Table of Contents

Advertisement

Quick Links

DO NOT USE EQUIPMENT BEFORE READING THIS MANUAL

Epic

120V Pump Only - 702-405

230V Pump Only - 702-102-CE

This manual contains important warnings and instructions.

Please read and retain for reference. Never operate this unit unless it is properly grounded.

660HPX

™

Epic 660HPX

120V Complete - 702-410

230V Complete - 702-104-CE

OWNER'S MANUAL

FOR PROFESSIONAL

USE ONLY

313 - 1229

REV 0498

Advertisement

Table of Contents

Summary of Contents for Titan Epic 660HPX

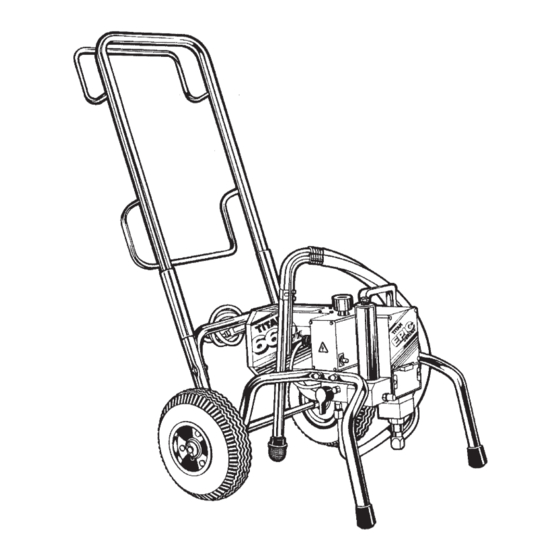

- Page 1 REV 0498 DO NOT USE EQUIPMENT BEFORE READING THIS MANUAL Epic 660HPX ™ Epic 660HPX 120V Pump Only - 702-405 120V Complete - 702-410 230V Pump Only - 702-102-CE 230V Complete - 702-104-CE This manual contains important warnings and instructions.

-

Page 2: Table Of Contents

Epic 660HPX Equipment Job History......26 Parts Drawings & High Rider Frame.........27 Repair Information 15-25 Skid Frame.......... 27 Low Rider Frame......... 16 Specifications........28 Replacement Labels......17 Warranty..........28 Armature Replacement......18 Table of Contents Electrical Schematics......20 Accessories Motor Housing........19 General Repairs/Service Gear Box.......... -

Page 3: General Repairs/Service

Flat-blade Screwdriver 1/8" Allen Wrench 5. If you have any further questions concerning your 1/2" Open End Wrench TITAN Airless Sprayer, call TITAN: Customer Service Department Tel.1-800-526-5362 1. Before repairing any part of the sprayer, read the Fax 1-800-528-4826 instructions carefully, including all warnings. -

Page 4: Maintenance/Service Record

COMPANY NAME Titan Tool is in the business of designing and manufacturing spray systems and accessories that make today’s Painting Professional become more efficient and profitable. We feel that if you accurately track the maintenance of your equipment on this chart it will improve the performance of this valuable tool to help you get the most out of your investment. -

Page 5: Warnings

DO NOT USE EQUIPMENT BEFORE READING THIS SECTION WARNING HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY Maximum Working Pressure 3200 psi, 221 bar An airless spray gun requires that fluid develop. NEVER exceed the pressure instructions are not completely rating of any component in the system. understood, or if in doubt as to whether be introduced to it at very high pressure. -

Page 6: Aviso (En Español)

NO USE EL EQUIPO ANTES DE LEER ESTA SECCION ADVERTENCIA LA ROCIADURA A PRESION ALTA PUEDE CAUSAR LESION GRAVE. Presión de Trabajo Máxima 3200 libras por pulgada cuadrada (psi), 221 bar Una pistola rociadora sin aire requiere que se giratorias y demás elementos accesorios estén está... -

Page 7: Attention (En Français)

