Geeetech Prusa I3 Pro C Assemble Instruction

Hide thumbs

Also See for Prusa I3 Pro C:

- Building instruction (114 pages) ,

- Assemble instruction (98 pages) ,

- User manual (35 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Geeetech Prusa I3 Pro C

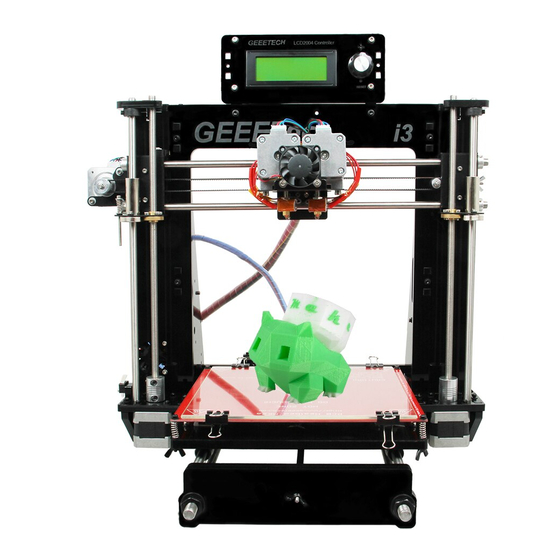

- Page 1 Assemble Instruction of Geeetech Acrylic Prusa I3 Pro C Version 04-11-2016...

- Page 2 GEEETECH Safety Instructions Building the printer will require a certain amount of physical dexterity, common sense and a thorough understanding of what you are doing. We have provided this detailed instruction to help you assemble it easily. However ultimately we cannot be responsible for your health and safety whilst building or operating the printer, with that in mind be sure you are confident with what you are doing prior to commencing with building or buying.

-

Page 3: Preparation

GEEETECH Preparation 1. Unpack the kit and check if all parts are in the box and check the condition of each part, there might be some damage during shipping. To help you with this, there is BOM in the box and each bag was labeled with part number. -

Page 4: Table Of Contents

CONTENT Assemble Instruction of Geeetech Acrylic ..............0 Prusa I3 Pro C ........................ 0 Safety Instructions ......................1 Preparation ........................2 1 Unfold the box and check the package ............... 1 2 Assemble the rods of a Y axis ..................3 3 Attach the front and rear Acrylic support plates of the rods. -

Page 5: Safety Instructions

GEEETECH 1 Unfold the box and check the package Unfold the package and take all the parts out to check the condition of the items. As you can see, all the parts are packed very carefully. - Page 6 GEEETECH All the acrylic plate has been etched with part ID and the plate is covered with a sheet of Kraft paper, you need to tear them off.

-

Page 7: Assemble The Rods Of A Y Axis

GEEETECH Tips: 1. Before assembly, you are advised to put all the parts, especially the screws and nuts in order, which will save you a lot of time looking for the required parts. 2. The part ID is corresponding to the number labeled on the bag of every part. Some parts may not have label, you can refer to the pictures on the package list. - Page 8 GEEETECH on the left 3) Thread theM10 washer < M8 spring washer < M10 nut < M10 nut< M8 spring washer < M10 washer on the right...

- Page 9 GEEETECH Step2. Assemble the 2 smooth rods Required parts Required number Part ID M8 smooth rod NO.2 LM8UU Linear NO.36 bearings Slide 2 bearings on each smooth rod. Before you slide the bearings please make sure they are clean.

-

Page 10: Attach The Front And Rear Acrylic Support Plates Of The Rods

GEEETECH 3 Attach the front and rear Acrylic support plates of the rods. For some of the kit, the locking rings are the silver color, which will not affect the assembly here, but in some steps, for the X axis, there is difference, please pay attention to the note. - Page 11 GEEETECH Required parts Required number Part ID NO. A9, Acrylic plate( front) A 10 Acrylic NO. A 11, A plate( rear) M10 washer NO.9 M10 nut NO.13 Screw locking NO.20 ring Step1.Slide the locking ring on the smooth rods, thread the rods into the acrylic plate;...

-

Page 12: Assemble The Y Idler

GEEETECH * Tips: Try to keep the rods parallel and the four acrylic pieces parallel. The Y-axis must be a rectangle, that is the rods on both side should be parallel, so is the front and back plate. Otherwise it will cause obstruction for the belt later. You can use a Digital Caliper to measure. - Page 13 GEEETECH Driven wheel No.45 M3 x 20 screw NO.28 M3 wing nut NO.16 M4 x25 screw NO.33 M4 lock nut NO.15 Step1. Thread the M3 x 20mm screw through the bearing holder.

