Table of Contents

Advertisement

Quick Links

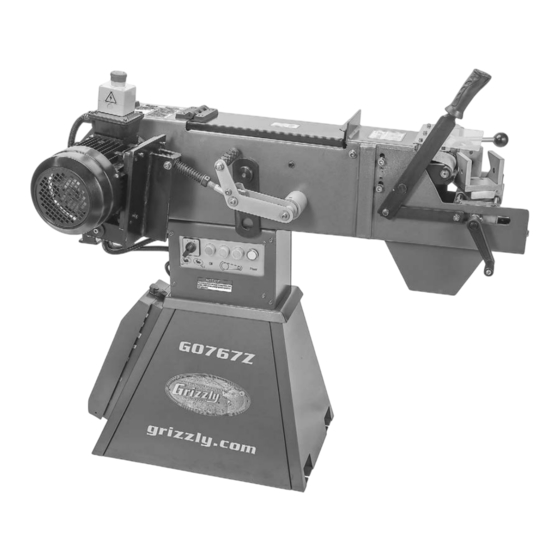

MODEL G0767Z

ABRASIVE TUBE NOTCHER

OWNER'S MANUAL

(For models manufactured since 11/17)

COPYRIGHT © FEBRUARY, 2018 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#ESABJH19158 PRINTED IN CHINA

V1.02.18

Advertisement

Table of Contents

Summary of Contents for Grizzly G0767Z

- Page 1 (For models manufactured since 11/17) COPYRIGHT © FEBRUARY, 2018 BY GRIZZLY INDUSTRIAL, INC. WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC. #ESABJH19158 PRINTED IN CHINA V1.02.18...

- Page 2 This manual provides critical safety instructions on the proper setup, operation, maintenance, and service of this machine/tool. Save this document, refer to it often, and use it to instruct other operators. Failure to read, understand and follow the instructions in this manual may result in fire or serious personal injury—including amputation, electrocution, or death.

-

Page 3: Table Of Contents

Table of Contents INTRODUCTION ..........2 SECTION 5: ACCESSORIES ......31 Machine Description ........2 SECTION 6: MAINTENANCE ......33 Contact Info............ 2 Schedule ............33 Manual Accuracy ........... 2 Cleaning ............33 Identification ........... 3 Lubrication ........... 33 Controls & Components ......... 4 Machine Data Sheet ........ -

Page 4: Introduction

Machine Description Manual Accuracy We are proud to provide a high-quality owner’s The Model G0767Z Abrasive Tube Notcher is manual with your new machine! designed to quickly notch or cope the ends of metal tubing, so two pieces of tubing can be weld- We made every effort to be exact with the instruc- ed together with clean, strong joints. -

Page 5: Identification

Rear Station Deburring Station Front Base Workpiece Vise Rest Assembly Dust Port Spark Trap Profile Roller Floor Mounts Storage Rack Rear To reduce your risk of serious injury, read this entire manual BEFORE using machine. Model G0767Z (Mfd. Since 11/17) -

Page 6: Controls & Components

M. Spark Shield Lock Handle: Secures spark wise. shield in place. E. Power Lamp: Indicates power to machine is N. Clamp Crank: Adjusts distance between turned ON. jaws and clamp plate to accommodate diam- eter of tube. Model G0767Z (Mfd. Since 11/17) -

Page 7: Machine Data Sheet

Number of Profile Rollers .................................7 Profile Roller Sizes .........................3/4, 1, 1-1/4, 1-1/2, 2, 2-1/2, 3 in. Grinding Capacity ............................... 3/4 - 3 in. O.D. Grinding Angle Range ............................... 0 - 60 deg. Model G0767Z Page 1 of 2 Model G0767Z (Mfd. Since 11/17) - Page 8 Self-Aligning Vise with Side-to-Side Adjustment to Prevent Uneven Belt Wear Vise Rotates 0 - 60 degrees Transparent Safety Guard Removable Spark Tray Accessories: Seven Rollers: 3/4", 1", 1-1/4", 1-1/2", 2", 2-1/2", 3" Toolbox with Service Tools Page 2 of 2 Model G0767Z Model G0767Z (Mfd. Since 11/17)