NE PAS UTILISER LE MATERIEL AVANT D’AVOIR LU CETTE SECTION ATTENTION! LES PULVERISATEURS A HAUTE PRESSION PEUVENT PROVOQUER DE SERIEUSES LESIONS Pression de travail maximale: 3200 psi — 221 bar enlevez toujours la buse de pulvérisation et réglez électriques. Si le cordon ou la fiche doit être réparé Le liquide introduit dans un pistolet pulvérisateur sans air doit l’être à... - Page 8 ELECTRIC MOTOR The electric motors used by TITAN are not explosion proof. Therefore, it is essential to keep the working area around the pump well ventilated. Additionally, the pump itself should be a minimum of 25' (7.5m) from the spray area.

- Page 9 Los líquidos de limpieza, revestimientos, pinturas, etc. pueden contener solventes a base de hidrocarburos halogenados. El equipo de rociadura ofrecido por Titan Tool Inc. tiene componentes galvanizados o de aluminio y será afectado por solventes a base de hidrocarburos halogenados.

-

Page 10: Start-Up Procedure

Certains produits d'entretien, revêtements, peintures et autres liquides contiennent des solvants à hydrocarbure halogéné. Les appareils pulvérisateurs de la Titan Tool Inc. comportent des pièces en aluminium et des composants galvanisés sensibles aux solvants à hydrocarbure halogéné. N’EMPLOYER PAS D’HYDROCARBURES HALOGÉNÉS DANS LE MATÉRIEL TITAN. - Page 11 B. Preset pressure control by turning the pressure control knob counterclockwise to lowest setting. C. Place on-off switch in the off position. D. Be sure to fill the Wet Cup 1/3 full with Piston Seal Lubricant. Step 2E: ELECTRIC MOTOR A.

-

Page 12: Application Techniques

Shrubs next to houses should be tied back and covered with a canvas cloth. The cloth should be removed as soon as possible. Titan Gun Extensions are extremely helpful in these situations. Nearby objects such as automobiles, outdoor furniture, etc., should be moved or covered whenever in the vicinity of a spray job. -

Page 13: Cleaning Procedure

If cleaning with water, pump a small The following chart indicates the most common sizes and the amount of mineral spirits or TITAN LS- appropriate materials to be sprayed. 10 solution through pump. This will .011 - .013... -

Page 14: Airless Pump

Flushing TROUBLESHOOTING AIRLESS PUMP Specifications PROBLEM PROBABLE CAUSE REMEDY 1. New Sprayer: Oil is used by the Electric motor won't run 1. Unit unplugged or circuit fuse 1. Check factory for testing and protection. It is necessary to flush unit before blown spraying. - Page 15 230V Service Instructions Electrical Schematic for 230 Volt Motors PRESSURE SWITCH POWER MOTOR SWITCH NEUTRAL (BLUE) FUSES 240V 50.0 A SOLID STATE RELAY LINE (BROWN) GROUND (YELLOW-GREEN) Figure 3A For 230 Volt Units: ITEM NO PART NO DESCRIPTION 761-725 Power Cord 770-593 On/Off Plate 765-083 Toggle Switch 765-072 Wire...

-

Page 16: Low Rider Frame

Figure 2 Figure 16 Low Rider Frame Assembly ITEM NO PART NO DESCRIPTION 702-057 Handle 730-101 Hinge Lock 702-116 Rear Cross Member 700-802 Cap Nut 700-801 1/4” Carriage Bolt 702-127 Main Frame Right 710-045 Pin Axle 710-058 Washer Axle 702-048 Wheel 702-087 Spacer... -

Page 17: Replacement Labels

Epic 660HPX Replacement Labels PART NO DESCRIPTION 700-418 Front Plate (Front Cover Label) 313-175 “Warning/Attention” Label in French 313-1205 Wraparound Label Syphon Down Tube for use with the High Rider Frame Only... -