- Page 14 GEEETECH Step2. Insert the two MR84zz ball bearings into both ends of the driving wheel. For your convenience, this step is already finished by us.

- Page 15 GEEETECH Step3. Put the M4 x25 screw and M4 washer through the driving wheel. Lock the other end with a M4 lock nut. You may need a wrench to tighten locking nut.

- Page 16 GEEETECH...

- Page 17 GEEETECH *Do not screw it too tight, you should leave enough room for the wheel to turn freely. Step4. Mount the assembled bearing holder onto the front support plates from inside to outside. And screw it with a wing nut.

-

Page 18: Mount The Y Motor

GEEETECH 5 Mount the Y motor Watch the video Required parts Required number Part ID Y motor fix plate NO. A13... - Page 19 GEEETECH Stepper motor NO.62 Pulley NO.44 M3 x 12 screw NO.26 M3 x 20 screw NO.27 M3 square nut NO.17 Step1. Mount the pulley on the motor shaft, one of the screws should be screwed on the cross section of the shaft. Screw it as tight as possible.

- Page 20 GEEETECH Step2. Then screw the motor on the Y motor holder with 3 M3 x 12 screws and M3 washers.

- Page 21 GEEETECH Step3. Push the Y Motor holder tab into the square hole in Rear -Outside Plate and Rear - Inside Plate. You may need to use a little force, but be careful not to break or crack any of the Acrylic pieces.

-

Page 22: Build The Printing Platform

GEEETECH 6 Build the printing platform Watch the video Required parts Required number Part ID Y platform support NO.A15 Y bearing block NO.A16... - Page 23 GEEETECH Belt mount NO.42 Nylon tie NO.66 M3 x 10 screw NO.25 M3 x 20 screw NO.28 M3 nut NO.11 Step1. Mount the belt mount on the bottom side of the platform with 2 M3 x 10 screws.

- Page 24 GEEETECH Step2. Mount the 4 bearing blocks on the platform with M3 x 20 screws on the same side with the belt-mount. Screw with M3 nuts. Step3. Get the build platform plate zip-tied to the 4 linear bearings of Y- Axis.

-

Page 25: Mount The Y -Axis Belt

GEEETECH 7 Mount the Y –axis belt Watch the video Required parts Required number Part ID Timing belt NO.39 M3 x 10 screw NO.25 M3 washer NO.7 Step1. Drill a hole on one end of the belt(the hole can be as the diameter of the M3 screw, leave enough margin )... - Page 26 GEEETECH Step4. Drill a hole on the other end of the belt and fix it on the belt -mount with a M3 x 10 screw and M3 washer. *Tips: 1. before you drill your second hole, make sure to pull belt tightly to make sure to find proper placement of hole for a tight belt, if it is too loose, it will hinder the move of t he print platform.

-

Page 27: Mount The End Stop Of Y-Axis

GEEETECH 8 mount the End stop of Y-axis Watch the video Required parts Required number Part ID End stop NO.56 M2.5 x 16 screw NO.22 M2.5 Hex nut NO.10 Mount the end stop on the rear support plate of Y axis with M2.5 X 16 screw and... -

Page 28: Assemble The Right And Left Side Panel

GEEETECH 9 Assemble the right and left side panel Watch the video Required parts Required number Part ID XZ frame NO.A1 Acrylic left frame NO.A2 Acrylic right NO.A3 frame M3 x 16 screw NO.27... - Page 29 GEEETECH M3 square nut NO.17 Step1. Screw up the X-Z frame and the side panel with M3 x 16 screws and M3 square nuts.

-

Page 30: Mount The Fan

GEEETECH 10 Mount the fan Watch the video Required Required parts Part ID number NO.53 M3 x 30 screw NO.29 M3 locknut NO.14 Fix the fan on the right side of the frame with 4 M3 x 30 screw and lock nut. Mind the direction of the wires. -

Page 31: Assemble The Z-Axis Bottom Mount

GEEETECH 11 Assemble the Z-axis bottom mount Watch the video Required parts Required number Part ID Z Motor fixed plate NO.A4 Z Motor fixed plate NO.A5... - Page 32 GEEETECH Z Motor support plate NO.A6 Z Motor support plate NO. A7 M3 x 16 screw NO.27 M3 square nut NO.17 Step1. It would be easier to mount the A4/A5 to A6 and A7 first, and then mount the assembled part to A1.

- Page 33 GEEETECH left right...