-

Page 9: Section 1: Safety

Everyday ery. Never operate under the influence of drugs or eyeglasses are NOT approved safety glasses. alcohol, when tired, or when distracted. Model G0767Z (Mfd. Since 11/17) - Page 10 EXPERIENCING DIFFICULTIES. If at any time debris. Make sure they are properly installed, you experience difficulties performing the intend- undamaged, and working correctly BEFORE ed operation, stop using the machine! Contact our operating machine. Technical Support at (570) 546-9663. Model G0767Z (Mfd. Since 11/17)

-

Page 11: Additional Safety For Abrasive Tube Notchers

Emergency area. Anyone working with or around this machine Stop button to avoid a sudden startup once power MUST wear a NIOSH-approved respirator rated is restored. for the workpiece material. Model G0767Z (Mfd. Since 11/17) -

Page 12: Section 2: Power Supply

To reduce the risk of these hazards, avoid over- loading the machine during operation and make sure it is connected to a power supply circuit that meets the specified circuit requirements. -10- Model G0767Z (Mfd. Since 11/17) - Page 13 Maximum Length (Shorter is Better)..50 ft. To reduce the risk of these hazards, avoid over- loading the machine during operation and make sure it is connected to a power supply circuit that meets the specified circuit requirements. -11- Model G0767Z (Mfd. Since 11/17)

-

Page 14: Section 3: Setup

IMPORTANT: Save all packaging materials until you are completely satisfied with the machine and have resolved any issues between Grizzly or the shipping agent. You MUST have the original pack- aging to file a freight claim. It is also extremely helpful if you need to return your machine later. -

Page 15: Inventory

H. Spanner Wrenches 22, 26mm ....2 ing or they are pre-installed at the factory. Open-End Wrench 13/16mm ...... 1 Toolbox ............1 Figure 4. Model G0767Z inventory. -13- Model G0767Z (Mfd. Since 11/17) -

Page 16: Hardware Recognition Chart

Hardware Recognition Chart USE THIS CHART TO MATCH UP HARDWARE DURING THE INVENTORY AND ASSEMBLY PROCESS. Flat Head Screw -14- Model G0767Z (Mfd. Since 11/17) -

Page 17: Site Considerations

Only install in an Shadows, glare, or strobe effects that may distract access restricted location. or impede the operator must be eliminated. " " Figure 5. Minimum working clearances. -15- Model G0767Z (Mfd. Since 11/17) -

Page 18: Lifting & Placing

Screw (1 of 4) Electrical Box Figure 6. Location of cap screws that secure electrical box. Slide electrical box out of riser column and place on top of machine. -16- Model G0767Z (Mfd. Since 11/17) - Page 19 (4) cap screws removed in Step 4 (see and attach lifting chain and safety hook Figure 12). between lifting bar and lifting device. Lifting Bar Figure 10. Example of lifting machine with chain Figure 12. Electrical box re-installed. and hook. -17- Model G0767Z (Mfd. Since 11/17)

-

Page 20: Cleanup

Because of the top heavy nature of the There are many ways to remove this rust preven- Model G0767Z and the dynamic forces exert- tative, but the following steps work well in a wide ed during operation, this machine MUST be variety of situations. -

Page 21: Assembly

Feed Lever Slide spark trap into grooves on right side of Assembly machine, as shown in Figure 16. Grooves Figure 14. Feed lever assembly attached. Spark Trap Figure 16. Spark trap positioned in grooves. -19- Model G0767Z (Mfd. Since 11/17) -

Page 22: Dust Collection

Explaining how to cal- culate these variables is beyond the scope of this manual. Consult an expert or purchase a good dust collection "how-to" book. Figure 18. Metal duct starter kit. -20- Model G0767Z (Mfd. Since 11/17) -

Page 23: Power Connection

Belt procedure on Page 24 and Abrasive Belt Tracking procedure on Page 25 to make sure the belt is properly tensioned and tracked, and will not fall off the rollers during the test run. -21- Model G0767Z (Mfd. Since 11/17) - Page 24 This safety feature must work properly before proceeding with regular operations. Call Tech Support for help. Note: To re-install abrasive belt, perform Replacing/Tensioning Abrasive Belt procedure on Page 24. -22- Model G0767Z (Mfd. Since 11/17)

