CO.,LTD 23 Mount the extruder Required parts Required Number Part ID Picture Extruder NO.59 M4 x 6mm screw NO.28 Mount the assembled extruder on the extruder holder and use 2 M4 x 6 mm screws to fix. www.geeetech.com... - Page 81 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 82: Mount The Lcd Panel

Shenzhen GETECH CO.,LTD 24 Mount the LCD panel Required parts Required quantity Part ID Picture LCD 2004 NO.61 Spacer NO.43 M3 x 16mm NO.24 screw www.geeetech.com... - Page 83 Shenzhen GETECH CO.,LTD M3 nut NO.10 Konb NO.48 No. 7 M3 washer www.geeetech.com...

-

Page 84: Attach The Heated Bed

Shenzhen GETECH CO.,LTD 25 Attach the heated bed Required parts Required quantity Part ID Picture Heat bed set NO.55 M3 x35mm screw NO.26 M3 washer NO.7 www.geeetech.com... - Page 85 Mount the heat bed on the platform with 4 M3 x35 screws, M3 washers and wing nuts. Clamp the heat bed and the glass sheet. *The soldered side is better to be attached downwards. The order should be: M3 x35mm screw—washer—Heat bed—Spring—washer—Wood support plate— washer—Wing nut www.geeetech.com...

-

Page 86: Mount The Psu

Shenzhen GETECH CO.,LTD 26 Mount the PSU Required parts Required quantity Part ID Picture Power supply unit NO.57 M3 x 10 mm screw NO.22 M3x16mm Countersunk head NO.30 screw M3 nut NO.10 www.geeetech.com... - Page 87 M3 washer No. 7 Power input cable NO.53 Power output cable NO.54 Step1. Take off the wires connected to the socket; before you do, please take a photo of the wire connection, in case you connect them wrongly later. www.geeetech.com...

- Page 88 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 89 Shenzhen GETECH CO.,LTD Step2. Mount the socket on the bottom of the right side panel with 2 M3 x 16 Hex Counter- sunk-head screws ,M3 washer and M3 hex nut. www.geeetech.com...

- Page 90 Shenzhen GETECH CO.,LTD Step3. Put the power outout cable in the bottom of the printer, then thread it out from the hole on the right side panel. www.geeetech.com...

- Page 91 Pay attention to the switch on the right side of the PSU, there are two options of voltage: 110 V and 220V, choose according the standard in your country. As shown in the following picture. Remove the yellow paper; you can use some hard sticks to reach the switch. www.geeetech.com...

- Page 92 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 93 Shenzhen GETECH CO.,LTD www.geeetech.com...

- Page 94 As you can see, there are 7 wires terminals in total. Note the correspondence between the color of wires and the connector. After finish the connecting, close the cover of the connector in case any electric shock. Brown------L Blue ------N Yellow------ GND Red ------ --+ V Black------COM www.geeetech.com...

-

Page 95: Mount The Control Board

Shenzhen GETECH CO.,LTD 27 Mount the control board Required parts Part ID Required quantity Picture Control board No.60 Sticker No.46 Heat sink No.45 www.geeetech.com... - Page 96 Step2. Insert the spacer into the holes of the board from back to front, Mount the board kit on the left side panel with 4 M3 x 10mm screws and M3 washers on the side panel. Note the direction of the board; the section insered A988 is are upwards. www.geeetech.com...

- Page 97 Shenzhen GETECH CO.,LTD www.geeetech.com...

-

Page 98: Wiring

Shenzhen GETECH CO.,LTD 28 Wiring Mainboard:GT2560 Before you start wiring; please take a look at the wiring schematics. www.geeetech.com... - Page 99 You can see original picture here. For your convenience, the first two steps are finished, you can directly start fron step Step1. The subdivision of stepper motor can be setup by jumper cap, plug all the jumper caps. www.geeetech.com...

- Page 100 Shenzhen GETECH CO.,LTD Step2. Plug the 4 A4988 into the stepper motor driver slot. Mind the directions of A4988. www.geeetech.com...

- Page 101 Shenzhen GETECH CO.,LTD Step3. Connect wires for motors. 1) Connect wires for X-axis motor. 2) Connect wires for Y-axis motor. www.geeetech.com...

- Page 102 Shenzhen GETECH CO.,LTD 3) Connect wires for 2 Z-axis motors. ( ) Z-axis motors-left www.geeetech.com...

- Page 103 Shenzhen GETECH CO.,LTD ( ) Z-axis motors-right 4) Connect the cables of Extruder motors. There are two interfaces of the extruder motors,here is coonecting with the extruder 1. www.geeetech.com...

- Page 104 Loosed the screws in the green terminal and put the red wires into the slot and screw it up. * There is no “+” and “-“for heating wires 1) Connect heating wires for heatbed. 2) Connect heating wires for extruder 1. www.geeetech.com...

- Page 105 Shenzhen GETECH CO.,LTD Step5. Connect wires for thermistor. 1) Connect wires for thermistor of heatbed. 2) Connect wires for thermistor of extruder 1. www.geeetech.com...

- Page 106 Shenzhen GETECH CO.,LTD Step6. Connect wires for endstop. Connect wires for endstop of X-axis at X-Min. 2) Connect wires for endstop of Y-axis at Y-Min. www.geeetech.com...

- Page 107 Shenzhen GETECH CO.,LTD 3) Z-Min Connect wires for endstop of Z-axis at Z-Min. Step7. Connect wires for Fan. 1) Connect fan for control board at FAN3. www.geeetech.com...

- Page 108 Shenzhen GETECH CO.,LTD 2) Connect fan for extruder at FAN1. www.geeetech.com...

- Page 109 Shenzhen GETECH CO.,LTD Step8. Connect wires for LCD panel. There are two cables, one is for LCD encoder, the other is for SD card, do not connect them reversed. www.geeetech.com...

- Page 110 Shenzhen GETECH CO.,LTD Step9. Connect wires for power input. www.geeetech.com...

-

Page 111: Tidy Out The Wires

That is all for the wiring of GT2560.If any questions, please contact with us in any time. 29 Tidy out the wires Use the wire coil to tie put those wires together. There are holes on the wood plates for the wires, you can arrange them as you like. www.geeetech.com... -

Page 112: Mount The Filament Spool

Shenzhen GETECH CO.,LTD 30 Mount the filament spool. Required parts Required quantity Part ID Picture Filament side panel M3 x 16 mm scew NO.24 M3 square nut NO.15 PVC tube www.geeetech.com... -

Page 113: Warm Tips

Each machine may have its own calibration procedure and this manual will not attempt to cover all the variations. Instead here is a list of key points that should be addressed. www.geeetech.com... - Page 114 For how to set up the printer, please visit: To know how to set up, please refer to the user manual. www.geeetech.com...

Need help?

Do you have a question about the Prusa I3 pro W and is the answer not in the manual?

Questions and answers