-

Page 34: Assemble Y - Z Axis

GEEETECH 12 Assemble Y - Z axis Watch the video Required parts Required number Part ID M3 x 16 screw NO.27 M3 x 20 screw NO.28 M3 nut NO.11 M3 square nut NO.17 Step1. Put the Y axis into the main frame. - Page 35 GEEETECH Step2. Screw up the main frame to the acrylic fender with 4 M3 x 20 screws. And screw up the M10 nuts. Step3. Screw up the Y axis rear plate and the side panel with M3 x16mm screws and...

-

Page 36: Mount The End Stop Of Z-Axis

GEEETECH 13 Mount the End stop of Z-axis Watch the video Required parts Required number Part ID End stop NO.56 M 2.5 X 16 screw NO.22 M 2.5 nut NO.10 Mount the endstop on the outside of A7 with M2.5 x 16mm screw and M2.5 hex nut. -

Page 37: Assemble The 2 Z Motors

GEEETECH 14 Assemble the 2 Z motors Watch the video Required parts Required number Part ID Stepper Motor NO.62 M3 x 12screw NO.26... - Page 38 GEEETECH Step1.Thread the wires of the motors through the holes Step2. Screw up the motors with 4 M3 x 12 screws. Do the same with the other Z motor.

-

Page 39: Assemble The Coupling

GEEETECH 15 Assemble the coupling Watch the video Required parts Required number Part ID Couplings NO.43 Step1. Fix the two couplings on both of the motor shaft. Please note: 1. The opening of both end, one is 5mm, another is 8mm, connect the 5mm hole to the motor shaft. - Page 40 GEEETECH...

-

Page 41: Attach He Heated Bed

GEEETECH 16 Attach he heated bed Watch the video Required parts Required number Part ID Heat bed set NO.59 M3 x35 screw NO.30 M3 washer NO.7 Spring NO.35... - Page 42 GEEETECH clamp NO.48 Wing nut NO.16 Borosilicate glass NO.60 *All our heated bed is pre-soldered or attached before shipping; you can attach the bed directly here. Mount the heat bed on the platform with 4 M3 x35 screws and wing nuts with springs in between.

-

Page 43: Mount The X-Axis Motor End

GEEETECH 17 Mount the X-axis motor end Watch the video Part name Part ID Required number Z-axis nut No.18 X-axis motor end No.M1 Linear Bearing No. 38 LMH8LUU... - Page 44 GEEETECH M3 x 30 screw No.29 M3 x 6mm screw No. 23 M3 washer No. 7 Spring No. 35 Step1. Mount the Z nut on the X-axis left end from bottom to up, fix with M3 x 6mm screws. Step2. Mount the linear bearing on X-axis motor end from bottom to up. Fix it up with M3 x 6mm screws.

- Page 45 GEEETECH Mount the X motor Part name Part ID Required number M3 x 6 mm screw No. 23 Stepper motor No.62 Pulley No.44 In some of the picture, the pulley is a bit different but it won’t affect your assembly.

- Page 46 GEEETECH...

- Page 47 GEEETECH Mount the endstop Part name Part ID Required number M2.5 x 8 mm No. 21 screw End stop No.56 Mount the endstop on the top of X-axis motor end with two M2.5 x 8mm screws...

-

Page 48: Assemble The Right End Of The X Axis. (X Idler End)

GEEETECH 18 Assemble the right end of the X axis. (X idler end) Watch the video Part name Part ID Required number Z-axis nut No.18 X-axis idle end No.M2 Linear Bearing No. 38 LMH8LUU... - Page 49 GEEETECH M3 x 6mm screw No. 23 Step1.Mount the Z axis nut on the bottom of X-axis right end with 4 M3 x 6mm screws. Step2. Mount the linear bearing on X-axis motor end from bottom to up. Fix it up...

- Page 50 GEEETECH...

-

Page 51: Assembly Of The Extruder Carriage

GEEETECH 19 Assembly of the extruder carriage Watch the video Part name Part ID Required number Carriage No.M3 Bearing Bracket No.M4 Extruder holder No.M5 Linear Bearing No.37 LM8LUU Belt bracket No.51 Endstop trigger No.51A M3x6mm screw No. 23 M3x12mm screw No. - Page 52 GEEETECH Step1. Fix the 4 Bearing Brackets on the back of the X Carriage loosely with M3x6mm screws. Insert the linear bearing into the slot and screw the bracket tightly. Please notice the front and back of the plate. Step2. Fix the belt mount on the back of the carriage with 2 M3x 12mm screws and M3 hex nuts.