-

Page 25: Section 4: Operations

Read books/magazines or get formal training before beginning any proj- ects. Regardless of the content in this sec- tion, Grizzly Industrial will not be held liable for accidents caused by lack of training. To reduce risk of eye or face injury from... -

Page 26: Replacing/Tensioning

Replacing/ Tensioning Abrasive Belt Whenever the abrasive belt becomes worn or damaged, replace it. The Model G0767Z uses a 4" x 79" silicon-carbide abrasive belt (refer to Cap Screw Page 31 for abrasive belts available from Grizzly). Use coarser grit belts for fast cutting and hard Figure 23. -

Page 27: Changing Profile Rollers

Sanding Belt Tracking Changing Profile Abrasive Belt Rollers Tracking The Model G0767Z includes seven profile rollers The abrasive belt must track in the center of the ranging from ⁄ " to 3". The size of profile roller drive pulley and profile roller to avoid presenting you use will depend on the size of tubing your an injury hazard or damaging the belt or machine. -

Page 28: Operational Tips

— If abrasive belt tracks to the right (as viewed from front of machine), rotate tracking adjustment cap screw clockwise in small amounts until abrasive belt tracks in center. -26- Model G0767Z (Mfd. Since 11/17) -

Page 29: Making Notches

Lever Figure 29. Feed lever pushed toward motor. Loose hair and cloth- ing could get caught in machinery and cause seri- ous personal injury. Keep loose clothing and long hair away from moving machinery. -27- Model G0767Z (Mfd. Since 11/17) - Page 30 11. Tighten clamp lever to lock tube in place. Note: If it is difficult to secure tube with clamp lever, use crank handle to slightly increase distance between clamp plate and tube, then try again. -28- Model G0767Z (Mfd. Since 11/17)

-

Page 31: Deburring

Figure 34. Example of notch in end of tubing. 16. Turn machine OFF, wait for abrasive belt to completely stop, then loosen clamp lever and remove tube. -29- Model G0767Z (Mfd. Since 11/17) - Page 32 Move and rotate tube as deburring station cover. needed to remove burrs. When finished, turn machine OFF, wait for abrasive belt to completely stop, and close deburring station cover. -30- Model G0767Z (Mfd. Since 11/17)

-

Page 33: Section 5: Accessories

90° serious personal injury or machine damage. • Schedule 40 wall thickness To reduce this risk, only install accessories recommended for this machine by Grizzly. NOTICE Refer to our website or latest catalog for additional recommended accessories. 4" x 79" Silicon-Carbide Abrasive Belts T26604—60-Grit, 10-Pk. - Page 34 Figure 42. H5843 and H5844 Phase Converters. coolant system prevents the blade from overheat- ing. A perfect choice for clean, precise, spark-free metal cutting! Figure 41. G0783 11" Slow-Speed Cold Cut Saw. -32- Model G0767Z (Mfd. Since 11/17)

-

Page 35: Section 6: Maintenance

Wipe the profile rollers clean with shop rags and mineral spirits. When dry, apply a light coat of rust Figure 44. Locations of vise leadscrews. preventative. -33- Model G0767Z (Mfd. Since 11/17) -

Page 36: Section 7: Service

1. Motor mounting loose. 1. Retighten motor mount fasteners. noise coming from 2. Motor fan hitting cover. 2. Repair/replace motor fan; remove any dents in machine. cover. 3. Replace abrasive belt (Page 24). 3. Abrasive belt worn/damaged/torn. -34- Model G0767Z (Mfd. Since 11/17) - Page 37 1. Use new abrasive belt with appropriate grit. marks at notch. 2. Feed rate too fast. 2. Reduce feed rate. Notch not centered 1. Profile roller not even with center of tube. 1. Adjust profile roller height (Page 36). on tube. -35- Model G0767Z (Mfd. Since 11/17)

-

Page 38: Adjusting Profile Roller Height

Loosen roller support bracket cap screws Spark Trap (see Figure 45). Move profile roller up or down to center Figure 46. Spark trap positioned in grooves. profile roller with center of tube. Retighten cap screws loosened in Step 3. -36- Model G0767Z (Mfd. Since 11/17) -

Page 39: Section 8: Wiring

Technical Support at (570) 546-9663. The photos and diagrams included in this section are best viewed in color. You can view these pages in color at www.grizzly.com. -37- Model G0767Z (Mfd. Since 11/17) -