Page 18: Armature Replacement

Epic 660HPX UNITEC Motor Complete Figure 5 Armature Replacement ITEM NO PART NO DESCRIPTION 761-023 Screw WARNING: Before proceeding, follow the Pressure 702-046 Rear Cover Relief Procedure outlined on Page 5. Additionally, 611-405 Snap Ring follow all other warnings to reduce the risk of an... -

Page 19: Motor Housing

Epic 660HPX Figure 6 ITEM NO PART NO DESCRIPTION Motor Housing Replacement 702-404 Outer Housing (Excludes 141) WARNING: Before proceeding, follow the Pressure 761-244 Screw Relief Procedure outlined on Page 5. Additionally, 702-084 Motor Field follow all other warnings to reduce the risk of an... -

Page 20: Electrical Schematics

• • 120V Electrical Schematic Epic 660HPX Gear Box • FUSE 100V-20A • See Figure 7 for the Wiring Diagram. 110V-15A • 230V-10A • See page 15 for 230V Service Instructions • • • • Figure 7 Figure 9 ITEM NO... -

Page 21: Gear Repair

Gear Replacement Power Supply Cord Replacement WARNING: Before proceeding, follow the Pressure Relief Procedure outlined on Page 5. Additionally, WARNING: Before proceeding, follow the Pressure follow all other warnings to reduce the risk of an Relief Procedure outlined on Page 5. Additionally, injection injury, injury from moving parts or electric follow all other warnings to reduce the risk of an shock. -

Page 22: Filter Block

Epic 660HPX Filter Block ITEM NO PART NO DESCRIPTION 710-069 Plug 702-011 Maxi Filter HSG 730-083 Filter Spring 730-067 Filter Cartridge 757-105 Filter Spring 702-303 O-Ring 702-009 Filter HSG 702-251 Adapter 730-262 1/4-20 UN Screw 227-006 1/4” Nipple 700-537 Gasket... -

Page 23: Pressure Switch

Pressure Switch Replacement Service / Replacement of Filter WARNING: Before proceeding, follow the Pressure Relief WARNING: Before proceeding, follow the Pressure Relief Procedure outlined on page 5. Additionally, follow all Procedure outlined on Page 5. Additionally, follow all other other warnings to reduce the risk of an injection injury, warnings to reduce the risk of an injection injury, injury injury from moving parts or electric shock. -

Page 24: Fluid Section

Fluid Section 660HPX Install smaller ITEM NO PART NO DESCRIPTION Upper Packing (700-603) 700-735 Crank & Slide with raised lip and O Ring facing down Connecting Rod Assy. 730-508 Retainer O RINGS 700-587 Upper Guide 700-603 Upper Seal RAISED 730-505 Pump Housing 700-678 Head Cap Screw 700-601 Lower Seal 730-506 Piston Rod... -

Page 25: Pump Repair

SEAT SERVICE & REPAIR mount assembly. The design of Titan's Epic Fluid Section allows access to 18. Reattach Retainer (#301) and make sure that the the inlet and outlet valves and seat without completely upper guide (#302) is cleaned and undamaged. -

Page 26: Equipment Job History

Equipment Job History In order to help you track the superior performance of your Titan Sprayer we recommend you keep this log for your records. We feel you may find it useful for gauging on-site performance, invoicing or overtime and your estimator's reference. -

Page 27: High Rider Frame

115V DOMESTIC PUMPS 702-405 660HPX Pump Only With low rider frame 702-410 660HPX Pump Complete With low rider frame 702-420 660HPX Pump Only With high rider frame 702-425 660HPX Pump Complete With high rider frame 702-43 5 660HPX Pump Only With skid frame Figure 14 100V EXPORT PUMPS... -

Page 28: Specifications

© 1998 Titan Tool Inc. Franklin Lakes, NJ 07417 Woodbridge, Ontario L4L 5Z8 Franklin Lakes, NJ 07417 USA 313-1229 Printed in the U.S.A. REV 0498 Titan and Speeflo are registered trademarks and Epic is a trademark of Titan Tool Inc.

Need help?

Do you have a question about the Epic 660HPX and is the answer not in the manual?

Questions and answers