- Page 53 GEEETECH screws. This picture is for the single extruder, but the way to assemble is the same. * If the carriage cannot reach to the X axis endstop, you need to add a small block on the carriage; we have prepared one for you, the No.51A. (Only for orders after 8th, December, 2015) If you do not have it in your package, you can make one by yourself.

-

Page 54: Assemble The X&Z Axis

GEEETECH Mount it on the carriage with an M3x8mm screw and a M3 hex nut. 20 Assemble the X&Z axis Watch the video Part name Part ID Required number L300mm threaded No.4 L322mm smooth No.1 L410mm smooth No.3 locking ring No.20... - Page 55 GEEETECH distance of the both side so that they are at the same level when you put them up. Step2. Plug the threaded rod on the X motor end to the left coupling on the left bottom of the Z axis. Then thread the 320mm smooth rod into the linear bearing.

- Page 56 GEEETECH Step3. Thread the L410mm smooth rod into the X motor end > thread the extruder carriage on the two rods.

- Page 57 GEEETECH Step4. Thread the two X axis smooth rods into the hole of X idler end. Plug the vertical threaded rod into the coupling on the right bottom of the Z axis. Then thread the 340mm smooth rod into the linear bearing.

- Page 58 GEEETECH vertical Note: the smooth rods and the threaded rod of Z axis are and the X axis is horizontal, which is very important, or it will hinder the move of the Z axis. Step5. Fix the locking rings on the end of the rod if you got the silver rings.

- Page 59 GEEETECH...

- Page 60 GEEETECH NOTE: If you got the black lock ring (No.20), you need to fix all the 4 locking rings on the right end, as shown on the following picture.

-

Page 61: Assemble The Z Axis Top Mount

GEEETECH 21 Assemble the Z axis top mount Watch the video Part name Part ID Required number Z top mount No.A8 M3 x 16mm screw No.27 M3 Square nut No.17 locking ring No.20... - Page 62 GEEETECH M3 washer No. 7 Step1. Put the locking ring on the two smooth rods separately. Step2. Add the Z top mount (No.A8) to the top of A1. Slowly rotate the rods into the holes, or add some lubricants on the rods. Do not force it, or u will break the acrylic piece.

-

Page 63: Mount The Extruder

GEEETECH 22 Mount the extruder Watch the video This video shows the mounting of the single extruder, this step is very easy, you can refer to the pictures below. If you have any problems here, please feel free to contact... - Page 64 GEEETECH M3 x 16mm screw NO.27 M4 x 6mm screw NO.32 M4 washer NO.8 Step1. Mount the assembled extruder on the extruder support. Use 2 M4 x 6 mm screws and M4 washers to fix. Step2. Mount the fan on the extruder holder with 2 M3 x16mm screw.

-

Page 65: Belt Driving Wheel

GEEETECH 23 X belt driving wheel Watch the video This video is just for referring, you need to use M3 x40mm screw. Part name Part ID Required number Driven wheel No.41 holder Driven wheel No.45 MR84zz Ball No.46 Bearing... - Page 66 GEEETECH M3 x40mm screw No.31 M4 x 25mm screw No.33 M3 washer No.7 M4 washer No.8 M4 lock nut No.15 wing nut No.16 Step1. Thread the M3 x 40 screw and M3 washer through the Driven wheel holder. Step2. Insert the two MR84zz ball bearings into both ends of the driving wheel.

- Page 67 GEEETECH For your convenience, this step is already finished by us.

- Page 68 GEEETECH Step3. Put the M4 x25 screw and M4 washer through the driving wheel. Lock the other end with a M4 lock nut. You may need a wrench to tighten locking nut.

-

Page 69: Add The Belt

GEEETECH *Do not screw it too tight, you should leave enough room for the wheel to turn freely. 24 Add the belt Watch the video Part name Part ID Required number Timing belt No.40 Step1. Insert one end of the belt in the groove. Pay attention to the tooth mesh of the belt and the groove. - Page 70 GEEETECH...

- Page 71 GEEETECH...

-

Page 72: Mount The Lcd Panel Frame

GEEETECH *Note the direction of the driving wheel, the side with bolt head should be towards the A1, or it will scratch the acrylic plate. 25 Mount the LCD panel frame Watch the video Required parts Required number Part ID LCD 2004 NO.65... - Page 73 GEEETECH...

- Page 74 GEEETECH...

-

Page 75: Mount The Psu

GEEETECH 26 Mount the PSU Watch the video This video shows the mounting of the PSU for single extruder, this step is the same; you can refer to the pictures below. The only difference is that there are 9 connectors for the PSU for dual extruder. - Page 76 GEEETECH...