Page 40: Electrical Components

Control Box Wiring Figure 47. Wiring component overview. E-Stop Button Figure 48. Emergency stop button wiring. Figure 50. Control panel and control box wiring. Figure 49. Motor junction box wiring. READ ELECTRICAL SAFETY -38- Model G0767Z (Mfd. Since 11/17) ON PAGE 37! -

Page 41: Wiring Diagram

Power Motor OFF Motor ON Motor ON Lamp VIEW ONPOW AD16-22DS 220V Motor Junction Box Emergency Stop 220V 3-Phase Motor IDEC YW-E01 Ground 220 VAC 3-Phase 15-15 PLUG READ ELECTRICAL SAFETY -39- Model G0767Z (Mfd. Since 11/17) ON PAGE 37! -

Page 42: Section 9: Parts

SECTION 9: PARTS We do our best to stock replacement parts when possible, but we cannot guarantee that all parts shown are available for purchase. Call (800) 523-4777 or visit www.grizzly.com/parts to check for availability. Body 25 26 REF PART #... -

Page 43: Motor & Belt Rollers

Motor & Belt Rollers 164-3 164-1 164-4 164-5 164-2 134 135 BUY PARTS ONLINE AT GRIZZLY.COM! -41- Model G0767Z (Mfd. Since 11/17) Scan QR code to visit our Parts Store. - Page 44 P0767Z142 PUSH-ON HANDLE GRIP P0767Z184 E-STOP BUTTON IDEC YW-E01 P0767Z143 DOWEL PIN 5 X 20 P0767Z185 WOOD SCREW M4 X 3 P0767Z144 RATCHET SHAFT BUY PARTS ONLINE AT GRIZZLY.COM! -42- Model G0767Z (Mfd. Since 11/17) Scan QR code to visit our Parts Store.

-

Page 45: Pipe Vise Assembly & Accessories

Pipe Vise Assembly & Accessories BUY PARTS ONLINE AT GRIZZLY.COM! -43- Model G0767Z (Mfd. Since 11/17) Scan QR code to visit our Parts Store. - Page 46 232 P0767Z232 CAP SCREW M6-1 X 20 266 P0767Z266 SLIDE BAR BRACKET (TOP) 233 P0767Z233 BUSHING 267 P0767Z267 HEX NUT M12-1.75 234 P0767Z234 PRESSURE BRACKET (LEFT) BUY PARTS ONLINE AT GRIZZLY.COM! -44- Model G0767Z (Mfd. Since 11/17) Scan QR code to visit our Parts Store.

-

Page 47: Electrical Box

OL RELAY SCHNEIDER LRE21N 12-18A P0767Z304 POWER LAMP ONPOW AD16-22DS AC220V P0767Z309 TERMINAL BAR 2P P0767Z305 ROTARY SWITCH GLELE LW28-20A 1/2 22MM BUY PARTS ONLINE AT GRIZZLY.COM! -45- Model G0767Z (Mfd. Since 11/17) Scan QR code to visit our Parts Store. -

Page 48: Labels & Cosmetics

Safety labels help reduce the risk of serious injury caused by machine hazards. If any label comes off or becomes unreadable, the owner of this machine MUST replace it in the original location before resuming operations. For replacements, contact (800) 523-4777 or www.grizzly.com. BUY PARTS ONLINE AT GRIZZLY.COM! -46- Model G0767Z (Mfd. - Page 49 Would you recommend Grizzly Industrial to a friend? _____ Yes _____No Would you allow us to use your name as a reference for Grizzly customers in your area? Note: We never use names more than 3 times. _____ Yes _____No 10.

- Page 50 FOLD ALONG DOTTED LINE Place Stamp Here GRIZZLY INDUSTRIAL, INC. P.O. BOX 2069 BELLINGHAM, WA 98227-2069 FOLD ALONG DOTTED LINE Send a Grizzly Catalog to a friend: Name_______________________________ Street_______________________________ City______________State______Zip______ TAPE ALONG EDGES--PLEASE DO NOT STAPLE...

-

Page 51: Warranty & Returns

WARRANTY & RETURNS Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance.

Need help?

Do you have a question about the G0767Z and is the answer not in the manual?

Questions and answers