- Page 77 GEEETECH...

- Page 78 GEEETECH Step2. Mount the socket on the bottom of the right side panel with 2 M3 x 16 Hex Counter- sunk-head screws and M3 hex nut. Step3. Thread the wires out.

- Page 79 GEEETECH Step3. Mount the PSU (Power supply unit) on the right side panel with 3 M3 x 10 screws. Step5. Now we can connect the wires to the PSU. 1) Mind the color of the wires. The wrong connection of the wire will cause serious damage to the PSU and even to the control board of the printer.

- Page 80 GEEETECH 2) Pay attention to the switch on the right side of the PSU, there are two options of voltage: 110 V and 220V, choose according the standard in your country. As shown in the following picture. Remove the yellow paper; you can use some hard sticks to...

-

Page 81: Mount The Control Board

GEEETECH Close the cover of the connector in case any electric shock. 27 Mount the control board Watch the video This video shows the control board of proB, this step is the same. You can refer to the pictures below. If you have any problems here, please feel free to contact us. -

Page 82: Wiring

GEEETECH Note the direction of the board; the green connectors are downwards to get enough heat dissipation from the fan. 28 Wiring GT2560 Before you start wiring, please take a look at the wiring schematics. - Page 83 GEEETECH You can see original picture here. Step1. The subdivision of stepper motor can be setup by jumper cap, plug all the jumper caps (For A4988)

- Page 84 GEEETECH If you are using DRV8825 instead of A4988, the jumper caps should be changed as follow: Note please, as your printer is single extruder, you will not use the extruder 2.

- Page 85 GEEETECH Step2. Plug the 4 A4988 into the stepper motor driver slot. Mind the directions of A4988.

- Page 86 GEEETECH If you are using DRV8825 instead of A4988, The correct connections are as follow: For your convenience, the above two steps is finished by us. you can skip them.

- Page 87 GEEETECH Step3. Connect wires for motors. 1) Connect wires for X-axis motor. 2) Connect wires for Y-axis motor.

- Page 88 GEEETECH 3) Connect wires for Z-axis motor.

- Page 89 GEEETECH 4) Connect Extruder motors. You are advised to mark them as extruder 1 and extruder 2, in respond to the silk-screen on the board. extruder 1 extruder 2...

- Page 90 GEEETECH Step4. Connect heating wires. Loosed the screws in the green terminal and put the red wires into the slot and screw * There is no “+” and “-“for heating wires it up. 1) Connect heating wires for heatbed. 2) Connect heating wires for extruder 1.

- Page 91 GEEETECH 3) Connect heating wires for extruder 2. Step4. Connect wires for thermistor. 1) Connect wires for thermistor of heatbed. 2) Connect wires for thermistor of extruder 1.

- Page 92 GEEETECH 3) Connect wires for thermistor of extruder 2. Step5. Connect wires for endstop. * There is no “+” and “-“for endstop 1) Connect wires for endstop of X-axis at X-Min.

- Page 93 GEEETECH 2) Connect wires for endstop of Y-axis at Y-Min. 3) Connect wires for endstop of Z-axis at Z-Min.

- Page 94 GEEETECH Step6. Connect wires for Fan. 1) Connect fan for control board at FAN3.

- Page 95 GEEETECH 2) Connect fan for extruder at FAN1. You will need to use the extension wire for fan.

- Page 96 GEEETECH Step7. Connect wires for LCD panel. There are two cables, one is for LCD encoder, the other is for SD card, do not connect them reversed. EXP1 to LCD EXP2 to SD card BTW, do you see the small screw above the SD card reader, if the text in of the LCD phases in an out or there is only blocks on the screen, you can adjust this screw to recovery it.

- Page 97 GEEETECH Step8. Connect wires for power input. That is all for the wiring of GT2560.

-

Page 98: Tidy Out The Wires

GEEETECH 29 Tidy out the wires. Use the wire coil to tie put those wires together. There are holes on the acrylic plates for the wires, you can arrange them as you like. 30 Mount the filament spool. Required parts... - Page 99 GEEETECH The whole printer assembly work is already done.

-

Page 100: Tips

GEEETECH 31 Tips Before even attempting the first print it is vital that the printer is correctly calibrated. Skipping or rushing this step will result in frustration and failed prints later, so it is important to take the time to make sure the machine is correctly set up.

Need help?

Do you have a question about the Prusa I3 Pro C and is the answer not in the manual?

Questions and answers